Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

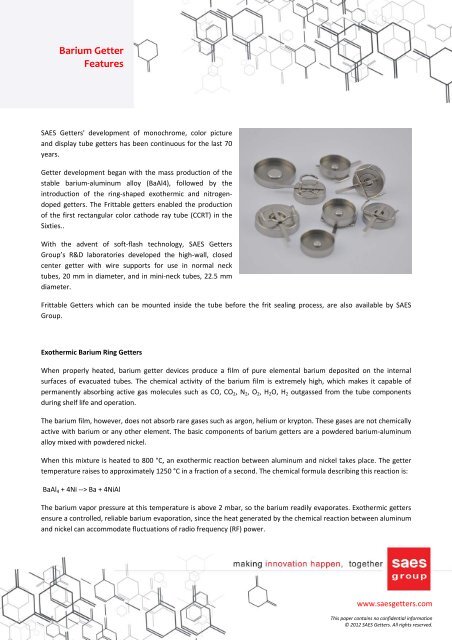

<strong>Barium</strong> <strong>Getter</strong><strong>Features</strong><strong>SAES</strong> <strong>Getter</strong>s' development of monochrome, color pictureand display tube getters has been continuous for the last 70years.<strong>Getter</strong> development began with the mass production of thestable barium‐aluminum alloy (BaAl4), followed by theintroduction of the ring‐shaped exothermic and nitrogendopedgetters. The Frittable getters enabled the productionof the first rectangular color cathode ray tube (CCRT) in theSixties..With the advent of soft‐flash technology, <strong>SAES</strong> <strong>Getter</strong>sGroup’s R&D laboratories developed the high‐wall, closedcenter getter with wire supports for use in normal necktubes, 20 mm in diameter, and in mini‐neck tubes, 22.5 mmdiameter.Frittable <strong>Getter</strong>s which can be mounted inside the tube before the frit sealing process, are also available by <strong>SAES</strong>Group.Exothermic <strong>Barium</strong> Ring <strong>Getter</strong>sWhen properly heated, barium getter devices produce a film of pure elemental barium deposited on the internalsurfaces of evacuated tubes. The chemical activity of the barium film is extremely high, which makes it capable ofpermanently absorbing active gas molecules such as CO, CO 2 , N 2 , O 2 , H 2 O, H 2 outgassed from the tube componentsduring shelf life and operation.The barium film, however, does not absorb rare gases such as argon, helium or krypton. These gases are not chemicallyactive with barium or any other element. The basic components of barium getters are a powdered barium‐aluminumalloy mixed with powdered nickel.When this mixture is heated to 800 °C, an exothermic reaction between aluminum and nickel takes place. The gettertemperature raises to approximately 1250 °C in a fraction of a second. The chemical formula describing this reaction is:BaAl 4 + 4Ni ‐‐> Ba + 4NiAlThe barium vapor pressure at this temperature is above 2 mbar, so the barium readily evaporates. Exothermic gettersensure a controlled, reliable barium evaporation, since the heat generated by the chemical reaction between aluminumand nickel can accommodate fluctuations of radio frequency (RF) power.www.saesgetters.comThis paper contains no confidential information© 2012 <strong>SAES</strong> <strong>Getter</strong>s. All rights reserved.

<strong>Barium</strong> <strong>Getter</strong><strong>Features</strong><strong>Getter</strong> ActivationThe getter releases barium rapidly, due to the exothermic reaction which occurs above 800°C. This action preventsdamage to the internal electronic parts of the tube and allows for maximum throughput in the production facility. Thegetter is usually heated by induced currents generated inside it by closely positioning an external coil connected to aradio frequency generator.This getter activation process is known as “getter flash”.Relevant <strong>Getter</strong> ParametersAnother important characteristic of a barium getter is the melting point. If too much power is applied to the coil, thegetter will show a very short start time and the expected barium yield will be very high. When this occurs, the getter isnot able to dissipate all of the energy generated by the external coil and locally melt, or the powder packet may liftupward. Melting of the getter container or lifting of the powder packet must of course be avoided, since in both casesparticles may be lost from the getter, thus causing mask aperture blockage or arcing between the grids. It is veryimportant to follow the recommended flashing conditions, for instance the start time and the total time, reported inthe getter yield curves, to avoid insufficient barium yields or melting of the getter container.<strong>Getter</strong>s Parameters ‐ Term DescriptionTotal TimeThe time that elapses between the switch‐on and switch‐off of the radio frequency generator connected to the coil:total time is, therefore, the duration of the external getter heating process performed by means of the RF coil. This isgenerally a fixed parameter, such as 30, 35 or 40 seconds.Start TimeThe time that elapses between switch‐on of the RF generator and the beginning of the exothermic reaction. The start ofthe exothermic reaction can be observed when the getter suddenly becomes very bright. The getter color changesdramatically from dark red to bright red due to the intense heat generated by the exothermic reaction. This reactionincreases the getter temperature from 800 to 1250 °C in a fraction of a second and initiates barium evaporation.<strong>Barium</strong> YieldThe amount of barium, expressed in milligrams, evaporated from the getter. From the description of the getter heatingprocess, this yield signifies the barium released between the start time and the R.F. generator switch‐off.www.saesgetters.comThis paper contains no confidential information© 2012 <strong>SAES</strong> <strong>Getter</strong>s. All rights reserved.