alkamax datasheet.pdf - SAES Getters

alkamax datasheet.pdf - SAES Getters

alkamax datasheet.pdf - SAES Getters

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

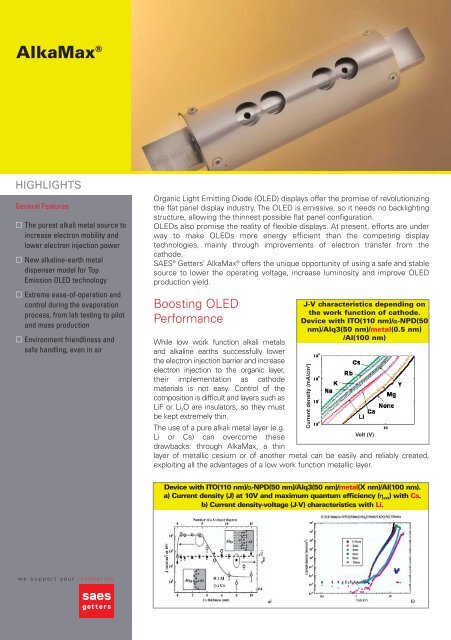

AlkaMax ®HIGHLIGHTSGeneral Features The purest alkali metal source toincrease electron mobility andlower electron injection power New alkaline-earth metaldispenser model for TopEmission OLED technology Extreme ease-of-operation andcontrol during the evaporationprocess, from lab testing to pilotand mass production Environment friendliness andsafe handling, even in airOrganic Light Emitting Diode (OLED) displays offer the promise of revolutionizingthe flat panel display industry. The OLED is emissive, so it needs no backlightingstructure, allowing the thinnest possible flat panel configuration.OLEDs also promise the reality of flexible displays. At present, efforts are underway to make OLEDs more energy efficient than the competing displaytechnologies, mainly through improvements of electron transfer from thecathode.<strong>SAES</strong> ® <strong>Getters</strong>’ AlkaMax ® offers the unique opportunity of using a safe and stablesource to lower the operating voltage, increase luminosity and improve OLEDproduction yield.Boosting OLEDPerformanceWhile low work function alkali metalsand alkaline earths successfully lowerthe electron injection barrier and increaseelectron injection to the organic layer,their implementation as cathodematerials is not easy. Control of thecomposition is difficult and layers such asLiF or Li 2 O are insulators, so they mustbe kept extremely thin.J-V characteristics depending onthe work function of cathode.Device with ITO(110 nm)/α-NPD(50nm)/Alq3(50 nm)/metal(0.5 nm)/Al(100 nm)The use of a pure alkali metal layer (e.g.Volt (V)Li or Cs) can overcome thesedrawbacks: through AlkaMax, a thinlayer of metallic cesium or of another metal can be easily and reliably created,exploiting all the advantages of a low work function metallic layer.Current density (mA/cm 2 )Device with ITO(110 nm)/α-NPD(50 nm)/Alq3(50 nm)/metal(X nm)/Al(100 nm).a) Current density (J) at 10V and maximum quantum efficiency (η ext )withCs.b) Current density-voltage (J-V) characteristics with Li.we support your innovation

With AlkaMax concept it is also possible to realize Alkali Metal Doped OrganicLayer (AMDOL) between the cathode and the emission layer to lower the deviceoperating voltage. Cs has been the most effective alkali metal for this layer, as ithas the lowest work function among all alkali metals and still retains this superiorfeature even when co-deposited with the organics.The AMDOL can be made thick enough to prevent spikes in the ITO anode layerfrom causing shorts in the device.Moreover, magnesium or Mg composite cathodes (using the co-deposition ofsilver for instance) are widely used for many OLED and TOLED device cathodestructures.<strong>SAES</strong> metal dispensing technology can assure, also in case of magnesium, stableand accurate deposition rates.AlkaMax: an Advanced Solution for OLED MassProductionAlkali Metal Dispensers (AMD) have been available from the <strong>SAES</strong> <strong>Getters</strong> Groupfor over 30 years and offer an efficient and safe method of depositing ultrapurealkali metals. AMDs keep the alkali metal pure in the form of a stable salt.Traditional AMD configurations release a few mg of alkali metal. To meet thespecific needs of OLED manufacturers, larger AMD dispensers were necessary:AlkaMax products have been designed purposely to release enough alkali andalkaline earth metals to deal with the demands of OLED mass production.AlkaMax models developed at <strong>SAES</strong> <strong>Getters</strong>’ Research & Innovation laboratoriesensure safe handling in any condition, thanks to the unique nature of the metalprecursors. This also ensures that AlkaMax is fully compliant with theenvironmental regulations.AlkaMax Characterization and PerformanceAlkaMax ®The <strong>SAES</strong> <strong>Getters</strong> Groupmanufacturing companies areISO9001 certified, the Asianand Italian companies arealso ISO14001 certified.Full information about ourcertifications for eachcompany of the Group isavailable on our website at:www.saesgetters.comD.FP.63.2The special design of AlkaMax can achieve the required alkali metal evaporationrate in a homogeneous, fast and easily controllable way.A simple feedback controlloop can be used toefficiently control theevaporation rate, through acalibrated Quartz CrystalMonitor with forced cooling.The <strong>SAES</strong> <strong>Getters</strong> Groupintegrates its offer toOLED manufacturers withmathematical modeling,which assures that alkalidistribution is fully optimizedfor ultimate display success.Current (A)Typical AlkaMax evaporation rateand current vs. time for Li30010,92500,80,72000,61500,5 0,4100500,30,20,1000 10 20 30 40 50 60 70 80Time (h)Schematic of a typical AlkaMax evaporationcontrol loop using a cooled QCMDeposition rate ( Å/s)SubstrateQCMMeasureddepositionrateControl unitfeedbackAlkaMaxDC Power Supply300 A – 5 V© 2008 <strong>SAES</strong> <strong>Getters</strong>. Printed in Italy. All rights reserved. <strong>SAES</strong> ® , DryFlex ® and AlkaMax ® are registeredtrademarks of <strong>SAES</strong> <strong>Getters</strong> S.p.A., its subsidiaries and affiliates.<strong>SAES</strong> <strong>Getters</strong> reserves the right to change or modify product specifications at any time without notice.<strong>SAES</strong> <strong>Getters</strong> Groupwww.saesgetters.comflat_panels@saes-group.com