Free Cutting High Carbon Steel C Si Mn P S Fe REFERENCE ...

Free Cutting High Carbon Steel C Si Mn P S Fe REFERENCE ...

Free Cutting High Carbon Steel C Si Mn P S Fe REFERENCE ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

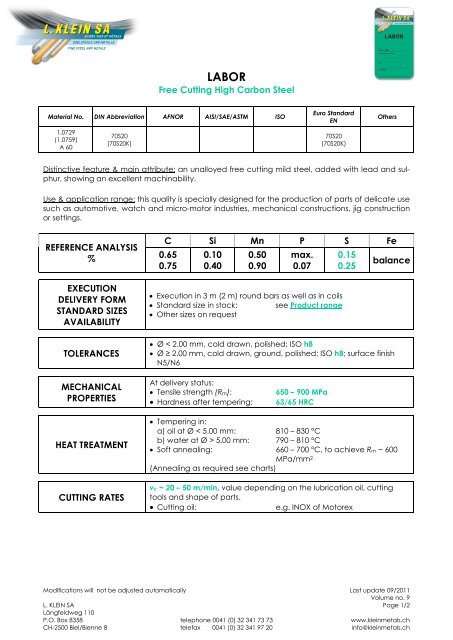

LABOR<strong>Free</strong> <strong>Cutting</strong> <strong>High</strong> <strong>Carbon</strong> <strong>Steel</strong>Material No. DIN Abbreviation AFNOR AISI/SAE/ASTM ISO1.0729(1.0759)A 6070S20(70S20K)Euro StandardEN70S20(70S20K)OthersDistinctive feature & main attribute: an unalloyed free cutting mild steel, added with lead and sulphur,showing an excellent machinability.Use & application range: this quality is specially designed for the production of parts of delicate usesuch as automotive, watch and micro-motor industries, mechanical constructions, jig constructionor settings.<strong>REFERENCE</strong> ANALYSIS%EXECUTIONDELIVERY FORMSTANDARD SIZESAVAILABILITYTOLERANCESC <strong>Si</strong> <strong>Mn</strong> P S <strong>Fe</strong>0.650.750.100.400.500.90max.0.07 Execution in 3 m (2 m) round bars as well as in coils Standard size in stock:see Product range Other sizes on request0.150.25balance Ø < 2.00 mm, cold drawn, polished; ISO h8 Ø ≥ 2.00 mm, cold drawn, ground, polished; ISO h8; surface finishN5/N6MECHANICALPROPERTIESAt delivery status: Tensile strength (Rm): Hardness after tempering:650 – 900 MPa63/65 HRCHEAT TREATMENTCUTTING RATES Tempering in:a) oil at Ø < 5.00 mm: 810 – 830 °Cb) water at Ø > 5.00 mm: 790 – 810 °C Soft annealing: 660 – 700 °C, to achieve Rm ~ 600MPa/mm 2(Annealing as required see charts)vc ~ 20 – 50 m/min, value depending on the lubrication oil, cuttingtools and shape of parts. <strong>Cutting</strong> oil:e.g. INOX of MotorexModifications will not be adjusted automatically Last update 09/2011Volume no. 9L. KLEIN SA Page 1/2Längfeldweg 110P.O. Box 8358 telephone 0041 (0) 32 341 73 73 www.kleinmetals.chCH-2500 Biel/Bienne 8 telefax 0041 (0) 32 341 97 20 info@kleinmetals.ch

LABOR1.0729(1.0759)HARDENING CURVEHRC67666564636261800 820 840 860 880 900 HARDENING TEMPERATURE °CANNEALING CURVE½ hourHRC65605550454035100 200 300 400 500 ANNEALING TEMPERATURE °CIf your harden in oil, we recommend to not pass over the annealing temperature of 820 °C to avoidcracks. The water should be pre-heated at about 50 °C. The above curves indicate the results ofdeterminate section of a curtain size of 5 mm. The result after heat treatment can be slightlydifferent than shown on this curve, depending on the shape and size of the part.Modifications will not be adjusted automatically Last update 05/2007Volume no. 9L. KLEIN SA Page 2/2Längfeldweg 110P.O. Box 8358 telephone 0041 (0) 32 341 73 73 www.kleinmetals.chCH-2500 Biel/Bienne 8 telefax 0041 (0) 32 341 97 20 info@kleinmetals.ch