Electrical Contact Cleaner - American Polywater

Electrical Contact Cleaner - American Polywater

Electrical Contact Cleaner - American Polywater

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

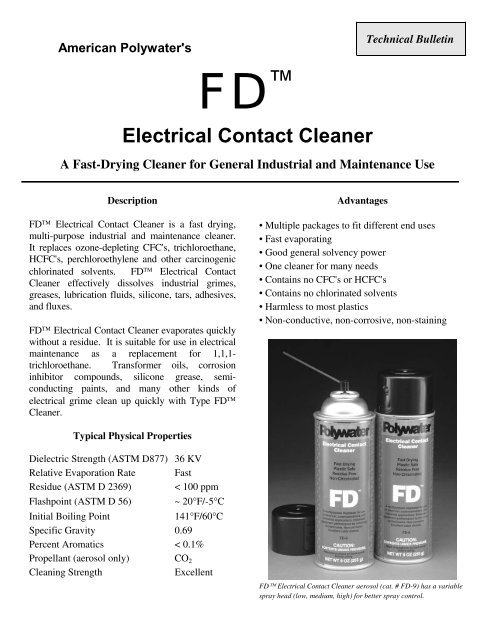

<strong>American</strong> <strong>Polywater</strong>'sTechnical BulletinFD <strong>Electrical</strong> <strong>Contact</strong> <strong>Cleaner</strong>A Fast-Drying <strong>Cleaner</strong> for General Industrial and Maintenance UseDescriptionFD <strong>Electrical</strong> <strong>Contact</strong> <strong>Cleaner</strong> is a fast drying,multi-purpose industrial and maintenance cleaner.It replaces ozone-depleting CFC's, trichloroethane,HCFC's, perchloroethylene and other carcinogenicchlorinated solvents. FD <strong>Electrical</strong> <strong>Contact</strong><strong>Cleaner</strong> effectively dissolves industrial grimes,greases, lubrication fluids, silicone, tars, adhesives,and fluxes.FD <strong>Electrical</strong> <strong>Contact</strong> <strong>Cleaner</strong> evaporates quicklywithout a residue. It is suitable for use in electricalmaintenance as a replacement for 1,1,1-trichloroethane. Transformer oils, corrosioninhibitor compounds, silicone grease, semiconductingpaints, and many other kinds ofelectrical grime clean up quickly with Type FD<strong>Cleaner</strong>.Advantages• Multiple packages to fit different end uses• Fast evaporating• Good general solvency power• One cleaner for many needs• Contains no CFC's or HCFC's• Contains no chlorinated solvents• Harmless to most plastics• Non-conductive, non-corrosive, non-stainingTypical Physical PropertiesDielectric Strength (ASTM D877) 36 KVRelative Evaporation Rate FastResidue (ASTM D 2369) < 100 ppmFlashpoint (ASTM D 56) ~ 20°F/-5°CInitial Boiling Point141°F/60°CSpecific Gravity 0.69Percent Aromatics < 0.1%Propellant (aerosol only) CO 2Cleaning StrengthExcellentFD <strong>Electrical</strong> <strong>Contact</strong> <strong>Cleaner</strong> aerosol (cat. # FD-9) has a variablespray head (low, medium, high) for better spray control.

Usage Directions/PerformanceFD <strong>Electrical</strong> <strong>Contact</strong> <strong>Cleaner</strong> is suitable formany types of cleaning and degreasing, includingcontact cleaning and electrical maintenancecleaning. It can be used as a spray, wipe, or solventrinse. FD <strong>Cleaner</strong> is effective at roomtemperature. It does not freeze and can be used incold weather applications. FD <strong>Electrical</strong> <strong>Contact</strong><strong>Cleaner</strong> is authorized by the USDA for use infederally inspected meat and poultry plants.FD <strong>Cleaner</strong> has good solvency power. Cleaningtime and effectiveness will vary based on thecontaminant and cleaning method. Wiping oragitation speeds the cleaning. Experiment with yourparticular contaminant and conditions.A comparison of FD <strong>Cleaner</strong> to other solventtypes is charted below. A stainless steel surface iscoated with 50 mils of contaminating compound.The surface is immersed and lightly agitated inFD <strong>Cleaner</strong>. The time at which the contaminanthas dissolved is noted.Silicone <strong>Electrical</strong> Insulating Compound<strong>Cleaner</strong>FD <strong>Electrical</strong> <strong>Contact</strong> <strong>Cleaner</strong>Odorless Mineral SpiritsIsopropyl AlcoholHydrocarbon Lubricating Grease<strong>Cleaner</strong>FD <strong>Electrical</strong> <strong>Contact</strong> <strong>Cleaner</strong>Odorless Mineral SpiritsIsopropyl AlcoholCable Filling Grease (PE/PJ)<strong>Cleaner</strong>FD <strong>Electrical</strong> <strong>Contact</strong> <strong>Cleaner</strong>Odorless Mineral SpiritsIsopropyl AlcoholCleaning Time5 MinutesCleaning Time5 Minutes>>5 MinutesCleaning Time5 Minutes>5 Minutes>>5 MinutesOxide Inhibiting Compound<strong>Cleaner</strong>Type FD <strong>Cleaner</strong>Odorless Mineral SpiritsIsopropyl AlcoholCleaning Time5 MinutesFD <strong>Electrical</strong> <strong>Contact</strong> <strong>Cleaner</strong> contains nosurfactants and leaves no residue once dried. Forprecision cleaning (residue free use), preventrecontamination with existing grime by finishingwith a fresh wipe, spraying until the solvent runsclear, or rinsing in a fresh bath of FD <strong>Cleaner</strong>.FD <strong>Electrical</strong> <strong>Contact</strong> <strong>Cleaner</strong> is fast evaporatingand does not require forced air to dry. In areaswhere solvent has pooled, the part may be wipedwith an absorbent, lint-free towel.Evaporation RateFD <strong>Electrical</strong> <strong>Contact</strong> <strong>Cleaner</strong>: 40 mg/min.111 Trichloroethane: 50 mg/min.Perchloroethylene:20 mg/min.Isopropyl Alcohol:10 mg/min.Odorless Mineral Spirits: .3 mg/min.CompatibilityFD <strong>Electrical</strong> <strong>Contact</strong> <strong>Cleaner</strong> will not corrode orstain metal parts. It does not tarnish or corrodecopper per ASTM D130 and D1729.FD <strong>Electrical</strong> <strong>Contact</strong> <strong>Cleaner</strong> is compatible withmost plastics and elastomers. Tables I and II showthe effect of FD <strong>Cleaner</strong> on various plastics andrubbers.Testing, shown in charts I and II, is based on asoak test described in ASTM D543. FD <strong>Cleaner</strong>may temporarily swell some rubber compounds.These rubbers should return to their original stateafter the cleaner has evaporated. Immersion willaffect sensitive materials more than incidentalcontact of a spray or wipe. It is recommended thatall plastic parts, gaskets, seals and O-rings betested for specific use and exposure method.

FD Solvent Compatibility with Plastics and ElastomersTABLE IPLASTICS AGING 72 HOURS AT 50°C% WEIGHTCHANGE% THICKNESSCHANGEAPPEARANCEABS +0.81 0 NCAcrylic +0.06 +0.15 NCCPE Thermoplastic +6.49 0 NCCPE Thermoset -6.51 0 NCDelrin® +0.24 0 NCEpoxy +0.08 0 NCNylon 101 +0.70 +0.27 NCPolycarbonate +0.18 0 NCPhenolic +6.99 +9.00 NCPolyethylene +12.46 +3.78 NCPolystyrene +31.49 +33.12 SFPVC -0.03 0 NCTeflon® +0.07 0 NCTygon® -0.17 +6.62 NCUltem® 1000 -0.08 +0.27 NCValox® 420 +0.10 +1.12 NCTABLE IIELASTOMERS AGING 72 HOURS AT 50°C% WEIGHT CHANGE % THICKNESSCHANGEAPPEARANCEEPDM +100.88 +37.15 SNeoprene +2.36 +2.72 NCNitrile +2.00 +5.26 NCSBR +16.96 +31.53 SSSilicone +65.97 +47.50 SViton® +1.98 +4.43 NCKEY:NC = NO CHANGES = SWELLINGSS = SLIGHT SWELLINGSF = SOFTENINGFD <strong>Cleaner</strong> is a trademark of <strong>American</strong> <strong>Polywater</strong> CorporationDelrin®, Teflon®, and Viton® are trademarks of Du PontUltem® 1000 and Valox® 420 are trademarks of G.E. PlasticsTygon® is a trademark of Norton Performance Plastics

SafetyFD <strong>Electrical</strong> <strong>Contact</strong> <strong>Cleaner</strong> has a low level oftoxicity. As with any solvent, ventilation should besufficient to keep vapors at safe levels. Avoid eyecontact and excessive skin contact. Wash handswith soap and water after using.FD <strong>Electrical</strong> <strong>Contact</strong> <strong>Cleaner</strong> is an extremelyflammable liquid. It should not be used onenergized equipment. FD <strong>Electrical</strong> <strong>Contact</strong><strong>Cleaner</strong> should not be used for high temperaturecleaning or exposed to pilot lights, flames or heatedsurfaces. Good industrial hygiene practice andappropriate precautions should be employed duringuse. See MSDS for specific details.StorageFD <strong>Electrical</strong> <strong>Contact</strong> <strong>Cleaner</strong> is classified asflammable. Keep containers cool, dry and awayfrom sources of ignition and oxidizing materials.Do not expose aerosol cans to direct sunlight ortemperatures above 120°F. Do not puncture orincinerate aerosol cans.Catalog No.FD-9FD-16LFFD-35LFST-RFD-128FD-640FD-DrumPackage OptionsDescription9-wt. oz. aerosol with adjustablenozzle (16 oz can) (12/cs)16-fl. oz. bottle with flip top(12/ cs)1-quart bottle with flip top(12/cs)Trigger sprayer fits pt. & qt.Bottles (12/cs)1-gallon can (4/cs)5-gallon pail (1 ea).55-gallon drum (1 ea)Copyright © 1996-2004. <strong>American</strong> <strong>Polywater</strong> Corporation. All Rights ReservedImportant Notice: The statements here are made in good faith based on tests and observations webelieve to be reliable. However, the completeness and accuracy of the information is notguaranteed. Before using, the end-user should conduct whatever evaluations are necessary todetermine that the product is suitable for the intended use.<strong>American</strong> <strong>Polywater</strong> expressly disclaims any implied warranties and conditions of merchantabilityand fitness for a particular purpose. <strong>American</strong> <strong>Polywater</strong>'s only obligation shall be to replace suchquantity of the product proven to be defective. Except for the replacement remedy, <strong>American</strong><strong>Polywater</strong> shall not be liable for any loss, injury, or direct, indirect, or consequential damagesresulting from product’s use, regardless of the legal theory asserted.LIT-FDTECHB/4-03/C1000(8/04)Makers of <strong>Polywater</strong>® and Dyna-Blue® Cable Lubricantsand Pull-Planner 2000 Softwarewww.polywater.com(URL)P.O. Box 53Stillwater, MN 55082U.S.A1-800-328-93841-651-430-2270fax 1-651-430-3634custserv@polywater.com(e-mail)