W ITH A - ENR.com - McGraw Hill Construction

W ITH A - ENR.com - McGraw Hill Construction

W ITH A - ENR.com - McGraw Hill Construction

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

the <strong>Construction</strong> WeeklyEngineering News-RecordJuly 20, 2009 enr.<strong>com</strong>Pitchwith aTwistAbu Dhabi tower’s tiltslows scheduleDeck here One articles where,articleses perused very

PROTECTIONfor ContractorsBroad Coverage – Risk Management Services – Expert Claims Handling – FreePre-Claims Assistance – An A-rated Carrier –when you insure your business withSchinnerer, you get more than a policy. We’ve insured contractors just like you forover 15 years; and the construction industry for over 50 years! Our program forcontractors provides coverage for professional liability and pollution risks. And unlikemany others, our professional policy covers agency and at-risk construction managersand design builders, when professional services are performed in-house or bysub-consultants. We can also provide a resource for property & casualty coverage.We make the insurance buying process easy. Visit our new website,www.PlanetContractor.<strong>com</strong>, for purchasing guides, applications, brochuresand risk management information. Call your broker today! If you do not haveone, give us a call at (301) 961-9800 and we will direct you to one closest to you. This information is for illustrative purposes only and is not a contract. It is intended to provide a general overview of the policy described.Nothing contained herein should be construed as an acknowledgement by Schinnerer that a given situation may be covered under aparticular policy. © 2009, Victor O. Schinnerer & Company, Inc.

Brandenburg ®

On The Edge? Call Brandenburg.Toll free 800.932.2869 | email@brandenburg.<strong>com</strong> | www.brandenburg.<strong>com</strong>

A D V E R T I S E M E N TT H E N E C A - I B E W R E P O R TReady to Play BallFans streaming into baseball and football stadiumsacross the nation expect to see an electrifying performance.But some of the best major league action isn’t on the field.It’s in the work of the National Electrical Contractors Association(NECA) and the International Brotherhood ofElectrical Workers (IBEW), who have teamed up to helpbuild some of the nation’s most notable stadiums.From PNC Park in Pittsburgh to Petco Field in SanDiego, thousands of NECA-IBEW members have investedtheir talents in creating an array of baseball’s most impressive“fields of dreams.” In Washington, DC, at NationalsPark – opened in March 2008 – union electrical contractorsbrought state-of-the-art technology to baseball’s neweststadium, including a 4,500 square foot high-definitionscoreboard and more than 600 linear feet of LED ribbonboard. The park as well features high efficiency field lighting,which uses 20% less energy than traditional lighting.That green solution contributed to the stadium earningLEED Silver certification from the U.S. Green BuildingCouncil, making it the first major stadium in the US toachieve the distinction.Says IBEW president Ed <strong>Hill</strong>, “It’s a wonderful exampleof how energy conservation can be built into thesemajor facilities without <strong>com</strong>promising the <strong>com</strong>fort of thefans or the aesthetics of the park.”At Petco Field in San Diego, a Project Labor Agreementopened the way for union electrical workers to installone million feet of conduit to support the ballpark’smyriad features, including 800 television sets, 50 speakers,200 amplifiers and a broadcast-ready cabling system forTV coverage.Said Eric Clevenger, project manager for contractor AudioAssociates, “The level of coordination on this job hasbeen amazing. We haven’t had any work-related injuries.You never get that on a non-union job.” Clevenger creditsunion safety training and programs for the achievement.“The professionalism that came with the Project LaborAgreement was tremendous,” he added.America’s football stadiums as well have scored bigleaguehelp from NECA-IBEW teams. Renovation of theChicago Bear’s storied Soldier Field, originally built in1924, was powered by 14 NECA contractors and more than500 IBEW members who <strong>com</strong>pleted all electrical constructionin record time, including fire alarm, sound, lightingand <strong>com</strong>munications systems.Meanwhile, at the rival Green Bay Packer’s LambeauField in Wisconsin, a two-and-a-half year renovation of the50-year-old stadium involved more than 400 IBEW membersworking with an array of NECA contractors. Gamesare still played in sub-zero weather, but the stadium’s famed“frozen tundra” is now thawed by an underground heatingsystem installed with the help of IBEW.Notes NECA president E. Milner Irvin, “Stadiums suchas Lambeau Field are important features of <strong>com</strong>munitylife. And as electrical professionals, we take pride in ourcontributions in providing both players and spectators withthe best built places to enjoy America’s favorite games .”Nationals Park in Washington, DC, is the first majorstadium to receive LEED certification for going“green,” due such energy-saving features as highefficiency lighting. (Photo courtesy of the WashingtonNationals.)For more information, visitthequalityconnection.<strong>com</strong>and our online videomagazine, ElectricTV.net.

July 20, 2009 global edition ContentsCover Story Leaning Tower23 Builders of the 160-meter-tallCapital Gate tower in Abu Dhabiwere slowed down by the <strong>com</strong>plicatedgeometry caused by offsetfloors that create an 18° slantfrom the vertical axis.Cover photo courtesy of ADNEC; photo rightcourtesy of Macephoto left by ap/wideworld; photo right by Peter reina for enrNews9 Accidents: Fatal pier failure mars Indiametro project11 Canals: Spain-led team wins plum job inpanama expansion12 Military <strong>Construction</strong>: Fluor and CH2Mhill are on teams awarded Afghansupport jobs12 Nuclear Power: U.S. managers to crackmarket with Canadian contractors13 Materials: Chinese drywall tests beginamid investigationsDelhi metro accident. Page 9Engineering News-RecordServing the i n d u s t r y s i n c e 1874London rail modernization. Page 1513 Unions: White House proposes PLA rule15 Rail: Victorian-era tracks enter the21st century17 Wind Power: Remote sites, odd regulationspose India development issue17 Corruption: U.K. bridge maker is first tobe cited19 Bridges: New scheme preparedfor bridge truss installation<strong>ENR</strong> (Engineering News-Record), (ISSN 0891-9526).Published weekly except for one issue in each month; 40weeks a year by The <strong>McGraw</strong>-<strong>Hill</strong> Companies, 1221 Ave. of theAmericas, New York, N.Y. 10020. Founder: James H. <strong>McGraw</strong>(1860-1948). Executive, editorial, circulation, advertisingoffices: Two Penn Plaza, New York, N.Y. 10121-2298. Phone (212) 512-2000. Postmaster: Please send address changes to<strong>ENR</strong>/Engineering News-Record, Attention: Fulfillment Manager, P.O. Box 5730, Harlan, IA 51593. Periodicals postage paid at NewYork, N.Y., and at additional mailing offices. Canada Post Publication Mail Agreement No.40012501. Registered for GST as The<strong>McGraw</strong>-<strong>Hill</strong> Companies. GST #R123075673. RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: DPGM Ltd., 2-7496 Bath Road,Mississauga, ON L4T 1L2. Email: enrcustserv@cdsfullfillment.<strong>com</strong>. Copyright, printing and reprinting: Titles EngineeringNews-Record (<strong>ENR</strong>) and CONSTRUCTION WEEK reg. ® in U.S. Patent Office. Copyright © 2009 by The <strong>McGraw</strong>-<strong>Hill</strong> Companies.All rights reserved. Officers of The <strong>McGraw</strong>-<strong>Hill</strong> Companies, Inc.: Harold W. <strong>McGraw</strong> III, Chairman, President, and ChiefExecutive Officer; Robert J. Bahash, Executive Vice President and Chief Financial Officer; Kenneth M. Vittor, Executive Vice Presidentand General Counsel. <strong>McGraw</strong>-<strong>Hill</strong> <strong>Construction</strong>: Norbert W. Young, Jr., FAIA, President; John Murphy, Director, Finance. Wheredepartments8 <strong>Construction</strong> Week21 <strong>Construction</strong> Economics28 Products30 Around the World31 Viewpoint For subscriber services call:(877) 876-8208 or (515) 237-3681 Go to my.enr.<strong>com</strong> for passwordprotectedonline access. Not getting <strong>ENR</strong> Insider and NewsAlerts? Please call (877) 876-8208enr<strong>com</strong>additional content onlinenecessary, permission is granted by copyright owner for those registered with Copyright Clearance Center (CCC), 222 RosewoodDrive, Danvers, Mass. 01923, www.copyright.<strong>com</strong>, to photocopy any article herein for personal or internal reference use only forthe flat fee of $1.20 per copy for each article. <strong>ENR</strong> <strong>Construction</strong> Economics, Top Rankings and Sourcebooks available for a fee indownloadable PDF format at www.<strong>ENR</strong>.<strong>com</strong>. Send payment to CCC. ISSN 0891-9526/92. Copying for other than personal or internalreference use without express permission of The <strong>McGraw</strong>-<strong>Hill</strong> Companies is prohibited. Write the editor to request such permission.Printed in the USA. Subscription rates for individuals in the field of the publication: U.S. and possessions, $82 peryear (single copies $9.95 in U.S.); Canada and Mexico, $89 per year; outside North America, $195 per year. Please allow four tosix weeks for shipment. Subscriber service and single copies: (877) 876-8208 or (515) 237-3681. Send all correspondence,notices and subscription orders to Fulfillment Manager, <strong>ENR</strong>, P.O. Box 5730, Harlan, IA 51593. If possible, attach address label froma recent issue. Please contact customer service to change your name or address. If the postal authorities alert us thatyour magazine is undeliverable, we have no further obligation unless we receive a corrected address within two years. Please allowa month for change of address to take effect. Classified advertising: Send ads to <strong>ENR</strong>, Classified Advertising, Two Penn Plaza, 9thFloor, New York, NY 10121. Phone (212) 904-2815.enr.<strong>com</strong> July 20, 2009 <strong>ENR</strong> 6

Building a Foundationfor the FutureThe Port Authority of New York and New Jersey is a founding member of the ACE (architecture,construction and engineering) Mentoring Program and it remains a proud supporter and participant.Nine Port Authority mentors currently volunteer their time promoting careers in architecture, constructionand engineering among students from 17 high schools, seven from New York and ten from New Jersey.We’re proud to share the Port Authority’s value of public service by working with these studentson model design projects that will benefit their local urban <strong>com</strong>munities.Supporting the region with our airports, bridges, tunnels, bus terminals,PATH, AirTrain systems and seaport.panynj.info

enr.<strong>com</strong>EngineeringNews-RecordEDITOR-IN-CHIEFJanice L. Tuchman, jan_tuchman@mcgraw-hill.<strong>com</strong>MANAGING EDITORSJohn J. Kosowatz, kosowatz@mcgraw-hill.<strong>com</strong>William G. Krizan, krizanw@mcgraw-hill.<strong>com</strong>EDITORS-AT-LARGENadine M. Post, buildings, design and construction; postn@mcgraw-hill.<strong>com</strong>;Debra K. Rubin, business and management, rubind@mcgraw-hill.<strong>com</strong>ECONOMICS: Timothy J. Grogan, senior editor, grogant@mcgraw-hill.<strong>com</strong>;Rona Nadi-Wafajow, rona_wafajow@mcgraw-hill.<strong>com</strong>SURVEYSTop Lists: Gary J. Tulacz, senior editor, tulaczg@mcgraw-hill.<strong>com</strong>; Virgilio G.Mendoza, coordinator-survey database, virgilio_mendoza@mcgraw-hill.<strong>com</strong>;Sourcebooks: Pam Hunter, associate editor, pamela_hunter@mcgraw-hill.<strong>com</strong>; Theola A. King, data processing assistant, theola_king@mcgraw-hill.<strong>com</strong>TECHNOLOGY, PROJECTS, MARKETSTransportation: Aileen Cho, senior editor, acho@mcgraw-hill.<strong>com</strong>; InformationTechnology: Tom Sawyer, senior editor, tom_sawyer@mcgraw-hill.<strong>com</strong>;Energy, Environment: Thomas F. Armistead, southeast senior correspondent,tom_armistead@mcgraw-hill.<strong>com</strong>; Government: Tom Ichniowski, Washington,D.C., bureau chief, tom_ichniowski@mcgraw-hill.<strong>com</strong>; Project Delivery,Viewpoints: William J. Angelo, chief correspondent. william_angelo@mcgraw-hill.<strong>com</strong>; Pulse, Calendar, Books: Pearl Herndon, assistant editor,pherndon@mcgraw-hill.<strong>com</strong>EQUIPMENT & MATERIALS: Tudor Van Hampton, Midwest bureau chief,tudor_vanhampton@mcgraw-hill.<strong>com</strong>; Products: Rita Catinella Orrell, groupproducts editor, <strong>ENR</strong>_Products@mcgraw-hill.<strong>com</strong>WEB SITES: Richard A. Korman, managing senior editor, <strong>ENR</strong>.<strong>com</strong>, kormanr@mcgraw-hill.<strong>com</strong>; Ilan Kapla, senior manager, ilan_kapla@mcgraw-hill.<strong>com</strong>; Swati Scindia, production editor, swati_scindia@mcgraw-hill.<strong>com</strong>; KeithWallace, web producer, keith_wallace@mcgraw-hill.<strong>com</strong>REGIONAL EDITORSCalifornia <strong>Construction</strong>: Robert Carlsen, Robert_Carlsen@mcgraw-hill.<strong>com</strong>;Joe Florkowski, Joe_Florkowski@mcgraw-hill.<strong>com</strong>; Colorado <strong>Construction</strong>:Mark Shaw, Mark_Shaw@mcgraw-hill.<strong>com</strong>; Melissa Leslie, Melissa_Leslie@mcgraw-hill.<strong>com</strong>; New York <strong>Construction</strong>: Jack Buehrer, jack_buehrer@mcgraw-hill.<strong>com</strong>; Carolina Worrell, carolina_worrell1@mcgraw-hill.<strong>com</strong>;Southeast <strong>Construction</strong>: Scott Judy, Scott_Judy@mcgraw-hill.<strong>com</strong>; Southcentral<strong>Construction</strong>: Sam Barnes, Sam_Barnes@mcgraw-hill.<strong>com</strong>; Midwest<strong>Construction</strong>: Mike Larson, mike_larson@mcgraw-hill.<strong>com</strong>; IntermountainContractor: Brad Fullmer, brad_fullmer@mcgraw-hill.<strong>com</strong>; Northwest<strong>Construction</strong>: Lucy Bodilly, Lucy_Bodilly@mcgraw-hill.<strong>com</strong>; SouthwestContractor: Scott Blair, Scott_Blair@mcgraw-hill.<strong>com</strong>; Texas <strong>Construction</strong>:Eileen Schwartz, Eileen_Schwartz@mcgraw-hill.<strong>com</strong>SPECIAL CORRESPONDENTSEurope (London): Peter Reina, Reina@btinternet.<strong>com</strong>; Las Vegas: Tony Illia,Tonyillia@aol.<strong>com</strong> Lima, Peru: C.J. Schexnayder, c.j.schexnayder@gmail.<strong>com</strong>;New Orleans: Angelle Bergeron, ang.bergeron@gmail.<strong>com</strong>; Washington D.C.:Bruce Buckley, bruce_buckley@<strong>com</strong>cast.net CorruptionTwo Plead Guilty To SupplyingFaulty Concrete to CA/T ProjectTwo former employees of Aggregate IndustriesNE Inc., Saugus, Mass., pleadedguilty on July 8 to 12 charges involving aconspiracy to deliver substandard concreteto the $15-billion Central Artery/Tunnel project. Four more employees arescheduled to go to trial this week in U.S.District Court in Boston. Gerard M. Mc-Nally and Keith H. Thomas pleadedguilty to two counts of conspiracy, fivecounts of mail fraud and five counts offiling false reports stemming from a 2006indictment alleging that, between 1996and 2005, the six defendants delivered atleast 5,000 10-yd truckloads of “nonspecification”concrete to the project. Theindictment charged the concrete was over90 minutes old, had been adulterated andnot batched to CA/T standards. Aggregatepaid a $50-million settlement in2007. The trial of the other defendantswill begin July 15, says a spokeswoman forthe U.S. attorney for the District ofMassachusetts. <strong>Construction</strong> Week PeopleNew Team at FHWAA new team is taking over at the FederalHighway Administration, as debate heatsup about the Highway Trust Fund’s problemsand legislation to reauthorize surfacetransportation programs. The Senate onJuly 10 confirmed former Arizona Dept.of Transportation Director Victor M.Mendez as FHWA administrator. Mendezserved as ADOT’s director from 2001until February 2009. Indoor-Air StandardsProposed Energy-Code ChangesAre Out for Public CommentThe American Society of Heating, Refrigeratingand Air-Conditioning Engineershas released for <strong>com</strong>ment 18 proposedair-side control changes to itsenergy-use standard, ASHRAE/IESNAStandard 90.1. The proposals are intendedto move toward 30% energy-cost savingsin buildings. Specific <strong>com</strong>ments can befiled by either July 19 or Aug. 3. Detailsare available at www.ashrae.org. Good Shake-Up in JapanHistoric-Size Quake Test Validates ‘Performance’ Seismic DesignA magnitude-7.5 quake, simulated by a shake table on July 14, proved performance-based seismicdesign is valid for a six-story, wood-frame residential building on a one-story steel frame. Damagewas negligible, say investigators from Colorado State University and Simpson Strong-Tie. ART DEPARTMENTGuy Lawrence, art director, guy_lawrence@mcgraw-hill.<strong>com</strong>; Susan Pearsall,associate art director, sue_pearsall@mcgraw-hill.<strong>com</strong>; Nancy Soulliard,associate art director, nancy_soulliard@mcgraw-hill.<strong>com</strong>; Michael Goodman,contributing photographer, mgoodphoto@aol.<strong>com</strong>EDITORIAL PRODUCTIONAgnes Barbara B. Montalban-Salvio, production manager, agnesms@mcgraw-hill.<strong>com</strong>; Virginia J. Camasca, production editor, vcamasca@mcgraw-hill.<strong>com</strong>EDITORIAL RESEARCHScott Lewis, director, scott_lewis@mcgraw-hill.<strong>com</strong>; Grace Alicea, research/editorial assistant, grace_alicea@mcgraw-hill.<strong>com</strong>Photo courtesy of Simpson Strong-Tie Company Inc.EDITORS EMERITUSHoward B. Stussman, hbstussman@gmail.<strong>com</strong>; Arthur J. Fox, Jr.,artfox1944@<strong>com</strong>cast.netMCGRAW-HILL CONSTRUCTION NEWS DIRECTORAndrew G. Wright, wrighta@mcgraw-hill.<strong>com</strong>MCGRAW-HILL CONSTRUCTION DIGITAL MEDIABryant W. Rousseau, director, bryant_rousseau@mcgraw-hill.<strong>com</strong>;Susannah Shepherd, design director, susannah_shepherd@mcgraw-hill.<strong>com</strong>MCGRAW-HILL CONSTRUCTION Senior GROUP ART DIRECTORFrancesca Messina, francesca_messina@mcgraw-hill.<strong>com</strong>VICE PRESIDENT, GROUP EDITORIAL DIRECTORRobert Ivy, robert_ivy@mcgraw-hill.<strong>com</strong>enr.<strong>com</strong> July 20, 2009 <strong>ENR</strong> 8

News July 20, 2009AccidentsFatal Pier FailureMars India MetroIn a second similar tragedy within a year, a pier collapses under a launching girder, killing sixworkers building Delhi rail extension; officials will file investigation report before month’s endAtwofold collapse failure on a construction site for anextension of the Delhi Metro has officials investigatingand rail opponents incensed. An elevated sectionof track came crashing down on July 12, killing sixworkers and injuring 20. One day later, three cranestrying to remove the launching girder had a“mechanical failure,” says Delhi Metrospokesman Anuj Dayal.The design-build contract on the 20-km new corridor being built from Delhi’scentral core to the southeast is held byGammon India Ltd., a private firm contractedby Delhi Metro Rail Corp. Ltd.(DMRC). It established a four-memberpanel to investigate the tragedy and producea report within 10 days. Much of theattention will be on the failure of the piercap to balance the weight of the launchinggirder. “A <strong>com</strong>mittee is investigating...thecause,” Gammon India Vice PresidentR.L. Telang told a news wire, adding,“There is no design fault.”In a non-Delhi Metro-related incident,Gammon India also was held responsiblefor a construction scaffolding collapse inHyderabad that claimed two lives in September2007. It paid 10% of the projectcost in that case.The first Delhi accident took place onJuly 12 between two bridge piers, accordingto DMRC Managing Director ElattuvalapilSreedharan. Five of 10 segmentshad been erected. “Pier 67 was taking themain load [of 25 tons] with the longestall photos by ap/wideworld Too Heavy. Launching girder was placing a concrete segment when pier cap failed beneath it.9 <strong>ENR</strong> July 20, 2009 enr.<strong>com</strong>

Cracks. The boom on a 250-tonne crane used in the cleanup developed cracks and snapped, sending the load to two adjoining cranes.cantilever,” he says. “In this case, the cantileverwas 4.2 m long.” The pier collapsed,and the launching girder camecrashing down. Sreedharan says the collapsedcantilever was the longest to beused on any DMRC project. It was holdingone launching girder as well as the Load. The boom of a 350-tonne cranesnapped and a 250-tonne crane upended.girder to be erected, he added.The next day’s cleanup operation faredlittle better. “When the lifting operationstarted, one of the high-capacity[250-tonne] cranes developed mechanicalfailure as its boom developed cracks andsnapped,” says Dayal. The load thencaused the boom of an adjoining350-tonne craneto snap and another250-tonner to topple.Red-FacedThe accidents left authoritiesred-faced as residentgroups stepped up theircampaign against DelhiMetro lines running overhead.“Some 300 km ofelevated Metro tracks onconcrete pillars are hanginglike the Sword ofDamocles over our heads,”says Rajiv Kakaria, a ResidentWelfare Association member.Sreedharan, known as the “MetroMan,” submitted his resignation, claiming“moral responsibility.” However, the nextday, he was convinced by the Delhi governmentto return to work. He had overseenthe first 65-km phase of Metro construction,which was <strong>com</strong>pleted threeyears ahead of schedule in 2005 within abudget of $2.3 billion. The Delhi accidentoccurred during the 123-km secondphase, expected to cost $4.5 billion.Among the planned 15 corridors is a highspeedairport link, scheduled to openwhen Delhi hosts the 2010 CommonwealthGames.The 20-km section inwhich the accident occurredwas slated to openby September 2010, amonth before the CommonwealthGames. Metroofficials do not believeschedule pressure islargely to blame for theincreasing number of accidents.This was the secondmajor accident in the historyof Delhi Metro. In Upset. Metro leader SreedharanOctober 2008, a launchinggirder collapsed whileunsuccessfully tried to resign.placing precast concrete girders, killingtwo in east Delhi. The contractor on thatproject, AFCONS, was blacklisted fromfurther contracts.Delhi Metro, which started operationsin 2002, runs 70 trains and carries over800,000 people daily. By Neelam Mathews in Indiaenr.<strong>com</strong> July 20, 2009 <strong>ENR</strong> 10

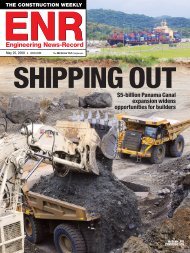

NewscanalSpain-Led Team Wins Plum JobIn Panama Canal Expansion Locked Up. Firms will design and build new locks at two entrances of the aging waterway.Aconstruction team led by Spanishcontractor Sacyr Vallehermoso SAhas won the mammoth PanamaCanal expansion’s largest contract to date:the design-build job to build a third set oflocks on the waterway’s Atlantic and Pacificopenings.The locks contract is the heart of the$5.2-billion effort begun in September2007 to expand the historic waterway.The winning team, which includes twoU.S. engineering firms, proposes to constructthe locks for $3.12 billion. The jobhad been estimated by owner PanamaCanal Authority (ACP) to cost $3.48 billion,the quasi-government agency revealedon July 8.The winning team, known as GrupoUnidos por el Canal, also includes threeother contractors: Impregilo SpA of Italy,Belgium’s Jan De Nui NV and ConstructoraUrbana SA (CUSA) of Panama. ConstructoraUrbana is already working at thesite on other canal-related projects.Also on the team are two U.S. firms—Broomfield, Colo.-based MWH and11 <strong>ENR</strong> July 20, 2009 enr.<strong>com</strong>Tetra Tech, Pasadena, Calif.—along withHolland’s IV Groep. Heerema FabricationGroup, also based in the Netherlands,is a team member as well.The selection was based on GrupoUnidos’ total score, including technicalevaluation and price proposal, ACP officialssaid. Technical proposals were evaluatedbased on execution of constructionand operations, design of electronic andmechanical systems and design of thelocks’ structures, gates and hydraulics, theofficials explained. More than 50 technicalexperts who participated in proposal reviewsigned confidentiality and conflictof-interestagreements, according toACP.The selection is the culmination of aprocess that drew into the <strong>com</strong>petitionfour teams <strong>com</strong>prising 30 global firms.One team chose not to submit a proposal,but the other two whose proposals fellshort in the final <strong>com</strong>petition were led byBechtel International Inc., San Francisco,which offered $4.2 billion for the job, andSpain’s ACS Servicios, Comunicaciones yEnergía, S.L., whose proposal was closeto $6 billion, according to ACP. TheBechtel team included Taisei Corp. andMitsubishi Corp., both of Japan. TheACS team included Germany’s Hochtief<strong>Construction</strong> AG and Constructoras ICASA de CV of Mexico.ACP initially sought proposals for thelocks contract in December 2007, withsubmittals due the following August. Participatingteams requested the agencyextend that deadline until March 2009,but ACP officials say the delay will haveno effect on the overall timeline of theexpansion.The proposed third set of locks willemploy sliding gates similar to those atthe Barendregt canal in Amberes, Belgium,and a series of water-saving basinsused in Germany. ACP chose to integrateboth the Atlantic and Pacific locks into asingle design-build contract in order toensure consistency in the final product.The single-lane, three-step set of lockswill consist of lock chambers measuring427 m long x 55 m wide x 18.3 m deep.When <strong>com</strong>plete, it will allow larger post-Panamax ships to use the waterway. Observerssay the team will be challenged inbuilding such mammoth structures and incoordinating the locks construction effortssimultaneously on either side of theIsthmus of Panama.The expansion is to be <strong>com</strong>pleted in2014, in time for the canal’s centennial,and will more than double the capacity ofthe historic waterway. “Today’s eventmarks a critical milestone for ACP andPanama as we determine which consortiumwill design and build the canal’s newlocks,” said agency administrator AlbertoAlemán Zubieta. “Throughout the reviewperiod, the ACP’s Technical EvaluationBoard and external auditors ensured anairtight course of action that reflects ourstaunch <strong>com</strong>mitment to a fair, rigorousand transparent contracting process.”ACP has spent nine months organizingproject management in conjunctionwith its program manager, Denver-basedCH2M <strong>Hill</strong> Cos. By C.J. Schexnayder andDebra K. Rubinphoto by c.j. schexnayder for enr

military constructionFluor and CH2M <strong>Hill</strong> on TeamsAwarded Afghan Support Jobsnuclear power Military Support. Work covers construction, troop logistics.Two teams, one led by FluorCorp. and the other withCH2M <strong>Hill</strong> Cos. Ltd. as apartner, were <strong>com</strong>petitively awardedhuge task orders on July 8 by theU.S. Army to provide construction,operations and other logistical supportto troops in Afghanistan. Theawards, made under the teams’ existingLogistics Civil AugmentationProgram (LOGCAP) IV contracts,could total more than $13 billionover the next five years. KBR Inc., a thirdLOGCAP IV contractor that vied for thetask-order work, was not selected.Under the awards by the Army SustainmentCommand in Rock Island, Ill.,the teams will split U.S. base support inAfghanistan geographically. Irving, TexasbasedFluor will manage work at 74 basesin the country’s northern section. Its taskorder is worth up to $1.5 billion in its firstyear, with the option to win similarly valuedawards in four additional years. Fluorsays this award is its fourth “and most significant”task order assigned under LOG-CAP IV. The <strong>com</strong>pany says the scope ofwork will include “construction services,power, water, housing, base operations,sustainment services and logistics support.”The <strong>com</strong>pany could add 100 jobsin its Greenville, S.C., location to supporttask-order work, according to publishedreports.Denver-based CH2M <strong>Hill</strong>’s team, ledby defense contractor DynCorp International,Falls Church, Va., will work at anundisclosed number of bases in the south.Its task order is worth $643.5 million inits first year and up to $5.9 billion overfive years. DynCorp says it has other taskorders for logistics work in Kuwait.Houston-based KBR currently issupporting the Army in Iraq underits separate LOGCAP III contract,under which task orders are not<strong>com</strong>petitively bid. The Army says itmay issue a new task order there underLOGCAP IV but did not specifytiming or scope.The three firms were selected asLOGCAP IV contractors in 2007.A KBR spokeswoman says the firmhas requested a debriefing from the Armyon the task-order selection process. “Nodecision will be made on a possible [bid]protest until we have a chance to reviewthat information,” she says. “We remainproud of the work we have performed.KBR has a proven track record of servingthe military in austere and unpredictableenvironments. Our <strong>com</strong>mitment in thisregard will continue.” By Debra K. RubinU.S. Managers To Crack Market With Canadian Contractorsphoto top courtesy of u.s. army; bottom courtesy of Bruce Power L.P.To break the routine of costand schedule overruns inCanadian nuclear construction,the operator of North America’slargest nuclear powerplanthopes to <strong>com</strong>bine U.S. nuclearproject management expertise withCanadian engineering and constructionskills in a <strong>com</strong>pany totarget construction in Ontario andelsewhere in Canada. It could beready for business by next year.The <strong>com</strong>pany is in “the formativestages,” says John Sauger, seniorvice president for Bruce Power Ltd.,Tiverton, Ontario. “The concept is aholding <strong>com</strong>pany, structured as alimited-liability partnership.” Withmanagers from U.S. nuclear contractorsand Bruce Power, the newentity will buy 51% of five to sixengineering and construction firms,mostly in Canada. “We want controlbut will incent good performancewith money,” Sauger says.Sauger was senior vice presidentfor Shaw Group’s federal operationswhen Bruce Power hiredhim in March 2008 to put the“Bruce A” nuclear powerplant refurbishmentprogram in Tivertonback on track. The plant has fourreactors, and the cost estimate torestart units 1 and 2, laid up sincethe late 1990s, hadrisen from $2.4 billionto $2.9 billion at 60%<strong>com</strong>pletion.U.S. nuclear constructorswill not workin Canada becausethere is no liabilityshield like the Price-Anderson Act, says Sauger. “TheCanadian contracting <strong>com</strong>munity isnot as developed, robust or matureas it is in the U.S.,” he adds. “Theydid not understand how to put togetheran engineering package inmanageable pieces.”With the restart project back on Talking. Sauger (center) is negotiating.track, Sauger is negotiating with ahalf-dozen nuclear-experiencedCanadian firms to tackle the nuclearmarket. He declines to namethe <strong>com</strong>panies but praises the workdone by E.S. Fox Ltd. and RCMTechnologies Inc. on Bruce A. By Thomas F. Armisteadenr.<strong>com</strong> July 20, 2009 <strong>ENR</strong> 12

NewsmaterialsChinese-Made Drywall TestsBegin Amid InvestigationsAs reports grow of health problemsand metal corrosion suspected of<strong>com</strong>ing from U.S. imports of Chinese-madedrywall, federal agencies aremoving ahead on a multipronged investigationof the material. Initial results oflaboratory and in-home tests are due inAugust and September.The Consumer Product Safety Commissiontold Senate Appropriations Committeeleaders on July 6 it has received608 reports of Chinese drywall problemsfrom 21 states and the District of Columbia.That is a sharp increase since May 21,when CPSC testified at a Senate hearingit had recorded 320 drywall reports from16 states (<strong>ENR</strong> 6/1 p. 13). Most are fromFlorida, Louisiana and Virginia.CPSC is leading the multi-agency federaldrywall probe. One part of the investigationaims to determine whether Chinesedrywall’s <strong>com</strong>position differs fromthat of U.S.-made products.Federal agencies and contractors alsoare running a range of tests. A U.S. EnvironmentalProtection Agency team isanalyzing 14 samples of uninstalled importedand domestic drywall to determinewhat organic and inorganic <strong>com</strong>pounds,13 <strong>ENR</strong> July 20, 2009 enr.<strong>com</strong>metals and other properties are present.EPA is to finish the analysis by Aug. 21.Under a contract awarded June 9, theLawrence Berkeley National Laboratoryis carrying out “chamber studies” on thedrywall samples to identify gases theyemit and isolate the gases from emissionsfrom other household products, such ascarpets and paints. Phase one will be finishedby late August. CPSC also will <strong>com</strong>pletea preliminary health assessment bymid- to late September. Phase two of thechamber studies will look at “higheremittingmaterials” found in phase one.Environmental Health and EngineeringInc., Needham, Mass., was awarded acontract on June 1 to conduct indoor-airsampling in 50 homes. That work is expectedto be <strong>com</strong>pleted by late August.Sen. Bill Nelson (D-Fla.), who haspushed for action on drywall, is pleasedagencies are “finally looking at the coreissues,” an aide says. But Nelson also hasintroduced a bill directing CPSC to determinewhether a drywall safety standardis needed. The bill also mandates an “interimban” on drywall with more than 5%organic <strong>com</strong>pounds by weight. By Tom Ichniowski Widespread. Chinese drywall suspected in health problems, metal corrosion in 21 states.unionsNew PLA RuleIs UnveiledThe Obama administration has proposedrules that would encourageagencies to consider project laboragreements (PLAs) on large projects, includingeconomic-stimulus work. The proposedFederal Acquisition Regulation change, publishedon July 14, says agencies shouldconsider requiring PLAs on jobs of $25 millionor more. It follows President Obama’sFeb. 6 directive overturning the Bush administration’sban on federal PLAs.Labor unions lobbied for the rule changein the 2008 presidential campaign. AFL-CIOBuilding and <strong>Construction</strong> Trades Dept.spokesman Tom Owens says the rule will“be a great opportunity for us to demonstrateour value in certain regions of thecountry where we haven’t been as successfulin the private markets.”Although the rule is not yet final, Office ofManagement and Budget Director PeterOrszag sent a memo calling on agencies tobegin to consider “the value of PLAs on aproject-by-project basis and to require theuse of PLAs in appropriate circumstancesand to the extent permitted by law.”Associated Builders and ContractorsChairman Jerry Gorski says the proposedrule violates procurement laws and regulations.“Any agency that issues an unlawfulunion-only PLA should expect to face a legalchallenge,” he warns.The Associated General Contractors alsoopposes government-mandated PLAs. AGChopes agencies “will leave the decision ofwhether to perform construction work undera collective bargaining agreement up to thecontractor employers and employees asprovided under federal labor law,” says DeniseGold, general counsel for labor and employmentlaw. She says AGC is pleased thatunder the proposal, the government wouldnot take part in PLA negotiations. AGC hopesthe policy will apply to <strong>com</strong>panies that actas contract managers for the agencies.By Bruce Buckleyphoto by ap/wideworld

Be better at it.At URS, we believe that a successful result seldom <strong>com</strong>esabout by chance and that a <strong>com</strong>pany should be measured bywhat it ac<strong>com</strong>plishes, not by what it promises. So whetherit’s an airport, bridge, highway, or rail line, our determinationnever changes. To do it better. Which is why, when it <strong>com</strong>esto transportation, more people are turning to us to get it done.We are the new URS.POWERINFRASTRUCTUREFEDERALINDUSTRIAL & COMMERCIALURSCORP.COM

NewsrailVictorian-Era TracksEnter the 21st CenturyEngineers and up to 2,000 workers inLondon have been stitching togetherand modernizing sections of three19th-century urban railroads—two defunctand one live—to close a gap of under3 km in the northeast corner of thecity’s emerging orbital route.Over $1 billion is the expected endcost for the three-year project extendingand improving this short stretch of Victorian-erainfrastructure in the crowdedmetropolis. “It is a very <strong>com</strong>plex projectbecause here you are dealing with oldVictorian [viaduct] arches,” says AshokKothari, a board director of ParsonsBrinckerhoff Inc., New York City.Kothari heads program management forthe owner, Transport for London (TfL).“In the U.S., they probably wouldhave demolished the whole thing andbuilt a new one,” says Kothari. “Trying tokeep the heritage…is a good thing in mybook.” It also has caused constructionchallenges to abound all along TfL’s projectto extend its East London Line(ELL).The Balfour Beatty-Carillion JointVenture (BB-C) is replacing track andequipment along 7.5 km of the existingELL from New Cross, south of the RiverThames, to Whitechapel. It includes thetwin 365-meter-long river crossing, <strong>com</strong>pletedin 1843 as the world’s first tunnelunder navigable water. The tunnels wererelined and retracked 12 years ago.ELL crosses the mid-19th-century-eraBishopsgate Goods Yard, about 1.1 kmnorthwest of Whitechapel. About a thirdof this section is all new; the rest is upgradedwith new track and systems.Covering nearly 5 hectares, the goodsyard was the project’s most controversialelement. Challenges by conservationists,including the official English Heritage,over how much of the yard’s historic brickviaducts should be torn down raged formany months about sixyears ago.Until now, ELL terminatedin the Bishopsgatearea. Extending it about2.7 km north to DalstonJunction is the main goalof the project. Near Dalston,ELL will connect toan existing urban lineacross north London, servingthe 2012 OlympicGames site at Stratford.Completing the projectin under three years bynext June will require fasttrackwork, “and we didnot really get started untilFebruary or March 2007,”says Adam Stuart, BB-C’sconstruction director. AlthoughKothari says theteam is still on schedule,he adds, “A lot of workneeds to be done.” BB-Chas about 10% of the constructionand half the systemsto do, he says.To extend the line toDalston, the viaduct containing170 brickworkarches in Kingsland is beingrevived after sittingunused for more than 20years. “The old viaductwas leaking and had a lotof rubbish on top,” saysMartijn Donders a seniorengineer with TfL’s technicaladviser Mott Mac-Donald Group, London.Taylor Woodrow <strong>Construction</strong>,Watford, <strong>com</strong>pletedthe viaduct’s refurbishmentplus constructionof 22 bridges along its15 <strong>ENR</strong> July 20, 2009 enr.<strong>com</strong>

length in 2006 under a $50 million contractwith TfL. To link ELL and the restoredKingsland arches, BB-C has builta tightly curving, 175-m-long concreteviaduct from the goods yard.The new link includes a 35-m-longLondon’s Revamped Northeast Rail LinesDalstonJunctionExtensionWhitechapelRiver Thames0 1 2 kilometersNorth London LineHaggerstonHoxtonShoreditch High Street(Bishopsgate Goods Yard)East London LineNewCrossGateNew CrossStratfordspan bow-string arch bridge over ShoreditchHigh Street. It was placed in March2008 with a 1,200-tonne-capacity crane,the U.K.’s. largest, according to MottMacDonald. That placement went withouta hitch, but installation of the project’sbiggest bridge nearby came closeto disaster. In late May 2008, thenewly launched 84-m-long Warrentruss bridge, just east of thegoods yard, slipped off temporarybearings. One end dropped 20 cm,shedding five heavy sections ofpermanent precast-concrete deckformwork onto live tracks beneath.Nobody was hurt, and no damagewas reported.A BB-C subcontractor had assembledthe 1,300-tonne bridgenext to the six tracks it would spanand slid it into place early thatmonth. Before being lowered ontothe permanent level, the bridgerested on temporary steel packingplates over final bearings. Becauseof the bridge’s 1:30 slope, packingplates under the bridge’s Teflonwere wedge-shaped and vulnerableto slippage.Thermal movements on thebridge are suspected to haveejected the wedges at two piers,toppling a jack supporting the Tight. In less than 3 km, rail reconstruction entails a 175-m new viaduct (above), a refurbishedarch viaduct, a 35-m bow-string arch bridge, an 84-m-long Warren truss and four stations.bridge, according to an investigation byTfL. Engineering errors and inadequatesupervision were the root causes.“Two individuals working for a subcontractordid not follow the rules,” saysStuart. “As it happens, it did not end upbeing very serious.” Internal investigationswent “up to managing-directorlevel,” he adds. “There have been lessonslearned.” No prosecutions by safety authoritiesfollowed. Because the bridge wasoff the critical path, the schedule was unaffected,adds Stuart. The financial cost iscurrently being assessed.With construction largely <strong>com</strong>pleted,BB-C’s focus is now on the systems and<strong>com</strong>pleting the extension’s four new stations.Two smaller stations at Haggerstonand Hoxton are aboveground. But the oneat Dalston Junction is “like an invertedcathedral,” says Stuart.Set just belowground, the stations iscovered with a just <strong>com</strong>pleted 220-m x45-m slab consuming over half the site’s25,000 cu m of concrete. Designed to supportapartment buildings with up to 19stories, the 1.5-m-deep slab sits on bearingsbig enough for a major bridge abovepiles up to 2 m in dia., says Stuart.Designs for the new Shoreditch HighStreet station, in the goods yard, also caterto future development. As the financialdistrict’s last vacant large plot, the site willlikely be developed when markets allow.To shelter the elevated track fromoverhead work, 475 m of it is enclosed ina hefty precast concrete enclosure. Itovershadows the yard’s remaining grasscoveredviaduct, a 166-year-old structuresaved from demolition.BB-C’s design-build contract startedwith a value of about $600 million but wassubstantially expanded with extra work,says Kothari. The project’s total budget,including trains and other costs, stands atabout $1.6 billion, he adds.Agreeing on prices for the additionalwork has been “the easy bit,” says Stuart.But, he notes, getting the work done ontime has been trickier because the <strong>com</strong>pletiondeadline has been “set in tabletsof stone.” mBy Peter Reina.Photos by peter reina for enrenr.<strong>com</strong> July 20, 2009 <strong>ENR</strong> 16

Newswind powerRemote Sites, Odd RegulationsPose India Development IssueWith an installed capacity of over10,500 MW, India is currentlythe fifth-largest generator ofwind power in the world. As it adds about1,200 MW of wind capacity per year, thepotential is far from depleted, but developersare faced with challenges in erectingthe turbines in remote areas.Unlike their Western counterparts,Indian developers often must find innovativemeans to transport large turbinesthrough narrow, crowded roads to illequipped,hilly sites. “Non-availability oftransport and cranes, lack of experiencedmanpower and infrastructure [lacking]such things as cement mixers, electricallines, substations, new roads and cables,distinguish India from its Western counterparts,”says a spokesman for PunebasedSuzlon Energy, the world’s fifthlargestwind turbine maker.Most wind farms are located in remoteareas, and curved winding roads to thehills pose a logistical nightmare,says M. Chandrashekhar, generalmanager of logistics for ReGenPowertech, a Chennai-based winddeveloper. In addition, in India itis illegal to transport large elementssuch as turbine blades bytruck, so it be<strong>com</strong>es necessary to“go around” the rules by transportingequipment at night, saysan observer.“We often have to build threeto four kilometers of roads or bypassesthrough villages in certain17 <strong>ENR</strong> July 20, 2009 enr.<strong>com</strong>locations in the hills of Andhra Pradeshin South India that pose different challenges,”says Chandrashekhar.With infrastructure on sites limited,Enercon India recently set up an 8,000-sq-meter tent to house a mobile prefabconcrete-tower factory for its 800-kWturbines in the western state of Gujarat.Transporting prefab towers in the remote,undeveloped region is difficult.Towers will be produced in 18 segments;each will have a 5.50-m base diameterand a tower-top diameter of 1.80 m.A tower crane in the center distributesconcrete in the production area. A mobileconcrete mixer also is used to provideconcrete for the foundations, ensuring auniform quality of concrete.“We now have a production plantwhich we can set up anywhere in theworld within a short period of time,” saysan Enercon spokesman. By Neelam Matthews Bending the Rules. Transporting large turbine blades to construction sites poses challenges.corruptionU.K. Bridge MakerIs First To Be CitedBritish steel-bridge fabricatorMabey & Johnson wascharged with corruption abroad.British steel-bridge manufacturerMabey & Johnson Ltd. pleaded guiltyon July 10 to corrupt practices in Jamaicaand Ghana between 1993 and 2001and violating United Nations’ sanctionsagainst trade with Iraq in 2001 and 2002.The <strong>com</strong>pany is the first to be prosecuted inthe U.K. for corruption overseas and facescourt sentencing later this summer, says theSerious Fraud Office, the independent governmentagency that investigated and prosecutedthe case.Mabey & Johnson, based in Reading,England, supplies small to medium size prefabricatedmodular bridges. The firm volunteeredevidence of corruption to authoritieslast year following its own internal investigationin 2007, says a fraud office official.Allegations of corruption were made by aformer employee, says a <strong>com</strong>pany spokesman.The firm says five of eight directorsquit in spring 2008, and new managementwas installed. Fraud office officials declineto say whether they are pursuing chargesagainst individuals.“We deeply regret the past conduct of our<strong>com</strong>pany, and we have <strong>com</strong>mitted to makinga fresh start, wiping the slate clean ofthese offences,” says Peter Lloyd, Mabey’snew managing director. Disclosing its corruptionfindings to U.K. authorities could bea “template for others facing a similar situation,”he adds.“It is significant that Mabey & Johnsonhas cooperated with us to get to this landmarkpoint,” says Richard Alderman, fraudoffice director. “This has enabled this caseto be dealt with in just over a year and is amodel for other <strong>com</strong>panies who want toself-report corruption and have it dealt withquickly and fairly.” mBy Peter Reinaphotos courtesy of Regen Wind

InsuranceRisk ManagementZurich HelpP intOur surety bonds help youget the job done.Zurich HelpPoint is here when you need more than just insurance.With more than 115 years as a leader in the surety market, we offer theglobal expertise, insight and flexibility to address your most challengingcontract and <strong>com</strong>mercial surety needs. In fact, Zurich provides reliable suretycapacity to 40% of the Engineering News Record’s largest 100 contractorsand 25% of the Fortune 100 <strong>com</strong>panies. Around the corner or aroundthe world, Zurich Surety helps make getting the job done a little easier.For more details about Zurich HelpPoint, visit www.zurichna.<strong>com</strong>/surety.Here to help your world.Coverages underwritten by member <strong>com</strong>panies of Zurich in North America, including Zurich American Insurance Company. Certain coverages not available in all states.Some coverages may be written on a nonadmitted basis through licensed surplus lines brokers.

NewsBridgesNew Scheme PreparedFor Bridge-Truss Installation Prepped. Piers have been enlarged and new bracing added to prepare for widened spans.The contractor for the $453-millionsteel-superstructure portion of thewidening of the Huey P. LongBridge in New Orleans is working out thelast details of an erection sequence that isfaster, safer and interferes less with motorand marine traffic than the stick-buildsequence the owner originally proposed.MTI, a joint venture of Massman<strong>Construction</strong> Co., Kansas City; TraylorBros. Inc., Evansville, Ind.; and IHI Inc.,New York City, with consulting engineerHNTB Corp, Kansas City, have devised19 <strong>ENR</strong> July 20, 2009 enr.<strong>com</strong>a plan to barge-position, lift and connectpre-assembled trusses on three of theMississippi River bridge’s four spans. Thefinished bridge will be “triple-barrel,”with four parallel trusses separating tworoadways and a center rail line. “Singlebarreltrusses have been hoisted like thisbefore, but I don’t believe anyone has everhoisted triple-barrel,” says Steve Underwood,MTI project manager.The Louisiana Dept. of Transportationand Development, the marine industry,U.S. Coast Guard and U.S. ArmyCorps of Engineers have approved theplan, Underwood says. “The marine industryis as excited as we are,” he says.Stick-built would have taken a lot of falseworkon the river, which would increasemarine traffic restrictions and hazards.The plan improves safety for the contractoras well, says Sean McInerney, MTI’sassistant project engineer, because workersaccess the job from the bridge, notfalsework on the river.“Another reason we went with thissystem is to take the stresses away fromthe existing truss,” Underwood says.“That was one of the selling points to theowner. It puts the existing structure in asafer condition at all times.”There is no way to tie the two independentchords together and lift aroundthe existing operative bridge, so MTI devisedtwo U-shaped stability frames tohold the trusses plumb. The base of eachframe is formed by 6-ft-deep by 160-ftlongbox-section floor beams. Towers,100 ft tall, 18 ft deep and 113 ft wide, arebraced to the beams to hold the trusses inposition.Prior to erection, MTI will set 140-ftwidehorn beams over the bridge’s existingtrusses. Once the new trusses are on thebridge bearings, the horn beams will holdand brace them until secondary membersare installed and other attachments aremade. The trusses will be lifted by four900-ton lifting-strand jacks placed ontowers over the bridge bearings. They willbe guided into place by 150-ton horizontaljacks on the floor beams. The heaviestspan, with its stability frames, is 4.9 millionlb, McInerney says.MTI expects the first truss erectionwill take about 48 hours to position, liftand attach, Underwood says. “Withinthose 48 hours, rail and motor traffic willcontinue, and there will be only 20 hoursof full closure to marine traffic.”“We expect to start assembling stabilityframes in late September and receivepermanent steel by late July or early August,”Underwood says. MTI plans to usethe new sequence to erect the east-bankanchor span in April 2010. By Angelle BergeronPhoto top courtesy of HNTB; bottom by Angelle Bergeron for Enr

Building Information Modeling & Integrated Project Delivery:An Advantage to Your Business in a Challenging EconomyOUR INDUSTRY IS CHANGING – FOR THE BETTER.September 21-22, 2009 | San Francisco, CaliforniaCompanies that have embraced BIM and IPD are reaping their benefits on thedesign, delivery and operation of every project – integrated design solutionsthat are optimized for quality, aesthetics, constructability, affordability, andseamless flow into lifecycle management.As recognition of the benefits of BIM and IPD grows, the ability of designand construction <strong>com</strong>panies to work effectively in this new environment willincreasingly be<strong>com</strong>e a <strong>com</strong>petitive differentiator in winning work. And ownersthat can more accurately control costs, quality and schedule, can use theircapital resources much more effectively. In challenging economic times,this kind of “edge” is critically important to survival.The 2009 Business of BIM Conference will provide you with an in-depth lookat <strong>McGraw</strong>-<strong>Hill</strong> <strong>Construction</strong>’s research on the specific business aspects ofBIM and IPD, with a focus on benefits, emerging contracting strategies,and actual case studies.September 21-22, 2009San Francisco, CALEARN MORE. VISIT:construction.<strong>com</strong>/events/natlbim/$325 EarlybirdRegistration Fee$425 if You RegisterAfter August 14thEARN7 AIACONTINUINGEDUCATIONCREDITSJOIN US AT THE 2009 BUSINESS OF BIM CONFERENCE.To register, GO TO construction.<strong>com</strong>/events/natlbim/OR CALL 800-371-3238.

<strong>Construction</strong> EconomicsCost Indexes<strong>Construction</strong> Cost IndexInflation rolled back 1.5% as thismonth’s modest decline was overpoweredby July 2008’s 1.3% gain.july 2009 % CHG. % CHG.20-CITY: 1913=100 InDex VALUE MONTH YEARCONSTRUCTION COST 8566.14 –0.1 +3.3COMMON LABOR 18201.18 0.0 +5.6WAGE $/HR. 34.58 0.0 +5.6Building Cost IndexJuly’s 0.2% decline in the BCI <strong>com</strong>paresto a 1.8% increase in July 2008,dropping annual inflation to 0.8%.JULY 2009 % CHG. % CHG.20-CITY: 1913=100 INDEX VALUE MONTH YEARBUILDING COST 4761.54 –0.2 +0.8SKILLED LABOR 8199.67 +0.1 +4.5WAGE $/HR. 45.51 +0.1 +4.5Materials Cost IndexSteel prices fell for the fourth consecutivemonth, helping to pull theMCI 1.4% below last year’s level.july 2009 % CHG. % CHG.20-CITY: 1913=100 INDEX VALUE MONTH YEARMATERIALS 2660.80 –0.7 –5.5CEMENT $/TON 101.33 +0.5 +0.9STEEL $/CWT 43.51 –1.2 –6.6LUMBER $/MBF 411.43 0.0 –4.1<strong>Construction</strong> Down by Double DigitsTotal construction put-in-place isdown 12% from a year ago,according to the U.S. Dept. ofCommerce data through May of thisyear. Through the first five months of2009, the seasonally adjusted annualrate for construction was $964 billion,down 0.9% from a month ago and11.6% from May 2008 (see chart).On a year-to-date basis, the dollarvalue of all construction put-in-placethrough the first five months of theyear was $377 billion (see table). Thatwas 3.8% better than the previousmonth but still 11.7% below the sameperiod of a year ago.The housing market posted thebiggest year-to-year decline, down34% from last year’s alreadydepressed level. However, severalnonresidential building markets havealso slipped into negative double-digitnumbers. Compared to the first fivemonths of last year, the market isdown 26% for <strong>com</strong>mercial buildings,18% for office buildings and 11% forhotel and motel work.On the plus side, the health-caremarket is up 1.9% over a year ago.Private power construction is up 14%from 2008’s levels, while privatemanufacturing construction is up 52%for the same period.10501000950900Total <strong>Construction</strong>In $ Billion850Dec. Jan. Feb. March April May2008–2009SOURCE: U.S. DEPT OF COMMERCE. CONSTRUCTION PUT-IN-PLACE,SEASONALLY ADJUSTED ANNUAL RATE IN CURRENT DOLLARS.Private <strong>Construction</strong>Annual Value of <strong>Construction</strong> 2009 2008 % CHG. % CHG.$ Bil. MAY MAY MOnth YEARTOTAL CONSTRUCTION 368.78 417.54 +3.8 –11.7TOTAL PRIVATE CONSTRUCTION 255.20 308.13 +2.6 –17.2RESIDENTIAL BUILDINGS 95.16 143.79 +3.9 –33.8LODGING 12.69 14.30 –2.6 –11.2OFFICE 19.16 23.30 +1.0 –17.8COMMERCIAL 24.92 33.63 –3.3 –25.9HEALTH CARE 15.48 15.19 +0.6 +1.9EDUCATIONAL 7.00 7.19 +4.7 –2.6RELIGIOUS 2.75 2.80 –2.3 –1.7AMUSEMENT & RECREATION 3.70 4.43 –4.5 –16.4TRANSPORTATION 3.55 3.96 +7.3 –10.4COMMUNICATION 7.96 11.25 –2.9 –29.2POWER 29.42 25.80 +5.8 +14.0MANUFACTURING 32.80 21.55 +6.0 +52.2SOURCE: Dept. of Commerce. <strong>Construction</strong> put-in-place. Details may not add totalsince all types of construction are not shown separately.Lumber, Plywood, PlyformITEM UNIT ATLANTA BALTIMORE BIRMINGHAM BOSTON CHICAGO CINCINNATI CLEVELAND DALLAS DENVER DETROIT KANSAS CITY2” x 4”: S4SPine mbf –365.30 365.00 325.00 362.80s –474.70 — 300.00s +488.00 — 290.00 —Fir mbf — — 250.00 — –498.11 360.00 — — –442.10 300.00 –450.00Common mbf –394.65 365.00 325.00 –387.50s –577.95 +265.00 320.00s +542.00 –444.70 300.00 –400.002” x 6”: S4SCommon mbf 452.00 +345.00p 300.00p 346.00s 498.15 +275.00p 600.00c 475.00p –506.90 590.00s –450.00f2” x 8”: S4SCommon mbf 475.00 +360.00p 260.00p 367.50s 575.50c +300.00p 730.00c 472.00p –489.90h 640.00s –470.00f2” x 10”: S4SCommon mbf 492.93 +425.00p 325.00p 401.12s 497.00h +340.00p 505.00p 578.19p 422.00h 760.00s –550.00f4” x 6”: S4SCommon mbf 782.30 465.00p 550.00 648.88s 754.00f +425.00 695.00 672.00 1180.00 620.00p —4” x 12”: S4SCommon mbf — 750.00p — — 904.58 850.00 — — 1135.00 720.00p 1685.00PLYWOOD: 5/8” THICK msf 669.00 +445.00 400.00p 641.13 726.55f +395.00 475.00p +708.00 719.00 620.00 –590.00PLYFORM: 3⁄4” THICK msf 929.55 –725.00 875.00 712.00 945.40p 1145.00 910.00 +992.45 946.39 940.00 –1330.00PARTICLE BOARD: UNDERLAYMENT5/8” msf 400.82 275.00 250.00 501.80 419.08 280.00 330.00 +538.30 407.51 408.00 230.00GYPSUM BOARD: REGULAR1/2” msf 255.49 195.00 185.00 376.50 243.55 +190.00 240.00 +254.20 260.10 240.00 –215.005/8” msf 264.25 215.00 270.00 222.65 244.50 250.00 — +279.15 303.65 — 245.00Type-X:1/2” msf 279.10 215.00 215.00 239.10 263.45 200.00 240.00 +300.00 307.00 240.00 260.005/8” msf 292.00 215.00 215.00 270.00 281.10 220.00 270.00 +304.55 311.19 270.00 245.00ROOFING INSULATION: UNFACED sf 5.52 6.05 4.40 7.70 6.42 6.00 7.00 6.05 6.10 6.80 8.05WALL INSULATION: UNFACED sf 5.28 5.52 4.40 5.22 5.28 5.05 6.40 6.71 5.75 5.50 7.50PIPE INSULATION: FIBERGLASS sf 6.35 6.75 6.19 7.05 5.90 6.00 8.80 7.00 6.99 8.40 6.73+ or – denotes price has risen or fallen since previous report. c=spf, d=dougfir, f=fir, h=hemfir, p=pine, s=spruce. Monthly market quotations by <strong>ENR</strong> field reports as of July 10, 2009. All prices arespot prices quoted from a single source. Common lumber prices are those quoted for the most popular species in the area. Quotes are delivered prices. Some prices may include taxes or discountsfor prompt payment, etc. Product specification may vary, depending on what is most <strong>com</strong>monly used or most acces sible in a city. All quantities are truckloads unless noted. Quotes for Montreal and21 <strong>ENR</strong> July 20, 2009 enr.<strong>com</strong>

Lumber Prices Seek BottomThe depressed housing market is stillpushing lumber prices down. <strong>ENR</strong>’s 20-cityaverage price for the most <strong>com</strong>monly usedspecies of 2X4s fell another 2.5% this month,pushing prices 5.2% below a year ago. In part,this reflects the 4.8% decline in the mill pricereported for May by Random Lengths, Eugene,<strong>ENR</strong>’s Materials Price Indexes1992=1002182172162152142131992=100142141140139138137GYPSUM WALLBOARDO N D J F M A M J J2008-2009Prices slipped 0.1% this month,continuing a long decline.PLYWOODO N D J F M A M J J2008-2009This month’s 0.8% price declinerolls back June’s rebound.1992=1001611601591581571561992=100118116114112110108Source: <strong>McGraw</strong>-<strong>Hill</strong> <strong>Construction</strong> research & Analytics/enr.Ore. Random Lengths’ <strong>com</strong>posite mill priceindex for framing lumber rebounded 12% inJune, but that is still 17% below June 2008’slevel and 48% below June 2004’s peak.Random Lengths’ <strong>com</strong>posite price for panels,including plywood and OSB panels, is down22% for the year and 45% from 2004’s peak.PARTICLE BOARDO N D J F M A M J J2008-2009The housing depressionhas flattened out prices.LUMBERO N D J F M A M J J2008-2009July’s 2.5% price declineseeks a new bottom for lumber prices.20-City Averageenr.<strong>com</strong>For a <strong>com</strong>plete history of costindexes, visit our Website, enr.<strong>com</strong>.% CHG. % CHG.ITEM UNIT PRICE MO. YEAR2” x 4”: S4SPine mbf 379.04 –0.2 –4.9Fir mbf 428.69 –3.1 –6.4Common mbf 388.22 –2.5 –5.22”x 6”: S4SCommon mbf 425.89 –0.3 –4.42” x 8”: S4SCommon mbf 461.42 –2.4 –3.92” x 10”: S4SCommon mbf 491.14 0.0 –2.84” x 6”: S4SCommon mbf 756.31 +0.1 –0.34” x 12”: S4SCommon mbf 1023.86 0.0 –0.5PLYWOOD: 5/8” THICK msf 589.42 –0.8 –2.7PLYFORM: 3⁄4” THICK msf 1019.53 –1.1 –2.8PARTICLE BOARD: UNDERLAYMENT5/8” msf 387.01 0.0 +0.6GYPSUM BOARD: REGULAR1/2” msf 255.52 –0.1 –2.35/8” msf 261.51 +0.1 –0.7Type-X, 1/2” msf 264.14 +0.1 –0.35/8” msf 277.13 +0.1 –1.6ROOFING INSULATION: UNFACED sf 6.54 0.0 +0.8WALL INSULATION: UNFACED sf 5.35 0.0 +1.5PIPE INSULATION: FIBERGLASS sf 6.81 0.0 +0.8CanadaITEM UNIT Los Angeles Minneapolis New Orleans New York Philadelphia Pittsburgh St. Louis San Francisco Seattle Montreal Toronto2” x 4”: S4SPine mbf 409.26 290.00s –392.50 — — 473.00 280.00 416.08 –454.00h +320.00s 470.00Fir mbf 480.68 — — 560.00f –450.28 532.00 310.00 489.76 –450.00 — —Common mbf 418.91 300.00f –417.00 380.00 +383.50 370.00 310.00p 420.49 –442.65 +320.00s 470.002” x 6”: S4SCommon mbf 450.27 480.00s –434.85p — 382.75 428.00s 254.00p 450.82 –434.15 +355.00p 490.00s2” x 8”: S4SCommon mbf 470.35 690.00s –465.00p — 384.50 439.00s 280.00p 472.51 –512.05f +365.00p 570.00s2” x 10”: S4SCommon mbf 498.71 900.00f –557.75p — 444.75 337.00s 301.00p 499.33 –553.00f — 560.00s4” x 6”: S4SCommon mbf 780.60 1000.00 840.00 — 1252.00 530.00 414.00p 783.29 677.50 — —4” x 12”: S4SCommon mbf 1030.44 1077.00 — — 1298.00 — 520.00f 1035.19 930.00 — —PLYWOOD: 5⁄8” THICK msf 621.49 621.00 577.00 — 699.00 469.00 530.00f 623.51 688.67 +685.00 715.00PLYFORM: 3⁄4” THICK msf 1000.09 1198.00 885.90 — 1200.85 1221.00 1380.00 1010.41 1018.50 1150.00 820.00PARTICLE BOARD: UNDERLAYMENT5/8” msf 390.74 340.00 382.58 — 487.95 330.00 385.00 393.20 450.22 +385.00 620.00GYPSUM BOARD: REGULAR1/2” msf 284.52 240.00 257.82 — 289.25 270.00 240.00 286.91 267.00 +305.00 340.005/8” msf 267.11 — 259.95 — 293.75 — — 268.09 278.00 — —Type-X1/2” msf 269.39 — 270.35 — 303.95 295.00 240.00 270.01 266.00 +385.00 530.005/8” msf 290.94 270.00 277.89 — 305.10 300.00 270.00 292.77 282.00 –385.00 —ROOFING INSULATION: UNFACED sf 7.91 6.30 6.34 — 6.87 6.90 6.80 7.99 7.00 +8.48 6.00WALL INSULATION: UNFACED sf 5.01 4.80 5.80 — +4.87 4.10 5.50 5.06 5.18 +5.85 4.30PIPE INSULATION: FIBERGLASS sf 6.00 9.60 6.28 — 6.92 3.43 8.69 6.33 6.39 10.06 11.01Toronto are in Canadian dollars and a mix of metric and American units. Montreal prices do not include 15% sales tax. The above prices are not intended to represent the prevailing or average price in acity but are designed to track price movement from a single source for a given quantity and specification over time.enr.<strong>com</strong> July 20, 2009 <strong>ENR</strong> 22

Cover Story Tall BuildingsBy Peter ReinaWrenches Put InTower’s WorksArchitect’s twisty slant impedes construction of 160-meter high-rise in Abu Dhabi23 <strong>ENR</strong> July 20, 2009 enr.<strong>com</strong>

An Abu Dhabi developer is putting an eye-catching spinon its 160-meter-tall flagship building by giving it a startling18° list with a slight twist. Swathed in a structuralsteeldiagrid, Capital Gate’s wavy profile, currently twothirdsup, makes the Tower of Pisa, tilting only 5° from its verticalaxis, seem positively upright. Getting the newer leaning tower totake on its deceptively leisurely lean is creating geometrical puzzlesfor its contractors. “Every steel member is different,” saysWerner Matyas, senior project manager with the owner’s managementfirm, Mace Group Ltd., London. Around 7,000 tonnes of Triangles. Diamond-shaped curtain-wall panels fitover diagrid perimeter framing of tilted, twisted tower,the icon for a development in Abu Dhabi (right).structural steel is going into thebuilding’s primary diagrid and asmaller one around an atrium.Because of the lazy-S profileand elliptical floor plates, each ofover 12,000 glass panes formingthe prefabricated diamond-shapedcladding units is a different size.The need to precamber and posttensionthe core is novel even forthe job’s seasoned managers.To achieve the westward tilt,successive floors are being staggeredby varying amounts fromlevel 10, explains architect RobinGibson, project director withRMJM Group Ltd., Edinburgh,the building’s design architectengineer.The elliptical floor plates “areall more or less the same sizethroughout the tower,” says Gibson.Between levels 10 and 27, theroughly 50-m x 35-m floors stepout between 80 centimeters to1.40 m. They then stagger back in90-cm to 30-cm increments. Fi-nally, the top will be displaced some 30 moff center.The 33-story Capital Gate is intendedto be “one of the key visual icons” of theemirate’s growing Capital Centre mixedusedevelopment, says an official with theowner, Abu Dhabi National ExhibitionsCo. Looming over the two-year-old NationalExhibition Centre, the 53,000-sq-mbuilding will ac<strong>com</strong>modate offices in thefirst 16 floors, below two equipment levels.Above these floors, a 200-room, fivestarhotel will rise from a sky-lobby startingat floor 18. A glazed internal diagridenclosing the lobby will rise to form anatrium reaching the roof. At floor 19, anopen-air swimming pool will cantileverfrom the building against the lean.photo opposite courtesy of Waagner Biro Stahlbau; left courtesy of Mace; right courtesy of ADNECDiagridThe main perimeter diagrid is a mesh ofdiagonal elements of 60-cm x 40-cm rectangularsteel sections, with horizontal perimeterbeams between the nodes. Compositefloors span from the truly vertical,tilt-free structural concrete core to theperimeter diagrid nodes.Eighteen diagrid triangles encircleeach level of the building. With its shelllikebehavior, the diagrid provides a perimeterstructure with a varying verticalgeometry, which eliminates the need forcolumns that would otherwise have tochange positions and intrude in the interiorspaces. “The diagrid...is really an obviouschoice in this context over the conventionalapproach, which would not besuitable,” explains Gibson.Diagrid elements transfer perimetervertical and lateral forces to the ground.Some act as stays for the tilting tower. Axenr.<strong>com</strong>July 20, 2009 <strong>ENR</strong> 24

Cover Story Tall BuildingsSKYSCRAPER’s Big Lean is 18° FROM the Vertical AxisElements for steel diagrids (above and right)are prefabricated into crosses before crewserect them. The concrete core (left) hadto be precambered to ac<strong>com</strong>modate theeccentric loads of the diagrid. The <strong>com</strong>plexgeometry slowed the work.ial tensions reach 850 tonnes in places,according to the project director.The eccentric loading also puts someof the building’s 490 piles, up to one meterin diameter, into tension. However,because of the podium’s large footprint,“piles are not predominantly in tension,”says Gibson.In November 2007, crews began workon the piles, which support the tower’s2-m-deep, 6,000-cu-m foundation slab.Core work followed five months later.The local main contractor, Al HabtoorEngineering, is self-performing concretework. It contracted structural-steel workto Malaysia’s Eversendai Corp., KualaLumpur.Al Habtoor’s roughly $250-millionmain contract, started two years ago, coversvirtually all aspects of construction,except fitting out office floors, says ColinWillats, Al Habtoor’s project director.Lower-level core walls have dense reinforcement,with about 700 kilogramsper cu m of rebar. Initially, it took workersabout two weeks to cast one level, saysDavid Fullarton, MACE’s project director.Currently, “we are doing a cycle everysix days,” adds Willats.Because the rising core bends underthe eccentric loads of the structural steel,it is precambered by a total of 35 cm toensure correct final positioning, says Fullarton.“I’ve not seen it being done before,”he adds.With the precambered core addingpressure to the formwork, Austrian-basedsupplier Doka Industrie GmbH, Amstetten,has reinforced its panels with extrawaling, says an official. The firm hassupplied 78 automatic climbing formworkunits to the job.At least four floors below the top of thecore, Eversendai’s steel erectors are puttingup the diagrid. The main diagrids willinclude 2,124 structural elements, withanother 384 roughly 50-cm-dia steel tubesaround the atrium, according to RMJM.Under its approximately $55-millionsubcontract, Eversendai is welding one-story-deep, X-shaped steel modules togetherto build up the diagrids. A crew ofover 60 welders is at work, says Willats.Welding, to reduce the size of joints, isbeing used much more extensively thanin a typical U.K. project, he adds.Horizontal beams of the perimeter diagridsand the 80-cm-deep girders of the<strong>com</strong>posite floors are bolted to the nodes.Because of the ever-changing geometry,“we have to make individual jigs forevery diagrid,” says P. Baskaran, Eversendai’sproject manager.Building Information ModelEversendai is fabricating modules at plantsin Sharjah and Dubai with steel mainlyfrom Europe. The firm is using Finland’sTekla Structures steel-building informationmodeling software to transfer membergeometry from the detailing phasestraight to fabrication and, finally, to setout diagrids for erection.The subcontractor is building up thediagrid’s heavier pieces from steel plate,renderings left and bottom right courtesy of Tekla Corp.; photos left and top right courtesy of Mace25 <strong>ENR</strong> July 20, 2009 enr.<strong>com</strong>

enderings top courtesy of rmjm; bottom courtesy of ADNECCapital Gate tower at Capital Centre has ahotel above mechanical levels that top officespace. The high-rise’s novel shape is createdby staggering elliptical-in-plan floor plates.The concrete core remains vertical throughout.which is up to 8 cm thick. Lighter elementsfor higher up the building are standardrectangular hollow sections. Diagridsare sprayed with a three-hour fire-protectioncoating during fabrication.It took until last September beforeEversendai’s erectors were at “full speed,”finishing one floor every five and a halfdays, says Baskaran. Since starting in Junelast year, workers were stalled by the concretecore’s initially slow rise and theirown learning curve, he adds.The steel erectors’ ascent over the pastcouple of months was also close to a snail’space because of the three structurally<strong>com</strong>plicated mechanical levels above floor16, says Willats. Eversendai has nowcleared those heavily structured floors andis moving at a fuller tilt again, using extrashifts, he adds.While steel erection was beginning,engineers with Austria-based Waagner-Biro Stahlbau A.G., Vienna, were workingout how to enclose the oddly shapedbuilding. The roughly $45-million claddingcontract includes the facade’s 6,500-sq-m portion of sunscreen mesh, whichwill flow decoratively down the east sidefrom the 19th-floor swimming pool. Theplan is for the “splash” of stainless steel toalso cover the adjacent exhibition grandstand.To ease the logistics, Waagner-Birosaid no to the architect’s idea of having thecladding built up with triangular glasspanes within a mullion system supportedat each floor, says Johann Sischka, thefirm’s senior vice president.Though the cladding is more <strong>com</strong>plicatedthat most curtain-wall systems, Sischkaadopted a prefabrication method tofacilitate the installation. “I believe nobodyhas done it before...with such astructure,” he says.The firm is prefabricating roughly8-m-tall diamond-shaped panels, whichcrews are currently superimposing on thediagrids. The two-story-deep panels are7 m to 9 m wide and include 18 pieces ofglass panes of different sizes.Over 700 panels will form the roughly23,000 sq m of cladding, according to Sischka.Nearly 23,000 pieces of steel willform the cladding’s framework, and eachis different, he adds. In the hotel areas andsome other places, plans call for a ventilateddouble facade, which will reduceenergy use.Waagner-Biro is having the facadesteel laser-cut in Germany and Slovakiaand shipped in containers to the Gulf.Workers are assembling and paintingcladding panels in Abu Dhabi in an offsiteplant.Having started in January, crews fromWaagner-Biro have installed the panelsabout halfway up the tower. The team isrigidly attaching each diamond-shapedpanel to the diagrid at its center point.Additional fixings at the panels’ top cornersallow vertical and horizontal movementrelative to the diagrid. Fixings atcorners on either side can slide onlyhorizontally.The panels must be free to move relativeto the building both to ac<strong>com</strong>modatenormal tolerances and the effect of theprecambering, says Sischka. Joints betweenpanels are 5.5 cm wide with 0.2 cmtolerance. Sischka estimates total movementbetween panels due to the precamberat 1 cm.The main contract called for work toend next month. But, “at the moment weare heading for a shell, core and cladding<strong>com</strong>pletion at the end of October,” saysFullarton. The building at least must look<strong>com</strong>plete for Abu Dhabi’s first-ever FormulaOne car Grand Prix race on Nov. 1,he adds.MACE joined the job in July 2007,when construction prices were going“through the roof,” says Fullarton. “Mostcontractors were hit.”Speaking generally, he says owners inthe region have since tried to gain fromthe recession by pushing for price cuts.But with prices typically fixed in contracts,the situation has be<strong>com</strong>e “tricky,” addsFullarton. Anyway, the regional constructionrecession may now be turning, hehints. “Steel is going up in price as is concrete,”Fullarton points out. enr.<strong>com</strong> July 20, 2009 <strong>ENR</strong> 26

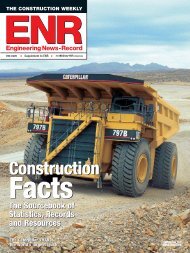

ProductsUpgraded Tractor-Scraper: More PowerThe G Series of the 613 Wheel Tractor-Scraper features several upgrades to itsdesign, including increases in powertrain efficiency, rim pull, elevator speedand travel speed. The 613G has a 11-cu-yd capacity and is able to cut and fill,finish grade, stockpile and condition material. A new safety valve preventsaccidental articulation when the operator is entering or exiting the cab whileholding the steering wheel. Caterpillar; 309-675-1000; www.cat.<strong>com</strong>Seismic Bracing:Easy-To-Install ClampFits Many SizesCompact Press Tool: Small Sizeand Better Battery LifeThe Model RP 210-B press tool is the smallest toolin the RIDGID line. The tool is able to makeconnections up to 1 1 ⁄4-in. The tool has a 270-degreerotation and a flattened top for easier use inconfined spaces; it is powered by a lithium-ionbattery. RIDGID; 800-769-7743; www.ridgid.<strong>com</strong>The mechanical FastClamp attachment is partof the TOLCO line ofseismic bracing. It providesup to 12 in. of adjustment,allowing faster installationwith less guesswork. Theattachment’s fast-attachyoke can handle varioushanger-rod sizes and types.TOLCO; 800-786-5266;www.tolco.<strong>com</strong>Retractable-Cord ReelS: Many Customizable OptionsThe industrial-grade retractable-cord reels from K&H Industriesare designed for medium- and heavy-duty applications and areable to ac<strong>com</strong>modate cord lengths from 10 ft to 150 ft. The reelshave many possible mounting options, and the spring-ratchetedmechanism retracts the cord quickly. The reels can deliver up to 50amps of portable power and can be pre-wired with a number ofitems, including work lights and portable outlet boxes.They are available with many custom configurations,including cord type, length, reel colorand assorted pre-wired options. K&HIndustries; 716-549-0135; www.khindustries.<strong>com</strong>Air Compressor: Cover Keeps Valves SecureThe XAS 185 JD7 HardHat air <strong>com</strong>pressor delivers a discharge of 185 cu ftper minute and has a 49-hp Deere engine. The air <strong>com</strong>pressor features apolyethylene canopy that will not rust, corrode, dent or fade. The canopyprotects the discharge valves from damage on the jobsite. The control panelis conveniently located at waist level, with the discharge valves on the sameend. The HardHat <strong>com</strong>pressor is able to function in extreme temperaturesand harsh conditions and features a no-load start for cold weather. The Hard-Hat <strong>com</strong>pressor has removable baffles that allow easy cleaning andmaintenance on all four sides, with easy access to filters and the <strong>com</strong>pressor’soil separator tank. It has a fuel capacity of 25 gallons and a heavygauge body. Atlas Copco <strong>Construction</strong> Equipment; 303-287-8822; www.atlascopco.usenr.<strong>com</strong> July 20, 2009 <strong>ENR</strong> 28

ProductsHeavy-Pipe Fusion Machine: Powerful JawsThe MegaMc 1600 four-jaw fusion machine is able to butt-fuse high-densitypolyethylene pipe as small as 20 in. and as large as 65 in. in diameter. The fusionmachine has 30,000 lb of clamping power in each of its jaws and can handleheavy-walled pipe segments. The fourth jaw is removable for easier fitting, and theunit is road-ready and easily transported to jobsites. McElroy ManufacturingInc.; 918-836-8611; www.mcelroy.<strong>com</strong>Engine Additive: Smoother SurfacesGO-15 is a metal-surface conditioning treatment intendedto improve the durability and performance of constructionequipment and trucks. According to the maker, whenadded to motor oil, Go-15 reduces friction oninternal engine <strong>com</strong>ponents, reducing emissions andimproving performance. Engineous USA Inc.;847-372-0401; www.go-15.<strong>com</strong>Custom-Shape Sewer Pipe:Fits Non-Circular SewersThe new HOBAS NC-Line consists of glass-reinforcedpolyester pipes designed for constructionor rehabilitation of non-circular sewers. The pipescan be fabricated in virtually any shape—bothcircular and non-circular—to fit inside the oldsewer system needing rehabilitation. The NC-Lineof pipes contain polyester resin, quartz sand andglass. The pipes can be manufactured indiameters up to 118 in. and are available in a variety of wall thicknesses, depending on thecustomer’s design requirements. NC-Line sewer pipes are inherently corrosion-resistant and havebeen engineered to maintain maximum flow capacity after installation. HOBAS Pipe USA;800-856-7473; www.hobaspipe.<strong>com</strong>Testing for FirmFoundations:Wireless SensorsThe Pile Driving Analyzersystem allows the evaluationof the load-bearingcapacity of all types of deepfoundations using accelerometersand straintransducers. The piezoelectricaccelerometersseen below are capable ofreal-time data transmissionandare available with awireless-radio transmissionoption with a 100-meterrange. Pile Dynamics,Inc.; 216-831-6131; www.pile.<strong>com</strong>Info BoxSelect the product informationyou want and contact themanufacturer at either the Websiteor phone number provided.Manufacturers can send informationon new products to<strong>ENR</strong>_Products@mcgraw-hill.<strong>com</strong>29 <strong>ENR</strong> July 20, 2009 enr.<strong>com</strong>