ASTM 2178 and 2357 Explained

ASTM 2178 and 2357 Explained

ASTM 2178 and 2357 Explained

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Workshop Overview• Scope of the st<strong>and</strong>ards:

Workshop Overview• Scope of the st<strong>and</strong>ards:• <strong>ASTM</strong> E<strong>2178</strong>-11 St<strong>and</strong>ard Test method forAir Permeance of Building Materials

Workshop Overview• Scope of the st<strong>and</strong>ards:• <strong>ASTM</strong> E<strong>2178</strong>-11 St<strong>and</strong>ard Test method forAir Permeance of Building Materials• <strong>ASTM</strong> E<strong>2357</strong>-11 St<strong>and</strong>ard Test method forDetermining Air Leakage of Air BarrierAssemblies

Workshop Overview• Scope of the st<strong>and</strong>ards:• <strong>ASTM</strong> E<strong>2178</strong>-11 St<strong>and</strong>ard Test method forAir Permeance of Building Materials• <strong>ASTM</strong> E<strong>2357</strong>-11 St<strong>and</strong>ard Test method forDetermining Air Leakage of Air BarrierAssemblies• Step by step review of the st<strong>and</strong>ards

Workshop Overview• Scope of the st<strong>and</strong>ards:• <strong>ASTM</strong> E<strong>2178</strong>-11 St<strong>and</strong>ard Test method forAir Permeance of Building Materials• <strong>ASTM</strong> E<strong>2357</strong>-11 St<strong>and</strong>ard Test method forDetermining Air Leakage of Air BarrierAssemblies• Step by step review of the st<strong>and</strong>ards• The test report <strong>and</strong> its content

Scope of the st<strong>and</strong>ards

Scope of the st<strong>and</strong>ards<strong>ASTM</strong> E<strong>2178</strong>-11 St<strong>and</strong>ard Test method forAir Permeance of Building Materials

Scope of the st<strong>and</strong>ards<strong>ASTM</strong> E<strong>2178</strong>-11 St<strong>and</strong>ard Test method forAir Permeance of Building Materialsa) Determine the air permeance of buildingmaterials at various pressure differentials withthe intent of determining an assigned airpermeance rate of the material at the referencepressure difference (DP) of 75 Pa.

Scope of the st<strong>and</strong>ards<strong>ASTM</strong> E<strong>2178</strong>-11 St<strong>and</strong>ard Test method forAir Permeance of Building Materialsa) Determine the air permeance of buildingmaterials at various pressure differentials withthe intent of determining an assigned airpermeance rate of the material at the referencepressure difference (DP) of 75 Pa.b) Intended to assess flexible sheet or rigid panel-typematerials using a 1 m X 1 m specimen size.

Scope of the st<strong>and</strong>ards<strong>ASTM</strong> E<strong>2357</strong>-11 St<strong>and</strong>ard Test method forDetermining Air Leakage of Air BarrierAssembliesDetermination of the air leakage rate of air barrierassemblies that are used in building enclosures.Measures the air leakage of a representative airbarrier assembly before <strong>and</strong> after exposure tospecific conditioning cycles <strong>and</strong> then assigns arating dependent upon the results.The method may also be applied to site mockups.

Step by step review of the st<strong>and</strong>ards<strong>ASTM</strong> E<strong>2178</strong>-11 St<strong>and</strong>ard Test method forAir Permeance of Building Materials

Step by step review of the st<strong>and</strong>ards<strong>ASTM</strong> E<strong>2178</strong>-11 St<strong>and</strong>ard Test method forAir Permeance of Building Materials• Minimum of 5 samples to be tested;

Step by step review of the st<strong>and</strong>ards<strong>ASTM</strong> E<strong>2178</strong>-11 St<strong>and</strong>ard Test method forAir Permeance of Building Materials• Minimum of 5 samples to be tested;• At six differential pressures ranging from25 Pa to 300 Pa (0,52 psf to 6,25 psf);

Step by step review of the st<strong>and</strong>ards<strong>ASTM</strong> E<strong>2178</strong>-11 St<strong>and</strong>ard Test method forAir Permeance of Building Materials• Minimum of 5 samples to be tested;• At six differential pressures ranging from25 Pa to 300 Pa (0,52 psf to 6,25 psf);• The air permeance rate of the material at thereference pressure difference (DP) of 75 Pais determined by curve fitting of the test data(30 data points).

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureTest Apparatus:

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureTest Apparatus:• Airtight Test Chamber;

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureTest Apparatus:• Airtight Test Chamber;• Precise Flow Measuring Device;

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureTest Apparatus:• Airtight Test Chamber;• Precise Flow Measuring Device;• Precise Pressure Measuring Device;

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureTest Apparatus:• Airtight Test Chamber;• Precise Flow Measuring Device;• Precise Pressure Measuring Device;• Piping <strong>and</strong> Vacuum Blower.

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureTest Apparatus schematic:

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureSpecimen Preparation:

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureSpecimen Preparation:• Conditioning for 7 days at 21°C <strong>and</strong> 50%RH;

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureSpecimen Preparation:• Conditioning for 7 days at 21°C <strong>and</strong> 50%RH;• Flexible material to be supported by wiregrid;

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureSpecimen Preparation:• Conditioning for 7 days at 21°C <strong>and</strong> 50%RH;• Flexible material to be supported by wiregrid;• Wrapping of sample in 6 mils poly;

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureSpecimen Preparation:• Conditioning for 7 days at 21°C <strong>and</strong> 50%RH;• Flexible material to be supported by wiregrid;• Wrapping of sample in 6 mils poly;• Clamping of the specimen to the testchamber.

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureTest Sequence:

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureTest Sequence:• Measure the extraneous air leakage of thetest apparatus/specimen at various staticpressure differentials (DP) as follows:25,50, 75, 100, 150 <strong>and</strong> 300 Pa;

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureTest Sequence:• Measure the extraneous air leakage of thetest apparatus/specimen at various staticpressure differentials (DP) as follows:25,50, 75, 100, 150 <strong>and</strong> 300 Pa;• Cut the top section of the polyethylenefilm;

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureTest Sequence:• Measure the extraneous air leakage of thetest apparatus/specimen at various staticpressure differentials (DP) as follows:25,50, 75, 100, 150 <strong>and</strong> 300 Pa;• Cut the top section of the polyethylenefilm;• Measure the total air leakage at the samevarious static pressure differentials;

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureTest Sequence: (continued)• After measuring the air leakage at themaximum static pressure differential (DP),300 Pa, re-measure the air leakage at 100,75, <strong>and</strong> 50 Pa to determine if themeasurement process has affected the airleakage of the material;

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureTest Sequence: (continued)• After measuring the air leakage at themaximum static pressure differential (DP),300 Pa, re-measure the air leakage at 100,75, <strong>and</strong> 50 Pa to determine if themeasurement process has affected the airleakage of the material;• Maximum increase 10%.

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureCalculation of Air Permeance:

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureCalculation of Air Permeance:• At each pressure station, the flow ratethrough the specimen shall be determinedby subtracting the extraneous air flow ratefrom the total air leakage;

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureCalculation of Air Permeance:• At each pressure station, the flow ratethrough the specimen shall be determinedby subtracting the extraneous air flow ratefrom the total air leakage;• The flow rate equation of the formQ = C·A·(DP) n shall be established by fittingthe data (30 points) on a Log/Log graph;

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureCalculation of Air Permeance:• At each pressure station, the flow ratethrough the specimen shall be determinedby subtracting the extraneous air flow ratefrom the total air leakage;• The flow rate equation of the formQ = C·A·(DP) n shall be established by fittingthe data (30 points) on a Log/Log graph;• Calculate the material permeance at thepressure differences measured. (l/s/m 2 )

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureTest Report Content:

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureTest Report Content:• Identification of the material tested,including thickness <strong>and</strong> basis weight;

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureTest Report Content:• Identification of the material tested,including thickness <strong>and</strong> basis weight;• The material sampling procedure used;

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureTest Report Content:• Identification of the material tested,including thickness <strong>and</strong> basis weight;• The material sampling procedure used;• The measured air flow versus pressuredifference data in graphic form (log/loggraph) for the specimens. The air leakagerate in l/s/m 2 at the reference pressuredifference, DP, of 75 Pa shall be identifiedon the graph;

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureTest Report Content: (Continued)• The calculated air permeance versus thepressure difference in tabular form;

<strong>ASTM</strong> E<strong>2178</strong> Test ProcedureTest Report Content: (Continued)• The calculated air permeance versus thepressure difference in tabular form;• The error analysis of the measurement.

<strong>ASTM</strong> E<strong>2178</strong> Test Procedure

Step by step review of the st<strong>and</strong>ards<strong>ASTM</strong> E<strong>2357</strong>-11 St<strong>and</strong>ard Test method forDetermining Air Leakage of Air Barrier Assemblies

Step by step review of the st<strong>and</strong>ards<strong>ASTM</strong> E<strong>2357</strong>-11 St<strong>and</strong>ard Test method forDetermining Air Leakage of Air Barrier Assemblies• For each air barrier assembly, up to threespecimens shall be tested. The proponentmay elect not to prepare <strong>and</strong> test threespecimens <strong>and</strong> combine the details ofSpecimen 3 with Specimen 2;

Step by step review of the st<strong>and</strong>ards<strong>ASTM</strong> E<strong>2357</strong>-11 St<strong>and</strong>ard Test method forDetermining Air Leakage of Air Barrier Assemblies• For each air barrier assembly, up to threespecimens shall be tested. The proponentmay elect not to prepare <strong>and</strong> test threespecimens <strong>and</strong> combine the details ofSpecimen 3 with Specimen 2;• At seven differential pressures ranging from25 Pa to 300 Pa (0,52 psf to 6,25 psf).

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureTest Apparatus:

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureTest Apparatus:• Airtight Test Chamber;

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureTest Apparatus:• Airtight Test Chamber;• Precise Flow Measuring Device;

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureTest Apparatus:• Airtight Test Chamber;• Precise Flow Measuring Device;• Precise Pressure Measuring Device;

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureTest Apparatus:• Airtight Test Chamber;• Precise Flow Measuring Device;• Precise Pressure Measuring Device;• Piping <strong>and</strong> Vacuum Blower.

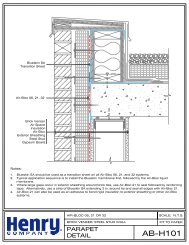

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureSpecimen Preparation:As the air barrier assembly is site-assembled, thespecimens tested shall be representative of thesite assembly. Therefore the test specimens shallbe fabricated as prescribed by the proponent inproviding for the specimen constructionrequired herein.

<strong>ASTM</strong> E<strong>2357</strong> Test Procedure

<strong>ASTM</strong> E<strong>2357</strong> Test Procedure

<strong>ASTM</strong> E<strong>2357</strong> Test Procedure

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureTest Sequence:

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureTest Sequence:• Measure the extraneous air leakage of thetest apparatus/specimen at various staticpressure differentials (DP) as follows:25,50, 75, 100, 150, 250 <strong>and</strong> 300 Pa (Bothunder positive <strong>and</strong> negative pressuredifferentials);

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureTest Sequence:• Measure the extraneous air leakage of thetest apparatus/specimen at various staticpressure differentials (DP) as follows:25,50, 75, 100, 150 <strong>and</strong> 300 Pa (Bothunder positive <strong>and</strong> negative pressuredifferentials);• Measure the total air leakage at the samevarious static pressure differentials;

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureTest Sequence: (continued)• After the initial leakage testing, thespecimen shall be exposed to a pressureloading. The loading schedule forapplication of positive <strong>and</strong> negativepressure shall be as outlined by the graphpresented here after at the predeterminedmaximum values for sustained loads, cyclicloads <strong>and</strong> gust loads.

<strong>ASTM</strong> E<strong>2357</strong> Test Procedure

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureTest Sequence: (continued)• The air leakage test shall be repeated afterthe conditioning sequence. The postconditioning permeance values shall beused to establish the system rate;• Maximum deflections of the air barriermaterial <strong>and</strong> the test specimen shall berecorded at the wind pressures equal to1,2 times the gust pressure for bothpositive <strong>and</strong> negative pressures.

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureCalculation of Air Permeance:

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureCalculation of Air Permeance:• At each pressure station, the flow ratethrough the specimen shall be determinedby subtracting the extraneous air flow ratefrom the total air leakage;

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureCalculation of Air Permeance:• At each pressure station, the flow ratethrough the specimen shall be determinedby subtracting the extraneous air flow ratefrom the total air leakage;• A flow rate equation of the formQ = C·A·(DP) n shall be established by fittingthe data (35 points) on a Log/Log graph,for both infiltration <strong>and</strong> exfiltration;

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureCalculation of Air Permeance: (Continued)• The referenced air leakage rate for eachwall assembly shall be the higher datapoint value leakage rate at 75 Pa for theexfiltration <strong>and</strong> infiltration case;

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureCalculation of Air Permeance: (Continued)• The referenced air leakage rate for each wallassembly shall be the higher data point valueleakage rate at 75 Pa for the exfiltration <strong>and</strong>infiltration case;• The reference base air leakage rate at 75 Padetermined for Specimen 1, the Opaque Wall,shall be the system air leakage rating assignedto the assembly provided that the air leakageat 75 Pa obtained for Specimen 2 is no morethan 10 % greater than the reference base airleakage for Specimen 1.

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureTest Report Content:

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureTest Report Content:• Testing agency, date <strong>and</strong> time of test, <strong>and</strong>date of report;

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureTest Report Content:• Testing agency, date <strong>and</strong> time of test, <strong>and</strong>date of report;• Sample description;

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureTest Report Content:• Testing agency, date <strong>and</strong> time of test, <strong>and</strong>date of report;• Sample description;• Drawings of specimen;

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureTest Report Content:• Testing agency, date <strong>and</strong> time of test, <strong>and</strong>date of report;• Sample description;• Drawings of specimen;• Location of air seal;

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureTest Report Content:• Testing agency, date <strong>and</strong> time of test, <strong>and</strong>date of report;• Sample description;• Drawings of specimen;• Location of air seal;• Test parameters;

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureTest Report Content:• Testing agency, date <strong>and</strong> time of test, <strong>and</strong>date of report;• Sample description;• Drawings of specimen;• Location of air seal;• Test parameters;• Pressure differences <strong>and</strong> leakage rate;

<strong>ASTM</strong> E<strong>2357</strong> Test ProcedureTest Report Content:• Testing agency, date <strong>and</strong> time of test, <strong>and</strong>date of report;• Sample description;• Drawings of specimen;• Location of air seal;• Test parameters;• Pressure differences <strong>and</strong> leakage rate;• Structural performance results.