Multiaqua Catalog Full Catalog - API of NH

Multiaqua Catalog Full Catalog - API of NH

Multiaqua Catalog Full Catalog - API of NH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Table <strong>of</strong> Contents (Hydronic)About UsSystem Modeling S<strong>of</strong>twareMulti-Zoning and Energy CostFeatures and BenefitsWater Products OverviewDX Products OverviewAccessory Products OverviewEquipment Sound DataMAC120 Air-Cooled ChillerNomenclature BreakdownGuide SpecificationsProduct SpecificationsCapacitiesInstallation and Operating ManualWiring DiagramsCertified DrawingMAC036,048 and 060 Air Cooled ChillerNomenclature BreakdownGuide SpecificationsProduct SpecificationsCapacitiesCirculating Pump CurveInstallation and Operating ManualWiring DiagramsCertified DrawingMHCCW (Ceiling Concealed) 2-pipe Chilled Water with Electric Heat. 1 to 3 TonsNomenclature BreakdownGuide SpecificationsProduct SpecificationsChilled Water CapacitiesHot Water CapacitiesElectric Heat CapacitiesCFM and Glycol AdjustmentsCapacity Adjustment FactorsInstallation and Operating ManualWiring DiagramsCertified DrawingMHNCCW (Ceiling Concealed) 4-Pipe Chilled and Hot Water. 1 to 3 TonsNomenclature BreakdownGuide SpecificationsProduct SpecificationsChilled Water CapacitiesHot Water CapacitiesCFM and Glycol AdjustmentsCapacity Adjustment FactorsInstallation and Operating ManualWiring DiagramsCertified DrawingPage1234567891011131517344344454648505657748384858688899499100101102113116117118119121122127132133134145147

Table <strong>of</strong> Contents (Hydronic Continued)MCCW (Ceiling Concealed) 2-Pipe Chilled and Hot Water. 4 to 5 TonsNomenclature BreakdownGuide SpecificationsProduct SpecificationsChilled Water CapacitiesHot Water CapacitiesCFM and Glycol AdjustmentsCapacity Adjustment FactorsInstallation and Operating ManualWiring DiagramsCertified DrawingMHWW (Hi-Wall) 2-Pipe Chilled and Hot Water. 1 to 3 TonsNomenclature BreakdownGuide SpecificationsProduct SpecificationsChilled Water CapacitiesHot Water CapacitiesCapacity and Glycol Adjustment FactorsInstallation and Operating ManualWiring DiagramsCertified DrawingCFFWA (Universal Mount) 2-Pipe Chilled and Hot Water. 1 to 5 TonsNomenclature BreakdownGuide SpecificationsProduct SpecificationsChilled Water CapacitiesHot Water CapacitiesCapacity and Glycol Adjustment FactorsInstallation and Operating ManualWiring DiagramsCertified DrawingCWA2 (Air Handler) 2-pipe Chilled Water with Electric Heat. 1.5 to 5 TonsNomenclature BreakdownGuide SpecificationsProduct SpecificationsChilled Water CapacitiesHot Water CapacitiesCFM and Glycol AdjustmentsCapacity Adjustment FactorsInstallation and Operating ManualWiring DiagramsCertified DrawingCWA4 (Air Handler) 4-pipe Chilled and Hot Water 2 to 5 TonsNomenclature BreakdownGuide SpecificationsProduct SpecificationsChilled Water CapacitiesHot Water CapacitiesCFM and Glycol AdjustmentsCapacity Adjustment FactorsInstallation and Operating ManualWiring DiagramsCertified DrawingPage148149150152153155157157158169170171172173175176181186187202206207208209211212218224225231232233234235237238243246247249257258259260261263264268269270271279280

Table <strong>of</strong> Contents (Direct Expansion)MHCCX (Ceiling Concealed) DX with Electric Heat. 1 to 3 TonsNomenclature BreakdownGuide SpecificationsProduct SpecificationsCapacitiesCFM AdjustmentsInstallation and Operating ManualWiring DiagramsCertified DrawingMCCX (Ceiling Concealed) DX Only. 4 to 5 TonsNomenclature BreakdownGuide SpecificationsProduct SpecificationsCapacitiesCFM AdjustmentsInstallation and Operating ManualWiring DiagramsCertified DrawingMHNCCX (Ceiling Concealed) DX with Hot Water. 1 to 3 TonsNomenclature BreakdownGuide SpecificationsProduct SpecificationsDX CapacitiesCFM AdjustmentsGlycol AdjustmentsCapacity Adjustment FactorsHot Water CapacitiesInstallation and Operating ManualWiring DiagramsCertified DrawingMHWX (Hi-Wall) DX Only. 1 to 3 TonsNomenclature BreakdownGuide SpecificationsProduct SpecificationsCapacitiesInstallation and Operating ManualWiring DiagramsCertified DrawingFSFCA (Universal Mount) DX Only. 1 to 5 TonsNomenclature BreakdownGuide SpecificationsProduct SpecificationsCapacitiesInstallation and Operating ManualWiring DiagramsCertified DrawingPage281282283285287288289300304305306307309309309310316317318319320322323323323324325330341343344345346348348349363371372373374376376377383384

Table <strong>of</strong> Contents (Accessories)AccessoriesStorage TanksExpansion Tank and Air ScoopLiquid Solution Bypass ValveLiquid Solution Control ValvesCondensate PumpControl ThermostatsWye StrainerCirculating Pumps (1,1.5 & 2 HP)Circulating Pump Curve (1,1.5 & 2 HP)Circulating Pumps (.5 HP)Circulating Pump Curve (.5 HP)Ceiling Concealed EnclosuresSample PipingBanked Chiller ConfigurationWarranty InformationPage385387388389391392395396397398399400407408409

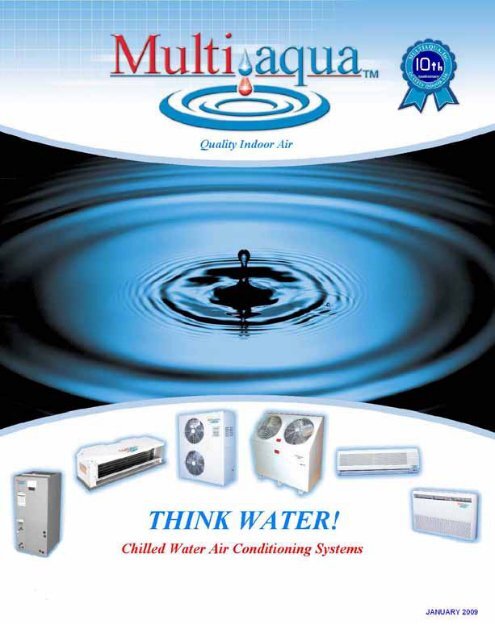

About UsSetting new industry standards is what we do best.At <strong>Multiaqua</strong>, our commitment to creating innovative air conditioning products has made us one<strong>of</strong> the most respected organizations in the industry. From concept to market, <strong>Multiaqua</strong> takes ahands-on approach to ensure that each and every step meets our stringent standards <strong>of</strong> quality,durability and dependability.All <strong>Multiaqua</strong> products are designed with the future in mind. That’s why all air conditioningproducts are flexible, which makes it easy to adapt to virtually all kinds <strong>of</strong> building applications.Whether it’s residential or commercial air conditioning needs, <strong>Multiaqua</strong> has the products tomeet or exceed all expectations.Manufacturing ExcellenceOur beliefs in quality is more than just a practice, it is something we take great pride in. Ourquality management system is integrated with international quality requirements <strong>of</strong> ISO 9002.That is why some <strong>of</strong> the biggest OEM names in the air conditioning industry use <strong>Multiaqua</strong>products in their units. In fact, <strong>Multiaqua</strong> chillers were part <strong>of</strong> air conditioning system that wonfirst place awards in the Quality Home Comfort Awards Competition, which was created tohonor the best in residential comfort system design and application.Our products are tested and certified to the UL, CE, ETL, UL1995 and ARI standards; the mostrespected and stringent in the world.Experience The FutureAt <strong>Multiaqua</strong>, we invite you to come experience the future <strong>of</strong> air conditioning and see why moreand more companies are discovering the new standard <strong>of</strong> air conditioning excellence. And bycombining cost effectiveness, innovation and quality, <strong>Multiaqua</strong> will continue to provide airconditioning products that will be the most sought after in the world.1

<strong>Multiaqua</strong> Makes Hydronic System Design EasyNAME: MULTIAQUALOCATION: SOUTH CAROLINA36000 BTU/H7.6 GPM24000 BTU/H5 GPM24000 BTU/H5 GPM24000 BTU/H4.9 GPM30000 BTU/H6.3 GPM36000 BTU/H7.6 GPMICL-2ICL-3ICL-4ICL-5ICL-6ICL-745°F55°F 45°F55°F 45°F55°F1"45°F1"55.4°F45°F55°F45°F55°F60000 BTU/H12.6 GPM55°F145'1" 1" 1"145'145'1"5'5'1"5'1"1.5"1'5' 1.25"5'1.25"1.25" 5'1' 1.5"5' 1.25"ICL-145°F100' 1.25"1.25"145'1.25"1.25"1.25"1.5"145'1.5"55°F117000 BTU/H9.8 TONS24.5 GPM(50%)1.25"100'1.5"1.5"145'2"49 GPM66.7 FT2.5"0'10'1"BYPASS VALVE1'2.5"73.1 GALSTOR-1ET-111.5 GAL2.5"5'5'2"5' 2.5"5'2"0'1'2"45°F55°F45°FCH-2117000 BTU/H9.8 TONS24.5 GPM(50%)CH-1P-1Sample Design ShownIntroducing System Modeling S<strong>of</strong>tware<strong>Multiaqua</strong> has teamed up with HVAC Solutions and would like to introduce the newest version <strong>of</strong> the HSSS<strong>of</strong>tware. This s<strong>of</strong>tware will contain a selection model that includes Mutiaqua’s Air Cooled Chillers, Fan Coilsand Air Handling Units.HSS s<strong>of</strong>tware will allow you to drag and drop components to design hydronic systems. It includes the necessarypiping, piping components and equipment. It is capable <strong>of</strong> exporting calculation reports, equipment schedulesand a bill <strong>of</strong> material. Visit www.multiaqua.com for s<strong>of</strong>tware down load.2

Ductless and Ducted Hydronic Air Conditioning & Heating Systems.FOR MULTIZONING FACILITIES• Zoning saves energy• Better Control <strong>of</strong> Humidity• Separate Climate in each Room1. More Energy Efficient Thru Zoned Comfort Cooling.2. Zoning Allows For Diversity.3. Diversity and Load Calculations Allows For Reducing The Size <strong>of</strong> The OutdoorPower Plant.4. Banking Chillers Allows For Huge Efficiencies Thru Staging.5. Helps Control The Growth Of Mold, Mildew and Fungus.6. Low Installation Costs.7. No Refrigerant Handling.8. No Ductwork No Line Sets.9. Heat & Cool with the Same Units.10. No Line Length Limitations.11. Unlimited Tonnage with Single Phase Power.12. Easy To Expand System.Think Water !!!4

Water Product OverviewPage 44 Page 9MAC036, 048 & 060 Air Cooled Chiller• 3, 4 & 5 Ton Air Cooled Chiller• Copeland Scroll Compressor Technology• R 407c Refrigerant• Horizontal Air Discharge• Stainless Steel Pump IncludedMAC120 Air Cooled Chiller• 10 Ton Air Cooled Chiller• Copeland Scroll Compressor Technology• R 407c Refrigerant• Vertical Air Discharge• Two Stages <strong>of</strong> CoolingPage 84 Page 117MHCCW (Ceiling Concealed) Chilled Water 2-PipeWith or Without Electric Heat• 12,000- 36,000 BTUH• Available with or without Electric Heat• Ceiling Concealed Design for Clean Installation• Removes Equipment from Conditioned Space• Heavy Gauge Metal Cabinet• Powder Painted Galvanized Steel• Field Reversible Hand <strong>of</strong> Connection Coil• Manual Air Vents• Discharge May be Ducted for Small SpacesMHNCCW (Ceiling Concealed) Chilled/Hot Water 4-Pipe• 12,000-36,000 BTUH• Ceiling Concealed Design for Clean Installation• Removes Equipment from Conditioned Space• Heavy Gauge Metal Cabinet• Powder Painted Galvanized Steel• Double Field Reversible Hand <strong>of</strong> Connection Coil• Manual Air Vents• Discharge May be Ducted for Small SpacesPage 171 Page 148MHWW (Hi-Wall) Chilled/Hot Water 2-Pipe• 9,000- 36,000 BTUH• High Wall Mounting• Attractive Seamless Appliance Design• Cleanable Air Filter Provided• Wireless Infrared Remote Included• Wired Controller OptionMCCW (Ceiling Concealed) Chilled/Hot Water 2-Pipe• 48,000 – 60,000 BTUH• Ceiling Concealed Design for Clean Installation• Removes Equipment from Conditioned Space• Heavy Gauge Metal Cabinet• Powder Painted Galvanized Steel• Manual Air Vents• Discharge May be Ducted for Small SpacesPage 233Page 207Page 259CFFWA Universal Mount Fan Coil 2-Pipe• 12,000- 60,000 BTUH• Floor, Low Wall or Horizontal Ceiling Mounting• Attractive Modular Design• Cleanable Air Filter Included• Optional Wireless Remote5CWA2 With or Without Electric Heat 2-PipeCWA4 Chilled & Hot Water 4-Pipe• Available in 2 or 4-Pipe Configuration• 18,000- 60,000 BTUH• Up Flow, Left or Right Hand Horizontal Installation• Equipped with R4.2 Insulation• CWA2 in 208/240-1-60 & CWA4 in 120-1-60• Electric or Hot Water Heat

DX Product OverviewDX Fan Coils are Compatible with R410a Refrigerant and are 13 SEER CompatibleAll DX Coils come Shipped From the Factory with a TXV Installed.MHCCX (Ceiling Concealed) DX 2-PipeWith or Without Electric Heat• 12,000-36,000 BTUH• Available with or without Electric Heat• Ceiling Concealed Design for Clean Installation• Removes Equipment from Conditioned Space• Heavy Gauge Metal Cabinet• Powder Painted Galvanized Steel• Field Reversible Hand <strong>of</strong> Connection Coil• TXV Provided• Discharge May be Ducted for Small Places•13 SEER CompatibleMHNCCX (Ceiling Concealed) DX 4-Pipewith Hot Water• 12,000-36,000 BTUH• Ceiling Concealed Design for Clean Installation• Removes Equipment from Conditioned Space• Heavy Gauge Metal Cabinet• Powder Painted Galvanized Steel• Double Field Reversible Hand <strong>of</strong> Connection Coil• TXV Provided• Discharge May Be Ducted for Small Places• Hot Water Heating Coil•13 SEER CompatibleMCCX (Ceiling Concealed) DX• 48,000-60,000 BTUH• Ceiling Concealed Design for Clean Installation• Removes Equipment from Conditioned Space• Heavy Gauge Metal Cabinet• Powder Painted Galvanized Steel• TXV Provided• Discharge May be Ducted for Small SpacesFSFCA (Universal Mount) DX or Heat Pump• 12,000- 60,000 BTUH• Floor, Low Wall or Horizontal Ceiling Mounting• Attractive Modular Design• Cleanable Air Filter Included• Optional Wireless Remote• TXV Provided•13 SEER CompatibleMHWX (Hi-Wall) DX or Heat Pump• 9,000- 36,000 BTUH• High Wall Mounting• Attractive Seamless Appliance Desi• Cleanable Air Filter Provided• Wireless Infrared Remote Included• Wired Control Option6

Accessories OverviewPage 385 Page 387 Page 388Storage Tanks20 & 42 GallonExpansion Tank & Air ScoopLiquid Solution Bypass ValvePage 389 Page 395 Page 391Motorized Valves2 & 3-WayWye StrainerCondensate PumpPage 392 Page 396 Page 398ThermostatsCirculating PumpsEnclosures7

January 2008<strong>Multiaqua</strong> Equipment Sound LevelsThe following will detail the “Sound Levels” <strong>of</strong> the <strong>Multiaqua</strong> equipment line.Air Cooled ChillersMAC 036, 048, 060 Chillers: 69 dbs (A)MAC120 Chillers: 75 dbs (A)Hi-Wall Fan CoilsMHWX-09 / MHWW-09: DX and chilled water Hi-Wall fan coils: 42 dbs (A).MHWX-12 / MHWW-12: DX and chilled water Hi-Wall fan coils: 43 dbs (A).MHWX-18 / MHWW-18: DX and chilled water Hi-Wall fan coils: 45 dbs (A).MHWX-24 / MHWW-24: DX and chilled water Hi-Wall fan coils: 46 dbs (A).MHWX-36 / MHWW-36: DX and chilled water Hi-Wall fan coils: 48 dbs (A).Universal Mount Fan CoilsFSFCA-04 / CFFWA-04: DX and chilled water Universal Mount fan coils: 42 dbs (A).FSFCA-06, 08 / CFFWA-06, 08: DX and chilled water Universal Mount fan coils: 44 dbs (A).FSFCA-10 / CFFWA-10: DX and chilled water Universal Mount fan coils: 46 dbs (A).FSFCA-10, 12 / CFFWA-10, 12: DX and chilled water Universal Mount fan coils: 48 dbs (A).FSFCA-16, 20 / CFFWA-16, 20: DX and chilled water Universal Mount fan coils: 50 dbs (A).Hideaway Fan CoilsMHCCX-04 / MHCCW-04: DX / chilled water with electric heat Hideaway fan coils: 42 dbs (A)MHCCX-06 / MHCCW-06: DX / chilled water with electric heat Hideaway fan coils: 44 dbs (A)MHCCX-08 / MHCCW-08: DX / chilled water with electric heat Hideaway fan coils: 46 dbs (A)MHCCX-10 / MHCCW-10: DX / chilled water with electric heat Hideaway fan coils: 48 dbs (A)MHCCX-12 / MHCCW-12: DX / chilled water with electric heat Hideaway fan coils: 49 dbs (A)MHNCCX-04 / MHNCCW-04: DX / chilled water with hot water heat Hideaway fan coil: 40 dbs (A)MHNCCX-06 / MHNCCW-06: DX / chilled water with hot water heat Hideaway fan coil: 42 dbs (A)MHNCCX-08 / MHNCCW-08: DX / chilled water with hot water heat Hideaway fan coil: 44 dbs (A)MHNCCX-10 / MHNCCW-10: DX / chilled water with hot water heat Hideaway fan coil: 46 dbs (A)MHNCCX-12 / MHNCCW-12: DX / chilled water with hot water heat Hideaway fan coil: 48 dbs (A)MCCX-16 / MCCW-16: DX and chilled water Hideaway fan coil. 46 dbs (A)MCCX-20 / MCCW-20: DX and chilled water Hideaway fan coil. 46 dbs (A)Disclaimer: Specifications are subject to change without notice. All tests conducted in nonechoicchambers. Sound levels were measured at five feet from the unit. Levels were measuredusing free air delivery.8

MAC120 Air-Cooled ChillerAir-Cooled Chillers for Global Residentialand Light Commercial MicroClimates9

MAC120 NOMENCLATURE BREAKDOWNMAC120 - XX - X - R40710-TonAir-Cooled ChillerAccessoryOptionsN= No OptionsL= Low Ambient KitVoltage01 = 208/230-1-50/6002 = 208/230-3-50/6003 = 380/460-3-50/60Available Model NumbersMAC120-01-N-R407MAC120-01-L-R407MAC120-02-N-R407MAC120-02-L-R407MAC120-03-N-R407MAC120-03-L-R40710

HVAC Guide SpecificationsAir-Cooled Liquid ChillerNominal Size:10 Tons<strong>Multiaqua</strong> Model Number:MAC120-01-N-407, MAC120-01-L-407MAC120-02-N-407, MAC120-02-L-407MAC120-03-N-407, MAC120-03-L-407Part 1-General1.01 System Description<strong>Multiaqua</strong> air-cooled liquid chillers are designed using scroll compressors and low sound condenser fans.1.02 Quality AssuranceA. Certified in accordance with U.L. Standard 95, latest version (U.S.A.)B. Construction shall comply with ASHRAE 15 Safety Code, NEC and ASME applicable codes. (U.S.A.Codes)C. Manufactured in a facility registered to ISO 9002, Manufacturing Quality Standard.D. ETL certified.E. <strong>Full</strong>y load tested at the factory.F. Damage resistant packaging.1.03 Delivery, Storage and HandlingA. Packaged and readied for shipment from the factory.B. Controls shall be capable <strong>of</strong> withstanding 150°F storage temperatures in the control compartment.C. Stored and handled per manufacturer’s recommendations.Part 2-Product2.01 EquipmentA. General:1. Unit shall be a factory assembled and tested air-cooled liquid chiller.2. Shall be assembled on heavy gauge steel mounting/lifting rails.3. Contained within the unit cabinet shall be all factory wiring, piping, controls, refrigerant charge(R407c), POE oil and special accessories required prior to start up.4. Brass body strainer with 20 mesh screen and blow down shall be supplied in cabinet as afield installable accessory.B. Unit Cabinet:1. Composed <strong>of</strong> heavy gauge galvanized steel casing with a baked polyester powder.2. Capable <strong>of</strong> withstanding 500-hour salt spray test in accordance with the ASTM (U.S.A.) standard.C. Condenser Fans:1. 4-blade, aluminum construction and shall be dynamically balanced and corrosion resistant.2. Discharge air at a 45° vertical angle.3. Motors and blades shall be protected by coated steel wire safety guards.D. Fan Motors:1. Condenser fan motors shall be single speed, direct drive.2. Totally enclosed.3. Permanently lubricated sleeve bearings and Class F insulation.4. Internal overload protection.E. Compressors:1. Unit shall contain two fully hermetic scroll compressors.2. Direct-drive, 3500 rpm (60Hz)3. Compressor motor shall be suction gas cooled.4. Internal motor protection.5. Externally protected by low and high pressure cutout devices.6. Individual vibration isolators.11

F. Pump:1. Unit shall be capable <strong>of</strong> incorporating a field installed chilled liquid solution pump.(Space restricted)2. Unit shall have provisions to allow for chilled liquid solution piping to the exterior <strong>of</strong> the cabinet.G. Evaporator:1. Evaporator shall have two independent refrigerant circuits.2. Rated for a refrigerant side working pressure <strong>of</strong> 450 psig and a maximum water side workingpressure <strong>of</strong> 60 psig.3. Single pass, ANSI type 316 stainless steel, brazed plate construction.4. Externally insulated with closed cell, elastomeric foam. (ASTM518)H. Condenser:1. Condenser coil shall be air-cooled with integral subcooler.2. Two independent refrigerant circuits.3. Constructed <strong>of</strong> rifled copper tubing mechanically bonded to aluminum fins.4. Cleaned and dehydrated.5. Factory leak tested to 450 psig.I. Refrigerant Circuits:1. Each circuit shall contain a sight glass, liquid line filter, thermal expansion valve,refrigerant charge <strong>of</strong> R407c and POE compressor oil.Part 3-Controls and Safeties3.01 ControlsA. Chiller shall be completely factory wired and tested.B. Capacity control shall be based on leaving chilled liquid solution temperature.1. Temperature accuracy shall be + - 1.0°F.2. Controls shall be capable <strong>of</strong> staging the two compressors.C. Controls shall include the following components.1. 24vac transformer to serve all controllers relays and control components.2. Microprocessor based liquid solution temperature controller.3. Leaving water temperature thermistor.4. Pump bypass timer.5. Compressor recycle timer.6. Optional fan cycling control for low ambient operation.7. Chilled liquid solution flow switch.3.02 SafetiesA. Unit shall be equipped with thermistors and all necessary components in conjunction with thecontrol system to provide the following protectants.1. Low refrigerant pressure.2. High refrigerant pressure.3. Low chilled liquid solution temperature.4. Low chilled liquid solution flow.5. Thermal overload.6. Short cycling.Part 4-Operating Characteristics:4.01 TemperaturesA. Unit shall be capable <strong>of</strong> starting and running at outdoor temperatures from 55°F to 120°F.B. Optional Low Ambient Kit shall allow starting and running at outdoor temperatures to -20°F. Afield supplied and installed crank case heater must be used when operating at these temperatures.C. Unit shall be capable <strong>of</strong> starting up with a maximum 80°F and a sustained 70°F entering fluidsolution temperature to the evaporator.D. Minimum 10% Glycol solution is required. For outdoor temperatures below 32°F, referenceMAC Glycol Solution Data table.4.02 Electrical RequirementsA. Primary electrical power supply shall enter the unit at a single location.B. Electrical power supply shall be rated to withstand 120°F operating ambient temperature.C. Units shall be available in 1 or 3-phase power at the voltages shown in the equipment electrical data.D. Control points shall be accessed through terminal block.12

ModelNumberModelNumberMAC120 Product SpecificationsPhysical DataCondenser Coil Chiller Weight (lbs)CopperTubingDiameterHeight LengthCoil Height Length Width Refrigerant(in) (in)Rows (in) (in) (in) R407cNet Shipping(in)MAC120-01 52.5 48 3/8 3 60 58.25 25.25 104 oz x 2 650 700MAC120-02 52.5 48 3/8 3 60 58.25 25.25 104 oz x 2 650 700MAC120-03 52.5 48 3/8 3 60 58.25 25.25 104 oz x 2 650 700Electrical DataVolts/ Phase/ HertzCompressor(Qty 2)13Condenser FanMotor(Qty 2)(RLA) (LRA) (RLA) (RPM)Fuse or HACR CircuitBreakerMinimumAmpsMAC120-01 208/230-1-50/60 32.1 x 2 169 x 2 2.3 x 2 900 44.73 x 2“See note 1”MAC120-02 208/230-3-50/60 19.3 x 2 137 x 2 2.3 x 2 900 48.03“See note 2”MAC120-03 380/415/460-3-50/60 10 x 2 75 x 2 1.6 x 2 900 25.70“See note 2”Note:1. MAC120-01 has two independent line voltage terminations.2. MAC120-02 & MAC120-03 has one independent line voltage termination.Supply WireLength in FeetCopper Wire Size (1% Voltage Drop)200 6 4 4 4 3 3 2 2150 8 6 6 4 4 4 3 3100 10 8 8 6 6 6 4 450 14 12 10 10 8 8 6 615 20 25 30 35 40 45 50Supply Circuit AmpacityCompressorCopeland ScrollRefrigerantR407cHeat ExchangerBrazed PlateMax Flow Rate28.8 gpmMin Flow Rate18 gpmSupply Water Temp 44°Return Water Temp 54°Minimum SystemSolution Content50 GallonsExpansion Tank Size 3% <strong>of</strong> Total SystemWater Connections 1 3/8" OD Supply & ReturnInternal Pressure Drop18 ft <strong>of</strong> headMaximumAmps75 x 2“See note 1”65“See note 2”35“See note 2”<strong>Multiaqua</strong> chillers are designed to operate exclusively with R407c refrigerant in a self-contained, pre-charged refrigerant system. Donot access the closed refrigerant circuit for any reason other than after-sale, after installation component replacement. Routinemaintenance and service is to be performed by qualified personnel only.These specifications are subject to change without notice.

MAC120 Product SpecificationsMAC120 Capacity / Watts / EER*Outdoor Air °F82 95 100 105 110TONS 9.4 9.0 8.8 8.7 8.7KILOWATTS 10.9 11.5 11.5 12.1 12.4EER 10.35 9.39 9.18 8.63 8.42* Refrigerant system performance only, pump data not included.MAC120 Glycol Solution DataPropylene Glycol %WaterFlowCapacity Min. Ambient Temp GPM Adjustment= 100% Capacity10% x 1.020 x 0.99 26°F x 1.0120% x 1.028 x 0.98 18°F x 1.0330% x 1.036 x 0.98 8°F x 1.0740% x 1.048 x 0.97 -7°F x 1.1150% x 1.057 x 0.96 -29°F x 1.16Example: 30% glycol solution.Maximum Flow Rate = 12gpm x 1.036System capacity x .98*Use Propylene Glycol OnlyImportantIf the outside temperature is expected to fall below freezing (32°F) in the area the <strong>Multiaqua</strong> chiller is to beinstalled; the installer must take the following precautions. Failure to do so will void the warranty.To not engage in cold ambient mitigation will result in the failure <strong>of</strong> components such as the heatexchanger, piping, circulating pump, etc… and or property damage.• Keep the liquid solution at a minimum <strong>of</strong> 10% percent Propylene Glycol even in areas where there is nodanger <strong>of</strong> freezing.• The percentage amount <strong>of</strong> glycol recommended is dependent on the expected ambient temperatures and thesolution makeup recommendation <strong>of</strong> the glycol manufacturer. Refer to the MAC120 Glycol Solution Data tableabove.• Ensure the system circulating pump is in a constant energized mode to keep a continuous circulation <strong>of</strong> liquidsolution.The <strong>Multiaqua</strong> chiller is a self-contained air-cooled condenser, coupled with an insulated brazed plate heatexchanger (evaporator). The system utilizes a scroll compressor to circulate refrigerant between the condenserand heat exchanger. The refrigerant is metered into the heat exchanger with a thermal expansion valve.Protecting the system are high and low pressure switches as well as a pump flow switch.Liquid solution (water and Propylene Glycol; minimum 10 % is required) is circulated through the heatexchanger by an externally mounted pump. The liquid solution flows through the heat exchanger to the systemsupply piping and on to the air handlers.Low ambient kits are available for operating ambient temperatures down to -20 degrees Fahrenheit. A fieldsupplied and installed crankcase heater must be installed when operating at these temperatures. The lowambient kits consist <strong>of</strong> an ICM 325 (+) ICM (175) for single and three phase 208/230 vac chillers. For the threephase 380/460 vac chillers a pressure activated fan control is used.These specifications are subject to change without notice.14

MAC120 Cooling Performance DataLWT (°F)MAC120 CAPACITIES with 0% GlycolENTERING AIR TEMPERATURE (°F)82 95 100 105 110TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM35 7.9 7.6 7.4 7.3 7.140 8.8 8.4 8.2 8.1 8.142 9.1 8.7 8.5 8.4 8.444 9.4 9.0 8.8 8.7 8.745 9.6 9.2 9.0 8.8 8.828.8 28.8 28.8 28.846 9.7 9.3 9.1 9.0 9.028.848 10.1 9.7 9.4 9.3 9.350 10.4 10.0 9.7 9.6 9.655 11.3 10.9 10.5 10.4 10.360 12.3 11.8 11.4 11.2 11.1MAC120 CAPACITIES with 10% GlycolLWT (°F)ENTERING AIR TEMPERATURE (°F)82 95100 105 110TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM35 7.8 7.5 7.3 7.2 7.040 8.7 8.3 8.1 8.0 8.042 9.0 8.6 8.4 8.3 8.344 9.3 8.9 8.7 8.6 8.645 8.5 9.1 8.9 8.7 8.728.8 28.8 28.8 28.846 9.6 9.2 9.0 8.9 8.928.848 10.0 9.6 9.3 9.2 9.250 10.3 9.9 9.6 9.5 9.555 11.2 10.7 10.4 10.3 10.260 12.1 11.6 11.2 11.0 10.9MAC120 CAPACITIES with 20% GlycolLWT (°F)ENTERING AIR TEMPERATURE (°F)82 95 100 105 110TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM35 7.7 7.4 7.2 7.1 6.940 8.6 8.2 8.0 7.9 7.942 8.9 8.5 8.3 8.2 8.244 9.2 8.8 8.6 8.5 8.545 9.4 9.0 8.8 8.6 8.628.8 28.8 28.8 28.846 9.5 9.1 8.9 8.8 8.828.848 9.9 9.5 9.2 9.1 9.150 10.1 9.8 9.5 9.4 9.455 11.1 10.6 10.2 10.1 10.060 12.0 11.5 11.1 10.9 10.8These specifications are subject to change without notice.15

MAC120 Cooling Performance DataMAC120 CAPACITIES with 30% GlycolLWT (°F)ENTERING AIR TEMPERATURE (°F)8295 100 105 110TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM35 7.7 7.4 7.2 7.1 6.940 8.5 8.1 8.0 7.9 7.942 8.8 8.4 8.2 8.1 8.144 9.1 8.7 8.5 8.4 8.445 9.3 8.9 8.7 8.5 8.528.8 28.8 28.8 28.846 9.4 9.0 8.8 8.7 8.728.848 9.8 9.4 9.1 9.0 9.050 10.1 9.7 9.4 9.3 9.355 11.0 10.6 10.2 10.1 10.060 11.9 11.5 11.1 10.9 10.8MAC120 CAPACITIES with 40% GlycolLWT (°F)ENTERING AIR TEMPERATURE (°F)82 95 100 105 110TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM35 7.6 7.3 7.1 7.0 6.840 8.5 8.1 7.9 7.8 7.842 8.8 8.4 8.2 8.1 8.144 9.1 8.7 8.5 8.4 8.445 9.3 8.9 8.7 8.5 8.528.8 28.8 28.8 28.846 9.4 9.0 8.8 8.7 8.728.848 9.8 9.4 9.1 9.0 9.050 10.0 9.7 9.4 9.3 9.355 10.9 10.5 10.1 10.0 9.960 11.9 11.4 11.0 10.8 10.7MAC120 CAPACITIES with 50% GlycolLWT (°F)ENTERING AIR TEMPERATURE (°F)82 95 100 105 110TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM35 7.5 7.3 7.1 7.0 6.840 8.4 8.0 7.8 7.7 7.742 8.7 8.3 8.1 8.0 8.044 9.0 8.6 8.4 8.3 8.345 9.2 8.8 8.6 8.4 8.428.8 28.8 28.8 28.846 9.3 8.9 8.7 8.6 8.628.848 9.7 9.3 9.0 8.9 8.950 9.9 9.6 9.3 9.2 9.255 10.8 10.4 10.0 9.9 9.860 11.8 11.3 10.9 10.7 10.6These specifications are subject to change without notice.16

Table <strong>of</strong> ContentsPageIntroduction 19System Description & Sequence <strong>of</strong> Operation 20Electrical & Physical Data 21Description <strong>of</strong> Electrical Controls 23Chiller Controls Sequence <strong>of</strong> Operation 25Refrigeration System Operation 26Description <strong>of</strong> Refrigeration Components 26Piping System Components 28Layout & Design 29Banked Chiller Configuration 30Installation Notes 31Propylene Glycol Content 32Expansion Tank 32Filling the System with Propylene Glycol 33Air Elimination 3318

<strong>Multiaqua</strong> Chiller ManualThe <strong>Multiaqua</strong> Chiller System is the only air conditioning/refrigeration system <strong>of</strong> its kind in the worldtoday <strong>of</strong>fering the degree application flexibility described in the following manual.The <strong>Multiaqua</strong> Chiller System is not only unique in its application flexibility; it is unique in superiorquality, rated capacities and rugged durability. When installed in accordance with these instructions thesystem will deliver years <strong>of</strong> trouble free service.Proper equipment sizing, piping design and installation are critical to the performance <strong>of</strong> the chiller. Thismanual is meant to be a “how to” introduction to piping and installing the <strong>Multiaqua</strong> Chiller System.MAC120 Chiller Features• Copeland Scroll Compressors• Advanced Motor Protection• Loss <strong>of</strong> Flow Protection• Control Power Transformer• Low Ambient Option• Integrated Chilled Solution Pump Control• Flow Switch• Strainer Connection Kit• Painted Metal Condenser Protector Grille• Dual Refrigeration Circuits and Single Liquid Solution CircuitRECOGNIZE THIS SYMBOL AS AN INDICATION OF IMPORTANT SAFETY ORINSTRUCTION RELATED INFORMATION.Web site information addresses are supplied throughout this manual for piping and accessory information.The plumbing industry also has pressure drop information on ferrous and copper piping systems.The following sections will describe each component and how it functions within the system. Installationinformation is supplied where appropriate. The piping design section will explain the design and layoutthe piping system from a “how to” perspective. Following the examples provided will enable the installerto determine the correct pipe and accessory sizing, as well as equipment location. It is important to knowbefore installation if the proposed system will operate correctly and by doing a formal layout <strong>of</strong> a newapplication or review <strong>of</strong> an existing piping system will make that determination.Throughout this manual the term “liquid solution” is used in place <strong>of</strong> water. The chiller circulates asolution <strong>of</strong> water and Propylene Glycol.It is essential to operate the system with a minimum <strong>of</strong> 10% glycol. DO NOT OPERATE THISSYSTEM USING WATER ALONE.For proper liquid solutions mix ratios, refer to page 14 or the glycol manufacture’s recommended mixratios.19

System Description & Sequence <strong>of</strong> OperationThe <strong>Multiaqua</strong> Chiller is a self-contained, air-cooled condenser, coupled with an insulated brazed plateheat exchanger (evaporator). The system utilizes scroll compressors to circulate refrigerant between thecondenser and heat exchanger. The refrigerant is metered into the heat exchanger with a thermostaticexpansion valve. Protecting the system are high and low pressure switches as well as a pump flow switch.Liquid solution (water and Propylene Glycol is circulated through the heat exchanger by a field suppliedpump. The liquid solution flows through the heat exchanger to the system supply piping and on to the airhandlers.A solenoid-operated, motorized valve or circulator controls the flow <strong>of</strong> the chilled liquid solution throughthe air handlers. The valves or circulators can be actuated by a variety <strong>of</strong> different control schemes.Liquid solution temperature is controlled by a chiller mounted digital electronic controls. A systemsequence <strong>of</strong> operation, individual control description, troubleshooting information and a schematic areincluded in the controls section.It must be recognized that ferrous pipe may cause acceleration deterioration <strong>of</strong> the brazedplate heat exchanger and could void the heat exchanger warranty.Cooling load DiversityEquipment sizing for a chilled liquid solution system can utilize Cooling Load Diversity. Diversity isdescribed as the actual amount <strong>of</strong> cooling needed (heat load) by various sections <strong>of</strong> a structure at a giventime. Conventional air conditioning systems are designed for the highest structure heat load. Theconventional system determines and selects equipment based on the peak heat load demanded by thestructure. A system sized to take advantage <strong>of</strong> diversity would determine the heat load by the time <strong>of</strong> day,building exposure and usage. As an example the sections <strong>of</strong> a structure facing west, demand more coolingin the afternoon, than sections facing east. The opposite <strong>of</strong> this is true in the morning, where the eastsection is exposed to a higher heat load requiring more cooling. Utilizing diversity the chiller systemwould adapt to the needs <strong>of</strong> each side <strong>of</strong> the structure during peak demand by delivering more cooling tothat area and less to the areas that do not need it. A structure utilizing a conventional DX system, requires8 tons <strong>of</strong> cooling at peak load, could utilize a much smaller capacity system (potentially 4 or 5 tons) if thesystem installed could take advantage <strong>of</strong> load diversity, which would supply the necessary amount <strong>of</strong>cooling to the space, as and when needed instead <strong>of</strong> keeping a larger capacity available at all times.Cooling load diversity can best be determined by referring to ACCA. (Air Conditioning Contractors <strong>of</strong>America) Manual “J”, Refer to the appendix A-2, Multi-Zone Systems. ACCA’s Internet address ishttp://www.acca.org/Because <strong>of</strong> diversity a <strong>Multiaqua</strong> Chiller can serve more total air handler tonnage than chiller capacity. A10-ton chiller may be delivering chilled liquid solution to 15 or more tons <strong>of</strong> air handler capacity. Because<strong>of</strong> cooling load diversity, the building does not need equal amounts <strong>of</strong> cooling in each area at the sametime.20

ELECTRICAL AND PHYSICAL DATAThe information contained in this manual has been prepared to assist in the proper installation, operationand maintenance <strong>of</strong> the chiller. Improper installation, or installation not made in accordance with theseinstructions can result in unsatisfactory operation and/or dangerous conditions and can cause the relatedwarranty not to apply.Read this manual and any instructions packaged with separate equipment required to make up the systemprior to installation. Retain this manual for future reference.Separate and independent power supplies and disconnects must be provided. These chillers haveseparate and discreet power requirements within one cabinet.All power to the chiller must be turned <strong>of</strong>f prior to opening cabinet and or servicing.Failure to properly ground chiller can result in death.Disconnect all power wiring to chiller before maintenance or service work. Failure to do so cancause electrical shock resulting in personal injury or death.All wiring must be done in accordance with the NEC (National Electric Code) as well as state andlocal codes, by qualified electricians.Product warranty does not cover any damages or defect to the chiller caused by the attachment oruse <strong>of</strong> any components, accessories or devices (other than those authorized by the manufacturer) into,onto or in conjunction with the chiller. You should be aware that the use <strong>of</strong> unauthorized components,accessories or devices may adversely affect the operation <strong>of</strong> the chiller and may also endanger life andproperty. The manufacturer disclaims any responsibility for such loss or injury resulting from the use <strong>of</strong>such unauthorized components, accessories or devices.Upon receiving the chiller and components, inspect for any shipping damage. Claims for damage,either apparent or concealed should be filed immediately with the shipping company.No liquid other than the solution <strong>of</strong> water and Propylene Glycol (mixed in accordance with table6 page 32) shall be used in the piping system.Corrosive environments may subject metal parts <strong>of</strong> the chiller to rust and deteriorate. Theoxidation could shorten the chiller’s useful life. Corrosive elements include salt spray, fog or mist in seacoastal areas, sulfur or chlorine from lawn watering systems and various chemical contaminants fromindustries such as paper mills and petroleum refineries.If the unit is to be installed in an area where contaminates are likely to be a problem, special attentionshould be given to the equipment location and exposure.• Avoid having lawn sprinklers spray directly on the chiller cabinet.• In coastal areas, locate the chiller on the side <strong>of</strong> the building away from the water front.• Elevating the chiller <strong>of</strong>f <strong>of</strong> its slab or base enough to allow air circulation will help avoid holding waterin contact with the cabinet base.• Regular maintenance will reduce the build-up <strong>of</strong> contaminants and help protect the cabinet finish.• In severe locations having the chiller coated with an “epoxy” or other coating formulated for airconditioning systems located in coastal areas may be necessary.21

Consult local building codes or ordinances for special installation requirements. Whenselecting a site to locate the chiller, consider the following:• A minimum clearance <strong>of</strong> 60” on the service access front, 12” on the rear air inlet and a 60” fan dischargeclearance.• The chiller can be located out or indoors. If installed indoors there must be 9000 cfm <strong>of</strong> outdoor airchanges circulated through the mechanical room to sufficiently operate the chiller. No ductwork can beconnected to the chiller’s condenser or condenser fans.• If a concrete slab is used, do not connect the slab directly to any building’s foundation or structure toprevent sound transmission.• Locate the slab on a level surface that is above grade to prevent ground water from entering the chillercabinet.60” Fan Discharge ClearanceStated Service Clearances12” Rear Clearance60” Front ServiceClearance0” Side Clearance58.25 60.00”60.00”58.25”Chiller Supply and ReturnPiping Access60.00”15”10”13”4.25”25.25”22

Description <strong>of</strong> Electrical ControlsControl Transformer: The control transformer is rated at 24 vac, 40 va(1.6 amps @ 24vac)Pump Bypass Timer: The pump bypass timer is a 24 vac, 3-wire control.When energized the timer will bypass the flow switch for 10 seconds (bycreating a circuit to the pump relay), energizing the pump relay, allowing thepump to operate long enough to close the flow switch. In a normally operatingsystem the flow switch will stay closed powering the pump relay in series withthe low and high- pressure switches. Should the flow switch open, the timercan only be reset by opening and closing the chiller's line voltage disconnect.Refrigerant System Timer: The refrigerant timer is a 24 vac, 5-minute delayon break, 20wire timer. The normally closed contacts <strong>of</strong> the timer energizethe compressor contactor through the chilled solution control. When the chilledsolution control contacts open, the timer delays by opening its contact for 5-minutes before resetting to the closed position.High Pressure Switch: The high-pressure switch is an automatic reset controlthat senses compressor discharge line pressure. It opens at 400 PSIG andcloses at 300 PSIG.23

Description <strong>of</strong> Electrical Controls (continued)Low Pressure Switch: The low-pressure switch is an automatic reset controlthat senses compressor suction line pressure. It opens at 40 PSIG andcloses at 80 PSIG.Flow Switch: The flow switch senses liquid solution flow. The paddle <strong>of</strong> theswitch is inserted through a fitting into the pump discharge line. Liquid solutionflow deflects the paddle closing the switch. The flow switch is position sensitive.The arrow ↑ on the switch must point in the direction <strong>of</strong> liquid solution flow.Compressor Contactor: The compressor contactor energizes the compressorthrough the two or three normally open contacts. The contactor coil operates(closes the contacts) when energized by 24 vac.Liquid Solution Temperature Control: The liquid solution temperature controlis an adjustable microprocessor based temperature control. This control receivestemperature information from a thermistor located on the liquid solution supplyline. A liquid crystal display continually indicates liquid solution temperature. Thecontrol is mounted inside the chiller cabinet.24

Chiller Controls Sequence <strong>of</strong> OperationWhen powered up, the <strong>Multiaqua</strong> chiller system energizes the control transformer creating 24 vac control voltage.First the pump bypass timer is energized and temporarily bypasses the flow switch, energizing the pump relay. Thepump then starts to move liquid solution through the piping system (in a properly filled and air purged system). Themovement <strong>of</strong> liquid solution from the pump discharge keeps the flow switch closed. After a 10 second delay the pumpcontact opens, connecting the flow switch in series with the high and low pressure switches. The pump will now runcontinually unless the power supply is interrupted, or the flow switch opens.If the liquid solution temperature controller is calling for cooling the control circuit is routed through the short cycletimer and the three safety switches (the flow, high and low pressure switches) to the compressor contactor. This willenergize the compressor(s) and condenser fan motors. The liquid solution controller will open at the user programmedset point, causing the refrigerant short cycle timer to open it's contact for 5 minutes as it delays before resetting to theclosed position. This will de-energize the compressor. Power fluctuations will also initiate a 5 minute time delay. The5 minute delay allows the refrigerant system a period for pressure equalization, protecting the compressor(s) fromshort cycling.The chiller temperature controller utilizes a thermistor to monitor the liquid solution temperature change. Thetemperature is then compared to the set point and differential temperatures programmed into the control by the user.The set point is the liquid solution temperature which will cause the control switch to open. For example: The controlset point is programmed at 44°F LWT with a 10°F differential, which opens the controller at 44°F LWT and closes at54°F. The differential temperature is the number <strong>of</strong> degrees above set point temperature programmed into thecontroller. If liquid solution temperature falls to the set point, the controller cycles the compressors <strong>of</strong>f.Chillers are shipped with the control set point adjusted to 44°F LWT and a 10°F differential. Liquid solutiontemperature set point should not be set below 35°F.25

SYSTEM FAULTS:Flow Switch Opening: The flow switch is normally closed during pump operation. Should liquid solution flow beinterrupted for any reason, the control will open shutting down and locking out the chiller operation. The only exceptionto this is when power is first applied to the chiller and the pump bypass timer bypasses the flow switch for 10 seconds.When the system is first filled with liquid solution and the pump is started, expect the system to cycle <strong>of</strong>fon the flow switch until all <strong>of</strong> the air is removed from the piping system. The system will have to bereset by opening and then closing the disconnect switch or circuit breaker powering the chiller.Low Pressure Switch Opening: Should the compressor suction pressure go low enough (40 PSI) to open the lowpressureswitch, the compressor and condenser fan motors will shut down. Check for a refrigerant leak, inoperativethermal expansion valve, low liquid solution control setting, low ambient operation, low liquid solution flow, etc.High Pressure Switch Opening: Should the compressor discharge pressure go high enough to open the high- pressureswitch the compressor and condenser fan motors will shut down. Check for a dirty condenser coil, inoperable fan motor(s)or the recirculation <strong>of</strong> condenser air.Refrigeration System OperationThe refrigeration system is a closed loop consisting <strong>of</strong> 2 compressors, dual circuit heat exchanger (evaporator), meteringdevices (TXVs) and condenser coil. The refrigerant circulated is R407c. Hot gas is pumped from the compressors to theto the condenser coil where the two condenser fans pull cooler air across the coil condensing and sub cooling the refrigerant.The now liquid refrigerant flows through the liquid line to the thermal expansion valves, where the refrigerant pressuredrops causing the refrigerant to boil at a much lower temperature (34-40°F). The refrigerant leaves the expansion valves andswirls through the plates <strong>of</strong> the heat exchanger absorbing heat from the circulating liquid solution.The evaporator or heat exchanger is designed to operate with an 8-10 °F superheat. The condenser is designed tocondense the refrigerant and sub cool it to 10 °F below condensing temperature.Description Of Refrigerant ComponentsScroll Compressor: All <strong>Multiaqua</strong> chillers feature Scroll compressors. Scrolltechnology ensures reliable high performance at a low sound level over a wide range<strong>of</strong> operating conditions.Caution the top half <strong>of</strong> the scroll compressor operates at a temperature highenough to cause serious injury.26

Description Of Refrigerant Components (continued)Brazed Plate Heat Exchanger: The "Heat Exchanger" or evaporator is <strong>of</strong> abrazed copper and stainless steel design. Refrigerant and liquid solution is channeledthrough narrow openings between plates and flows in opposite directions. The counterflow design and fluid turbulence ensures maximum heat exchange at minimal pressuredrop.Thermal Expansion Valve: <strong>Multiaqua</strong> chillers are equipped with Thermal Expansionvalves. The valves feature a liquid charged sensing bulb for consistent superheat atvarious load conditions.Condenser Coil: The air-cooled condenser coil is <strong>of</strong> copper tube with aluminum finconstruction. The coil is protected by a painted metal condenser grille.27

Piping System ComponentsSupply Storage Tank: The supply storage tank must be used in the system with lessthan 25 gallons <strong>of</strong> liquid solution. The tank prevents rapid cycling <strong>of</strong> the compressorsand acts as a reserve for chilled liquid solution.Supply storage tank must be insulated in the field.Part Number: WX202H (20 Gallon)WX202H (42 Gallon)Expansion Tank and Air Scoop: The Expansion Tank and Air Scoop assembly isused to compensate for the expansion and contraction <strong>of</strong> liquid in the system. Theair scoop eliminates air entrance in the liquid solution.Part Number: 1500/1"Liquid Solution Bypass Valve: The liquid solution bypass valve relieves systempressure from the liquid solution supply to the return as system air handler controlare cycled <strong>of</strong>f.Part Number: D146M1032- 3/4"D146M1040- 1 1/4"Motorized Valve: The air handler motorized valve controls the flow <strong>of</strong> liquid solutionto the systems air handlers. Each air handler in the system should have a motorizedor solenoid valve.Part Number: MZV524E-T 1/2" 2-Way Zone ValveMZV525E-T 3/4" 2-Way Zone ValveMZV526E-T 1" 2-Way Zone ValveVT3212G13A020 1/2" 3-Way Zone ValveVT3212G13A020 3/4" 3-Way Zone Valve28

Composite Piping Layout and DesignUnderstanding the function and friction loss <strong>of</strong> each part <strong>of</strong> the piping system is important to the layout and successfulinstallation <strong>of</strong> a chilled liquid solution system.1-2-3-4-5-6-7-2-Way Liquid Solution Control ValvesBypass ValveStorage TankExpansion TankCoilChillerPumpThe circulation pump is the key performer in the piping system. The pump must circulate the liquid solution through theheat exchanger and piping system to the air handlers. Pumps are designed to deliver a flow rate measured in gallonsper minute(GPM). The pump must be able to overcome the resistance to flow (pressure drop) imposed by the chillercomponents, piping system and air handlers while maintain the necessary flow rates in gallons per minute. Pumpcapacities in gallons per minute and pressure drop (feet <strong>of</strong> head) are listed in table 1.An adjustable valve must be used to throttle the discharge liquid solution flow rate to appropriate levels basedon capacity and glycol mix percentages.Table 1Chiller System DataMAC SeriesMin. Liquid Solution Flow RateMax.Liquid Flow RateMin. Liquid Solution Content in SystemExpansion Tank SizeInternal Chiller Pressure LossChiller Liquid Solution ContentGPMGPMGallonsGallonsFt.<strong>of</strong> HeadGallonsMAC-1201828.8503% <strong>of</strong> Total1.851.5Piping resistance or pressure drop is measured in feet <strong>of</strong> head. A foot <strong>of</strong> head is the amount <strong>of</strong> pressure drop imposedin lifting liquid solution one foot. Pumps in the <strong>Multiaqua</strong> system are designed to move rated liquid solution flow (seetable 1) in GPMs.29

Banked Chiller ConfigurationNotes:Installing <strong>Multiaqua</strong> chillers in parallel is recommended.30

Installation Notes:Piping such as PEX,steel, copper or PVC can be used with the <strong>Multiaqua</strong> system. Check local building codes formaterial conformation. Care must be taken when using PVC as the presence <strong>of</strong> propylene glycol may destroyplastics. Pressure drop data for the selected piping material is readily available and should be used. Should the<strong>Multiaqua</strong> chiller be installed using existing steel (ferrous metal) piping system, dielectric fittings must be usedat the chiller and air handler. The factory supplied wye strainer will capture particles <strong>of</strong> rust and sedimentinherent with steel piping and should be checked and cleaned after initial start up and open a regular maintenanceduring the life <strong>of</strong> the system.Any piping used to conduct liquid solution must be insulated in accordance with local and national mechanicalcodes. Information on insulation installation and application can be obtained from Armaflex web site atwww.armaflex.com and Owens-Corning site at www.owenscorning.com/mechanical/pipe/. For future servicing<strong>of</strong> the chiller and air handlers, it is suggested that shut<strong>of</strong>f valves be installed at the chiller and air handler(s). Ifball valves are used, they can double as balancing valve(s) in the supply piping at each air handler. Chillershut<strong>of</strong>f valves should be attached at the chiller connections with unions.The air handlers are to be controlled with electrically operated "slow-opening" solenoid valves, circulators ormotorized zone valves as manufactured by Erie controls (www.eriecontrols.com/products/index.htm) A remotethermostat or air handler installed digital control operate the valves.Bypass valves as shown in drawing 1, should be installed between the supply and the return chilled liquidsolution supply pipes at a convenient location to the installation. The bypass valve operates to bypass liquid solutionbetween the supply and return chilled liquid solution lines. In the event air handlers valves should shut down, thebypass valve is set to open up and bypass liquid solution between the supply and return lines, relieving pressureand eliminating the possibility <strong>of</strong> pump cavitations. To adjust the valve, run the system with one air handlersolenoid actuated. De-energize the solenoid valve, (at this point no liquid solution will be flowing through the airhandlers.) and adjust the bypass valve to relieve pressure between the supply and return piping.Bleed ports will be factory installed on all <strong>Multiaqua</strong> air handlers. Bleed ports are opened to eliminate air trappedin the air handlers after filling the system with liquid solution and Propylene Glycol and before operating therefrigerant compressor in the chiller.The minimum liquid solution content in the chiller system,(piping, chiller, and air handlers), is 50 U.S. gallons.Estimate the system liquid solution content. Should the system have less than 50 gallons <strong>of</strong> liquid solutioncontent, a chilled liquid solution storage tank must be installed. The tank stores enough chilled liquid solutionto prevent frequent chiller compressor cycles at light load and prevents chilled liquid temperature swings athigher load conditions when the chiller compressor is waiting to cycle on the time delay control.Propylene Glycol must be added to the water used in the system. Propylene helps prevent freeze-ups due tolow ambient temperature conditions and low chilled liquid solution temperatures. In comparison to water,Propylene Glycol slightly lessons the temperature exchange in the chiller heat exchanger. However, that is<strong>of</strong>fset by the increased flow <strong>of</strong> liquid solution through the piping system enabled by the Propylene Glycol. Todetermine the Propylene Glycol content for various ambient temperatures refer to table 6 page 32.In no instance should a <strong>Multiaqua</strong> chiller be installed with less than 10% Propylene Glycol content in the pipingsystem. Using less than the recommended Propylene Glycol percentage content voids equipment warranty.31

Polypropylene Glycol System Content vs.Minimum Ambient TemperatureTo not engage in cold ambient mitigation will result in the failure <strong>of</strong> components, property damage andvoid warranty.Table 6Percent <strong>of</strong> Propylene Glycol to Water ContentPropylene Water Min. AmbientCapacityGlycol % Flow Temperature10% x 1.020 x .99 26°F20% x 1.028 x .98 18°F30% x 1.036 x .98 8°F40% x 1.048 x .97 -7°F50% x 1.057 x .96 -29°FGPM Adjustment= 100 % Capacityx 1.01x 1.03x 1.07x 1.11x 1.16Ethylene Glycol is environmentally hazardous and not recommended. Inhibited Propylene Glycol ( typicalautomotive coolant) is not to be used in a <strong>Multiaqua</strong> Chiller under any circumstances. Dow Chemical's "Ambitrol"family <strong>of</strong> Glycol-based coolants <strong>of</strong> food grade Propylene Glycol is suggested. Information on Ambitrol is availablefrom Dow at www.dow.com, search word "Ambitrol".Expansion Tanks:Liquid solution expansion and contraction within the closed system must be compensated for with an expansiontank. The expansion tank used with the <strong>Multiaqua</strong> system, is a steel tank with a rubber bladder attached to itinternally. There is air pressure on one side <strong>of</strong> the rubber bladder that keeps the bladder pushed against thesides <strong>of</strong> the tank before the system is filled with liquid solution (illustration above). As the liquid solution heatsup the bladder will be pushed further away from the tank walls, allowing for expansion and contracting as theliquid solution temperature changes. By flexing, the bladder controls the system pressure adjusting totemperature variations <strong>of</strong> the chilled liquid solution system.It is critical that the expansion tank's air bladders pressure be less than the system solution pressure. Airpressure can be measured with an automotive tire gauge at the bicycle valve port on the expansion tank. Bleedingair out <strong>of</strong> the bladder or increasing the pressure with a bicycle pump will adjust pressure.System must use a liquid solution storage tank if system volume is less than 50 U.S. gallons.32

Filling System with Liquid Solution and Coolant(Propylene Glycol)Before filling system with Propylene Glycol and water, pressure test the piping system with compressed air.Testing should be done at a maximum <strong>of</strong> 50 psi.The system should hold air pressure for a minimum <strong>of</strong>one hour with no leakage.Concentrations <strong>of</strong> Propylene Glycol in excess <strong>of</strong> 50% will destroy o-rings in fittings and pump. Water shouldbe added to the system first or a liquid solution diluted Propylene Glycol mix.System that contains 50 or more U.S. gallons should have a tee fitting with a stopcock installed in the returnline close to the chiller. The stopcock can be opened and attached to a hose with a female X female hosefitting. In the open end <strong>of</strong> the hose section (1 -1.5 feet long) insert a funnel and pour into the system thediluted Propylene Glycol/liquid solution mixture or add water first and then the quantity <strong>of</strong> Propylene Glycolneeded for minimum ambient protection (refer to Table 6). After adding the Propylene Glycol/water mixture, orliquid solution and then coolant proceed to add enough water to the system to achieve a 15 psi gauge pressure.To measure system pressure shut <strong>of</strong>f the stopcock, remove hose and attach a water pressure gauge. Openthe stopcock to read system pressure.Systems that use the Chilled Liquid Solution Storage Tank should be filled at the tee/stopcock fitting in theoutlet fitting <strong>of</strong> the storage tank. Fill the tanks with 10 gallons <strong>of</strong> water and with a funnel pour the calculated(refer to Table 6) amount <strong>of</strong> Propylene Glycol into the tank. The amount <strong>of</strong> Propylene Glycol added should becalculated to achieve minimum ambient protection. After adding Propylene Glycol, fill the system with enoughliquid solution to bring system pressure to approximately 15 psi gauge pressure. To measure system pressureshut <strong>of</strong>f the stopcock and attach a water pressure gauge. Open the stopcock to read system pressure.Air EliminationSince we have the system filled we must eliminate the air left in the system. Briefly open each bleed valve atthe air handlers and allow trapped air to escape. This will eliminate much <strong>of</strong> the air left in the system.Next we will start the pump and continue bleeding air from the system. Be sure the chiller has line voltageavailable to it and set the chilled liquid solution control up to 100 °F, which will ensure that only the pump runsat this point. The pump should now start and remain running. Should the pump stop at any time during thisprocess it is an indication that the flow switch had air move across it allowing the circuit to be interrupted.Continue to bleed some air out <strong>of</strong> the system at the highest locations before resetting the pump bypass timerto get the pump running again. Open and close the power supply switch to the chiller to restart the pump.Continue bleeding air with the pump operating. You may have to start and re-start the pump a few times tocomplete air removal.If you continue having air entrapment issues, it will be necessary to install a micro bubble remover device.All piping systems should have a minimum <strong>of</strong> 10% Propylene Glycol in the system even in climates with nonfreezingambient temperatures.Using less than the recommended Propylene Glycol percentage content voids equipment warranty.Liquid solution control valves (solenoid or motorized valves) should be selected for low pressure drop. If a selectedvalve contributes to pushing your total head calculation to more than 50 feet <strong>of</strong> head, a larger valve may beneeded to bring your total head below the maximum <strong>of</strong> 50 feet.Liquid Solution Balancing:Liquid solution balancing will require an accurate digital thermometer to measure return line liquid solutiontemperature at each air handler. Set the chilled liquid solution temperature control in the chiller at a normaloperational temperature (44°F) and measure pump discharge temperature with the digital thermometer to checksystem solution temperature. After the chilled liquid solution temperature has lowered to the set point begin thebalancing process. The system must be free <strong>of</strong> air and each air handler set at a temperature low enough tocontinue cooling operation (and liquid solution flow) during the balancing process. Begin by measuring the returnline chilled liquid solution temperature <strong>of</strong> each air handler. Begin incrementally closing the supply line balancevalve at the air handlers with the lowest return line chilled liquid solution temperature. Continue this processuntil each air handler has close to the same return line chilled liquid solution temperature.33

MAC120-3 Ladder Wiring Diagram380/460-3-50/6034

MAC120-3 Wiring Diagram380/460-3-50/60MULTIAQUABL380/460-3-50/60BKL1RDL2BKCON1`BKBKRDWHT1COMPT21T3BKBK380/460-3TRANSFORMER24 vacBLYLYLRDBKBLFSLPS1BLGNDL3WHCON2BKRDWHT1T2T3COMP21234BKBKHPS1BKBKTIMER1BKBKBKWHREL 1REL 2BKBKBK2TM21NOTE 112BLLPS2BLBLBL34BL BLDTC 1 NO C DTC 2 NO CBKBLBKBKHPS2BK24 vac COM 24 vacWHWHBKCOMBKFC1BKFAN1FC2FAN2BKBK2TM21RDWHTITLEAUTHORMAC120-03 380/460-3-50/60kjgLEGEND:FACTORY WIRINGFIELD WIRINGCON COMPRESSOR CONTACTORFS FLOW SWITCHLPS LOW PRESSURE SWITCHNOTES:1.PUMP STARTER RELAYDATEREVISION09/22/080807300029 REV 1DTC DIGITAL TEMPERATURE CONTROLLERFC CONDENSER FAN CONTACTORREL CONDENSER FAN RELAYHPSTIMERTM2HIGH PRESSURE SWITCHPUMP BYPASS TIMERREFRIGERANT SYSTEM TIMER35

MAC120-3-L with Low Ambient Kit Wiring Diagram380/460/-3-50/60MULTIAQUA380/460-3-50/60BKL1RDL2BKCON1`BKBKRDWHBLT1COMPT21T3BKBK380/460-3TRANSFORMER24 vacBLYLYLRDBKBLFSLPS1BLGNDL3WHCON2BKRDWHT1T2T3COMP21234BKBKHPS1BKBKTIMER1BKBKBKNOTE 1REL 1REL 2BKBKBK2TM21FAN CYCLEPRESSURESWITCH12BLLPS2BL34FAN CYCLEPRESSURESWITCHBL BLDTC 1 NO C DTC 2 NO C24 vac COM 24 vac COMFC1NOTE 2BL1FAN134 6BKFC24FAN21 36BKBKBKHPS22TM21BKNOTE 3TITLEAUTHORDATEREVISIONMAC120-03 WITH LOW AMBIENT KITkjg09/22/080608400097 REV 1LEGEND:FACTORY WIRINGFIELD WIRINGDTC DIGITAL TEMPERATURE CONTROLLERFC CONDENSER FAN CONTACTORREL CONDENSER FAN RELAYCONFSLPSHPSTIMERTM2COMPRESSOR CONTACTORFLOW SWITCHLOW PRESSURE SWITCHHIGH PRESSURE SWITCHPUMP BYPASS TIMERREFRIGERANT SYSTEM TIMERNOTES:1. PUMP STARTER RELAY2. LOW AMBIENT RELAY #13. LOW AMBIENT RELAY #236

MAC120-2 Ladder Wiring Diagram208/230-3-50/6037

MAC120-2 Wiring Diagram208/230-3-50/6038

MAC120-2-L with Low Ambient Kit Wiring Diagram208/230-3-50/6039

MAC120-1 Ladder Wiring Diagram208/230-1-50/6040

MAC120-1 Wiring Diagram208/230-1-50/6041

MAC120-1-L with Low Ambient Kit Wiring Diagram208/230-1-50/6042

MAC120 CERTIFIED DRAWING43

MAC036,048 & 060 Air-Cooled ChillerAir-Cooled Chillers for Global Residentialand Light Commercial MicroClimates44

MAC036,048 & 060 NOMENCLATURE BREAKDOWNMACXXX - XX - XAir-Cooled Chiller036= 36,0000 BTUH048= 48,0000 BTUH060= 60,0000 BTUHAccessoryOptionsN= No OptionsL= Low Ambient KitVoltage01 = 208/230-1-50/6002 = 208/230-3-50/6003 = 380/460-3-50/60Available Model NumbersMAC036-01-NMAC036-01-LMAC036-02-NMAC036-02-LMAC048-01-NMAC048-01-LMAC048-02-NMAC048-02-LMAC060-01-NMAC060-01-LMAC060-02-NMAC060-02-LMAC060-03-NMAC060-03-L45

HVAC Guide SpecificationsAir-Cooled Liquid ChillerNominal Size:3, 4 & 5 Tons<strong>Multiaqua</strong> Model Number:MAC036-01-N-407, MAC036-01-L-407: MAC036-02-N-407, MAC036-02-L-407,MAC048-01-N-407, MAC048-01-L-407: MAC048-02-N-407, MAC048-02-L-407,MAC060-01-N-407, MAC060-01-L-407, MAC060-02-N-407, MAC060-02-L-407,Part 1-General1.01 System Description<strong>Multiaqua</strong> air-cooled liquid chillers are designed using scroll compressors, low sound condenser fans and highefficiency pumps.1.02 Quality AssuranceA. Certified in accordance with U.L. Standard 95, latest version (U.S.A.)B. Construction shall comply with ASHRAE 15 Safety Code, NEC and ASME applicable codes. (U.S.A.Codes)C. Manufactured in a facility registered to ISO 9002, Manufacturing Quality Standard.D. ETL CertifiedE. <strong>Full</strong>y load tested at the factory.F. Damage resistant packaging.1.03 Delivery, Storage and HandlingA. Packaged and readied for shipment from the factory.B. Controls shall be capable <strong>of</strong> withstanding 150°F storage temperatures in the control compartment.C. Stored and handled per manufacturer’s recommendations.Part 2-Product2.01 EquipmentA. General:1. Unit shall be a factory assembled and tested air-cooled liquid chiller.2. Shall be assembled on heavy gauge steel mounting/lifting rails.3. Contained within the unit cabinet shall be all factory wiring, piping, controls, refrigerant charge(R407c), POE oil and special accessories required prior to start up.4. Brass body strainer with 20 mesh screen and blow down shall be supplied in cabinet as afield installable accessory.B. Unit Cabinet:1. Composed <strong>of</strong> heavy gauge galvanized steel casing with a baked polyester powder.2. Capable <strong>of</strong> withstanding 500-hour salt spray test in accordance with the ASTM (USA) standard.C. Condenser Fans:1. 4-blade, aluminum construction and shall be dynamically balanced and corrosion resistant.2. Horizontal discharged air.3. Motors and blades shall be protected by coated steel wire safety guards.D. Fan Motors:1. Condenser fan motors shall be single speed, direct drive.2. Totally enclosed.3. Permanently lubricated sleeve bearings and Class F insulation.4. Internal overload protection.E. Compressors:1. Unit shall contain one fully hermetic scroll compressors.2. Direct-drive, 3500 rpm (60Hz)3. Compressor motor shall be suction gas cooled.4. Internal motor protection.5. Externally protected by low and high pressure cutout devices.6. Individual vibration isolators.46

F. Pump:1. Circulating pump shall be stainless steel with high efficiency enclosed motor.2. Unit shall have chilled liquid solution piping to the exterior <strong>of</strong> the cabinet.G. Evaporator:1. Evaporator shall have one independent refrigerant circuit and one liquid solution circuit.2. Rated for a refrigerant side working pressure <strong>of</strong> 450 psig and a maximum water side workingpressure <strong>of</strong> 150 psig.3. Single pass, ANSI type 316 stainless steel, brazed plate construction.4. Externally insulated with closed cell, elastomeric foam. (ASTM518)H. Condenser:1. Condenser coil shall be air-cooled with integral subcooler.2. One independent refrigerant circuit.3. Constructed <strong>of</strong> rifled copper tubing mechanically bonded to aluminum fins.4. Cleaned and dehydrated.5. Factory leak tested to 450 psig.I. Refrigerant Circuits:1. Each circuit shall contain a sight glass, liquid line filter, thermal expansion valve,refrigerant charge <strong>of</strong> R407c and POE compressor oil.Part 3-Controls and Safeties3.01 ControlsA. Chiller shall be completely factory wired and tested.B. Capacity control shall be based on leaving chilled liquid solution temperature.1. Temperature accuracy shall be + - 1.0°F.2. Controls shall be capable <strong>of</strong> staging the two compressors.C. Controls shall include the following components.1. 24vac transformer to serve all controllers relays and control components.2. Microprocessor based liquid solution temperature controller.3. Leaving water temperature thermistor.4. Pump bypass timer.5. Compressor recycle timer.6. Optional low pressure bypass timer for low ambient operation.7. Optional fan cycling control for low ambient operation.8. Chilled liquid solution flow switch.3.02 SafetiesA. Unit shall be equipped with thermistors and all necessary components in conjunction with thecontrol system to provide the following protectants.1. Low refrigerant pressure.2. High refrigerant pressure.3. Low chilled liquid solution temperature.4. Low chilled liquid solution flow.5. Thermal overload.6. Short cycling.Part 4-Operating Characteristics:4.01 TemperaturesA. Unit shall be capable <strong>of</strong> starting and running at outdoor temperatures from 55°F to 120°F.B. Optional Low Ambient Kit shall allow starting and running at outdoor temperatures to -20°F. Afield supplied and installed crankcase heater must be used when operating at these temperatures.C. Unit shall be capable <strong>of</strong> starting up with a maximum 80°F and a sustained 70°F entering fluidsolution temperature to the evaporator.D. Minimum 10% Glycol solution is required. For outdoor temperatures below 32°F, referenceMAC Glycol Solution Data table.4.02 Electrical RequirementsA. Primary electrical power supply shall enter the unit at a single location.B. Electrical power supply shall be rated to withstand 120°F operating ambient temperature.C. Units shall be available in 1 or 3-phase power at the voltages shown in the equipment electrical data.D. Control points shall be accessed through terminal block.47

ModelNumberModel NumberHeight(in)MAC036, 048 & 060 Product SpecificationsPhysical DataCoil Chiller Weight (lbs)CopperLengthCoil Height Length Width RefrigerantDiameterNet Shipping(in)Rows (in) (in) (in) R407c(in)MAC036 38 48 3/8 1 49.75 39.75 16.25 84.66 oz 280 283MAC048 38 48 3/8 2 49.75 39.75 16.25 92.95 oz 292 295MAC060 38 48 3/8 2 49.75 39.75 16.25 92.95 oz 313 316Volts/ Phase/HertzElectrical DataCondenserCompressor Fan Motor(2 qty)Pump MotorFuse or HACR CircuitBreaker Per Circuit(RLA) (LRA) (FLA) (RPM) (FLA) (RPM) Minimum AmpsMAC036-01 208/230-1-50/60 18.4 95 1.05 1050 3.70 3450 28.80 45MAC036-02 208/230-3-50/60 11.4 77 1.05 1050 3.70 3450 20.05 30MAC048-01 208/230-1-50/60 22.1 137 1.05 1050 3.70 3450 33.43 50MAC048-02 208/230-3-50/60 16.4 91 1.05 1050 3.70 3450 26.30 40MAC060-01 208/230-1-50/60 32.1 169 1.05 1050 3.70 3450 45.93 70MAC060-02 208/230-3-50/60 19.3 137 1.05 1050 3.70 3450 29.93 45MAC060-03 380/460-3-50/60 10 75 0.60 1050 2.85 3500 16.55 25MaximumAmpsMAC036 MAC048 MAC060CompressorCopeland Copeland CopelandScrollScrollScrollRefrigerant R407c R407c R407cHeat Exchanger Brazed Plate Brazed Plate Brazed PlateMax. Head Pressure 50 ft. 50 ft. 50 ft.Max Flow Rate 8.6 gpm 11.5 gpm 14.4 gpmMin Flow Rate 5.5 gpm 6.5 gpm 9.0 gpmSupply Water Temp 44° 44° 44°Return Water Temp 54° 54° 54°Min. Solution Content 25 Gallons 25 Gallons 25 GallonsExpansion Tank Size 2 Gallons 2 Gallons 2 GallonsPump 0.5 HP 0.5 HP 0.5 HPWater Connections 1" S & 1.25" R 1" S & 1.25" R 1" S & 1.25" RInternal Pressure loss 1.77 ft <strong>of</strong> head 1.68 ft <strong>of</strong> head 1.85 ft <strong>of</strong> headSupply WireLength in FeetCopper Wire Size (1% Voltage Drop)200 6 4 4 4 3 3 2 2150 8 6 6 4 4 4 3 3100 10 8 8 6 6 6 4 450 14 12 10 10 8 8 6 615 20 25 30 35 40 45 50Supply Circuit Ampacity<strong>Multiaqua</strong> chillers are designed to operate exclusively with R407c refrigerant in a self-contained, pre-charged refrigerant system. Do notaccess the closed refrigerant circuit for any reason other than after-sale, after installation component replacement. Routine maintenanceand service is to be performed by qualified personnel only.These specifications are subject to change without notice.48

MAC036, 048 & 060 Product SpecificationsMAC036, 048 & 060 Capacity / Watts / EERMAC036 MAC048 MAC060O/A Temp (°F) Tons KW EER Tons KW EER Tons KW EER82 2.9 3.3 10.55 3.9 4.3 10.88 5.1 5.3 11.5595 2.8 3.7 9.08 3.7 4.6 9.65 4.9 5.9 9.97100 2.7 3.9 8.31 3.6 4.8 9.00 4.8 6.1 9.44105 2.7 4.0 8.10 3.5 5.0 8.40 4.7 6.4 8.81110 2.6 4.3 7.28 3.4 5.4 7.56 4.7 6.5 8.68Glycol Solution DataPropylene Glycol %WaterFlow CapacityMin. Ambient Temp GPM Adjustment= 100% Capacity10% x 1.020 x 0.99 26°F x 1.0120% x 1.028 x 0.98 18°F x 1.0330% x 1.036 x 0.98 8°F x 1.0740% x 1.048 x 0.97 -7°F x 1.1150% x 1.057 x 0.96 -29°F x 1.16Example: 30% glycol solution.Maximum Flow Rate = 12gpm x 1.036System capacity x .98Use Propylene Glycol OnlyImportantIf the outside temperature is expected to fall below freezing (32°F) in the area the <strong>Multiaqua</strong> chiller is to beinstalled; the installer must take the following precautions. Failure to do so will void the warranty.To not engage in cold ambient mitigation will result in the failure <strong>of</strong> components such as the heatexchanger, piping, circulating pump, etc… and or property damage.• Keep the liquid solution at a minimum <strong>of</strong> ten percent propylene glycol even in areas where there is no danger<strong>of</strong> freezing.• The percentage amount <strong>of</strong> glycol recommended is dependent on the expected ambient temperatures and thesolution makeup recommendation <strong>of</strong> the glycol manufacturer. Refer to the Glycol Solution Data table above.• Ensure the system circulating pump is in a constant energized mode to keep a continuous circulation <strong>of</strong> liquidsolution.The <strong>Multiaqua</strong> chiller is a self-contained air-cooled condenser, coupled with an insulated brazed plate heatexchanger (evaporator). The system utilizes a scroll compressor to circulate refrigerant between the condenserand heat exchanger. The refrigerant is metered into the heat exchanger with a thermostatic expansion valve.Protecting the system are high and low pressure switches as well as a pump flow switch.Liquid solution (water and propylene glycol; minimum 10 % is required) is circulated through the heatexchanger by an externally mounted pump. The liquid solution flows through the heat exchanger to the systemsupply piping and on to the air handlers.Low ambient kits are available for operating ambient temperatures down to 0 degrees Fahrenheit. The lowambient kits consist <strong>of</strong> an ICM 325 (+) ICM (175) for single and three phase 208/230 vac chillers. For the threephase 380/460 vac chillers a pressure activated fan control is used.These specifications are subject to change without notice.49

MAC036 Cooling Performance DataLWT (°F)MAC036 CAPACITIES with 0% GlycolENTERING AIR TEMPERATURE (°F)82 95 100 105 110TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM35 1.70 1.60 1.50 1.40 1.3040 2.30 2.20 2.10 2.10 2.0042 2.60 2.50 2.40 2.40 2.3044 2.90 2.80 2.70 2.70 2.6045 3.10 3.00 2.90 2.80 2.707.2 7.2 7.2 7.246 3.20 3.10 3.00 3.00 2.907.248 3.60 3.50 3.20 3.30 3.2050 3.90 3.80 3.50 3.60 3.5055 4.80 4.70 4.30 4.30 4.2060 5.80 5.60 5.20 5.20 5.00MAC036 CAPACITIES with 10% GlycolLWT (°F)ENTERING AIR TEMPERATURE (°F)82 95 100 105 110TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM35 1.68 1.58 1.49 1.39 1.2940 2.28 2.18 2.08 2.08 1.9842 2.57 2.48 2.38 2.38 2.2844 2.87 2.77 2.67 2.67 2.5745 3.07 2.97 2.87 2.77 2.677.2 7.2 7.2 7.246 3.17 3.07 2.97 2.97 2.877.248 3.56 3.47 3.17 3.27 3.1750 3.86 3.76 3.47 3.56 3.4755 4.75 4.65 4.26 4.26 4.1660 5.74 5.54 5.15 5.15 4.95MAC036 CAPACITIES with 20% GlycolLWT (°F)ENTERING AIR TEMPERATURE (°F)82 95 100 105 110TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM35 1.67 1.57 1.47 1.37 1.2740 2.25 2.16 2.06 2.06 1.9642 2.55 2.45 2.35 2.35 2.2544 2.84 2.74 2.65 2.65 2.5545 3.04 2.94 2.84 2.74 2.657.2 7.2 7.2 7.246 3.14 3.04 2.94 2.94 2.847.248 3.53 3.43 3.14 3.23 3.1450 3.82 3.72 3.43 3.53 3.4355 4.70 4.61 4.21 4.21 4.1260 5.68 5.49 5.10 5.10 4.90These specifications are subject to change without notice.50

MAC036 Cooling Performance DataMAC036 CAPACITIES with 30% GlycolLWT (°F)ENTERING AIR TEMPERATURE (°F)82 95 100 105 110TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM35 1.67 1.57 1.47 1.37 1.2740 2.25 2.16 2.06 2.06 1.9642 2.55 2.45 2.35 2.35 2.2544 2.84 2.74 2.65 2.65 2.5545 3.04 2.94 2.84 2.74 2.657.2 7.2 7.2 7.246 3.14 3.04 2.94 2.94 2.847.248 3.53 3.43 3.14 3.23 3.1450 3.82 3.72 3.43 3.53 3.4355 4.70 4.61 4.21 4.21 4.1260 5.68 5.49 5.10 5.10 4.90MAC036 CAPACITIES with 40% GlycolLWT (°F)ENTERING AIR TEMPERATURE (°F)82 95 100105 110TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM35 1.65 1.55 1.46 1.36 1.2640 2.23 2.13 2.04 2.04 1.9442 2.52 2.43 2.33 2.33 2.2344 2.81 2.72 2.62 2.62 2.5245 3.01 2.91 2.81 2.72 2.627.27.27.27.246 3.10 3.01 2.91 2.91 2.817.248 3.49 3.40 3.10 3.20 3.1050 3.78 3.69 3.40 3.49 3.4055 4.66 4.56 4.17 4.17 4.0760 5.63 5.43 5.04 5.04 4.85MAC036 CAPACITIES with 50% GlycolLWT (°F)ENTERING AIR TEMPERATURE (°F)82 95 100 105 110TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM35 1.63 1.54 1.44 1.34 1.2540 2.21 2.11 2.02 2.02 1.9242 2.50 2.40 2.30 2.30 2.2144 2.78 2.69 2.59 2.59 2.5045 2.98 2.88 2.78 2.69 2.597.2 7.2 7.2 7.246 3.07 2.98 2.88 2.88 2.787.248 3.46 3.36 3.07 3.17 3.0750 3.74 3.65 3.36 3.46 3.3655 4.61 4.51 4.13 4.13 4.0360 5.57 5.38 4.99 4.99 4.80These specifications are subject to change without notice.51

MAC048 Cooling Performance DataLWT (°F)MAC048 CAPACITIES with 0% GlycolENTERING AIR TEMPERATURE (°F)82 95 100 105 110TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM35 2.70 2.50 2.40 2.30 2.3040 3.30 3.10 3.00 2.90 2.9042 3.60 3.40 3.30 3.20 3.1044 3.90 3.70 3.60 3.50 3.4045 4.10 3.90 3.80 3.60 3.509.6 9.6 9.6 9.646 4.20 4.00 3.90 3.80 3.609.648 4.50 4.30 4.20 4.10 3.9050 4.80 4.60 4.50 4.40 4.2055 5.70 5.40 5.20 5.20 4.9060 6.60 6.20 6.10 6.10 5.80MAC048 CAPACITIES with 10% GlycolLWT (°F)ENTERING AIR TEMPERATURE (°F)82 95 100 105 110TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM35 2.67 2.48 2.38 2.28 2.2840 3.27 3.07 2.97 2.87 2.8742 3.56 3.37 3.27 3.17 3.0744 3.86 3.66 3.56 3.47 3.3745 4.06 3.86 3.76 3.56 3.479.6 9.6 9.6 9.646 4.16 3.96 3.86 3.76 3.569.648 4.46 4.26 4.16 4.06 3.8650 4.75 4.55 4.46 4.36 4.1655 5.64 5.35 5.15 5.15 4.8560 6.53 6.14 6.04 6.04 5.74MAC048 CAPACITIES with 20% GlycolLWT (°F)ENTERING AIR TEMPERATURE (°F)82 95 100 105 110TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM35 2.65 2.45 2.35 2.25 2.2540 3.23 3.04 2.94 2.84 2.8442 3.53 3.33 3.23 3.14 3.0444 3.82 3.63 3.53 3.43 3.3345 4.02 3.82 3.72 3.53 3.439.6 9.6 9.6 9.646 4.12 3.92 3.82 3.72 3.539.648 4.41 4.21 4.12 4.02 3.8250 4.70 4.51 4.41 4.31 4.1255 5.59 5.29 5.10 5.10 4.8060 6.47 6.08 5.98 5.98 5.68These specifications are subject to change without notice.52