Identification of Formaldehyde-induced Modifications in Proteins

Identification of Formaldehyde-induced Modifications in Proteins

Identification of Formaldehyde-induced Modifications in Proteins

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

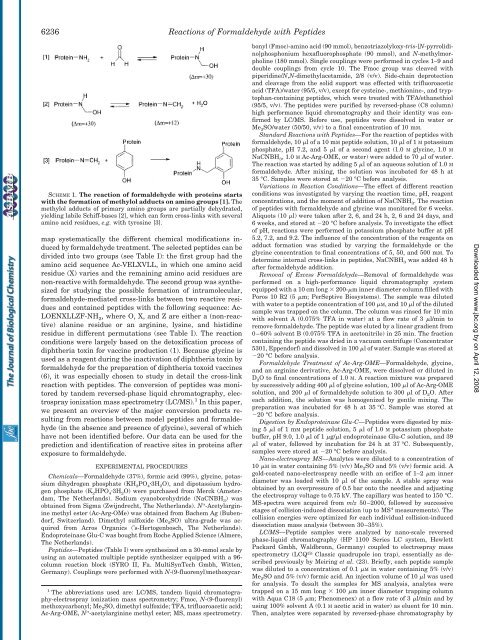

6236Reactions <strong>of</strong> <strong>Formaldehyde</strong> with PeptidesSCHEME 1. The reaction <strong>of</strong> formaldehyde with prote<strong>in</strong>s startswith the formation <strong>of</strong> methylol adducts on am<strong>in</strong>o groups [1]. Themethylol adducts <strong>of</strong> primary am<strong>in</strong>o groups are partially dehydrated,yield<strong>in</strong>g labile Schiff-bases [2], which can form cross-l<strong>in</strong>ks with severalam<strong>in</strong>o acid residues, e.g. with tyros<strong>in</strong>e [3].map systematically the different chemical modifications <strong><strong>in</strong>duced</strong>by formaldehyde treatment. The selected peptides can bedivided <strong>in</strong>to two groups (see Table I): the first group had theam<strong>in</strong>o acid sequence Ac-VELXVLL, <strong>in</strong> which one am<strong>in</strong>o acidresidue (X) varies and the rema<strong>in</strong><strong>in</strong>g am<strong>in</strong>o acid residues arenon-reactive with formaldehyde. The second group was synthesizedfor study<strong>in</strong>g the possible formation <strong>of</strong> <strong>in</strong>tramolecular,formaldehyde-mediated cross-l<strong>in</strong>ks between two reactive residuesand conta<strong>in</strong>ed peptides with the follow<strong>in</strong>g sequence: Ac-LOENXLLZF-NH 2 , where O, X, and Z are either a (non-reactive)alan<strong>in</strong>e residue or an arg<strong>in</strong><strong>in</strong>e, lys<strong>in</strong>e, and histid<strong>in</strong>eresidue <strong>in</strong> different permutations (see Table I). The reactionconditions were largely based on the detoxification process <strong>of</strong>diphtheria tox<strong>in</strong> for vacc<strong>in</strong>e production (1). Because glyc<strong>in</strong>e isused as a reagent dur<strong>in</strong>g the <strong>in</strong>activation <strong>of</strong> diphtheria tox<strong>in</strong> byformaldehyde for the preparation <strong>of</strong> diphtheria toxoid vacc<strong>in</strong>es(6), it was especially chosen to study <strong>in</strong> detail the cross-l<strong>in</strong>kreaction with peptides. The conversion <strong>of</strong> peptides was monitoredby tandem reversed-phase liquid chromatography, electrosprayionization mass spectrometry (LC/MS). 1 In this paper,we present an overview <strong>of</strong> the major conversion products result<strong>in</strong>gfrom reactions between model peptides and formaldehyde(<strong>in</strong> the absence and presence <strong>of</strong> glyc<strong>in</strong>e), several <strong>of</strong> whichhave not been identified before. Our data can be used for theprediction and identification <strong>of</strong> reactive sites <strong>in</strong> prote<strong>in</strong>s afterexposure to formaldehyde.1 The abbreviations used are: LC/MS, tandem liquid chromatography-electrosprayionization mass spectrometry; Fmoc, N-(9-fluorenyl)methoxycarbonyl; Me 2 SO, dimethyl sulfoxide; TFA, trifluoroacetic acid;Ac-Arg-OME, N -acetylarg<strong>in</strong><strong>in</strong>e methyl ester; MS, mass spectrometry.EXPERIMENTAL PROCEDURESChemicals—<strong>Formaldehyde</strong> (37%), formic acid (99%), glyc<strong>in</strong>e, potassiumdihydrogen phosphate (KH 2 PO 4 3H 2 O), and dipotassium hydrogenphosphate (K 2 HPO 4 3H 2 O) were purchased from Merck (Amsterdam,The Netherlands). Sodium cyanoborohydride (NaCNBH 3 ) wasobta<strong>in</strong>ed from Sigma (Zwijndrecht, The Netherlands). N -Acetylarg<strong>in</strong><strong>in</strong>emethyl ester (Ac-Arg-OMe) was obta<strong>in</strong>ed from Bachem Ag (Bubendorf,Switzerland). Dimethyl sulfoxide (Me 2 SO) ultra-grade was acquiredfrom Acros Organics (’s-Hertogenbosch, The Netherlands).Endoprote<strong>in</strong>ase Glu-C was bought from Roche Applied Science (Almere,The Netherlands).Peptides—Peptides (Table I) were synthesized on a 30-mmol scale byus<strong>in</strong>g an automated multiple peptide synthesizer equipped with a 96-column reaction block (SYRO II, Fa. MultiSynTech Gmbh, Witten,Germany). Coupl<strong>in</strong>gs were performed with N-(9-fluorenyl)methoxycarbonyl(Fmoc)-am<strong>in</strong>o acid (90 mmol), benzotriazolyloxy-tris-[N-pyrrolid<strong>in</strong>o]phosphoniumhexafluorophosphate (90 mmol), and N-methylmorphol<strong>in</strong>e(180 mmol). S<strong>in</strong>gle coupl<strong>in</strong>gs were performed <strong>in</strong> cycles 1–9 anddouble coupl<strong>in</strong>gs from cycle 10. The Fmoc group was cleaved withpiperid<strong>in</strong>e/N,N-dimethylacetamide, 2/8 (v/v). Side-cha<strong>in</strong> deprotectionand cleavage from the solid support was effected with trifluoroaceticacid (TFA)/water (95/5, v/v), except for cyste<strong>in</strong>e-, methion<strong>in</strong>e-, and tryptophan-conta<strong>in</strong><strong>in</strong>gpeptides, which were treated with TFA/ethanethiol(95/5, v/v). The peptides were purified by reversed-phase (C8 column)high performance liquid chromatography and their identity was confirmedby LC/MS. Before use, peptides were dissolved <strong>in</strong> water orMe 2 SO/water (50/50, v/v) to a f<strong>in</strong>al concentration <strong>of</strong> 10 mM.Standard Reactions with Peptides—For the reaction <strong>of</strong> peptides withformaldehyde, 10 l <strong>of</strong>a10mM peptide solution, 10 l <strong>of</strong>1M potassiumphosphate, pH 7.2, and 5 l <strong>of</strong> a second agent (1.0 M glyc<strong>in</strong>e, 1.0 MNaCNBH 3 , 1.0 M Ac-Arg-OME, or water) were added to 70 l <strong>of</strong> water.The reaction was started by add<strong>in</strong>g 5 l <strong>of</strong> an aqueous solution <strong>of</strong> 1.0 Mformaldehyde. After mix<strong>in</strong>g, the solution was <strong>in</strong>cubated for 48 h at35 °C. Samples were stored at 20 °C before analysis.Variations <strong>in</strong> Reaction Conditions—The effect <strong>of</strong> different reactionconditions was <strong>in</strong>vestigated by vary<strong>in</strong>g the reaction time, pH, reagentconcentrations, and the moment <strong>of</strong> addition <strong>of</strong> NaCNBH 3 . The reaction<strong>of</strong> peptides with formaldehyde and glyc<strong>in</strong>e was monitored for 6 weeks.Aliquots (10 l) were taken after 2, 6, and 24 h, 2, 6 and 24 days, and6 weeks, and stored at 20 °C before analysis. To <strong>in</strong>vestigate the effect<strong>of</strong> pH, reactions were performed <strong>in</strong> potassium phosphate buffer at pH5.2, 7.2, and 9.2. The <strong>in</strong>fluence <strong>of</strong> the concentration <strong>of</strong> the reagents onadduct formation was studied by vary<strong>in</strong>g the formaldehyde or theglyc<strong>in</strong>e concentration to f<strong>in</strong>al concentrations <strong>of</strong> 5, 50, and 500 mM. Todeterm<strong>in</strong>e <strong>in</strong>ternal cross-l<strong>in</strong>ks <strong>in</strong> peptides, NaCNBH 3 was added 48 hafter formaldehyde addition.Removal <strong>of</strong> Excess <strong>Formaldehyde</strong>—Removal <strong>of</strong> formaldehyde wasperformed on a high-performance liquid chromatography systemequipped with a 10 cm long 200-m <strong>in</strong>ner diameter column filled withPoros 10 R2 (5 m; PerSeptive Biosystems). The sample was dilutedwith water to a peptide concentration <strong>of</strong> 100 M, and 10 l <strong>of</strong> the dilutedsample was trapped on the column. The column was r<strong>in</strong>sed for 10 m<strong>in</strong>with solvent A (0.075% TFA <strong>in</strong> water) at a flow rate <strong>of</strong> 3 l/m<strong>in</strong> toremove formaldehyde. The peptide was eluted by a l<strong>in</strong>ear gradient from0–60% solvent B (0.075% TFA <strong>in</strong> acetonitrile) <strong>in</strong> 25 m<strong>in</strong>. The fractionconta<strong>in</strong><strong>in</strong>g the peptide was dried <strong>in</strong> a vacuum centrifuge (Concentrator5301, Eppendorf) and dissolved <strong>in</strong> 100 l <strong>of</strong> water. Sample was stored at20 °C before analysis.<strong>Formaldehyde</strong> Treatment <strong>of</strong> Ac-Arg-OME—<strong>Formaldehyde</strong>, glyc<strong>in</strong>e,and an arg<strong>in</strong><strong>in</strong>e derivative, Ac-Arg-OME, were dissolved or diluted <strong>in</strong>D 2 O to f<strong>in</strong>al concentrations <strong>of</strong> 1.0 M. A reaction mixture was preparedby successively add<strong>in</strong>g 400 l <strong>of</strong> glyc<strong>in</strong>e solution, 100 l <strong>of</strong> Ac-Arg-OMEsolution, and 200 l <strong>of</strong> formaldehyde solution to 300 l <strong>of</strong>D 2 O. Aftereach addition, the solution was homogenized by gentle mix<strong>in</strong>g. Thepreparation was <strong>in</strong>cubated for 48 h at 35 °C. Sample was stored at20 °C before analysis.Digestion by Endoprote<strong>in</strong>ase Glu-C—Peptides were digested by mix<strong>in</strong>g5 l <strong>of</strong>1mM peptide solution, 5 l <strong>of</strong>1.0 M potassium phosphatebuffer, pH 9.0, 1.0 l <strong>of</strong>1g/l endoprote<strong>in</strong>ase Glu-C solution, and 39l <strong>of</strong> water, followed by <strong>in</strong>cubation for 24 h at 37 °C. Subsequently,samples were stored at 20 °C before analysis.Nano-electrospray MS—Analytes were diluted to a concentration <strong>of</strong>10 M <strong>in</strong> water conta<strong>in</strong><strong>in</strong>g 5% (v/v) Me 2 SO and 5% (v/v) formic acid. Agold-coated nano-electrospray needle with an orifice <strong>of</strong> 1–2 m <strong>in</strong>nerdiameter was loaded with 10 l <strong>of</strong> the sample. A stable spray wasobta<strong>in</strong>ed by an overpressure <strong>of</strong> 0.5 bar onto the needles and adjust<strong>in</strong>gthe electrospray voltage to 0.75 kV. The capillary was heated to 150 °C.MS-spectra were acquired from m/z 50–2000, followed by successivestages <strong>of</strong> collision-<strong><strong>in</strong>duced</strong> dissociation (up to MS 4 measurements). Thecollision energies were optimized for each <strong>in</strong>dividual collision-<strong><strong>in</strong>duced</strong>dissociation mass analysis (between 30–35%).LC/MS—Peptide samples were analyzed by nano-scale reversedphase-liquid chromatography (HP 1100 Series LC system, HewlettPackard Gmbh, Waldbronn, Germany) coupled to electrospray massspectrometry (LCQ Classic quadrupole ion trap), essentially as describedpreviously by Meir<strong>in</strong>g et al. (23). Briefly, each peptide samplewas diluted to a concentration <strong>of</strong> 0.1 M <strong>in</strong> water conta<strong>in</strong><strong>in</strong>g 5% (v/v)Me 2 SO and 5% (v/v) formic acid. An <strong>in</strong>jection volume <strong>of</strong> 10 l was usedfor analysis. To desalt the samples for MS analysis, analytes weretrapped on a 15 mm long 100 m <strong>in</strong>ner diameter trapp<strong>in</strong>g columnwith Aqua C18 (5 m; Phenomenex) at a flow rate <strong>of</strong> 3 l/m<strong>in</strong> and byus<strong>in</strong>g 100% solvent A (0.1 M acetic acid <strong>in</strong> water) as eluent for 10 m<strong>in</strong>.Then, analytes were separated by reversed-phase chromatography byDownloaded from www.jbc.org by on April 12, 2008