Download magazine - Mercedes-Benz UK

Download magazine - Mercedes-Benz UK

Download magazine - Mercedes-Benz UK

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

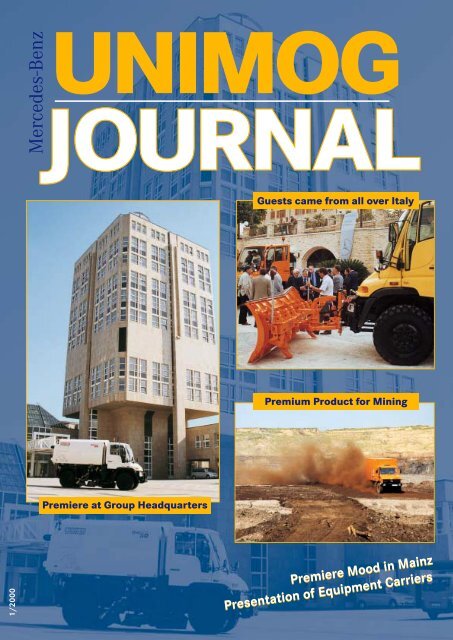

1/2000<br />

<strong>Mercedes</strong>-<strong>Benz</strong><br />

UNIMOG<br />

JOURNAL<br />

Premiere at Group Headquarters<br />

Guests came from all over Italy<br />

Premium Product for Mining<br />

Premiere Premiere Mood Mood in Mainz Mainz<br />

Presentation Presentation of Equipment Equipment Carriers Carriers

The Unimog concept re-defined 4<br />

Admiration from all sides 5<br />

Presentation at the European specialist symposium 6-7<br />

Rescuers on tour 18<br />

A cyclist for the future 18<br />

Worth seeing again and again 18<br />

Austrian premiere 18<br />

Partnership 19<br />

Swiss species 19<br />

P U B L I S H E R ’ S I M P R I N T<br />

Editorial<br />

A new chapter in Unimog’s history 3<br />

The new Unimog generation<br />

Sales organisation<br />

As good as new – or a wonderful “comeback” 8-9<br />

Flowers in bloom again after mining 10-11<br />

A well-maintained fleet 12-13<br />

U nimog International<br />

“Specialists” in Spain 14-16<br />

Guests came from all over Italy 17<br />

UNISCOPE<br />

Publisher:<br />

DaimlerChrysler AG, Unimog Division<br />

Publisher’s responsibility:<br />

Dieter Sellnau, Unimog Division<br />

Coordination:<br />

Martin Adam, Unimog Division<br />

Editorial committee:<br />

Martin Adam, Erwin Kirschner,<br />

Dieter Mutard, Karin Weidenbacher<br />

Contributors to this issue:<br />

Texts: Michael Brettnacher, Stefan Loeffler,<br />

Dieter Mutard, Angelika Ruoff<br />

Photos: DWM Pressebüro und Verlag<br />

Unimog Division<br />

Editorial office address:<br />

DaimlerChrysler AG, Produktbereich Unimog,<br />

Vertrieb Marketing, 76568 Gaggenau, Germany<br />

Production:<br />

Dieter Mutard DWM Pressebüro und Verlag,<br />

Ringstrasse 11, 89081 Ulm, Germany<br />

Phone +49 731/9 62 89-0, Fax +49 731/9 62 89-30<br />

The next issue will be published in the fall of 2000.<br />

The publisher assumes no responsibility for voluntarily<br />

submitted texts and photographs.<br />

Printed on paper bleached without the use of chlorine.<br />

Printed in the Federal Republic of Germany<br />

WWW<br />

UNIMOG HOMEPAGE:<br />

www.mercedes-benz.com/d/ecars/unimog/default.htm<br />

The cover photographs<br />

The clouds stood no<br />

chance as the sun broke<br />

through, providing the<br />

right atmosphere for the<br />

presentation of the U 300<br />

and U 400 models in Italy<br />

Premium product<br />

for mining: the<br />

Unimog from<br />

Gaggenau is in demand<br />

wherever<br />

the brown coal<br />

flags fly and<br />

gigantic bucket<br />

excavators mine<br />

coal by open-cast<br />

methods<br />

Company stamp<br />

Premiere at the Group’s<br />

headquarters: The main<br />

DaimlerChrysler<br />

administration building in<br />

Stuttgart-Möhringen is a<br />

location where the Unimog,<br />

although a <strong>Mercedes</strong>-<strong>Benz</strong><br />

product, is only rarely<br />

seen. For the presentation<br />

of the new Unimog U 300/<br />

U 400 to the European specialised<br />

press, however, the<br />

attractive main administration<br />

building provided an<br />

impressive backdrop

A new chapter<br />

in Unimog’s history<br />

Dear friends of Unimog, in this issue of<br />

UNIMOG JOURNAL I am particularly<br />

pleased to be able to present our new<br />

Unimog generation to you.<br />

With this Unimog generation we are<br />

beginning a new chapter in more than fifty<br />

successful years of the Unimog (a German<br />

acronym for Universal Motor Appliance ).<br />

More than perhaps any other commercial<br />

vehicle built by our Group, the Unimog<br />

symbolizes the virtues of the <strong>Mercedes</strong>-<br />

<strong>Benz</strong> brand: reliability, strength, longevity<br />

and diversity. You can be sure that what<br />

was true yesterday remains true today and<br />

will continue to hold good in the future!<br />

We have re-interpreted the Unimog<br />

concept at the beginning of the new millennium.<br />

Its design has now been revised<br />

for the fourth time. Why this re-interpretation,<br />

you may ask: in fact it reflects our<br />

desire to design the Unimog, this versatile<br />

equipment carrier, to meet our customers<br />

requirements as closely as possible. This<br />

new multiple talent on the equipment<br />

operating sector satisfies all the demands<br />

we face on the market today and that have<br />

naturally changed in recent years. Furthermore,<br />

it still has the best off-road capabilities<br />

of all equipment-carrier vehicles.<br />

The new model series are all-round solutions<br />

for the most varied employment<br />

conditions in winter and summer alike,<br />

for public authorities, private companies,<br />

the construction and energy industries<br />

and agriculture. In a so far unique partnership<br />

with certified equipment manufacturers,<br />

we offer highly specialised and focused<br />

solutions for just about every task. The interfaces<br />

on the vehicle make it possible to<br />

continue using older Unimog attachments.<br />

We had the driver specifically in mind<br />

when designing our new vehicle. The<br />

new Unimog is safer and more convenient<br />

to drive. For those who use it every day,<br />

work is made easier by the comprehensive<br />

standard equipment specification, consisting<br />

of air conditioning, EPS, ABS, permanent<br />

four-wheel drive and other technical<br />

innovations such as the VarioPilot<br />

person operating system. The completely<br />

re-designed driver s cabin is now even<br />

more spacious, with better visibility.<br />

On a regional tour of Germany we<br />

recently introduced the new Unimog<br />

generation to customers, business associates<br />

and the specialised press. The heavy<br />

series 500 which will be launched in February<br />

2001 will be presented for the first<br />

Dr. Klaus Maier<br />

Editorial<br />

time at the German IAA Commercial<br />

Vehicle Show in Frankfurt in September.<br />

The widespread response and the overwhelmingly<br />

positive feedback we have<br />

received so far confirm our belief that we<br />

are on the right path to maintain and<br />

develop our leading position on the European<br />

equipment carrier market with the<br />

new Unimog.<br />

Come with us on this successful<br />

journey and join me in looking forward to<br />

a continuation of the Unimog legend!<br />

Dr. Klaus Maier,<br />

Head of the <strong>Mercedes</strong>-<strong>Benz</strong> truck division<br />

UNIMOG<br />

JOURNAL<br />

3

‘Telligent’ gearshift system – The driver can<br />

locate the broad knob of the new gear lever<br />

without being distracted from the task in<br />

hand. The Telligent gearshift system prevents<br />

shifting errors: computer-controlled<br />

electronics calculate and preselect the<br />

starting and subsequent gears<br />

Cabin comfort – The spacious, ergonomically<br />

designed driver’s cabin with its non-glare<br />

instruments is impressive. The vehicle and<br />

equipment controls are arranged according<br />

to frequency of use on middle console<br />

VarioPilot – The VarioPilot changeover<br />

steering is designed for operating comfort<br />

and a one-person working situation. The<br />

steering wheel, instruments and pedals can<br />

be transferred from one side to the other<br />

in a matter of seconds<br />

Joystick – the power hydraulic system and<br />

the Vario Power hydraulic system are controlled<br />

conveniently by a removable joystick<br />

which can also be used as a remote control<br />

The Unimog concept re-defined<br />

After nearly five decades of unique success for this<br />

specialised off-road “Universal Motor Appliance” on global<br />

markets, <strong>Mercedes</strong>-<strong>Benz</strong> has now re-defined the idea<br />

behind the Unimog.<br />

In the long period since 1951 in which<br />

more than 320,000 Unimogs were sold<br />

and during which market structures have<br />

changed profoundly as well, designing a<br />

fully system-based equipment carrier<br />

became a necessity. Dr. Klaus Maier, Head<br />

of the world-wide <strong>Mercedes</strong>-<strong>Benz</strong> truck<br />

division and therefore responsible for the<br />

Unimog, stressed the term future capability<br />

during presentation of the new Unimog<br />

model generation. Future capability also<br />

New U 300/U 400 features:<br />

3 + ➃ additional installation<br />

space in the front between<br />

the axles, at the rear,<br />

on the platform, on ball<br />

points, frames and<br />

between the driver’s cabin<br />

and the platform<br />

means that the Unimog product area has to<br />

adapt to today‘s level of business and product<br />

innovation. The successful result is the<br />

new, highly versatile equipment carrier<br />

presented to interested guests in Stuttgart<br />

and Mainz during March and on the regional<br />

tour in May. Its economical system<br />

solutions for equipment operation and<br />

its driving comfort will make it hard for<br />

competitors from the system tractor and<br />

equipment carrier truck segments to rival<br />

the new Unimog U 300/U 400 in combined<br />

equipment operation and slow-speed travel<br />

characteristics, for example.

The new Unimog appears<br />

relatively small in front of<br />

DaimlerChrysler’s administrative<br />

headquarters in<br />

Stuttgart-Möhringen.<br />

As a powerful system<br />

equipment carrier, however,<br />

the new Unimog generation<br />

vehicle is greater than ever<br />

before.<br />

While Dr. Klaus Maier, Head of the<br />

<strong>Mercedes</strong>-<strong>Benz</strong> truck division,<br />

and Hans-Jürgen Wischhof,<br />

Head of the Unimog division, present the<br />

new Unimog U 300 and U 400 to European<br />

journalists in the Forum , a model of the<br />

new series stands in the sunlight in front<br />

of the Stuttgart headquarters of the group<br />

of companies .<br />

The big star turns constantly on top of<br />

the main building on 13 March. This is<br />

something the new, white Unimog 400<br />

cannot do but it is nevertheless appreciated<br />

from all sides: So this is how it looks<br />

like, is a sentence you hear often when<br />

employees and visitors walk across the<br />

square and around the new Unimog model<br />

with curiosity.<br />

Some 120 journalists are seeing this<br />

modern vehicle for the first time today.<br />

But not only that: with the presentation of<br />

the U 300 /U 400, an entirely new era has<br />

begun. In the words of Dr. Klaus Maier:<br />

We have re-defined the Unimog philosophy<br />

Admired from all sides<br />

because despite the vehicle s unchanging<br />

fascination, the Unimog market structure<br />

has changed. Realising the new concept<br />

has been the task of the developers in<br />

Gaggenau for the past three and a half<br />

years.<br />

After explanatory remarks from Dr.<br />

Klaus Maier and Hans-Jürgen Wischhof,<br />

the specialised journalists rushed to the<br />

terrace of the Forum to take pictures of<br />

the Unimog with its equipment from<br />

every perspective.<br />

Some of them got into<br />

the driver s cabin,<br />

finished in gentian<br />

blue, for a closer look<br />

at the VarioPilot<br />

changeover steering.<br />

Shortly before this,<br />

the Head of the<br />

Unimog Division had<br />

drawn attention to an<br />

important cornerstone<br />

of the Unimog system,<br />

the basic version of<br />

which is equipped<br />

with ABS, EPS, an<br />

engine in accordance<br />

with the Euro 3<br />

standard and air conditioning<br />

and has an<br />

The new Unimog generation<br />

Sales Manager Winfried Blum (right) was<br />

very much in demand as a conversation<br />

partner (above, centre)<br />

From left to right: Hans-Jürgen Wischhof,<br />

Head of the Unimog Product Division,<br />

Dr. Klaus Maier, Head of the <strong>Mercedes</strong>-<strong>Benz</strong><br />

Truck Division and Sales Manager Winfried<br />

Blum during the conference for the specialised<br />

press (above, right)<br />

Erich Rid, Unimog Product Manager, explains<br />

the transmission of the new models<br />

increased payload: Its value for money<br />

corresponds to the market situation and<br />

applies not only to the equipment carrier<br />

itself but to the entire system. With the<br />

Unimog equipment system partnership ,<br />

a new quality was introduced in cooperation<br />

with leading equipment manufacturers<br />

in Germany and abroad: the vehicle and<br />

the equipment were and will continue to<br />

be developed and tested jointly.<br />

UNIMOG<br />

JOURNAL<br />

5

Presentation at the European experts’ symposium<br />

Presentation of the new<br />

Unimog model series and<br />

equipment systems to<br />

customers and world-wide<br />

sales staff took place in<br />

Mainz, Germany. During a<br />

European experts’ symposium,<br />

interesting ways of<br />

optimising quality management<br />

and vehicle operation<br />

in road maintenance work<br />

were demonstrated. More<br />

than 500 experts from the<br />

road maintenance and<br />

service areas attended this<br />

event.<br />

6 UNIMOG<br />

JOURNAL<br />

After the experts’ symposium, an impressive show with dancers from the State Ballet<br />

in Mainz was staged to introduce the new Unimog.<br />

At the end, these three models emerged from the dry-ice fog on stage. Sales Manager<br />

Winfried Blum introduced the artists and their “works of art”<br />

In connection with the presentation<br />

and market launch of the new Unimog<br />

models, Durth Roos Consulting GmbH<br />

conducted a European experts symposium<br />

on New Scope for Road Maintenance<br />

Services . Durth Roos Consulting is<br />

an internationally active engineering company<br />

specialising in planning and consulting<br />

services in the traffic planning, road<br />

design, road operation, project management<br />

and road construction areas. Its experts —<br />

the company is owned by professors from<br />

several technical universities — develop<br />

EDP solutions for waste disposal planning,<br />

road cleaning and winter services.<br />

More than 500 expert participants<br />

from all over Europe confirmed that for<br />

public authorities, municipalities and<br />

road construction administrations, economic<br />

aspects and well-founded quality<br />

management are focal points today when<br />

planning and executing municipal tasks.<br />

The topic of the symposium and the<br />

speakers papers, among them a representative<br />

from the Swedish road construction<br />

administration, proved that communal<br />

services can be optimised despite the difficult<br />

public budget situation so that users<br />

are satisfied, notably traffic participants,<br />

tax payers, local organizations and residents.<br />

According to<br />

the speakers, improving<br />

the quality of<br />

road maintenance and<br />

operating services<br />

is a precondition for<br />

appropriate travel<br />

standards and road<br />

safety, with minimum<br />

harm for the environment<br />

and economical<br />

budget spending.<br />

The new Unimog<br />

model series and their<br />

equipment systems<br />

were cited as decisive

and calculable elements in such optimising<br />

processes.<br />

According to Durth Roos Consulting,<br />

this is why the product range is a decisive<br />

factor when a vehicle is purchased. The<br />

main aspects here are:<br />

• Can one operate at high capacity with<br />

this system combination of vehicle and<br />

equipment?<br />

• How much effort is required when<br />

exchanging equipment?<br />

• Are the vehicle and the equipment<br />

available from a single source?<br />

• Are the vehicle and the equipment well<br />

matched ?<br />

• Are support and after-sales service<br />

coordinated and customers looked after<br />

well?<br />

Equipment carrier concept highlights<br />

The new Unimog model series meets<br />

all these more demanding technical<br />

requirements. The highlights of the equipment<br />

carrier concept include its compact<br />

dimensions, the short hood concept, the redesigned<br />

driver s cabin made of compound<br />

fibre material (FVW) and the excellent field<br />

of vision for the driver and passenger.<br />

Other advantages are the increased<br />

transport capacity with four attachment and<br />

superstructure areas for equipment, a<br />

choice of engines in accordance with the<br />

Euro 3 standard, the high-performance<br />

Hans-Jürgen Wischhof, Head of the Unimog<br />

division (left) and Prof. Dr. Ralf Roos during<br />

the opening ceremony of the symposium,<br />

which was well received by the participants<br />

Top left: Winfried Blum<br />

presents three vehicles from the new series<br />

after the premiere show<br />

VarioPower hydraulic system and the<br />

VarioPilot changeover steering. The Vario-<br />

Pilot is a decisive advantage, particularly<br />

in low budget periods, as 75 percent of all<br />

Unimog are used all the year round with<br />

different attachments and superstructures.<br />

Operation of the vehicle and the equipment<br />

by one person is becoming more and more<br />

important for budget reasons.<br />

Another speaker at the symposium<br />

investigated requirements for economical<br />

vehicle and equipment operation. As far as<br />

vehicle operation costs are concerned,<br />

he concluded that the degree to which the<br />

capacity of the vehicle and machine is<br />

used is the decisive calculation factor. A<br />

higher purchase price with low operating<br />

costs yields a more positive result than<br />

low purchase costs which then lead to<br />

higher operating costs due to poorer quality.<br />

Decisive factors for savings on the<br />

New Unimog-Generation<br />

equipment side are the high residual value<br />

of the vehicle, low maintenance and<br />

repair costs, operation of the equipment by<br />

one person and the power hydraulics.<br />

The Unimog equipment system<br />

partnership launched with the new model<br />

series is therefore of profound importance<br />

for customers and users as far as technical<br />

preconditions and business targets are<br />

concerned. The result of this intensive collaboration<br />

with twenty equipment manufacturers<br />

is a significant increase in the<br />

value for money for the entire equipment<br />

carrier — vehicle and attachments.

Genuine exchange<br />

engines available at low<br />

prices and short notice<br />

As good as new or an “impressive comeback”<br />

Modern vehicles such as the Unimog<br />

have a long life. The engine has been<br />

designed for low wear and infrequent<br />

maintenance, so it will rarely have to be<br />

replaced or repaired. Even the best engine,<br />

however, will reach the end of its working<br />

life at some point, even if the overall<br />

condition of the vehicle is still quite good.<br />

This is the moment when the Unimog<br />

celebrates its second life and is restored<br />

to health for the next hard tasks with a<br />

genuine <strong>Mercedes</strong>-<strong>Benz</strong> exchange engine<br />

— the best and most economical solution.<br />

The term exchange engine tends to be<br />

associated with mediocre quality, which is<br />

not justified since exchange engines are as<br />

good as new as far as their quality and<br />

potential working life are concerned; they<br />

allow a Unimog to enjoy an impressive<br />

comeback after they have been installed.<br />

<strong>Mercedes</strong>-<strong>Benz</strong> exchange engines have<br />

been available for many years with the<br />

same warranties as new engines. At the<br />

DaimlerChrysler factory in Mannheim,<br />

commercial vehicle engines from the 300<br />

and 400 model series and also the 500 and<br />

900 series are restored. All engines are<br />

treated with special care and experienced<br />

and qualified staff reconditions them<br />

thoroughly.<br />

The first step is a comprehensive visual<br />

check of the delivered engine which must<br />

not have suffered accident, fire or severe<br />

8 UNIMOG<br />

JOURNAL<br />

mechanical damage. Residual fluids are<br />

drained out and disposed of in an environmentally<br />

acceptable way. As with all<br />

<strong>Mercedes</strong>-<strong>Benz</strong> products, environmental<br />

protection is an important factor when<br />

disassembling engines. The engine is<br />

cleaned thoroughly and stripped down<br />

into its individual components. Worn parts<br />

are discarded and components that can be<br />

re-used are selected for reconditioning.<br />

Every single part is checked carefully,<br />

down to the smallest bolt or nut. Crankshafts<br />

can be inspected under ultra-violet<br />

light in such detail, for example, that even<br />

the smallest hairline cracks are visible.<br />

Cylinder heads are milled flat and combustion<br />

chambers remachined. All relevant<br />

parts are checked and restored in accordance<br />

with the same quality standards<br />

used in series or new parts production.<br />

The exchange process saves valuable raw<br />

materials and energy that would otherwise<br />

have to be devoted to the production<br />

of new parts.<br />

Parts subject to normal wear such as<br />

bearing shells, pistons, cylinder liners,<br />

seals or V-belts are always replaced by<br />

new <strong>Mercedes</strong>-<strong>Benz</strong> parts. All auxiliaries<br />

such as the water pump or the generator<br />

are also reconditioned. The engines are<br />

re-assembled by methods similar to those<br />

used during the manufacture of new engines.<br />

Absolute precision is essential on<br />

the conveyor belt. Every exchange engine<br />

is checked on the dynamometer, with a<br />

special test programme for every engine.<br />

This procedure involves a lot of effort,<br />

but it guarantees that the customer receives<br />

a state-of-the-art exchange engine.<br />

Customers benefit from the rapid avail-<br />

ability of the engines after reconditioning,<br />

and their prices are clearly defined.<br />

Guaranteed performance and environmental<br />

protection<br />

All parts and auxiliaries are restored<br />

in every detail or replaced by new parts.<br />

Every engine is put through the same tests<br />

as a new engine. Every exchange item<br />

has the same warranty as a new one and<br />

is built to the latest state-of-the-art engineering<br />

standards. A <strong>Mercedes</strong>-<strong>Benz</strong> exchange<br />

engine is the optimum basis for<br />

maintaining the economy and enhancing<br />

the value of your Unimog.<br />

The advantages at a glance:<br />

• engines available at short notice<br />

• inexpensive replacement parts<br />

• quality identical to that of new parts<br />

• same warranty as for original parts<br />

• state-of-the-art technical standards<br />

• clearly-defined, fixed prices

More genuine <strong>Mercedes</strong>-<strong>Benz</strong> exchange<br />

parts:<br />

Apart from replacement engines, the<br />

engine factory in Mannheim produces various<br />

other genuine exchange parts. Cylinder<br />

heads, injection pumps and flywheels<br />

for Unimog engines, for instance, have<br />

become available recently. The prices for<br />

genuine exchange flywheels and cylinder<br />

heads are fixed. They are up to 60 per<br />

cent less expensive than new parts if an<br />

acceptable old part is returned. The Unimog<br />

can now be repaired more inexpensively<br />

or, to put it another way, to a standard that<br />

suits the vehicle s remaining value better<br />

Advertisement<br />

— with the same quality<br />

and a one-year warranty.<br />

Next question:<br />

where would a newly<br />

installed <strong>Mercedes</strong>-<br />

<strong>Benz</strong> exchange engine<br />

be without an efficient<br />

cooling system? The<br />

radiators are subject to<br />

severe loads during<br />

hard winter operation<br />

or, for example, during<br />

the mowing season.<br />

<strong>Mercedes</strong>-<strong>Benz</strong> has<br />

reduced the prices for<br />

genuine Unimog radiators<br />

so that customers<br />

are not tempted into<br />

false economies. A<br />

genuine <strong>Mercedes</strong>-<strong>Benz</strong><br />

radiator helps to guarantee<br />

further successful years of operation<br />

for the Unimog. If you have any further<br />

questions about the engine exchange programme,<br />

genuine replacement parts or<br />

low-priced radiators, please contact your<br />

Unimog dealer.<br />

Sales organisation<br />

HIGH AND LOW PRESSURE TECHNOLOGY<br />

FOR THE NEW UNIMOG U 300 / U 400<br />

MODEL SERIES<br />

Our range of products for the Unimog:<br />

✻ Universal high pressure cleaning<br />

equipment for front and rear installation<br />

✻ High-pressure surface cleaning<br />

equipment, also combined with front-end<br />

sweepers<br />

✻ High-pressure drain cleaning equipment<br />

for mounting on the platform subframe<br />

✻ Suction and rinsing containers with a<br />

total capacity of up to 7,000 litres<br />

✻ Municipal sludge suction vehicles with a<br />

total capacity of up to 8,000 litres<br />

✻ Water containers of up to 7,000 l<br />

✻ Special superstructures upon request<br />

(e.g. low pressure equipment, watering<br />

arms, hot water devices)<br />

Engines are restored according to the same<br />

quality standards and test criteria as series<br />

production units (top)<br />

A much sought-after and inexpensive replacement<br />

part is the Unimog radiator (left)<br />

Joachim Leistikow GmbH<br />

Altkönigstrasse 2<br />

61138 Niederdorfelden, Germany<br />

Phone +49 6101 / 5364-0<br />

Fax +49 6101 / 33461<br />

Internet: http://www.leistikow-gmbh.de<br />

E-Mail: Vertrieb@leistikow-gmbh.de

❶<br />

Flowers bloom again after mining<br />

Romonta GmbH in Amsdorf near Halle/Saale (Saxony-Anhalt) is one of<br />

Germany’s most modern basic-material companies. It has purchased six Unimogs<br />

so far as open-cast lignite mining has progressed.<br />

Transferring lignite transport from<br />

rails to conveyor belts in the entire<br />

mining area has called for renewal<br />

and adaptation of the entire auxiliary<br />

technology used in the compan’ s opencast<br />

lignite mining operations. Unimogs<br />

are important elements in the comprehensive<br />

support needed for the economical<br />

mining of lignite at this site in central<br />

Germany.<br />

In the future, about 11 million tonnes<br />

of coal will be excavated from this 150hectare<br />

site. Lignite from Amsdorf contains<br />

large amounts of bitumen, that is to<br />

say is enriched with fossilised hard resin<br />

of vegetable origin, which is used extensively<br />

in chemical engineering, for example<br />

in the manufacture of lipstick, shoe polish<br />

and sealing agents, brake linings, floor<br />

adhesives and bleaching agents. Romonta<br />

GmbH has a leading position with a global<br />

market share of 80 per cent in the crude<br />

mined wax products sector. The company<br />

produces approx. 20,000 tonnes of this<br />

raw material per year, which is derived<br />

from the leaves of subtropical stone-age<br />

plants, and exports its products to 51<br />

countries.<br />

10 UNIMOG<br />

JOURNAL<br />

The conveyor systems with trucks and<br />

the bucket wheel excavators require regular<br />

maintenance and fast technical support<br />

in an emergency. This is provided at any<br />

point within the mining area by the Unimog,<br />

whether it snows or rains, in mud or the<br />

very dry soil conditions which leave long,<br />

brown coal-dust trails behind these utility<br />

vehicles.<br />

For Jürgen Biermann, open-cast operations<br />

manager at Romonta GmbH in<br />

Amsdorf (which is in the Mansfelder Land<br />

administrative district), his Unimogs are<br />

an essential part of his work-process<br />

calculations. People and machines have<br />

to cooperate closely here, he says and<br />

stresses that our 85 employees produce<br />

500,000 tonnes of lignite annually, plus<br />

some 4.5 million cubic metres of excavated<br />

material. Standstill times must not be too<br />

long in this inter-related process chain.<br />

Unimogs for Romonta are looked after by<br />

Rainer Schöps, sales consultant at Unimog<br />

distributor Henne Unimog GmbH in Wiedemar,<br />

which provides all the necessary<br />

know-how and service.<br />

On the beautiful day in May when we<br />

visited the mine for this report, some<br />

rollers had seized at drive station 9 and<br />

the conveyor belts were overheating. The<br />

supervisory team arrived in double-quick<br />

time in two Unimogs, a U 1250 with a personnel<br />

cage for maintenance work and a<br />

U1450 with workshop and special lighting<br />

equipment. Everything needed for a<br />

rapid repair is contained within this compact<br />

service vehicle s body. If no urgent<br />

repairs are needed, this Unimog drives<br />

A classic open-cast mining picture: mining levels<br />

from grass to the lignite itself can be clearly seen.<br />

The layers of marl, coarse clay, clay and sand are<br />

up to 80 meters in depth above the coal seams

along the conveyor belts regularly to check<br />

for overheated rollers that could cause<br />

minor fires. In the event of a major fire,<br />

the U 2450 L 6x6 three-axle tank fire<br />

brigade vehicle with 4,800 litres of extinguishing<br />

agent reaches the fire location<br />

very quickly, since its 240 bhp engine can<br />

propel the fully loaded vehicle rapidly and<br />

safely over any terrain. During our visit,<br />

however, the firemen did not fight flames<br />

but tackled the coal dust that is quite common<br />

in dry weather. The roads in the mining<br />

area are sprayed with water before the<br />

dust can spread over the entire surroundings<br />

and the nearby villages. We also<br />

discover a Unimog that s used for environ-<br />

“They need you over there with your<br />

Unimog...” Jürgen Biermann (right), opencast<br />

operations manager, with Peter Harsin,<br />

conveyor team leader<br />

mental purposes: A U 1450 equipped with<br />

workshop facilities is located at the excavated<br />

material tip where the mining process<br />

comes to an end, to eliminate potential<br />

defects and make repairs. This is where<br />

the excavated material is filled to create<br />

new land that makes cultivation of the<br />

former mining area possible: flowers grow<br />

again there as soon as lignite mining is<br />

finished!<br />

❶ Green is beautiful ... At<br />

the end of the 5-kilometre<br />

conveyor, new areas for<br />

re-cultivation are created<br />

❷ U 1350 servicing the<br />

1546 bucket wheel<br />

excavator as a lubricating<br />

vehicle<br />

❸ A U 2450 L 6x6 is used<br />

for spraying to settle dust<br />

deposits in the mining<br />

area, and as a tank extinguishing<br />

vehicle by the<br />

mine’s fire brigade<br />

❹ Technical problems at<br />

drive station 9. In the form<br />

of a U 1250 with personnel<br />

cage and a U 1450 with<br />

workshop equipment, help<br />

is soon under way<br />

❸<br />

❹<br />

❷<br />

Sales organisation

A well-maintained fleet<br />

A well-maintained fleet<br />

There are many municipal fleets, consisting of a variety of<br />

vehicles in different colour-schemes and from various<br />

manufacturers. In Freyung, a town in Germany’s Bavarian<br />

Woods, the fleet consists almost exclusively of Unimogs.<br />

Hermann Petzi, the works manager, and<br />

his team swear by the Unimog system.<br />

It all began with a U 411 in 1963; in 1967,<br />

they purchased their first U 406. The fleet<br />

today consists of seven Unimogs, the oldest<br />

a U 406 built in 1970, the most recent<br />

a U 1400 delivered in 2000. If you didn t<br />

know that the U 406 was built with drum<br />

brakes until 1973 only, you would think<br />

that the two oldest Unimogs in Freyung —<br />

which Hermann Petzi affectionately calls<br />

my jokers — had been collected new in<br />

Gaggenau just a few days ago. Today, they<br />

are used mainly to tow two skip-loader<br />

trailers and two Müller-Mitteltal tippers for<br />

transport purposes.<br />

12 UNIMOG<br />

JOURNAL<br />

Freyung in the Bavarian Woods is a<br />

snow centre : most of the time in winter<br />

it snows there first, and in generous quantities.<br />

In this region the efficiency of a<br />

public services yard is judged by its winter<br />

service. The Unimogs prove their versatility<br />

and reliability every day in the cold season<br />

of the year. The Städtische Bauhof Grafenau<br />

clears away large quantities of snow every<br />

winter and spring. This includes not only<br />

public roads and pavements but the paths<br />

in a big forest as well. Due to the height often<br />

reached by the snow, a wedge-shaped<br />

plough, a side tiller, a rotary snow plough<br />

and a double snow tiller are used. These<br />

devices are attached to the U 1400 with its<br />

When clearing snow from<br />

roads in spring, the wedgeshaped<br />

plough is an essential<br />

attachment<br />

163 bhp engine and working and inching<br />

gears. A normal dumper body or a Ruthmann-Steiger<br />

can be installed on a U 1000,<br />

with a quick-change system so that the<br />

driver can change from one to the other in<br />

no more than 15 minutes.<br />

Apart from winter services, other work<br />

naturally has to be done during the year<br />

as well: the two U 406 Unimogs, for example,<br />

are used for grass care with special<br />

tyres for sports-ground operation.<br />

The town of Freyung uses the Unimog<br />

system almost exclusively. The only other<br />

vehicles are a four-wheel drive estate car<br />

and a four-wheel drive crew-cab truck<br />

with a tipper body. The Unimogs are all in<br />

When there is too<br />

much snow for the<br />

plough, the tiller is<br />

used on the U 1400.<br />

The 163-bhp engine<br />

drive the tiller drums<br />

via the front power<br />

take-off shaft (far left)<br />

For making paths<br />

broader, the side snow<br />

tiller is used. The snow<br />

plough for final clearing<br />

work can be seen<br />

waiting in the background<br />

(left)

excellent condition; 95 percent of all repairs<br />

are done in the yard s workshop. In<br />

the event of failure, spare parts can be obtained<br />

from Unimog distributor von Bassewitz<br />

even at weekends. It is important for<br />

the winter service that the Unimog and<br />

Advertisement<br />

the attached equipment are parked in a<br />

heated hall and cleaned regularly after use.<br />

Thanks to the reliability of the Unimog<br />

fleet, snow can be cleared and salt and<br />

grit spread on more than 100 kilometres<br />

of main road and another 100 km of local<br />

roads and hiking paths. Hermann Petzi<br />

and his team team rely on Unimog to prevent<br />

chaos due to snow.<br />

Sales organisation<br />

How long does a Unimog last? One of the<br />

two “jokers” in Grafenau, built in 1970, is<br />

seen here in top condition (top left)<br />

Designed for different superstructures: the<br />

Ruthmann-Steiger system on a U 1000<br />

which is also used for many other tasks (top<br />

right)<br />

UNIMOG<br />

JOURNAL<br />

13

Those who know Spain and its broad expanses of bizarre<br />

and diverse countryside will also appreciate the<br />

difficult terrain that supply vehicles sometimes have to face.<br />

From fire brigades to power and gas supply, from<br />

telecommunications companies to public television broadcasting<br />

– <strong>Mercedes</strong>-<strong>Benz</strong> Unimogs are in great demand as<br />

multi-talented “specialists”.<br />

“Specialists” in Spain<br />

Fire protection in the Basque region<br />

Since November 1999, a U 2450 L 38<br />

with a 177 kW (240 bhp) engine and<br />

WERNER equipment has been in use in the<br />

town of San Sebasti n directly on Spain s<br />

border with France, by the municipal<br />

fire brigade, the Diputación Foral de<br />

Guiùzcoa.In such a sparsely populated,<br />

14 UNIMOG<br />

JOURNAL<br />

mountainous area with extensive forests<br />

on the fringe of the Pyrenees, a vehicle<br />

with off-road capabilities is obligatory for<br />

the fire brigade. This is why a Unimog<br />

has been chosen for the first time, with<br />

the necessary equipment for operations<br />

and recovery work in places in this<br />

remote, mountainous region that are difficult<br />

to access.<br />

Tracing breaks in transmission<br />

The Spanish telecommunications company<br />

Telefónica operates five U 1350 L<br />

models with 93 kW/126 bhp engines (see<br />

picture above). The Unimogs were purchased<br />

for installation work in off-road terrain<br />

and to locate points where mobile communication<br />

transmissions are interrupted.<br />

This situation occurs quite often in the<br />

valleys between Spain s numerous mountains.<br />

In order to make sure the telephone<br />

network also functions efficiently in sparsely<br />

populated areas, the Unimogs have<br />

special bodies for the transmission-unit<br />

containers, a detachable HIAB crane and<br />

additional technical equipment. They are<br />

used all over Spain for installation, repair<br />

and maintenance of the system in difficult<br />

terrain. The equipment and superstructure<br />

were installed by Industrias Zamarbú.<br />

Fighting forest fires is still a problem every summer<br />

TheJunta of Castile and Léon operates the largest number of<br />

Unimog with special bodies and firefighting equipment. This<br />

administrative body has purchased 22 vehicles since 1992, among<br />

them 85 kW (115 bhp) U 100 L models, the U 1850 L with 136 kW<br />

(185 bhp) engine and the U 2150 L/32 rated at 155 kW (211 bhp).<br />

Fire fighting is a serious matter in Spain, and unfortunately always<br />

a topical one in summer.. Unimog are being used successfully in<br />

Valladolid, Palencia, Zamora, Salamanca and Léon, and as a result<br />

demand is clearly increasing (6 vehicles were purchased in 1999).<br />

Spanish manufacturers build the special bodies.

Gas supply company uses Unimog<br />

The U 100L Unimogs used by the gas<br />

supply company Empresa Nacional del<br />

Gas (Enagas) in Madrid are equipped<br />

with a tipping body, a HIAB crane, an<br />

exchangeable front winch and a workshop<br />

superstructure. The Unimog are used for<br />

material transport in difficult terrain and<br />

for repair and maintenance of the gas<br />

lines by maintenance teams at the natural<br />

gas supply locations in Spain. The tipping<br />

body and tool case were installed by<br />

Industrias Zamarbú, a Spanish manufacturer<br />

which cooperates closely with Unimog.<br />

Advertisement<br />

TV reception guaranteed<br />

The public TV broadcasting company<br />

Televisi n Espa ola has been able to<br />

guarantee reliable transmission of its programmes<br />

all over Spain since September<br />

1998 by using two Unimog U 2150 L<br />

(155 kW/ 211 bhp). Up to then, it was<br />

difficult to broadcast TV programmes<br />

U nimog International<br />

effectively in mountainous terrain as well,<br />

i. e. areas with bad feedback or without<br />

stationary broadcasting stations. The Unimogs<br />

are a great help in this respect.<br />

They have special bodies with broadcasting<br />

equipment and supply the TV programmes<br />

to the remotest areas in Spain where transmission<br />

is normally impossible.<br />

UNIMOG<br />

JOURNAL<br />

15

Investment for the future<br />

The municipality of Teruel in the province of<br />

Aragon is situated between the Iberian<br />

foothills and the Sierra de Cuenca at altitudes<br />

of between 1,800 and 2,000 metres. This explains<br />

why the work of Teruel s road service is<br />

quite hard: in winter, huge quantities of snow<br />

have to be cleared from roads and, after periods<br />

of bad weather, boulders and fallen trees<br />

removed. Not surprisingly, the municipality decided<br />

last year to purchase a U 2150 L 38 with<br />

155 kW (211 bhp) engine. Turuel is now<br />

well-prepared for the future, with the Unimog<br />

equipped with a snow plough made by<br />

SICOMETAL, a PALFINGER crane and a salt<br />

and grit sprayer from EPOKE.<br />

Advertisement<br />

Always at maximum<br />

It’s so easy with the CLUTCHMATE<br />

Less strain on the driver, less wear on the machine<br />

• Because it reduces physical strain and protects<br />

knees and backs<br />

• It is ideal when stuck in traffic jams and city traffic<br />

• It works like a “semi-automatic” transmission<br />

• It allows drivers to concentrate more on the traffic<br />

and the job in hand<br />

Unimog in the power supply<br />

industry<br />

Maintenance and repair of high<br />

voltage and overhead lines is the task<br />

of the family-owned power supply<br />

company Electricidad Barcenas S. A.<br />

in Valdepe as, Ciudad Real. This is not<br />

an easy task as the terrain is often<br />

difficult, but no problem for the Unimog<br />

U 2450 L 38. It is equipped with an<br />

ALTEC work platform which can be replaced<br />

with a HIAB crane if required.<br />

Additional equipment was installed by<br />

Industrias Zamarbú.<br />

Disguised as a locomotive for the tourists<br />

Tourists in Spain can enjoy the Unimog s reliability, too. In Catalonia, one of the<br />

main tourist centres in Spain with its Costa Brava and the Costa Dorada, tourists are<br />

taken around by a rubber-tyred train pulled by a Unimog U 1400 disguised as a<br />

locomotive. The Rosas Express company based in Rosas chose the Unimog because<br />

part of the sightseeing tour is in difficult, hilly terrain. The entire construction work<br />

for the train and the technical realisation was undertaken by Remolques Sañe.<br />

CLUTCHMATE protects man and machine<br />

• It is quick and easy to fit<br />

• It requires no modifications to existing mechanisms<br />

• It does not affect the licensing of the vehicle in any way<br />

• It has no effect on any mechanical auxiliaries or hydraulics<br />

• It is ideal for use with implements and attachments<br />

• It might even allow a disabled person to be employed<br />

TÜV approved<br />

Have you ever thought about how much strain is put on a Unimog driver’s left knee,<br />

and how often it happens?<br />

Depending on the type of work he might have to press the clutch up to three thousand times a<br />

day.<br />

And because human knees vary in strength and load capacity, serious injuries are always occurring.<br />

Sometimes it means that a driver is off work for a while, but it could even lead to<br />

permanent incapacity.<br />

Why choose CLUTCHMATE?<br />

Supply and installation by Unimog distributors only:<br />

T.C. Systems bv, Schelmseweg 1, 6816 PA Arnhem NL<br />

Tel: +31/2 64 42 23 43 Fax: +31/2 64 45 8136 Automatic coupling

Guests came from all over Italy<br />

The special event took place in Colli del<br />

Tronto, a small municipality in the Italian<br />

Marches province, on Wednesday, 7 June<br />

2000. The Hotel Casale was a special attraction<br />

on that day for customers and<br />

sales partners of the Unimog division of<br />

<strong>Mercedes</strong>-<strong>Benz</strong> Italy. Some 200 guests<br />

were there for the first presentation of the<br />

new Unimog equipment carriers outside<br />

Germany — an opportunity for a first look<br />

at the new vehicle concept. Before the<br />

numerous guests were allowed to see the<br />

U 300 and U 400, however, Italian Unimog<br />

sales manager Guido Corradi explained the<br />

technical innovations and special features<br />

of the new model family, including the redesigned<br />

driver s cabin, the VarioPower<br />

power hydraulics and the Vario-Pilot<br />

changeover steering, with which the entire<br />

steering column with instrument panel and<br />

pedals can be shifted from the driver s to<br />

the passenger s side in a matter of seconds.<br />

He also introduced the new Unimog equipment<br />

system partnership which aims<br />

to increase the quality of cooperation with<br />

equipment manufacturers and in which<br />

leading companies from Germany and<br />

abroad are already participating. The new<br />

U 300/U 400 will mainly be used by motorway<br />

and municipal road maintenance<br />

services in Italy.<br />

U nimog International<br />

The clouds stood no<br />

chance as the sun broke<br />

through, providing<br />

the right atmosphere<br />

for the presentation<br />

of the U 300 and U 400<br />

models in Italy.<br />

Photographs: DaimlerChrysler AG chose the<br />

Italian municipality of Colli del Tronto to<br />

launch the new Unimog U 300 and U 400<br />

model series. The response from customers<br />

who came from all over the country was<br />

overwhelming<br />

UNIMOG<br />

JOURNAL<br />

17

18 UNIMOG<br />

JOURNAL<br />

U·N·I·S<br />

Rescuers<br />

A cyclist for<br />

the future<br />

The sports cyclist Hubert Schwarz (centre<br />

front in picture), who is noted for his<br />

extreme projects, plans to ride through 21<br />

countries on four continents, including<br />

the Sahara, Gobi and Takla Makan deserts,<br />

covering a total of 25,000 kilometres. He<br />

relies on three <strong>Mercedes</strong>-<strong>Benz</strong> products for<br />

logistic support: a Unimog U 1550 L/37<br />

with double cabin and Hartmann box van<br />

body, an off-road vehicle (G model) and<br />

a four-wheel drive Sprinter. During his<br />

round-the-world cycling trip, Hubert<br />

Schwarz stopped briefly in Gaggenau on<br />

May 3rd. The EXPO’s special ambassador<br />

stressed that he wanted to give people a<br />

glimpse of the 21st century with this tour.<br />

The motto of the current world exhibition<br />

in Hanover, Visions for the Future , is the<br />

conceptual background for his round-theworld<br />

trip.<br />

Austrian premiere<br />

The new Unimog models have already been introduced to<br />

experts in Austria. The first time was at the construction industry<br />

trade fair MAWEV in Ennsdorf near Linz (from 6 to 9 April),<br />

where the picture was taken, and immediately afterwards at<br />

Salzburg airport. In this, the city of Mozart, the new Unimog concept<br />

was presented to customers on the airport apron and tested<br />

in practical operation. Winter service experts from Austria’s main<br />

commercial airports (Vienna-Schwechat, Linz, Graz, Innsbruck<br />

and Salzburg) were happy to seize this opportunity.<br />

on tour<br />

The Deutsche Gesellschaft zur RettungSchiffbrüchiger (DGzRS) (German Association<br />

for Rescuing the Shipwrecked), a charitable institution based in Bremen, recently<br />

presented its distress work on a city tour through the new Federal states of Germany.<br />

A Unimog U 2150 L transported the seven-metre long rescue boat Butt from town to town<br />

on a special trailer (see picture above). The Unimog is a reliable partner for rescue work<br />

in its own right. The flat-bottomed boat is transported from its storage location in<br />

Kühlungsborn near Bremen to any operating point with the Unimog. This takes less time<br />

than getting to the distress area through rough seas.<br />

Wörth seeing again and again<br />

The traditional demonstration of winter<br />

services presentation by Henne-Unimog<br />

GmbH was again well worth seeing this<br />

year. On 22 February 2000, more than a<br />

thousand visitors came to the Spitzingsee<br />

lake in the Bavarian Alps to witness an interesting<br />

programme of events with many<br />

vehicles and devices. Experts were particularly<br />

interested in innovations in the<br />

equipment sector. Seven Unimogs with a<br />

wide variety of winter service equipment<br />

were demonstrated. Expert response was<br />

particularly favourable after seeing the<br />

new Gmeiner swing floor technology<br />

spreaders and the new Vario snow plough<br />

from Schmidt for clearing snow in innercity<br />

areas with little room to manoeuvre.

·K·O·P<br />

Partnership Swiss species<br />

April 12, 2000, just a few weeks after<br />

the first official presentation of the new<br />

U 300/U 400, was an important date for<br />

Mulag-Fahrzeugwerk Heinz Wössner<br />

GmbH & Co. KG, based in Bad Peterstal,<br />

and the Unimog division of Daimler-<br />

Chrysler AG. This was the day when thecompanies<br />

two General Managers Werner<br />

Wössner from Mulagand Hans-Jürgen<br />

Wischhof, General Manager of the Unimog<br />

division, signed the Unimog equipment<br />

system partnership agreement.. The picture<br />

on the right was taken when Hans-<br />

Jürgen Wischhof (left) handed over of the<br />

certificate for the equipment system partnership<br />

to Werner Wössner. This was the<br />

official collaboration agreement between<br />

the two leading companies on innovative<br />

developments for the vehicle and equipment<br />

systems for use by municipalities.<br />

Advertisement<br />

Swiss Unimog general agent Robert<br />

Aebi AG and the Unimog equipment<br />

system partner Gerhard Dücker GmbH &<br />

Co. KG in Stadtlohn (Westphalia) have<br />

developed a Swiss species of Unimog<br />

U1650 with a tank trailer for cleaning<br />

road, noise protection and demarcation<br />

walls. The vehicles are used on motorways<br />

in the cantons of Wallis and Western<br />

Switzerland.