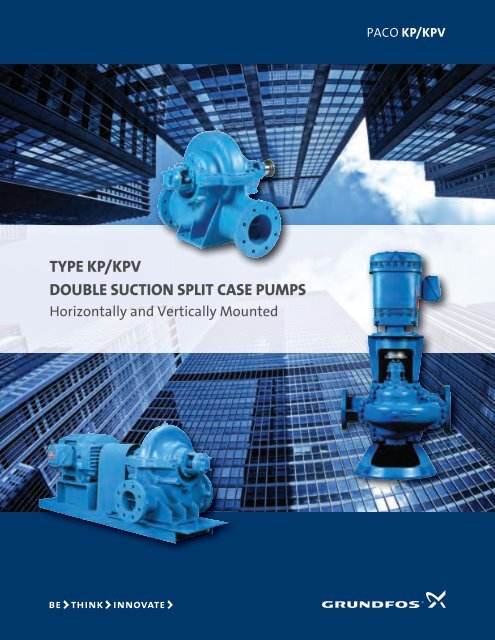

TYPE KP/KPV DOUBLE SUCTION SPLIT CASE PUMPS - Grundfos

TYPE KP/KPV DOUBLE SUCTION SPLIT CASE PUMPS - Grundfos

TYPE KP/KPV DOUBLE SUCTION SPLIT CASE PUMPS - Grundfos

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FEATURES AND BENEFITSWhat makes the <strong>KP</strong>/<strong>KP</strong>V pumps so special? Let’stake a closer look at the innovative designs andtechnologies of the pump.BEARINGS• Selected in conjunction with short bearing spanand large diameter shaft to provide a long life(minimum life of 10 years when calculated at50% of BEP)SLEEVE BEARING• Spiral grooves flush contaminates and particleswith recirculation line to reduce maintenance costSLEEVE BEARING HOUSING• Compact, robust construction has 360-degreemachined register fit to simplify removal andextend lifeBEARING HOUSING• Unique design combines seal and bearingchambers for ease of maintenance• Allows for seal, sleeve, and bearing inspectionwithout removing the top half of the casing• Compact, robust construction with 360-degreemachined register fit limits shaft deflection andoptimizes alignment<strong>CASE</strong> WEAR RINGS• Replaceable case wear rings protect pumpcasing from wear and tear and permit simplemaintenance of proper running clearances,reducing maintenance costs and helping tomaintain high operating efficienciesCASING• Suction and discharge flanges are integrally castinto the lower casing half, allowing removal of therotating assembly without disturbing the piping• <strong>KP</strong>V is supported at its base to minimize vibrationand extend pump lifeIMPELLERS• “Closed” (double-shrouded) with Francis Vane4 | Features and Benefits

An Inside Look at the <strong>KP</strong>VSingle Stage Double Suction Vertical Split Case PumpSHAFTBEARINGBEARING HOUSINGSHAFT SEALINGIMPELLER<strong>DOUBLE</strong> VOLUTESEAL / BEARINGFLUSH LINE<strong>SUCTION</strong> CHAMBER<strong>CASE</strong> WEAR RINGSSHAFT SLEEVESLEEVE BEARINGCASINGSLEEVE BEARING HOUSINGOptional Ball bearing design(bottom portion)PACO <strong>KP</strong>/<strong>KP</strong>V | 7

<strong>KP</strong>/<strong>KP</strong>VDouble Suction Split Case PumpsTechnical DataFlow, Q:60 to 15,000 gpmHead, H:15 to 700 feetFluid temperature: -20° to 275° FWorking pressure: max 400 psiHP range: ½ to 2000Discharge sizes: 2” to 20”Impellers: 7” to 24”<strong>KP</strong>V Sleeve BearingFluid temperature: -20° to 150° FApplications• Chilled water• Condensate water• Commercial pools and water parks• Direct and indirect cooling water• Service water• Water distribution systemsMarkets• HVAC• Recreation• Waterworks• Irrigation/Agriculture• General Industry (Steel Mills, Power Plants)• OEMStandard Features• Wide hydraulic range• Multiple material constructions and sealingarrangements• Self-contained bearing housing• Compensated dual volute design• Vertical or horizontal mount for space savings• Wear rings• Sleeve bearing designOptional Features• Bearing lubrication option• Impeller wear rings• Various materials of construction• Various seal materials and configurations,including cartridge (available in some models)and split seals• NSF/ANSI-50 or NSF/ANSI-61 certifications(available upon request)8 | Technical Specifications

<strong>KP</strong>/<strong>KP</strong>V Materials of Construction<strong>CASE</strong>Cast IronIMPELLERSi BronzeSHAFTSteelSLEEVEBronzeSealsType 21• Ductile Iron• SS(300 series)• Bronze• AL Bronze• Ni AL Bronze• Bronze,specialty• SS (300 series)• Cast iron• Ni-Resist• SS(300 series)• SS(400 series)• 17-4PH SS• SS(300 series)• SS(400 series)• Type 1• Type 1B• Type 8B• Cartridge• Splits• Packing<strong>KP</strong>/<strong>KP</strong>V Performance RangePACO <strong>KP</strong>/<strong>KP</strong>V | 9

TAKING RESPONSIBILITYWITH SUSTAINABLEPUMP SOLUTIONSWhen you specify or install a <strong>Grundfos</strong> pump, youhave the assurance that you’re doing your part toconserve valuable water, energy, and other preciousresources.It’s estimated that pumps use up to 20% of theworld’s electrical power. That’s why <strong>Grundfos</strong> isproud to say that sustainability has long been atthe forefront of our processes.We invest more financial resources than any otherpump manufacturer in order to push the limits forreaching energy-saving efficiency, and we continueto pioneer innovative designs and technologythat support sustainability. For example:> Double volute design increases pump life bybalancing and reducing net radial force.> ECM technology reduces energy consumptionby up to 80% and helps reduce carbon dioxideemissions.> Premium efficient “SMART” pump designsreduce operating and maintenance costs> Pumps are made from materials that are 95%recyclable at life cycle end.SAVE ENERGY. REDUCE WASTE.Power consumption can easily account for morethan 85% of all costs incurred during the life cycleof a pump. So, even the smallest improvement inefficiency can translate to sizeable savings for you.With low life cycle costs, reliable performance, highqualityconstruction, and easy maintenance, thePACO <strong>KP</strong>/<strong>KP</strong>V series of pumps are the smart choicefor providing customized, cost-efficient,energysavingpumps and pumping solutions for yourspecific application.10 | Sustainability and Efficiency

<strong>Grundfos</strong> SE<strong>Grundfos</strong> MAGNAPACO VSMWE’VE GOT YOUCOVEREDThe <strong>Grundfos</strong> product portfolio features a widerange of pump styles and configurations that aredesigned for stable, reliable, and efficient operation.These products maximize value while minimizingoperation, maintenance, and installation costsand reducing purchase price. Some of our StarProducts include:• MAGNA• TPE• SE• BoosterpaQ®• <strong>KP</strong>/<strong>KP</strong>H• LF• VL/VLS• VSM/VSMS• PACOFlo 9000 • QDSCTake a look and see if there’s a pump that would fityour application or installation needs.PACO LFPACOFlo 9000<strong>Grundfos</strong> BoosterpaQ®<strong>Grundfos</strong> TPEPACO QDSCPACO VLPACO <strong>KP</strong>/<strong>KP</strong>V | 11