DODGE SLEEVOIL RTL PILLOW BLOCKS - PTplace.com

DODGE SLEEVOIL RTL PILLOW BLOCKS - PTplace.com

DODGE SLEEVOIL RTL PILLOW BLOCKS - PTplace.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

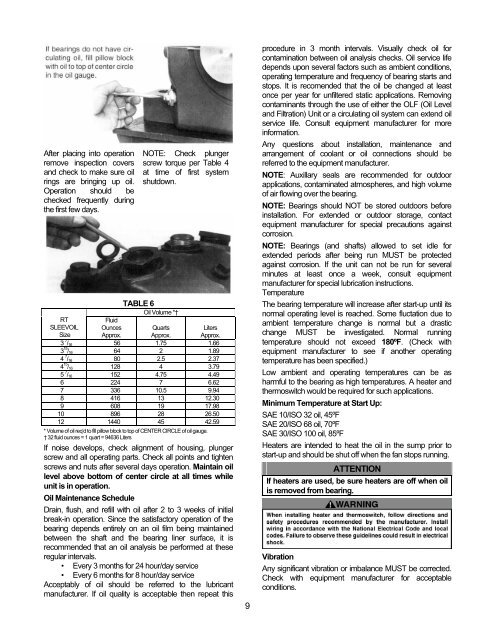

After placing into operationremove inspection coversand check to make sure oilrings are bringing up oil.Operation should bechecked frequently duringthe first few days.RT<strong>SLEEVOIL</strong>SizeFluidOuncesApprox.NOTE: Check plungerscrew torque per Table 4at time of first systemshutdown.TABLE 6Oil Volume *†QuartsApprox.LitersApprox.3 7 / 16 56 1.75 1.663 15 / 16 64 2 1.894 7 / 16 80 2.5 2.374 15 / 16 128 4 3.795 7 / 16 152 4.75 4.496 224 7 6.627 336 10.5 9.948 416 13 12.309 608 19 17.9810 896 28 26.5012 1440 45 42.59* Volume of oil req’d to fill pillow block to top of CENTER CIRCLE of oil gauge.† 32 fluid ounces = 1 quart = 94636 LitersIf noise develops, check alignment of housing, plungerscrew and all operating parts. Check all points and tightenscrews and nuts after several days operation. Maintain oillevel above bottom of center circle at all times whileunit is in operation.Oil Maintenance ScheduleDrain, flush, and refill with oil after 2 to 3 weeks of initialbreak-in operation. Since the satisfactory operation of thebearing depends entirely on an oil film being maintainedbetween the shaft and the bearing liner surface, it isre<strong>com</strong>mended that an oil analysis be performed at theseregular intervals.• Every 3 months for 24 hour/day service• Every 6 months for 8 hour/day serviceAcceptably of oil should be referred to the lubricantmanufacturer. If oil quality is acceptable then repeat this9procedure in 3 month intervals. Visually check oil forcontamination between oil analysis checks. Oil service lifedepends upon several factors such as ambient conditions,operating temperature and frequency of bearing starts andstops. It is re<strong>com</strong>ended that the oil be changed at leastonce per year for unfiltered static applications. Removingcontaminants through the use of either the OLF (Oil Leveland Filtration) Unit or a circulating oil system can extend oilservice life. Consult equipment manufacturer for moreinformation.Any questions about installation, maintenance andarrangement of coolant or oil connections should bereferred to the equipment manufacturer.NOTE: Auxillary seals are re<strong>com</strong>mended for outdoorapplications, contaminated atmospheres, and high volumeof air flowing over the bearing.NOTE: Bearings should NOT be stored outdoors beforeinstallation. For extended or outdoor storage, contactequipment manufacturer for special precautions againstcorrosion.NOTE: Bearings (and shafts) allowed to set idle forextended periods after being run MUST be protectedagainst corrosion. If the unit can not be run for severalminutes at least once a week, consult equipmentmanufacturer for special lubrication instructions.TemperatureThe bearing temperature will increase after start-up until itsnormal operating level is reached. Some fluctation due toambient temperature change is normal but a drasticchange MUST be investigated. Normal runningtemperature should not exceed 180ºF. (Check withequipment manufacturer to see if another operatingtemperature has been specified.)Low ambient and operating temperatures can be asharmful to the bearing as high temperatures. A heater andthermoswitch would be required for such applications.Minimum Temperature at Start Up:SAE 10/ISO 32 oil, 45ºFSAE 20/ISO 68 oil, 70ºFSAE 30/ISO 100 oil, 85ºFHeaters are intended to heat the oil in the sump prior tostart-up and should be shut off when the fan stops running.ATTENTIONIf heaters are used, be sure heaters are off when oilis removed from bearing.VibrationAny significant vibration or imbalance MUST be corrected.Check with equipment manufacturer for acceptableconditions.