Volume 9 Edition 3 2012 - The ASIA Miner

Volume 9 Edition 3 2012 - The ASIA Miner

Volume 9 Edition 3 2012 - The ASIA Miner

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

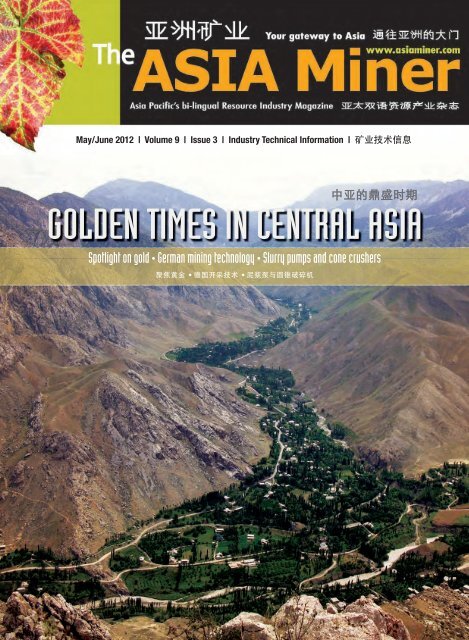

May/June <strong>2012</strong> | <strong>Volume</strong> 9 | Issue 3 | Industry Technical Information | 矿 业 技 术 信 息中 亚 的 鼎 盛 时 期GOLDEN TIMES IN CENTRAL <strong>ASIA</strong>Spotlight on gold • German mining technology • Slurry pumps and cone crushers聚 焦 黄 金 • 德 国 开 采 技 术 • 泥 浆 泵 与 圆 锥 破 碎 机

FEATURESGerman mining technology With the world showing a gradual recovery from the worst of the economiccrisis in 2009, Germany’s mining equipment manufacturers are meeting the challenges of a changing miningindustry. <strong>The</strong> annual supplement from German mining equipment association VDMA shows how manyof these companies continue to serve the industry around the world. .................................From page 71Slurry pumps Plant operators, pump suppliers and researchers continue to pursue higher efficiencyand reliability in slurry transport applications. ........................................................................................62Cone crushers Leading manufacturers offer their perspectives on the mining industry’s demand for conecrushers, the evolving technology and what the future holds. ...............................................................66LEADING DEVELOPMENTSAsian Intelligence Indonesia’s new mining regulations appear to be a case of two steps forward and onestep back. Two Indonesian experts in legal aspects of mining examine the implications of the recently announcedregulations and possible impacts on mining. ...........................................................................4Central Asia Ground gravity and magnetic surveys over a section of Alhambra Resources’ Uzboy GoldProject in Kazakhstan have resulted in the identification of 18 new exploration targets. ........................10Exploration High-grade gold intersections have been confirmed in the latest drill program at BlackhamResources’ Matilda project in Western Australia. ..................................................................................80AROUND THE REGIONChina Continuing growth is China’s aim but it wants this at as low a cost as possible. .........................24Mongolia Altan Rio <strong>Miner</strong>als has started drilling at the Khavchuu gold prospect. .................................36Indonesia PT Aneka Tambang (Antam) expects to raise gold production 16% this year. ......................38Philippines Resources have increased at the Taysan project of Crazy Horse Resources. .....................44Papua New Guinea Mining is one of the main drivers of PNG’s economic fortunes. .............................46Australia Evolution Mining reports a 70% boost in underground resources at Edna May. ....................50India Commissioning has started at NSL Consolidated’s iron ore beneficiation plant. ..........................54South Pacific Tests are being carried out on samples from the Tuvatu Gold Project in Fiji. ...................55Malaysia Drilling at the Bau Gold Project has expanded the prospective open pit resource. ................56Laos Catalyst Resource Group plans to acquire a stake in a gold concession. .....................................57Vietnam Asian <strong>Miner</strong>al Resources has received a funds boost for its Ban Phuc project. ......................58Manas Resources is one of the Australian companiesinvolved in the mining industry in Central Asia.<strong>The</strong> company has received positive results from afeasibility study on its Shambesai Gold Project in theKyrgyz Republic. <strong>The</strong> DFS will allow Manas to rapidlydevelop a low-risk, highly profitable gold operation atShambesai, which is 7km from another project, Obdilla,and in the same valley. It aims to developShambesai first and then examine incorporating Obdilla.This photo shows a view east from the Obdilladeposit up Chauvai Valley.Photo courtesy Manas Resources.DEPARTMENTSAdvertisers’ Index ........................................78Calendar of Events ....................................72From the Editor ............................................2Product News ............................................75Subscription Form ......................................78Supplier News ............................................73Centerra replaces reserves..................................18 Martabe production in July.................................38 New Phuoc Son ore sources...............................58May/June <strong>2012</strong> | <strong>ASIA</strong> <strong>Miner</strong> | 1

8 | <strong>ASIA</strong> <strong>Miner</strong> | May/June <strong>2012</strong>

Central AsiaUzboy surveys identify 18 new targets<strong>The</strong> north-south mineralization trend at Alhambra’s Uzboy Gold Project.THE interpretation of 1360sqkm ground gravityand magnetic surveys over the Dombraly-Shirotnaiagold tr end at Alhambra Resour ces’Uzboy Gold Project in north central Kazakhstanhas resulted in the identification of 18 new explorationtargets. Five of these targets havebeen deemed by the company as being highpriority for initial follow-up exploration.<strong>The</strong> Dombraly-Shirotnaia gold trend is inthe south-eastern portion of the 9800sqkmUzboy project area. More than 100 mineraltargets, including three advanced explorationareas, are contained within the pr oject. Alhambraanticipates that subsequent surveyswill be completed, potentially covering the remainderof the licence area.<strong>The</strong> gravity and high resolution magnetic surveyscarried out outlined numer ous variouslyoriented lineaments and demagnetizationzones. A map of 18 new primary explorationtargets overlaid with the r esults of ASTER satelliteimagery analysis combined with the historicallyknown gold showings was generated.Alhambra’s chairman and chief executiveofficer John Komarnicki says, “We are veryexcited that our recently completed surveyshave identified the new exploration targets.<strong>The</strong>se 18 new primary targets have beenprioritized, with five deemed as being highpriority. It is anticipated that a soil samplingprogram followed by a reverse circulation drillingprogram will be implemented in comingmonths to further test the gold potential.”Alhambra’s early exploration activities identifiedboth Shirotnaia and Dombraly as havingsignificant gold exploration upside. Shirotnaiaas a potential extension to the Aksu andQuartzite Hills multi-million ounce gold depositsheld by KazakhGold Gr oup about 3kmsoutheast of Shirotnaia, and Dombraly, as anabandoned but un-depleted Soviet gold mine.Subsequent exploration activities in Alhambra’seastern licence ar ea have alsoidentified gold mineralization at North Balusty,Kontaktovy, Kerbay and Zhusaly. <strong>The</strong>setargets form an emerging gold tr end of atleast 50km extending fr om Shirotnaia toNorth Balusty to the north.Alhambra has, in three separate deposits, atotal of 1.07 million ounces of NI 43-101 measuredand indicated resources and 1.37 millionounces of inferred mineral resources. Of thetotal, the Uzboy deposit amounts to 980,000ounces of measured and indicated resourcesand 420,000 ounces of inferred resources.<strong>The</strong> Shirotnaia project amounts to 10,000ounces of measured and indicated resourcesand 650,000 ounces of inferred resources.Copper production imminent at BenkalaFRONTIER Mining is set to become Kazakhstan’ssecond largest copper pr oducerafter Kazakhmys when it begins production atits Benkala project in the country’s northwestlater this year. <strong>The</strong> UK-based company couldbegin production as early as June and r eachas much as 5000 tonnes by the end of the yearbefore ramping up to 20,000 tonnes in 2014.Frontier has received all construction approvaland permits from the various local andcentral inspection, and licensing authoritiesthat form the Benkala plant commissioninggroup. <strong>The</strong> company’s CEO Erlan Sagadievsays, “Progress at the site continues at paceas we enter the next stage of commissioningprior to the commencement of production.”He says that Frontier expects the cash costof producing copper at Benkala will be aboutUS$2300 a tonne, rising to about $3800 atonne when taxes are included. <strong>The</strong> companyhas funding of $54 million in place to startoperations and will need a further $35 millionto meet its 2014 pr oduction target. This willbe funded through cashflow and debt.Frontier has also announced the first assayresults from a drill program at Baitemir CopperProject in northeast Kazakhstan, managedby subsidiary Fr ontier Mining LimitedKazakhstan (FMLK). A preliminary resourceestimate is pr ovisionally scheduled for thefourth quarter of <strong>2012</strong>.From 2005 to the end of 2011 FMLK undertookan aggressive exploration programon Baitemir that was accelerated in 2010and through 2011. During 2010 and 2011FMKL completed 6032 metr es of drillingand 7557 metres of trenching, bringing thetotal to more than 14,500 metres.<strong>The</strong> total volume of cor e drilling for thisperiod was almost 16,000 metres of which13,768 were drilled in 2010/11. This pr o-gram has resulted in the discovery of a significantnew copper mineralized footprint,with associated gold, silver and molybdenum,of a total length of 2000 metres and awidth of 400 metres.<strong>The</strong>re is 1000 metr es of drilling r emainingunder the program to complete the first stageof exploration drilling, which will then allowcommencement of a resource definition to theKazakhstan GKZ standard to be undertaken.10 | <strong>ASIA</strong> <strong>Miner</strong> | May/June <strong>2012</strong>

Central AsiaIndia and China lead charge in AfghanistanINDIA and China have already secured majormining projects in resource-rich Afghanistanand both are now eyeing off further opportunities.To support their investments, both resource-hungrynations are also contributingto infrastructure development.<strong>The</strong> Afghan government, eager to rebuildas well as attract investment, has pr oclaimedthat the country holds an estimatedUS$3 trillion in natural resources. <strong>The</strong> deposits,which yield copper and iron ore, oil andgas, niobium, cobalt, gold, molybdenum,silver and lithium, could lift the country’s coffersby US$3.5 billion a year.<strong>The</strong> Metallurgical Corp of China (MCC)owns 75% of the Aynak Copper Project, inLogar province, 30km southeast of Kabul,with Jiangxi Copper holding the balance. In2007 the two Chinese companies won atender to develop the mine, outbidding rivalsfrom the US, Canada and Kazakhstan.Production is expected to start at the endof 2014 at the earliest after delays causedby the discovery of historic relics and the relocationof local residents. <strong>The</strong> mine, whichwill cost about US$1.7 billion to develop, isexpected to have an annual copper outputof 200,000 tonnes. According to Soviet-eradata and a more recent study by the UnitedStates Geological Survey, Aynak could yieldmore than 11 million tonnes of copper.<strong>The</strong> Hajigak Iron Ore Project, whose developmentwas awarded last November toan Indian consortium of seven companiesled by state-owned Steel Authority of India,is the highest for eign direct investment inAfghanistan with a total pr oject cost estimateof US$11 billion.Hajigak, in Bamyan pr ovince, holds aniron oxide deposit that extends over 32kmand covers 16 separate zones, up to 5kmin length, 380 metres wide and extending550 metres down with an estimated 1.8 billiontonnes of iron ore.<strong>The</strong> consortium is part of India’s government-ledinitiatives to boost participationin Afghanistan, where India has pledged$2 billion in investments. It has so far undertakenprojects involving power, roads,agriculture, telecommunications, educationand health. It is also eyeing off furthermineral resources and is more than likelyto bid for further blocks to be released, includingothers in copper at Aynak as wellas gold and lithium.Feasibility studies for rail pr ojects havealso been lined up. To be financed by MCC,the first will run from the Pakistani border toAynak and to Kabul. It will link Hajigak toKabul and to the Uzbek frontier. <strong>The</strong> secondroute, being studied by the Asian DevelopmentBank, will head south to Iran, wher eminerals could be shipped to India.Kyzyl gold resources increase by 18%<strong>The</strong> Kyzyl Gold Project of Altynalmas Gold is in northeast Kazakhstan.AN independent feasibility study estimates mineralreserves of 5.76 million ounces of gold atAltynalmas Gold’s Kyzyl Gold Project in northeasternKazakhstan. <strong>The</strong> estimate is based onan underground mining operation annually producingan average of 337,000 ounces of goldduring an initial mine life of up to 15 years.<strong>The</strong> project encompasses the re-developmentof the Bakyrchik underground mine andthe construction of a new pr ocessing plantincorporating fluidized-bed ore-roasting technologyand supporting mine infrastructur e.Altynalmas is 50%-owned by Ivanhoe Mines.Other highlights of the study include:• <strong>The</strong> successful completion of performancetesting of a metallurgical process that recoversat least 88% of contained gold.• <strong>The</strong> development of an innovative andproprietary ore treatment process thatproduces an environmentally stable, ironarsenate mineral by-product that meetsinternational environmental standards.• An 18% increase in the indicated r esources,inclusive of reserves, at Kyzyl, whichnow contains an estimated 7.35 millionounces of gold as of December 1, 2011.<strong>The</strong> project also contains an additional 3million ounces of gold in inferr ed resources.<strong>The</strong> resources are within the Bakyrchikand Bakyrchik East deposits.<strong>The</strong> study, based on December 1, 2010 resources,confirms the economics supportingmineral reserves and describes an extended,20-year life-of-mine sensitivity case that includesadditional indicated and inferr ed resources.Drilling pr ograms focused onconverting inferred resources to indicated resources,before and after the 2010 estimate,have been successful, providing confidencein the sensitivity case.Altynalmas’ president and CEO David Woodallsays, “W ith our successful and continuingresource delineation and r eserveconversion, the confirmation of the gold r e-covery process and the support of the Government,we are pleased to be in a positionnow to start the construction and developmentof a state-of-the-art operation.12 | <strong>ASIA</strong> <strong>Miner</strong> | May/June <strong>2012</strong>

Central AsiaGold resource at Chaarat boosted 27%DRILLING by Chaarat Gold Holdings during2011 has resulted in a 27% incr ease in thegold resource at the Chaarat Gold Pr oject.<strong>The</strong> resource now stands at 5.59 million ounces,up from 4.406 million ounces announcedin February 2011.<strong>The</strong> Tulkubash section of the r esource,which includes mostly free milling mineralization,increased by 56% to 501,000 ouncesfrom 321,000 ounces while the sulphide orrefractory section of the r esource increasedMining of the non-refractory section of the Chaarat GoldProject – Tulkubash – is expected to start later this year.by 25% to 5.09 million ounces.During the 2011 exploration season 171new core drill holes for 29,094 metr es weredrilled and subsequently incorporated intothe resource database. Drilling has been focusedon three main projects, which Chaaratis developing into viable mining pr ojects, inorder to establish the foundation for a largescale,low-cost mining operation.At Tulkubash the company continues towork on the documentation required for theapplication for the grant of a mining licenceand it plans to start mining later this yearwith gold production due to commence in2013 once the processing plant has beencommissioned.<strong>The</strong> oxide mineralization hosted in the Tulkubashquartzite can be identified over a 6kmstrike length. Drilling has focused on a small500 metre section, where infill drilling has allowedthe delineation of a mineable r eserve.<strong>The</strong> considerable on-strike extension potential,which is likely to facilitate a rapid increasein the production rate, has been demonstratedby 440 metres of wide-spaced drilling tothe north of the deposit. Drilling has been focusedon the near surface part of the mineralizationwhich can be extracted by low-stripratio open pit mining, the oxide or e fromwhich is expected to be mostly free milling.<strong>The</strong> Contact pr oject hosts 2.78 millionounces, an increase of 39% over the pr e-vious resource update. This increase wasaccompanied by a small impr ovement ingrade to 4.32 grams/tonne. Contact is openboth on strike as well as down dip. <strong>The</strong>width of the mineralization and its grade improvewith depth.<strong>The</strong> Main pr oject, formerly known asM2400 and M3000, is now r ecognized as asingle large body of 1.51 million ounces, anincrease of 17%, with the combined gradefalling slightly to 4.14 grams/tonne. Only 13holes were drilled in this project in 2011, howeverit is expected that the size will increasesignificantly and the grade will improve onceunderground drilling can take place followingthe development of an adit.Chaarat’s CEO Dekel Golan says, “I believethat the tremendous potential of Chaarat isbeing demonstrated by successful, rigor ousexploration activity and the development ofthe infrastructure needed to support a largescaleoperation. <strong>The</strong> significantly impr ovedpolitical climate in the Kyrgyz Republic is givinga welcome added impetus to our operationsduring this development phase, whilstTulkubash, the non-refractory section of thedeposit, is being fast tracked to developmentin order to stimulate early cashflow.”Study shows feasibility of Oracle coal projectA TECHNICAL feasibility study conducted forOracle Coalfields on Block VI of the Thar Coalfieldin Sindh Province, Pakistan, demonstratesthe technical and economic viability of themining project. <strong>The</strong> Thar Coalfield is 380kmfrom Karachi, and covers a total ar ea of9100sqkm with Block VI covering 66.1sqkm.<strong>The</strong> exploration licence for Block VI is heldby Oracle’s 80%-owned subsidiary , SindhCarbon Energy, a private company incorporatedin Sindh Province. On November 2, 2011,Sindh Carbon submitted an application forconversion of the licence to a mining licence.<strong>The</strong> study found there are JORC-compliantcoal resources within the 20sqkm miningarea of 529 million wet tonnes with gross calorificvalue (CV) of 3182k calories per wet kilogramwith ash content at 5.89% andsulphur at 0.91%. <strong>The</strong>re are probable reservesin phase 1 of the mining area of 113 millionwet tonnes with gr oss CV of2831kcal/wkg, ash 11.50% and sulphur0.79% with a strip ratio of 8.54 bank cubicmetres per 1 wet tonne of lignite.<strong>The</strong> total capital expenditure for open castmine development is estimated at US$610million, including US$224 million for miningequipment, which will provide for annual ligniteproduction of 5 million wet tonnes overa mine life of 23 years. <strong>The</strong> total cash cost ofproduction is estimated at US$42.21 per wettonne and the coal is confirmed to be of aquality suitable for power generation.Oracle’s CEO Shahrukh Khan says, “This isanother important step for Oracle as we lookto provide a sustainable source of energy toPakistan and bring its first large scale openpitcoal mine into production. <strong>The</strong> study indicatesthe technical and economic viability ofthe project.“Further work is continuing to r efine theoverall project economics, specifically in r e-spect of offtake agreements with respect tothe proposed mine-mouth power and the miningcontractor opportunities, prior to makingany definitive announcements on the overalleconomics. <strong>The</strong> Government of Sindh, in recentpublished announcements, recognizesa project IRR in excess of 20% assumingcompletion of certain financing milestones.<strong>The</strong> Board looks forward to progressing thetechnical feasibility study to bankable standardlater this year, when we will also seek directfunding for the mining project.”<strong>The</strong> coalfield is in close pr oximity to goodinfrastructure, with ongoing development ofa road and power network in the region.14 | <strong>ASIA</strong> <strong>Miner</strong> | May/June <strong>2012</strong>

Central AsiaPositive study for Karchiga VMS projectORSU Metals has received positive results froma definitive feasibility study (DFS) for its 94.75%-owned Karchiga volcanogenic massive sulphide(VMS) copper pr oject in northeastKazakhstan. <strong>The</strong> DFS is based on indicated resourcesof 10.8 million tonnes of combined sulphideand oxide mineralization grading 1.73%copper for 412.7 million pounds of containedcopper and an inferred resource of 20,000 tonnesof sulphide mineralization grading 1.28%for 700,000 pounds of contained copper.Using only the indicated estimates, the DFSsupports a probable mineral reserve estimateof 8.5 million tonnes of sulphide or e in theCentral and North East pits containing 320million pounds of copper at an average gradeof 1.71% copper to be amenable to flotationand an additional 1.5 million tonnes of ore inthe Central pit containing 47.2 million poundsof copper at an average grade of 1.43% tobe amenable to heap leaching.<strong>The</strong> DFS was prepared by the company’slead mining consultant SRK Consulting (UK)Limited, which is independent of Orsu. <strong>The</strong>open pit mining schedule calculated a producingmine life of 11.5 years. <strong>The</strong> mining scheduleenvisages the mining of 10 milliontonnes of sulphide and oxide or e and 124million tonnes of waste. <strong>The</strong> average annualmining rate is 750,000 tonnes.For the first 2.25 years of the mine life, themining schedule includes open pit mining ofthe Central sulphide ore body alone to maximizethe sulphide copper grade and hencesulphide copper r ecovery. <strong>The</strong> optimizedOrsu Metals’ Karchiga project is in the far northeast of Kazakhstan.mine schedule has been developed to minimizethe stripping ratio in the initial thr eeyears. In addition, the use of stockpiling hasenabled the company to increase the processedore grade. From year 4 until year 7, sulphideore will be mined from the Central andNorth East open pits. Fr om year 8 until theend of mine life in year 12, all mining will continuein the North East pit.<strong>The</strong> plant is designed to annually pr ocessabout 750,000 tonnes of sulphide ore. A conventionalprocessing route was chosen usingrelatively fine grinding and selective sulphideflotation to produce a 27.9% bulk concentrate.First production has been scheduled forthe fourth quarter of 2013.Copper from the oxide ore will be extractedusing SXEW process. <strong>The</strong> oxides will be treatedover 4.5 years starting in 2018 at 360,000tonnes annually and is expected to pr oducean annual average of 6.22 million pounds ofcopper cathode. Production of cathode copperwill continue until 2022.To reduce initial CAPEX, SXEW plant constructionhas been delayed until after the initialCAPEX payback. <strong>The</strong> plant has been designedto treat a monthly average of 30,000 tonnes ofleachable oxide ore. <strong>The</strong> DFS demonstratesthat economically the best option is to delaySXEW construction until 2017, allowing thecost of construction to be financed fr om revenuegenerated by the sulphide ore treatment.Funds boost for Sekisovskoye UG developmentHAMBLEDON Mining has confirmed aUS$3 million boost from a major investor.<strong>The</strong> funds will be used to continue developmentof the Sekisovskoye undergr oundgold mining operation in Kazakhstan. <strong>The</strong>European Bank for Reconstruction and Development(EBRD) paid the funds as part ofa share subscription agreement. In return itwill receive a 6% stake in the company.In February, Hambledon announced a dealwith the EBRD which could pr ovide it withmore than US$20 million to invest in Sekisovskoye.<strong>The</strong> EBRD agreed terms of a US$15million loan facility and the US$3 million equityinvestment. In addition Hambledon has issuedthe EBRD warrants worth US$2.3 million.<strong>The</strong> bank was established after the ColdWar to help ex-Communist countries transitionto market economies. It injects about 9billion Euros a year into pr ojects supportingthe development of market economies inEurope and Central Asia.Hambledon’s growth plans have also includedthe acquisition of Akmola Gold LLP, whichoperates two gold projects – Tellur and Stepok- neighbouring Sekisovskoye. <strong>The</strong> pr oposedUS$5 million acquisition was announced lastSeptember but is yet to be completed. It wasplanned that ore from these operations wouldbe processed at Sekisovskoye.<strong>The</strong> company says the Kazakhstan state miningfirm is planning to take a pre-emptive stakein the deal while certain permits and waiversneeded to complete the acquisition have yet tobe received from Kazakh authorities. Becauseof the delay the sellers ar e in talks with Hambledonseeking to amend the terms of the deal.Hambledon was supposed to have paidUS$3 million by the end of Mar ch, withUS$2.5 million due to the sellers and the remainderto the gover nment. <strong>The</strong> companysays none of the payments have been madebecause of the delays.Hambledon is advancing underground drillingto validate and expand resources.16 | <strong>ASIA</strong> <strong>Miner</strong> | May/June <strong>2012</strong>

Central AsiaExploration replaces mined Kumtor reservesCENTERRA Gold’s 2011 exploration programhas replaced reserves mined during the year atthe Kumtor Central Pit in the Kyrgyz Republic.An estimated 704,000 ounces were added toreserves, representing an increase of 11%, beforeaccounting for 2011 production.After accounting for pr ocessing of about709,000 ounces of contained gold in 2011,Kumtor’s proven and probable mineral reservesremained at 6.3 million ounces of containedgold as of December 31, 2011. All of theincrease in the Central Pit open pit reserves isa result of additional exploration drilling primarilyon the Southwest Extension of the SB Zone.This drilling continues to outline a new zoneof mineralization immediately to the northwestof the Southwest Extension of the SB<strong>The</strong> Central Pit at Centerra Gold’s Kumtor Gold Project in the Kyrgyz Republic.Zone. <strong>The</strong> drilling has also increased the averagereserve grade for the Central Pit to 3.7grams/tonne gold, compar ed to 3.4grams/tonne in 2010.<strong>The</strong> company’s overall proven and probablereserves increased 694,000 contained ounces,before accounting for 2011 production,to 8.1 million ounces of contained gold, comparedto 8.2 million ounces as of December31, 2010. This represents an increase of 9%before accounting for 793,000 containedounces processed at Kumtor and Bor oo inMongolia during 2011.Centerra’s president and CEO Steve Langsays, “2011 was another successful explorationyear. We replaced reserves mined at Kumtor,generated initial resources at ATO and KaraBeldyr, and brought more than 2.4 million newounces of gold into r eserves plus resourcesand an additional 600,000 ounces of gold intoinferred resources at an average cost of lessthan $15 per ounce. We entered our first jointventure in China, added a second joint venturein Russia and our strong drill results at OrtacamNorth in Turkey should produce an initial r e-source statement by the end of <strong>2012</strong>.”<strong>The</strong> company’s production forecast for<strong>2012</strong> from Kumtor has been lower ed owingto increased ice movement in the southeastsection of the pit which has delayed scheduledaccess to the high grade SB zone. <strong>The</strong>company says the build-up of ice and wastewas exacerbated by a 10-day stoppage inFebruary by striking labour ers at the mine.This is expected to delay the cutback fr omlate <strong>2012</strong> to late 2013, resulting in the deferralinto 2013-2015 of production from the highgrade SB zone otherwise expected in <strong>2012</strong>.<strong>The</strong> company expects to partially mitigate theimpact of the movement and the resulting delayin cutback by accelerating mining in the southwestportion of the pit to access part of the newin September <strong>2012</strong> to provide higher grade ore.Preliminary engineering analysis indicates productionof 390,000 to 410,000 ounces of goldin <strong>2012</strong>, rather than between 575,000 and625,000 ounces as previously forecast.Kumtor gold mine is one of the largest in centralAsia and is 350km southeast of Bishkek,the Kyrgyz capital. <strong>The</strong> operation includes aconventional open pit and carbon-in-leach mill.Gold extraction under way at DalabaiGOLD explorer and developer Central AsiaResources has started the process of extractinggold at its Dalabai project in Kazakhstan.<strong>The</strong> initial shipment of gold resin, which wassent to mining services company Dank inSemey, Kazakhstan, has been returned.Test work on the resin indicated it was loadedwith about 5879 grams of gold and followingtreatment the company immediatelyrecovered 5181 grams, or 181 ounces ofgold. Central Asia also received 165 ouncesof silver. A further 490 grams of gold and3044 grams of silver were due to be deliveredto the company in mid-April.<strong>The</strong> cathode gold produced from the resin isbeing stored at Central Asia’s bank in Almaty,the capital of Kazakhstan, and will remain thereuntil the company received an export permit tosell the gold. While the permitting pr ocess inKazakhstan is transparent, it is a lengthy pr o-cedure and the company is unsure when it willreceive the export permit.Central Asia’s next target is to deliver 6 tonnesof resin to the processing facility. On thebasis of the initial run, this equates to about30kg, or 1050 ounces, of gold.<strong>The</strong> company curr ently has about 80,000tonnes of ore stacked and leaching at Dalabai,which is about 50% of the leach pad’s targetedcapacity. <strong>The</strong> company continues to ramp upthe production rate towards its name-plate rate.In mid-March the company was leachinggold at a rate of about 25% of expected productionfor low-grade material during theramp up phase. Rates of circulation throughthe plant wer e at 28-30 cubic metr es perhour and return solution gold concentrationswere in the range of 1.5mg/litre.Central Asia chairman Guy W arwick saidthe Dalabai plant was performing above companyexpectations during the ramp up phase.“Operations to date show we have no leaksin the plant, something to fear in the cold weatherwhere materials have a tendency to becomebrittle and shatter if not tr eated withcare. Reaching our targets will not happenovernight but will result from incremental improvementsover the next six months.”18 | <strong>ASIA</strong> <strong>Miner</strong> | May/June <strong>2012</strong>

Central AsiaStrong gold results from Chanach drilling<strong>The</strong> Chanach Gold-Copper Project of White Cliff <strong>Miner</strong>als is in the northwest of theKyrgyz Republic.DRILLING carried out by joint venture partners White Cliff <strong>Miner</strong>alsand T2Gold at the Chanach Gold-Copper Project in the Kyrgyz Republichas returned significant intersections which indicate the potentialfor a large copper-gold resource. One hole shows widespreadgold mineralization over 180 metres from 109 metres @ 0.15grams/tonne gold and 0.2% copper.Within this mineralized zone there are several zones with higher gradesof copper and gold, including 16 metres from 181 metres @ 0.65%copper and 0.46 grams/tonne gold within 34 metres from 163 metres@ 0.40% copper and 0.26 grams/tonne gold, 5 metres from 284 metres@ 0.97% copper and 0.12 grams/tonne gold, and 3 metres from109 metres @ 0.46% copper and 0.69 grams/tonne gold. <strong>The</strong> highestgold assay is 1.13 grams/tonne gold and the peak copper assay is2.06% with 0.35 grams/tonne gold. <strong>The</strong> same hole also returned 40metres from 36 metres @ 0.5% copper in the supergene oxide zone.Another hole drilled 300 metres to the west of the above hole intersectedsupergene copper mineralization from surface to 80 metresdepth with an average grade of 0.5% copper, including 10 metres at1.0% copper from 12 metres and 4 metres @ 0.75% copper from 65metres. Weak sulphide mineralization was also encountered over anadditional 120 metres @ 0.14% copper from 80 metres.White Cliff’s managing director Todd Hibberd says, “<strong>The</strong> gold andcopper results are quite outstanding considering that they occur onthe outer edges of the mineralized system. <strong>The</strong> new intersections continueto demonstrate that the Chanach project has the potential todevelop into a large copper-gold resource.“<strong>The</strong> identification of gold associated with copper in the 2011 drillingprogram substantially improves the potential economics of the project.<strong>The</strong> joint venture partners are planning the <strong>2012</strong> exploration programwhich is focused on identifying the core of the mineralized system.”White Cliff owns 45% of the 83sqkm project that is 350km westsouthwestof the Kyrgyz capital of Bishkek. Chanach is in the westernpart of the Tien Shan Belt, a highly mineralized zone extending formore than 2500km, from western Uzbekistan, through Tajikistan, KyrgyzRepublic and southern Kazakhstan to western China.Parliament asked to reconsider AndashTHE Government of the Kyrgyz Republic has asked the country’s Parliamentto reconsider a motion of last June against the developmentof Kentor Gold’s Andash Gold-Copper Project. Following the requestmade in March to a meeting of the Kyrgyz Parliamentary Committeeon Development of Economic Sectors, the committee has sought clarificationof the Government position.Australian-based Kentor Gold owns 80% of Andash which, while development-readyand supported by the Kyrgyz Government, requires theformal approval of the local community. Upon receiving final approval andgaining site access, Kentor will begin a three month geotechnical investigationprogram and then proceed with the construction program.Andash is a high-grade, very low-cost project. Kentor is targeting2013 to begin production at an annual rate of 70,000 ounces of goldand 7400 tonnes of copper for an initial six years.At the March meeting most committee members spoke in supportof the development on the following grounds:• Contribution to the national economy• Contribution to the state budget• Creation of employment• Contribution to local development• Speed of development• Reputable investor with funds to hand• Legal consequences of cancelling licence without adequate grounds• Impact on the investment climate as a result of government actionor inaction• Comprehensive social program.20 | <strong>ASIA</strong> <strong>Miner</strong> | May/June <strong>2012</strong>

Company ProfileOn the road to the Savoyardy project in the southof the Kyrgyz Republic.Study delivers positive outcomes for ShambesaiA DEFINITIVE Feasibility Study(DFS) has confirmed Manas ResourcesLimited’s (ASX code: MSR)Shambesai Gold Project in the KyrgyzRepublic as a low-cost, highmargingold leach project that is atechnically simple, low-risk operationwhich can be commissioned inless than 18 months, subject to permitting,for a very low capital cost.Drilling at the Shambesai project which will be developed first byManas Resources.<strong>The</strong> outcomes of the DFS willallow Manas to rapidly developa low-risk and highly profitableoperation at Shambesai. <strong>The</strong> projectis expected to pay back allcapital requirements within thefirst year of production.Manas Resources is an Australian-based,ASX-listed companyfocused on exploring and developingits 100%-owned gold projectsin the Tien Shan gold belt,Kyrgyz Republic. <strong>The</strong> companyhas a mineral resource base of1.251 million ounces at theShambesai and Obdilla projects,which are just 7km apart. Manasis the republic’s largest and mostactive gold explorer with a4400sqkm land package andnine projects under exploration.To date, Shambesai has 5.3 millionindicated tonnes @ 2.4grams/tonne gold for 411,000ounces and 6.3 million inferredtonnes @ 1.8 grams/tonne for355,000 ounces while Obdillahas 6.3 million indicated tonnes @1.8 grams/tonne for 353,000ounces and 2.9 million inferredtonnes @ 1.4 grams/tonne for132,000 ounces.<strong>The</strong> company intends to developShambesai first and then examineincorporating Obdilla. <strong>The</strong> DFS forShambesai has been completedby the Manas technical team in associationwith external consultants,and has been reviewed by independenttechnical consultantsSnowden Group United Kingdom.<strong>The</strong> DFS projects Shambesai willhave an average annual orethroughput of more than 600,000tonnes producing on average53,000 ounces of gold over a4.5-year mine life, assuming treatmentof indicated and inferredoxide and sulphide material fallingwithin the initial planned stage 1pit. <strong>The</strong> mine design targets extractionof the shallow, high-grade portionof the indicated and inferredresource with subsequent processingof all oxide and sulphide materialthat falls within the pit shell.<strong>The</strong> amount of ore to be minedis projected to be 3.2 milliontonnes @ 2.8 grams/tonne for285,000 ounces of gold, andconsists of a probable reserve of2.5 million tonnes of oxide andsulphide material @ 3.0grams/tonne for 245,000 ouncesand additional inferred oxide andsulphide material of 700,000tonnes @ 1.9 grams/tonne for40,000 ounces. <strong>The</strong> inferred materialwithin the design pit shell hasa very high likelihood of being updatedto indicated status after inclusionof results from the latestdrilling and completion of theshear zone drilling program.Manas’ managing directorStephen Ross says, “We are verypleased with the positive outcomeof the DFS and look forward to deliveringa low-cost, high-margingold operation. We are particularlyencouraged by the technical simplicityof the operation, the relativelylow capital costs to start up, highgold recoveries for a leach operationand low operating costs.“While the project initially targetsnear-surface, high-gradeoxide material, confirmation of excellentgold recoveries through theleaching of sulphide material hasunlocked substantial additionalproject value and allows us toevaluate ongoing reserve and productiongrowth from the current22 | <strong>ASIA</strong> <strong>Miner</strong> | May/June <strong>2012</strong>

Shambesai resource beyond thecurrent mine plan,” he says.NPV US$148 MILLION<strong>The</strong> DFS forecasts net cash flowsafter capital expenditure ofUS$37 million and operatingcosts to be US$208 million usinga US$1500/ounce gold price.<strong>The</strong> Net Present Value (NPV) hasbeen calculated to be US$148million with an IRR of 96% at an8% discount rate for the life-ofmine.All DFS cash flow estimatesare made assuming treatment of indicatedand inferred oxide andsulphide ore within the optimizedpit shell, and before tax.Cash costs for the life-of-mine averageUS$411 per ounce of goldproduced and reflect increasedgold production for the sulphide materialthat can be readily leachedand was not included in previousstudies. <strong>The</strong> capital costs to first productionand gold pour are estimatedto be US$32.6 million withpayback of this capital within thefirst 10 months of operation.Ongoing drilling and explorationat Shambesai and otherManas prospects has potential toadd to resources. Winter drillinghas returned encouraging resultswith all seven holes intersectingbroad zones of mineralization, themajority outside the current resourceand pit boundary.Highlights are a number of continuouswide, high-grade intersectionsalong the shear zone in oxide andsulphide mineralization. Best resultsare 22 metres from 97 metres @3.16 grams/tonne gold including8 metres from 103 metres @ 8.45grams/tonne; 22 metres from 221metres @ 2.16 grams/tonne goldincluding 5.15 metres from 237metres @ 4.77 grams/tonne; and12 metres from 69 metres @ 3.60grams/tonne gold.<strong>The</strong> DFS shows overall averagegold recoveries at Shambesai forall ore types over the life-of-mineare estimated to be 85.6%,which includes 90% recovery forthe non-refractory oxide and sulphideore and 42.8% for the refractorysulphide ore. Almost92% of the project revenue is attributableto non-refractory oresand only 8% attributable to refractorysulphide ore.SULPHIDE ORE NOW INCLUDEDShambesai was initially designed toprocess the oxide ore only, howeveras part of the DFS and due to extremelypositive testwork resultswhich show that Leachwell analysiscan be used to differentiate refractoryand non-refractory ore duringmining, the process design now incorporatestreatment of both formsof sulphide ore that falls within theoriginal oxide optimized pit design.All non-refractory oxide and sulphideore has then been dividedinto high-grade and low-grade oreusing a cut-off grade of 2.0grams/tonne to determine whichof either the vat-leach processroute or heap-leach process routeis most appropriate. Non-refractoryhigh-grade ore over 2.0grams/tonne will be vat leachedinitially while low-grade ore willbe sent for processing on the heapManas Resources has a number of projects in the far southwest ofthe Kyrgyz Republic.leach pads. Refractory sulphideore will be similarly split with highvaluehigh-grade ore being pretreatedto encourage oxidationbefore being stockpiled. This refractoryore will then be treated onthe heap leach after treatment ofnon-refractory ore is completed.<strong>The</strong> ability to process sulphideore through this simple processroute will allow re-evaluation of potentialreserve and production expansionthrough incorporatingfurther material from the 766,000ounce Shambesai resource. Workis continuing to fully define the proportionof non-refractory sulphidesand the potential operational recoveriesfor the sulphides. <strong>The</strong>company is also considering optionsto further process refractorymaterial to increase recoveries.COMMUNITY CONSULTATIONManas has ceased drilling and explorationat Shambesai to engagein a community consultationprocess with the local Maidan villagecommunity as a precursor tocompleting development plans.<strong>The</strong> community has provided recommendationsthat it would likedealt with as part of the developmentprocess to ensure that a goldmine can result in tangible benefitsfor the community. Exploration continueselsewhere on the company’sextensive portfolio.Stephen Ross says in a positivestep for commencement of mineraland subsoil licensing in the KyrgyzRepublic, in March the Director ofthe State Agency on Geology and<strong>Miner</strong>al Resources approved compositionof the commission on licensingof subsoil use, or the StateLicensing Committee, on behalf ofthe government. <strong>The</strong> committee willbe responsible for granting of all minerallicences and it was expected tocommence the formal granting ofmineral licences during April.He says company managementis now working closely with theState Agency for Geology andNatural Resources to approve theTEO Report (Russian interpretationfor Technological and EconomicJustification Study) in the shortesttime possible.A panoramic view along the valley from the Obdilla project at right to the Shambesai project at far left.May/June <strong>2012</strong> | <strong>ASIA</strong> <strong>Miner</strong> | 23

ChinaChina wants continuing growth but at a low costBy Keith Goode, Financial Services Representative of Taylor Collison and a consultant with Eagle Research Advisory.THERE has been much said recently aboutslowing Chinese growth and the impact onthe rest of the world but the fact is thatChina wants gr owth at as low a cost aspossible and the growth rate is being deliberatelyslowed in a bid to achieve an annualrate of about 7%. <strong>The</strong> r eality is Chinais being rebuilt and a vast number of its citizensare becoming increasingly wealthy.At China Mining 2011 in November it wasobvious that China appears likely to continueto fuel the commodities boom for atleast 10 years, but does not want to payhigh commodity prices, and will try and paylower prices any way it can.In the Equatorial Resources presentationat Sydney Mining Club on March 1, <strong>2012</strong>, aquote was given by Wu Xichun of China Iron& Steel Association that “By 2015, Chinawants to import 50% of its ir on ore fromChinese-owned mines elsewher e in theworld”. To back this up, China appears tobe buying as much as it can, as shown inSAMI statistics in a presentation at the AfricanMining Investment Conference in Sydneyon Mar ch 12, <strong>2012</strong>, which statedChinese companies have also gained Australianand Canadian personnel thr oughtheir acquisitions.For identifiable worldwide company acquisitionsin all sectors of mor e than US$100million, US$94 billion was spent in 2011 comparedto $110 billion in 2010 and $77 billionin 2009, up from $12 billion in 2005. EagleResearch Advisory is aware of other transactionsthat are not included in the totals.Just because growth is not clearly visible inthe Chinese city you ar e visiting does notmean growth has stopped, it simply means itis probably happening elsewher e. China isbuilding for the future as illustrated by the r e-ported US$62 billion pr oject to draw waterfrom four rivers in the south to China’ s driernorthwest using about 2905km of aqueducts.Although China is following its own path toimproving the environment through closinginefficient plants and combining smaller onesinto larger ones, it has also taken a dif ferentapproach to ‘gr eening’ existing minesthrough paying bonuses or tax exemptions tomining companies that ‘green’ or make theirmine areas become tourist attractions.<strong>The</strong> incentives are drawn from a RMB20 billiongovernment fund to support the mining industry.<strong>The</strong> national mine park plan was startedin 2005 and has resulted in creation of 21 nationalmine parks - a complete contrast toother countries that try and tax mines to themax. <strong>The</strong> current 12th 5-year plan also involvesimproved energy utilization and companies thatembrace it are apparently exempt from tax.At the China Mining conference CRU’s presentationshowed China accounting for about40% of global consumption of all base metalswhile China is trying to improve technology toincrease metal recycling percentages to morethan 50% from 20-25%. Although domesticproduction is incr easing in ar eas such ascopper, it is still r egarded as being way behind(it used to be about 65% imported).Copper is per ceived to still be in deficitthrough to 2013, mostly because the majorshave focused on developing ir on ore. Demandis expected to r emain high, driven bynew uses, especially battery-powered/electricvehicles, and China’s likelihood to continueits use in construction.Iron ore demand was seen by the Mysteelgroup as a function of China’s GDP and fixedasset investment growth, with faster growthin west and central ar eas because the easthas become largely built. GDP gr owth wasperceived as slowing to a mor e sustainablelevel closer to 8%, while steel production wasseen as beginning to plateau at about 830million tonnes in 2015, which still representssignificant demand.中 国 欲 以 低 成 本 维 持 增 长最 近 被 广 泛 谈 论 的 一 个 话 题 是 中 国 放 慢 的 增长 速 度 及 其 对 于 世 界 其 他 国 家 的 影 响 。 但 事实 上 中 国 希 望 以 尽 可 能 低 的 成 本 增 长 , 因 而将 增 长 速 度 有 意 地 略 为 放 慢 至 7% 左 右 的 年增 长 率 。 中 国 正 在 进 行 庞 大 规 模 的 建 设 , 有庞 大 数 量 的 国 民 正 变 得 越 来 越 富 裕 。在 2011 年 11 月 份 的 中 国 国 际 矿 业 大 会 上了 解 到 的 情 况 显 示 , 中 国 很 可 能 将 推 动 大 宗商 品 牛 市 持 续 至 少 十 年 。在 Equatorial Resources 公 司 于 <strong>2012</strong> 年 3 月1 日 在 悉 尼 矿 业 俱 乐 部 进 行 的 演 示 报 告 中 ,援 引 了 中 国 钢 铁 工 业 协 会 名 誉 会 长 吴 溪 淳 的话 :“ 中 国 希 望 到 2015 年 时 , 将 有 50% 的 铁矿 石 进 口 自 中 国 企 业 控 股 的 海 外 铁 矿 。” 作为 印 证 ,<strong>2012</strong> 年 3 月 12 日 在 悉 尼 召 开 的 非 洲矿 业 投 资 大 会 上 公 布 的 SAMI 统 计 报 告 显 示, 中 国 企 业 已 经 通 过 收 购 行 动 招 募 了 澳 大 利亚 和 加 拿 大 员 工 。在 全 球 范 围 内 所 有 领 域 中 交 易 价 格 超 过 1亿 美 元 的 可 确 认 的 企 业 收 购 行 动 中 ,2011年 中 国 投 入 的 资 金 合 计 达 到 940 亿 美 元 ,2010 年 这 一 数 据 为 1100 亿 美 元 ,2009 年 为770 亿 美 元 , 而 在 2005 年 还 仅 有 120 亿 美 元。 据 Eagle Research Advisory 了 解 , 还 有 交易 数 据 并 没 有 计 算 进 来 。如 果 在 你 到 访 的 中 国 城 市 中 增 长 并 不 明显 , 这 并 不 意 味 着 增 长 停 止 , 而 仅 仅 表 明 增长 可 能 发 生 在 其 他 地 方 。 中 国 正 在 为 未 来 建设 , 据 报 道 , 中 国 正 在 兴 建 一 个 投 资 额 为620 亿 美 元 的 项 目 , 将 南 方 四 条 河 流 的 河 水通 过 长 达 2905 公 里 的 引 水 渠 输 送 到 干 旱 的北 方 。尽 管 中 国 正 在 走 自 己 的 道 路 , 通 过 关 闭 效率 低 下 的 工 厂 以 及 将 规 模 较 小 的 工 厂 合 并 为大 工 厂 来 改 善 环 境 , 但 同 时 它 也 在 通 过 不 同的 方 式 来 “ 绿 化 ” 现 有 的 矿 场 , 如 对 那 些 “ 绿色 ” 采 矿 企 业 或 者 将 其 矿 区 改 造 为 旅 游 景 点的 企 业 给 予 奖 励 或 予 以 免 税 优 惠 。这 些 支 持 采 矿 业 的 激 励 措 施 来 自 于 一 项 政府 基 金 , 其 金 额 为 200 亿 人 民 币 。2005 年 开始 的 国 家 矿 山 公 园 计 划 已 经 推 动 建 立 了 21个 国 家 矿 山 公 园 —— 这 跟 其 他 国 家 对 矿 山 尽可 能 多 开 发 多 征 税 的 做 法 形 成 了 鲜 明 的 对比 。 正 在 执 行 的 十 二 五 计 划 同 样 包 括 了 提 高能 源 利 用 效 率 的 政 策 , 实 施 这 一 政 策 的 企 业将 获 得 免 税 优 惠 。CRU 在 中 国 矿 业 大 会 上 作 的 报 告 显 示 , 中 国占 全 球 贱 金 属 消 费 量 的 40%, 它 正 在 试 图 改 进技 术 水 平 , 将 金 属 回 收 利 用 率 从 20-25% 提 高到 50% 以 上 。 尽 管 在 诸 如 铜 等 一 些 领 域 的 国 内产 量 正 在 增 长 , 但 它 依 然 被 认 为 远 远 处 于 落后 水 平 ( 过 去 进 口 量 约 占 65%).铜 的 缺 口 被 认 为 将 持 续 到 2013 年 , 这 主 要 是 由于 主 要 的 采 矿 企 业 将 重 点 放 在 铁 矿 石 的 开 采 上 。在 新 的 用 途 —— 尤 其 是 电 池 驱 动 或 电 动 车 辆 ——的 拉 动 下 , 以 及 中 国 将 在 建 设 中 继 续 使 用 铜 , 预计 铜 的 需 求 将 持 续 处 于 高 位 。在 我 的 钢 铁 (Mysteel) 集 团 看 来 , 铁 矿 石的 需 求 量 是 中 国 GDP 和 固 定 资 产 投 资 增 长的 一 项 晴 雨 表 , 它 在 中 西 部 地 区 的 增 长 速 度更 快 , 因 为 东 部 地 区 的 建 设 基 本 上 已 经 完成 。 中 国 GDP 的 增 速 将 减 缓 到 接 近 8%, 这是 一 个 更 可 持 续 的 水 平 , 而 钢 产 量 将 在2015 年 开 始 稳 定 在 8.3 亿 吨 左 右 , 这 依 然 代表 着 巨 大 的 需 求 。24 | <strong>ASIA</strong> <strong>Miner</strong> | May/June <strong>2012</strong>

ChinaKey Dachang licences renewedTHREE key exploration licences have beenrenewed at Inter-Citic <strong>Miner</strong>als’ DachangGold Project, in addition to the combinationof two other licences covering the DachangMain Zone in order to facilitate permitting.<strong>The</strong> 279sqkm Dachang project now comprisesfour licenses, all of which have beenrenewed successfully as they have comedue in the past.China’s Ministry of Land and Resour ces(MOLAR) has granted a further two year extensionof three exploration licences at Dachangcovering about 173sqkm. <strong>The</strong> renewal<strong>The</strong> Dachang Gold Project is in southwest China, not far from major road infrastructure.is valid until November 25, 2013, when it willbe eligible for further renewal.In addition, the company asked for and r e-ceived from the Chinese Gover nment a r e-drawing of the boundaries of the remaining twoexploration licences within the property area tofacilitate permitting of the Dachang Main Zone(DMZ), which hosts most of Inter-Citic’s currentNI 43-101 compliant inferred mineral resourceestimate and is planned for open pit mine development.<strong>The</strong> overall area of these licencesremains unchanged at about 106sqkm.<strong>The</strong> company has recently received resultsfrom its 2011, 21,000 metr e trenching programat Dachang, which continues to be theprimary method for new discoveries due tothe thin soil cover and near-surface mineralizationobserved thr oughout the pr operty.Trenching is one of the most successful andcost-effective methods of gold exploration atDachang, and a consistent spatial r elationshiphas been observed between the gold-insoilanomalies, trench values and underlyingstrongly altered and mineralized fault zones.During 2011’s trenching four new areas ofsurface discovery were made - two in thesoutheast part of the pr operty, one north ofthe original DMZ and a final area of discoverysouthwest of the Placer Valley Zone (PVZ). Inaddition, the 861 and Acadia Zones of discoverywere expanded by this tr enching program.In all cases these discoveries are faultcontrolled sulphide gold mineralization similarto the DMZ. All new discoveries ar e open toexpansion by additional drilling and trenchingprograms being planned for <strong>2012</strong>.<strong>The</strong> most advanced new discovery expandedby the 2011 tr enching program is the861/XP fault system, which has now beendrill tested on its known western and easternextents. This fault system north of the DMZhad been delineated along a 2.8km extent.<strong>The</strong> 861 Zone on the fault’s west end is stillopen to the west and has been consistently intersectedin trenches and 40 metre spaced drillfences along a 1.4km strike length to depthsof 125 to 150 metres. A central section of thisfault requiring further drill testing lies betweenthe 861 Zone from the nearby XP Zone, whichremains open along strike to the east.大 场 的 主 要 勘 探 执 照 得 到 续 期Inter-Citic 矿 业 公 司 大 场 金 矿 项 目 除 为 推进 许 可 证 申 请 、 覆 盖 大 场 主 区 的 两 个 合 并执 照 外 的 其 他 三 个 主 要 的 勘 探 开 采 执 照 的有 效 期 已 经 得 到 延 长 。 大 场 项 目 占 地 279平 方 公 里 , 目 前 拥 有 4 个 勘 探 执 照 , 且 都 在到 期 时 成 功 续 期 。中 国 国 土 资 源 部 已 经 批 准 大 场 项 目 覆 盖面 积 为 173 平 方 公 里 的 3 个 勘 探 执 照 有 效 期延 长 两 年 。 有 效 期 截 至 2013 年 11 月 25 日 ,届 时 有 资 格 再 进 一 步 申 请 续 期 。另 外 , 公 司 向 中 国 政 府 申 请 重 新 划 分 其余 两 个 勘 探 执 照 的 界 线 以 推 进 大 场 主 区(DMZ) 获 得 许 可 证 , 已 经 得 到 中 国 政 府 准可 , 大 场 主 区 拥 有 Inter-Citic 公 司 目 前 符合 NI43-101 推 断 资 源 估 计 量 的 大 部 分 资源 , 该 区 域 计 划 采 用 露 天 开 采 方 式 。 这 些执 照 覆 盖 的 所 有 区 域 面 积 约 保 持 在 106 平方 公 里 。公 司 最 近 已 经 得 到 2011 年 的 测 试 结 果 ,由 于 该 矿 权 地 的 成 矿 带 土 壤 覆 盖 较 薄 且 近地 表 , 大 场 实 施 的 2.1 万 米 的 槽 探 作 业 将 继续 成 为 新 发 现 区 域 的 主 要 勘 探 方 法 。 槽 探是 大 场 项 目 黄 金 勘 探 使 用 的 最 成 功 和 最 具有 成 本 效 益 的 方 法 , 另 外 , 根 据 观 测 发 现土 壤 中 金 异 常 、 槽 探 值 和 潜 在 强 蚀 变 矿 化断 层 区 域 之 间 存 在 一 致 的 空 间 关 系 。在 2011 年 期 间 , 近 地 表 的 四 个 新 区 域 实施 了 槽 探 作 业 – 两 个 位 于 该 矿 权 地 的 东 南部 , 一 个 位 于 原 大 场 主 区 的 北 边 , 最 后 一个 位 于 Placer Valley 区 域 (PVZ) 的 西 南方 。 另 外 ,861 和 Acadia 区 通 过 此 次 钻 探作 业 得 到 了 扩 展 。 在 所 有 情 况 下 , 这 些 新区 域 都 是 断 层 控 制 的 硫 化 金 成 矿 带 , 与 大场 主 区 类 似 。 所 有 的 这 些 新 发 现 区 域 都 可以 通 过 计 划 在 <strong>2012</strong> 年 进 一 步 实 施 的 勘 探 和槽 探 作 业 扩 展 。通 过 2011 年 槽 探 作 业 扩 展 最 显 著 的 区 域是 861/XP 断 层 系 统 , 目 前 已 在 其 已 知 的 西部 和 东 部 边 界 上 进 行 了 钻 探 测 试 。 该 断 层系 统 位 于 大 场 主 区 北 部 , 目 前 已 经 沿 着 2.8公 里 的 延 伸 带 被 圈 定 出 来 。位 于 断 层 西 部 边 界 的 861 区 域 西 部 未 封闭 , 并 且 沿 走 向 1.4 公 里 长 、 位 于 125-150米 深 处 的 探 槽 和 40 米 间 距 的 钻 孔 持 续 见 矿。 该 断 层 中 心 区 域 位 于 从 附 近 XP 区 到 861区 之 间 , 需 要 进 一 步 进 行 钻 探 测 试 。XP 区沿 走 向 向 东 未 封 闭 。26 | <strong>ASIA</strong> <strong>Miner</strong> | May/June <strong>2012</strong>

ChinaBlackgold aims for 69% more productionBlackgold International’s coal mines are in Chongqing province.BLACKGOLD International is on track to increasecoal production from its Chongqingprovince operations by at least 69% this yearto around 1.6 million tonnes. Much of the increasewill come from about 400,000 tonnesat Changhong mine in the pr ovince’s southwhich was commissioned in February while itwill also be boosted by mechanization improvementsand increases in primary mining panelsat the norther n Caotang and Heiwanoperations. Changhong’s production is expectedto double to 800,000 tonnes in 2013as ramp-up continues while the company expectsto bring a fourth mine, Wushan, in thenorth, into operation by the end of <strong>2012</strong>.Blackgold’s chairman James Tong says thecompany is pleased with progress and confidentof further growth.<strong>The</strong> company’s mines are near the YangtzeRiver which provides a low-cost means oftransport to power plants downstr eam.James Tong says, “We are acquiring ChongqingGuoping Shipping Transportation Company(GPST) which operates a bargetransport business along the Yangtze with itsfleet comprising nine hollow hull barges withtotal annual capacity of 600,000 tonnes.GPST also has a number of storage facilitieswhich can be utilized to blend and wash coal.<strong>The</strong> acquisition increases ownership of thesupply chain as we also have a port and storagefacility which we aim to have operationalin quarter 2 of 2013.“Blackgold has also targeted a site for constructionof a coal washing plant which willprovide various types of coal based on customerrequirements. Applications have beenlodged and the company hopes to beginoperations in 2013. <strong>The</strong> integrated businessmodel will allow Blackgold to reduce the costof sales by shortening the shipment cycle aswell as meeting customer demands in a timelyand cost-efficient manner by providinga whole supply chain solution.”<strong>The</strong> company has proven reserves of 79.4million tonnes and probable reserves of 46.2million tonnes along with inferr ed resourcesof 42 million tonnes. “We will continue upgradingresources to reserves this year with theaim of having 150 million tonnes in r eservesby year-end. We are also continuing to explorenew areas and considering possible futureacquisitions which will incr ease ourresources,” James Tong says.“Blackgold is viewed favourably by theChongqing government as the regional consolidatorof smaller coal operations given ourstatus as a listed company, our safety trackrecord, corporate governance and financialresources. We will continue to focus on makingacquisitions in the Chongqing region andare negotiating for five additional mines whichwe expect to finalize this year . We are alsolooking to pursue further mechanization upgrades.”黑 金 国 际 计 划 将 产 量 提 高 69%黑 金 国 际 控 股 有 限 公 司 正 在 跟 进 提 高 其 位 于重 庆 省 的 运 营 煤 矿 产 量 , 预 期 今 年 最 少 提 高69%, 达 到 160 万 吨 左 右 。 其 中 约 40 万 吨 的增 加 量 将 来 自 位 于 该 省 南 部 于 2 月 份 试 运 行的 长 宏 矿 场 , 同 时 , 草 堂 北 矿 场 和 黑 湾 矿 场主 要 采 矿 车 间 的 机 械 化 提 升 和 增 加 也 将 提 高产 量 。 长 宏 矿 场 产 量 预 期 在 2013 年 提 高 一倍 至 80 万 吨 , 产 量 保 持 继 续 增 长 , 公 司 计划 在 <strong>2012</strong> 年 年 底 推 进 旗 下 第 四 个 矿 场 巫 山进 入 运 营 阶 段 。 黑 金 的 主 席 James Tong 称公 司 对 取 得 的 进 步 十 分 满 意 并 对 进 一 步 增 长充 满 信 心 .公 司 的 矿 场 位 于 长 江 附 近 , 为 下 游 的 电厂 提 供 了 低 成 本 的 传 输 方 式 。James Tong称 , “ 我 们 正 在 收 购 重 庆 国 平 货 运 公 司(GPST), 该 公 司 沿 长 江 经 营 驳 船 运 输 业务 , 其 船 队 包 括 9 只 驳 船 , 年 总 装 载 量 达 60万 吨 。GPST 还 拥 有 许 多 储 藏 设 施 , 可 以 用来 混 合 与 清 洗 煤 。 此 次 并 购 提 高 了 供 应 链 的所 有 权 , 因 为 我 们 持 有 了 港 口 和 储 藏 设 施 ,预 期 这 些 设 施 将 在 2013 年 第 二 季 度 运 营 。”“ 黑 金 还 为 建 造 洗 煤 厂 选 好 了 厂 址 , 该 厂将 以 客 户 要 求 为 基 础 提 供 多 种 煤 。 申 请 已 经提 交 , 公 司 期 望 在 2013 年 开 始 运 营 。”“ 综 合 业 务 模 型 使 黑 金 能 够 通 过 缩 短 发 货周 期 来 减 少 销 售 成 本 并 通 过 提 供 一 个 整 体 的供 应 链 解 决 方 案 来 采 取 及 时 、 具 有 成 本 效 益的 方 法 满 足 客 户 需 求 。”公 司 证 实 储 量 为 7940 万 吨 , 概 算 储 量 为4620 万 吨 , 推 断 资 源 量 为 4200 万 吨 。“ 今年 , 我 们 将 继 续 升 级 资 源 为 储 量 , 旨 在 到 年底 前 使 储 量 达 到 1.5 亿 吨 。 我 们 还 将 继 续 勘探 新 的 区 域 , 并 考 虑 能 够 增 加 我 们 资 源 量 的潜 在 并 购 ,”James Tong 说 道 。“ 黑 金 国 际 被 重 庆 政 府 视 为 一 家 积 极 地 小型 煤 矿 运 营 区 域 性 整 合 者 , 这 主 要 是 考 虑 到我 们 是 一 家 上 市 公 司 、 具 有 良 好 的 记 录 、 公司 治 理 和 金 融 资 源 , 我 们 将 继 续 致 力 于 重 庆区 域 的 市 场 并 购 , 目 前 正 在 与 另 外 5 个 期 望关 闭 的 矿 场 进 行 协 商 。 我 们 还 期 望 继 续 进 行机 械 化 升 级 和 扩 大 供 应 链 所 有 权 。”28 | <strong>ASIA</strong> <strong>Miner</strong> | May/June <strong>2012</strong>

ChinaSilvercorp expects 20% increase in silver productionSILVERCORP Metals has forecast silver productionto increase by 20%, gold by 90%,lead by 12% and zinc by 63% from its miningoperations in China during the next 12months. <strong>The</strong> 2013 financial year pr oductionto March 31, 2013 is expected to be theeighth consecutive year of incr eases in thecompany’s silver production.From the four mines at the Y ing MiningCamp in Henan province, production is expectedto increase to 695,000 tonnes of oreat a grade of 295 grams/tonne silver , 0.5grams/tonne gold, 5.1% lead and 1.5% zinc,yielding 5.9 million ounces of silver , 3350ounces of gold, and 87 million pounds of leadUnderground silver mineralization at Silvercorp’s LM mine within the Ying Mining Camp.and zinc. <strong>The</strong> GC mine in Guangdong pr o-vince is expected to begin initial pr oductionin the second quarter of fiscal 2013, betweenJune 1 and August 31, and is expected tomine 160,000 tonnes and to mill 153,000tonnes of ore, yielding about 630,000 ouncesof silver and 12 million pounds of lead andzinc. <strong>The</strong> BYP mine in Hunan province is expectedto mine and mill 175,000 tonnes ofore, yielding about 13,590 ounces of gold.At the newly-acquired XHP and XBG minesnear the Ying camp, Silvercorp will focus onexploration with only a minimal amount of byproductore expected to be pr oduced. <strong>The</strong>focus will be a 33,600 metre surface and undergrounddrilling pr ogram, budgeted atabout US$2.1 million. In addition, US$3.9million of capital expenditures is budgeted formine development, exploration tunnelling andupgrading existing mills. <strong>The</strong> company alsoplans to prepare an initial NI 43-101 resourcereport for the properties.At the GC project, Silvercorp has received apositive pre-feasibility study which establishedproven and probable reserves at the projectfor the first time and also reconfirmed GC’s robusteconomics. It defined mineral reserves of4.8 million tonnes in the proven and probablecategories grading 121 grams/tonne silver ,1.31% lead and 2.95% zinc, containing about18.5 million ounces of silver, 62,100 tonnes oflead and 140,200 tonnes of zinc, supportinga project life of 12 years.In preparation for production, facilities arebeing constructed with daily mining capacity of1500 tonnes and flotation milling capacity of1600 tonnes with the mining capacity enableto increase to 1570 tonnes after five years. <strong>The</strong>flotation mill is designed to generate silver-lead,zinc, and pyrite concentrates. <strong>The</strong> optionalgravity tin recovery circuit can be appended tothe main circuit to recover tin from tailings.<strong>The</strong> reserves have been estimated fr om atotal of more than 7.631 million measur edand indicated tonnes @ 122 grams/tonne silver,1.32% lead and 3.08% zinc for almost 30million ounces of silver, 100,900 tonnes oflead and 235,300 tonnes of zinc while ther eare also almost 8 million inferr ed tonnes @123 grams/tonne silver , 1.41% lead and2.66% zinc for more than 31.477 million ouncesof silver, 112,500 tonnes of lead and211,900 tonnes of zinc.希 尔 威 预 期 白 银 产 量 增 加 20%希 尔 威 金 属 矿 业 公 司 预 期 其 位 于 中 国 的 采 矿运 营 在 未 来 12 个 月 白 银 产 量 将 增 加 20%, 黄金 产 量 将 增 加 90%, 铅 和 锌 产 量 将 分 别 增 加12% 和 63%。 截 至 2013 年 3 月 31 日 财 年 的 产量 预 期 实 现 连 续 第 八 年 的 白 银 产 量 增 长 。对 河 南 省 月 亮 沟 采 矿 区 内 的 四 个 矿 山 来说 , 其 产 量 预 期 将 增 至 69.5 万 吨 矿 , 其 中银 、 金 、 铅 和 锌 的 品 位 分 别 达 295 克 / 吨 、0.5 克 / 吨 、5.1% 和 1.5%, 金 属 含 量 分 别为 590 万 盎 司 银 、3350 万 盎 司 金 、8700 万磅 铅 和 锌 。位 于 广 东 省 的 GC 矿 预 期 在 2013 财 年 的 第二 季 度 - 6 月 1 日 至 8 月 31 日 期 间 投 产 , 预 期开 采 16 万 吨 , 处 理 15.3 万 吨 矿 石 , 生 产 约63 万 盎 司 白 银 、1200 万 吨 铅 和 锌 。 位 于 湖南 省 的 BYP 矿 预 期 采 选 17.5 万 吨 矿 石 , 生 产约 13590 盎 司 金 。在 新 收 购 的 位 于 月 亮 沟 矿 附 近 的 XHP 和XBG 矿 场 , 希 尔 威 将 专 注 勘 探 , 预 期 仅 产生 少 量 副 产 矿 物 。 预 期 的 勘 探 将 包 括 33600米 的 地 表 和 井 下 钻 探 作 业 , 预 算 约 为 210 万美 元 。 另 外 ,390 万 美 元 的 资 本 支 出 预 算将 用 于 矿 场 开 发 、 坑 探 和 现 有 选 厂 的 改 造 工作 。 公 司 还 计 划 为 这 两 个 矿 场 准 备 一 份 初 步的 NI 43-101 资 源 报 告 。希 尔 威 GC 项 目 的 预 可 行 性 研 究 结 果 非 常乐 观 , 首 次 证 实 了 该 项 目 的 证 实 和 概 算 储量 , 并 重 新 确 认 了 GC 稳 健 的 经 济 状 况 。 确定 的 证 实 和 概 略 矿 产 储 量 为 480 万 吨 , 其 中银 、 铅 和 锌 品 位 分 别 为 121 克 / 吨 、1.31% 和2.95%, 银 、 铅 和 锌 含 量 分 别 约 达 1850 万 盎司 、6.21 万 吨 和 14.02 万 吨 , 从 而 支 持 了 12年 的 项 目 寿 命 。设 施 正 在 建 造 中 以 为 投 产 做 准 备 , 采 矿 量为 1500 吨 / 日 , 浮 选 设 施 处 理 能 力 为 1600吨 / 日 , 采 矿 能 力 能 够 在 五 年 后 增 加 至 1570吨 。 浮 选 厂 计 划 生 产 银 - 铅 、 锌 和 黄 铁 精矿 。 可 选 的 重 选 回 收 锡 回 路 可 以 加 到 主 回 路中 用 于 从 尾 矿 中 回 收 锡 。探 明 和 推 定 资 源 量 超 过 763.1 万 吨 , 其 中银 、 铅 和 锌 的 品 位 分 别 达 122 克 / 吨 、1.32%和 3.08%, 金 属 含 量 分 别 为 近 3000 万 盎 司银 、10.09 万 吨 铅 和 23.53 万 吨 锌 , 另 外 , 推断 资 源 量 接 近 800 万 吨 , 其 中 银 、 铅 和 锌 的品 位 分 别 达 123 克 / 吨 、1.41% 和 2.66%, 金属 含 量 分 别 为 3147.7 万 盎 司 以 上 的 银 、11.25 万 吨 铅 和 21.19 万 吨 锌 。30 | <strong>ASIA</strong> <strong>Miner</strong> | May/June <strong>2012</strong>

Paid Advertisement-Company ProfileBlasting operations done according to worldstandards in MongoliaWhat kind of changes doyou see in Mongolia’s blastingsector?Mining sector had developed for 90years in Mongolia. <strong>The</strong> first phase ofthe mining technology process whichis drilling and blasting work, untilnowadays has been done by nationalcompanies and specialists.Until 1990s Mongolia had beenbuying necessary explosive materialsfrom Russia /formally USSR/. Sincethen, after the democratic revolutionMongolia had a transition to marketeconomy thus importing explosiveaccessories from China, SouthKorea, Swiss and other countries. Atthe present, there are 13 domesticand foreign invested companies thatproduce ANFO, emulsion explosivematerials in Mongolia.How is the competition?At present, market demand for explosivesin Mongolia is about 80,000tons approximately. But the productivecapacity of explosive plantswhich are manufactured by domesticand foreign investment is about100,000 tons approximately.<strong>The</strong> international companies that operateworldwide are establishingbranches in Mongolia.What are the differences ineffectiveness of technology,human resources andquality between internationaland Mongolian nationalcompanies?<strong>The</strong> development level of companiesthat produce explosives and provideblasting services is relatively different.If in the above mentioned there areNational companies that providebetter blasting services and explosives,there may be companies withweak human resource effectivenessand technology. It is important tofocus on application of new technologiesto the blasting sector. 70%of the explosives plants which are inMongolia, manufacture explosiveswith Chinese, Russian technologyand 30% manufacture explosiveswith the latest advanced technologyof developed countries.Tell us about Mera LLCMERA LLC is the only NationalCompany that provides drill-blastingcomplex service in Mongolia. In2006 with 100% National investmentand US technology we establishedthe first explosives plant. Westarted to produce according to theinternational standards 3 types ofANFO explosives “Ayanga”,“Ayanga-X”, “Ayanga WR”.Through this work we were chosenas “<strong>The</strong> Best Domestic Investor” of2006 and “<strong>The</strong> best technology –Know How Entrepreneur” in 2011by establishing non-blasting ingredientsplant and applying Nitronitebrand emulsion in the blasting service.Also, the industrial explosivesmanufacturing, blasting operationsare done according to world standardsin Mongolia.What specifics and advantagesdoes the manufacturingtechnology have?Manufacturing technology has beentested in Siberian conditions and itcan work in temperature +50˚ to -40˚ Celsius, This makes it perfect forthe harsh climate of Mongolia. Otherthan the non-blasting ingredient plant(raw material), it provides safetywhen manufacturing, transporting,and charging with the help of chargingtrucks that produce explosive materialsduring the charging ofblastholes. Also we monitor, transformand adapt raw material quality,ingredients in advanced laboratory.By following this procedure we manufactureproducts with quality andwithout any waste thus providing customerrequirements. Since the manufacturingis fully automatic, it has lotof advantages such as ease of use,reduced cost and time, increasedwork efficiency and no quality defects.It’s a technology that has minimuminfluence on environmentbecause it uses minimal of water inmanufacturing process, doesn’tspread poisonous gas, and has lowsound and waste.What are the important factorsof high quality explosives,blasting services?<strong>The</strong>re are lot of factors such as safety,knowledge, skills, experienced employees,and advanced technologythat provide safety, application ofproduct quality standard, monitoringregulations, raw material quality.Also we view with utmost importancesuch factors as services andproducts that provide the customers’requirements, its influence on environment,cost reduction.What advantages do youget by applying the internationalstandards?Our company applied to its manufacturing,services and operationprocess the international quality managementsystem ISO 9001:2008 in2010. This means that our companyensures its products and service,services that meet the internationalquality standard requirements and itshows that we are the first to operatein the blasting service sector, manufactureexplosives in Mongolia andwe can provide services that meetrequirements of foreign standards.How many customers andcooperators does MERAhave?We have worked on many largemining projects in Mongolia. Atpresent we are doing drilling andblasting services in Olon Ovoot goldmine, Zasag Chandman open pitiron ore mine, Baruun Naran coalmine, Erdenes Tavan Tolgoi, UkhaaKhudag of Tawan Tolgoi deposit.Also we provide explosive materialcharging services in “Baganuur” LLCmine. We provide blasting servicesto companies such as “Tavan Tolgoi”joint venture, “Erdenet Mining Corporation”,“Mogoi Gol” joint venture,“Boldtumur Eruu Gol” LLC and wesupply explosives and accessories toother blasting service companies.What does the future hold?In 2011, we established complexfacilities and applied the latest technologiessuch as emulsion explosiveplant, shot plus blasting software,electronic detonators, gas bags forair decking, remote firing devices,sirens, blast hole stemming machine,a DM-45 HP drilling machine, specialvehicle that transports and producesexplosives.This year we are going to extend ouremulsion plant, increase our drillingmachines, and introduce occupationalhealth and safety managementsystem, environmental managementsystem according to the internationalstandard requirements.32 | <strong>ASIA</strong> <strong>Miner</strong> | May/June <strong>2012</strong>

MongoliaVoyager preparing KM resource estimateFURTHER drilling by Voyager Resources hasincreased the lateral extent of mineralizationintersected at the Aranjin prospect of the KMCopper Porphyry Project. Drilling at KM is ongoingand will assist the company in calculatinginitial resources before the end of June.Recent Aranjin drilling returned 104 metresVoyager’s KM (Khul Morit) project is in southern Mongolia, not far from the Chinese border.from 4 metr es @ 1.01% copper and 8.2grams/tonne silver, including 42 metres from20 metres @ 2.1% copper and 16.4 grams/tonne silver. This result is in addition to previousintersections from Aranjin that r eturned 168metres from 76 metres @ 0.74% copper and5.4 grams/tonne silver, 140 metres from 4 metres@ 0.6% copper and 5.3 grams/tonne silver,and 80 metr es from 60 metres @ 0.8%copper and 10.3 grams/tonne silver.Aranjin is the second of thr ee discoveriesidentified in a de-magnetized structural corridorthat hosts Aranjin, Cughur and CughurNE deposits where recent drilling returned 50metres from 6 metres @ 0.82% copper and1.87 grams/tonne silver. Further drilling isplanned to test mapped mineralized brecciasand strong copper-in-soil anomalies identifiedwithin the fault corridor. This corridor extendsfor more than 3km in strike with mineralizationbeing identified over its extent. V oyager believesthe corridor acts as a conduit to a porphyrystock to the southwest of Cughur withthe breccia pipes exploiting the weaker structureto intrude up the corridor.Voyager recently came to an agr eementwith a Mongolian-based reverse circulationdrilling contractor to complete 10,000 metresof drilling at KM. Drilling is primarily focusedon lateral and shallow extents to themineralized hydrothermal breccias intersectedand identified by Voyager.34 | <strong>ASIA</strong> <strong>Miner</strong> | May/June <strong>2012</strong>

MongoliaAltan Rio starts Khavchuu drillingALTAN Rio <strong>Miner</strong>als has started drilling at the Khavchuu gold prospectin northern Mongolia. <strong>The</strong> company has an option to acquir e 100%ownership of the project which hosts multiple gold targets and is undertakinga six hole, 1800 metre drill program.Anomalies identified on an IP chargeability map of Altan Rio’s Chandman-Yol project.Khavchuu is near infrastructur e and 8km away fr om CenterraGold’s Boroo mine and mill complex. <strong>The</strong> pr oject has never beendrilled and Altan Rio is keen to see the first holes into this pr ojectwith Boroo mine-style geology.Altan Rio’s director of exploration Kelly Cluer is experienced in the region,having worked previously as exploration manager for Centerra.He believes that Altan Rio’s geochemical surveys and the geologicalsetting show it as prospective for a ‘Boroo-style orogenic lode gold system’.<strong>The</strong> company has taken more than 1200 samples on the projectand used them to focus in on the better results of the IP survey to identifyand prioritize drill targets.Khavchuu is the Canadian-based company’s second exploration projectin Mongolia with the primary focus being the Chandman-Yol Copper-GoldProject in the Altai mountain range near Khovd in the country’swest. <strong>The</strong> company has spent Can$6 million in the past four years atthis project, including geophysics, geochemistry and IP surveys, whichresulted in the identification of seven targets. To date, drilling has focusedat the KY porphyry.<strong>The</strong> most recent 13-hole, 7800 metre program found strong molybdenumanomalies of up to 100ppm in the north-wester n sector,high-grade gold of up to 28 grams/tonne in the north-eastern sectorand unusually high silver of up 100+ grams/tonne, lead at10,000+ppm) and zinc at 10,000+ppm grades in the southeast. Elevatedcopper occurs throughout the 2km-diameter porphyry intrusivesystem with sporadic drill intersections of more than 1% copper.36 | <strong>ASIA</strong> <strong>Miner</strong> | May/June <strong>2012</strong>

MongoliaKincora acquires licences adjoining Bronze FoxKINCORA Copper has r eached an agr eementwith Canadian merchant bank Forbes& Manhattan and closely held private companyTemujin Mining Corp to acquire GoldenGrouse LLC, an indirect subsidiary of Temujin.Golden Grouse is a Mongolian companythat holds mineral two exploration licencesadjoining Kincora’s Bronze Fox project.Temujin, a portfolio company of Aber deenInternational, an investment corporation anda member of the Forbes & Manhattan Groupof Companies, will be issued 20 million sharesin Kincora, which r epresents a 12.6%equity stake in the combined entity on completionof the transaction. Upon the discoveryof a minimum of 1 million ounces of inferr edgold resources or gold equivalent in the propertiesacquired within four years of closingof the transaction, Kincora shall issue a further15 million shar es to Temujin. Kincoraplans to spend Can$2 million on the explorationof the properties over the next 2 years.Golden Grouse properties include TourmalineHills and North Fox which were previouslyowned and subject to preliminary explorationby Ivanhoe Mines. Exploration by Ivanhoeand since by Golden Grouse has identified acopper zone extending fr om Kincora’sBronze Fox licence with drilling and soil samplingidentifying a number of primary gold targetsat Tourmaline and Southwest Target.Kincora’s president and CEO Igor Kovar -sky says, “<strong>The</strong> acquisition of the pr opertiesis a great addition to the Bronze Fox project.We now hold two of Ivanhoe’ s former highpriority target pr operties in Mongolia, theBronze Fox and T ourmaline Hills. Kincoranow holds one of the largest land holdingsalong the highly prospective copper belt hostingOyu Tolgoi. “Tourmaline Hills is a midstageexploration licence with a number ofsignificant gold targets. This places Kincorain a strong position to identify a significantcopper-gold and gold deposit this year.”Bronze Fox and T ourmaline Hills ar e insoutheast Mongolia within the Oyu T olgoicopper belt. Extensive exploration has r e-vealed a significant footprint with extensivecopper and gold mineralization. <strong>The</strong> licencesare 120km northeast of the world-class OyuTolgoi copper gold project and 250km fromthe Chinese bor der. <strong>The</strong> latest drilling atBronze Fox has indicated further evidenceof copper and/or gold mineralization.Geochemistry of the two newly acquired exploration licencesto the north and west of Kincora’s Bronze Fox project.May/June <strong>2012</strong> | <strong>ASIA</strong> <strong>Miner</strong> | 37