grundfos data booklet

grundfos data booklet

grundfos data booklet

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

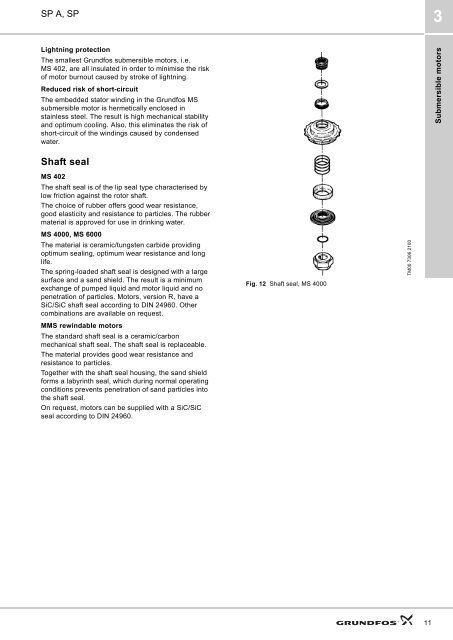

SP A, SP3Lightning protectionThe smallest Grundfos submersible motors, i.e.MS 402, are all insulated in order to minimise the riskof motor burnout caused by stroke of lightning.Reduced risk of short-circuitThe embedded stator winding in the Grundfos MSsubmersible motor is hermetically enclosed instainless steel. The result is high mechanical stabilityand optimum cooling. Also, this eliminates the risk ofshort-circuit of the windings caused by condensedwater.Submersible motorsShaft sealMS 402The shaft seal is of the lip seal type characterised bylow friction against the rotor shaft.The choice of rubber offers good wear resistance,good elasticity and resistance to particles. The rubbermaterial is approved for use in drinking water.MS 4000, MS 6000The material is ceramic/tungsten carbide providingoptimum sealing, optimum wear resistance and longlife.The spring-loaded shaft seal is designed with a largesurface and a sand shield. The result is a minimumexchange of pumped liquid and motor liquid and nopenetration of particles. Motors, version R, have aSiC/SiC shaft seal according to DIN 24960. Othercombinations are available on request.MMS rewindable motorsThe standard shaft seal is a ceramic/carbonmechanical shaft seal. The shaft seal is replaceable.The material provides good wear resistance andresistance to particles.Together with the shaft seal housing, the sand shieldforms a labyrinth seal, which during normal operatingconditions prevents penetration of sand particles intothe shaft seal.On request, motors can be supplied with a SiC/SiCseal according to DIN 24960.Fig. 12 Shaft seal, MS 4000TM00 7306 210011