sorb ac general.pdf - SAES Getters

sorb ac general.pdf - SAES Getters

sorb ac general.pdf - SAES Getters

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

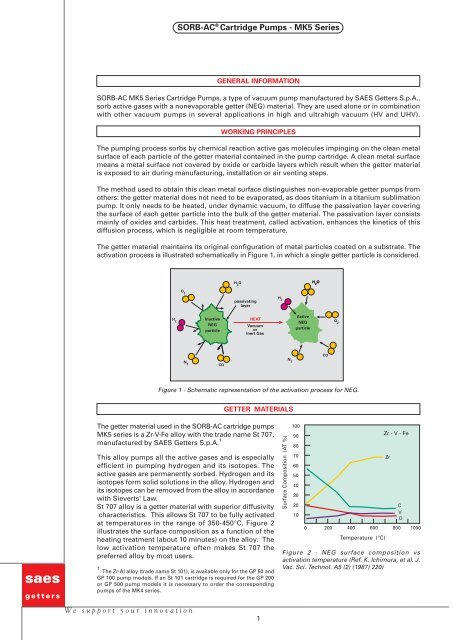

SORB-AC ® Cartridge Pumps - MK5 SeriesGENERAL INFORMATIONSORB-AC MK5 Series Cartridge Pumps, a type of v<strong>ac</strong>uum pump manuf<strong>ac</strong>tured by <strong>SAES</strong> <strong>Getters</strong> S.p.A.,<strong>sorb</strong> <strong>ac</strong>tive gases with a nonevaporable getter (NEG) material. They are used alone or in combinationwith other v<strong>ac</strong>uum pumps in several applications in high and ultrahigh v<strong>ac</strong>uum (HV and UHV).WORKING PRINCIPLESThe pumping process <strong>sorb</strong>s by chemical re<strong>ac</strong>tion <strong>ac</strong>tive gas molecules impinging on the clean metalsurf<strong>ac</strong>e of e<strong>ac</strong>h particle of the getter material contained in the pump cartridge. A clean metal surf<strong>ac</strong>emeans a metal surf<strong>ac</strong>e not covered by oxide or carbide layers which result when the getter materialis exposed to air during manuf<strong>ac</strong>turing, installation or air venting steps.The method used to obtain this clean metal surf<strong>ac</strong>e distinguishes non-evaporable getter pumps fromothers: the getter material does not need to be evaporated, as does titanium in a titanium sublimationpump. It only needs to be heated, under dynamic v<strong>ac</strong>uum, to diffuse the passivation layer coveringthe surf<strong>ac</strong>e of e<strong>ac</strong>h getter particle into the bulk of the getter material. The passivation layer consistsmainly of oxides and carbides. This heat treatment, called <strong>ac</strong>tivation, enhances the kinetics of thisdiffusion process, which is negligible at room temperature.The getter material maintains its original configuration of metal particles coated on a substrate. The<strong>ac</strong>tivation process is illustrated schematically in Figure 1, in which a single getter particle is considered.H 2OH 2 OpassivatinglayerH 2In<strong>ac</strong>tiveNEGparticleH 2O 2N 2 COHEATV<strong>ac</strong>uumorInert GasActiveNEGparticleO 2CON 2Figure 1 - Schematic representation of the <strong>ac</strong>tivation process for NEG.GETTER MATERIALSThe getter material used in the SORB-AC cartridge pumpsMK5 series is a Zr-V-Fe alloy with the trade name St 707,manuf<strong>ac</strong>tured by <strong>SAES</strong> <strong>Getters</strong> S.p.A. 1This alloy pumps all the <strong>ac</strong>tive gases and is especiallyefficient in pumping hydrogen and its isotopes. The<strong>ac</strong>tive gases are permanently <strong>sorb</strong>ed. Hydrogen and itsisotopes form solid solutions in the alloy. Hydrogen andits isotopes can be removed from the alloy in <strong>ac</strong>cordancewith Sieverts' Law.St 707 alloy is a getter material with superior diffusivitychar<strong>ac</strong>teristics. This allows St 707 to be fully <strong>ac</strong>tivatedat temperatures in the range of 350-450°C. Figure 2illustrates the surf<strong>ac</strong>e composition as a function of theheating treatment (about 10 minutes) on the alloy. Thelow <strong>ac</strong>tivation temperature often makes St 707 thepreferred alloy by most users.1 . The Zr-Al alloy (trade name St 101), is available only for the GP 50 andGP 100 pump models. If an St 101 cartridge is required for the GP 200or GP 500 pump models it is necessary to order the correspondingpumps of the MK4 series.Surf<strong>ac</strong>e Composition (AT %)100908070605040302010Temperature (°C)Zr - V - FeCVO0 200 400 600 800 1000Figure 2 - NEG surf<strong>ac</strong>e composition vs<strong>ac</strong>tivation temperature (Ref. K. Ichimura, et al. J.V<strong>ac</strong>. Sci. Technol. A5 (2) (1987) 220)ZrWe support your innovation1