Marginally lubricated

Marginally lubricated

Marginally lubricated

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

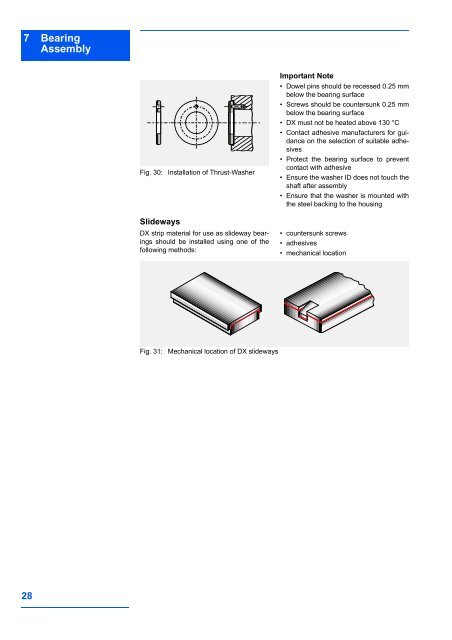

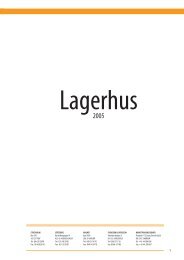

7 BearingAssemblyFig. 30:Installation of Thrust-WasherImportant Note• Dowel pins should be recessed 0.25 mmbelow the bearing surface• Screws should be countersunk 0.25 mmbelow the bearing surface• DX must not be heated above 130 °C• Contact adhesive manufacturers for guidanceon the selection of suitable adhesives• Protect the bearing surface to preventcontact with adhesive• Ensure the washer ID does not touch theshaft after assembly• Ensure that the washer is mounted withthe steel backing to the housingSlidewaysDX strip material for use as slideway bearingsshould be installed using one of thefollowing methods:• countersunk screws• adhesives• mechanical locationFig. 31:Mechanical location of DX slideways28