Marginally lubricated

Marginally lubricated

Marginally lubricated

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

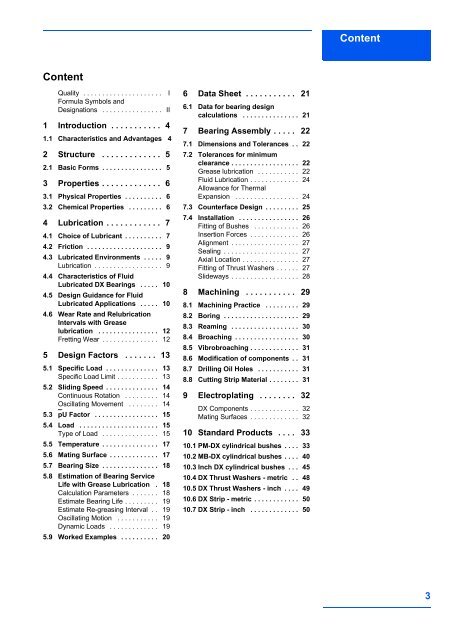

ContentContentQuality . . . . . . . . . . . . . . . . . . . . . IFormula Symbols andDesignations . . . . . . . . . . . . . . . . II1 Introduction . . . . . . . . . . . 41.1 Characteristics and Advantages 42 Structure . . . . . . . . . . . . . 52.1 Basic Forms . . . . . . . . . . . . . . . . 53 Properties . . . . . . . . . . . . . 63.1 Physical Properties . . . . . . . . . . 63.2 Chemical Properties . . . . . . . . . 64 Lubrication . . . . . . . . . . . . 74.1 Choice of Lubricant . . . . . . . . . . 74.2 Friction . . . . . . . . . . . . . . . . . . . . 94.3 Lubricated Environments . . . . . 9Lubrication . . . . . . . . . . . . . . . . . . 94.4 Characteristics of FluidLubricated DX Bearings . . . . . 104.5 Design Guidance for FluidLubricated Applications . . . . . 104.6 Wear Rate and RelubricationIntervals with Greaselubrication . . . . . . . . . . . . . . . . 12Fretting Wear . . . . . . . . . . . . . . . 125 Design Factors . . . . . . . 135.1 Specific Load . . . . . . . . . . . . . . 13Specific Load Limit . . . . . . . . . . . 135.2 Sliding Speed . . . . . . . . . . . . . . 14Continuous Rotation . . . . . . . . . 14Oscillating Movement . . . . . . . . 145.3 pU Factor . . . . . . . . . . . . . . . . . 155.4 Load . . . . . . . . . . . . . . . . . . . . . 15Type of Load . . . . . . . . . . . . . . . 155.5 Temperature . . . . . . . . . . . . . . . 175.6 Mating Surface . . . . . . . . . . . . . 175.7 Bearing Size . . . . . . . . . . . . . . . 185.8 Estimation of Bearing ServiceLife with Grease Lubrication . 18Calculation Parameters . . . . . . . 18Estimate Bearing Life . . . . . . . . . 19Estimate Re-greasing Interval . . 19Oscillating Motion . . . . . . . . . . . 19Dynamic Loads . . . . . . . . . . . . . 195.9 Worked Examples . . . . . . . . . . 206 Data Sheet . . . . . . . . . . . 216.1 Data for bearing designcalculations . . . . . . . . . . . . . . . 217 Bearing Assembly . . . . . 227.1 Dimensions and Tolerances . . 227.2 Tolerances for minimumclearance . . . . . . . . . . . . . . . . . . 22Grease lubrication . . . . . . . . . . . 22Fluid Lubrication . . . . . . . . . . . . . 24Allowance for ThermalExpansion . . . . . . . . . . . . . . . . . 247.3 Counterface Design . . . . . . . . . 257.4 Installation . . . . . . . . . . . . . . . . 26Fitting of Bushes . . . . . . . . . . . . 26Insertion Forces . . . . . . . . . . . . . 26Alignment . . . . . . . . . . . . . . . . . . 27Sealing . . . . . . . . . . . . . . . . . . . . 27Axial Location . . . . . . . . . . . . . . . 27Fitting of Thrust Washers . . . . . . 27Slideways . . . . . . . . . . . . . . . . . . 288 Machining . . . . . . . . . . . 298.1 Machining Practice . . . . . . . . . 298.2 Boring . . . . . . . . . . . . . . . . . . . . 298.3 Reaming . . . . . . . . . . . . . . . . . . 308.4 Broaching . . . . . . . . . . . . . . . . . 308.5 Vibrobroaching . . . . . . . . . . . . . 318.6 Modification of components . . 318.7 Drilling Oil Holes . . . . . . . . . . . 318.8 Cutting Strip Material . . . . . . . . 319 Electroplating . . . . . . . . 32DX Components . . . . . . . . . . . . . 32Mating Surfaces . . . . . . . . . . . . . 3210 Standard Products . . . . 3310.1 PM-DX cylindrical bushes . . . . 3310.2 MB-DX cylindrical bushes . . . . 4010.3 Inch DX cylindrical bushes . . . 4510.4 DX Thrust Washers - metric . . 4810.5 DX Thrust Washers - inch . . . . 4910.6 DX Strip - metric . . . . . . . . . . . . 5010.7 DX Strip - inch . . . . . . . . . . . . . 503