The W6 Chemical pilot plant is used to provide ... - GEA Messo PT

The W6 Chemical pilot plant is used to provide ... - GEA Messo PT

The W6 Chemical pilot plant is used to provide ... - GEA Messo PT

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

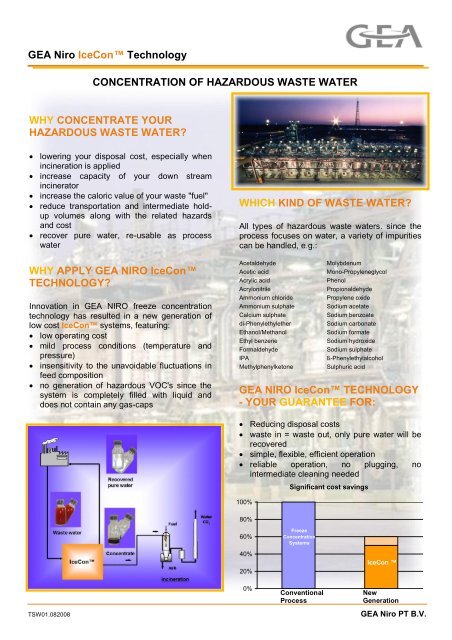

<strong>GEA</strong> Niro IceCon TechnologyCONCENTRATION OF HAZARDOUS WASTE WATERWHY CONCENTRATE YOURHAZARDOUS WASTE WATER? lowering your d<strong>is</strong>posal cost, especially whenincineration <strong>is</strong> applied increase capacity of your down streamincinera<strong>to</strong>r increase the caloric value of your waste "fuel" reduce transportation and intermediate holdupvolumes along with the related hazardsand cost recover pure water, re-usable as processwaterWHY APPLY <strong>GEA</strong> NIRO IceConTECHNOLOGY?Innovation in <strong>GEA</strong> NIRO freeze concentrationtechnology has resulted in a new generation oflow cost IceCon systems, featuring: low operating cost mild process conditions (temperature andpressure) insensitivity <strong>to</strong> the unavoidable fluctuations infeed composition no generation of hazardous VOC's since thesystem <strong>is</strong> completely filled with liquid anddoes not contain any gas-capsWHICH KIND OF WASTE WATER?All types of hazardous waste waters. since theprocess focuses on water, a variety of impuritiescan be handled, e.g.:AcetaldehydeAcetic acidAcrylic acidAcrylonitrileAmmonium chlorideAmmonium sulphateCalcium sulphatedi-PhenylethyletherEthanol/MethanolEthyl benzeneFormaldehydeIPAMethylphenylke<strong>to</strong>neMolybdenumMono-PropyleneglycolPhenolPropionaldehydePropylene oxideSodium acetateSodium benzoateSodium carbonateSodium formateSodium hydroxideSodium sulphateß-PhenylethylalcoholSulphuric acid<strong>GEA</strong> NIRO IceCon TECHNOLOGY- YOUR GUARANTEE FOR: Reducing d<strong>is</strong>posal costs waste in = waste out, only pure water will berecovered simple, flexible, efficient operation reliable operation, no plugging, nointermediate cleaning needed100%Significant cost savings80%60%FreezeConcentrationSystems40%20%IceCon 0%ConventionalProcessNewGenerationTSW01.082008<strong>GEA</strong> Niro <strong>PT</strong> B.V.

<strong>GEA</strong> Niro IceCon TechnologyPlease allow us <strong>to</strong> introduce ourselves:For over 30 years <strong>GEA</strong> Niro <strong>PT</strong> B.V. <strong>is</strong> activein the food-, chemical- and wastewaterindustry. We are a subsidiary of the ProcessEngineering Div<strong>is</strong>ion within <strong>GEA</strong> Niro A/S,part of the German technology group <strong>GEA</strong>AG. <strong>The</strong> group <strong>is</strong> one of the world's largestsuppliers of food processing equipment. <strong>The</strong><strong>GEA</strong> Niro technology range includes systemsfor liquid processing, drying, processing ofparticulates and solids, and pollutioncontrol/waste management. <strong>GEA</strong> Niro <strong>PT</strong> B.V.offers <strong>to</strong>tal engineering capability, havingaccess <strong>to</strong> vast know-how as regards thesystems and processes where thecrystallization and separation technology <strong>is</strong>fitted in. <strong>GEA</strong> Niro <strong>PT</strong> B.V. operates aworldwide network of sales and service officesand authorized representatives, whichensures quick and professional cus<strong>to</strong>mersupport.<strong>The</strong> main activities of <strong>GEA</strong> Niro <strong>PT</strong> B.V. are: Development and research in crystallizationandseparation technology. Constantinnovative research and development <strong>is</strong>taking place for process and equipmentdevelopment in order <strong>to</strong> create industrialsystems <strong>to</strong> purify and separate crystals froman organic or aqueous liquid. <strong>The</strong> separationtechnology <strong>is</strong> based on the wash columnprinciple where a selective separation of purecrystals <strong>is</strong> performed. Design and engineering of crystallization andseparation equipment. Assembly of equipment for crystallization andseparation Delivery of systems:o Freeze concentra<strong>to</strong>rso Scraped surface heat exchangerso Crystallizerso Wash column separa<strong>to</strong>rs Research, testing, training and maintenance<strong>The</strong>se activities are practiced in: the liquid food industry the chemical industry the pharmaceutical/biotechnological/cosmetic industry the waste water industry<strong>GEA</strong> Niro <strong>PT</strong> B.V. supplies its commercialsystems worldwide since 1975 for a wide varietyof applications.<strong>GEA</strong> Niro <strong>PT</strong> B.V. has been certified according<strong>to</strong> DIN ISO 9001 standard since 1996 andsince June 2003 the new ISO 9001:2000standards were implemented following anaudit by the international bureau Lloyd'sReg<strong>is</strong>ter Quality Assurance.<strong>GEA</strong> Niro <strong>PT</strong> B.V.De Beverspijken 7b5221 EE ‘s-Her<strong>to</strong>genbosch<strong>The</strong> NetherlandsTel: +31 736 390 390Fax: +31 736 312 349info.niropt.nl@geagroup.comwww.niro-pt.nlTSW01.082008<strong>GEA</strong> Niro <strong>PT</strong> B.V.