IceCon New Generation of Freeze Concentrators - GEA Messo PT

IceCon New Generation of Freeze Concentrators - GEA Messo PT

IceCon New Generation of Freeze Concentrators - GEA Messo PT

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

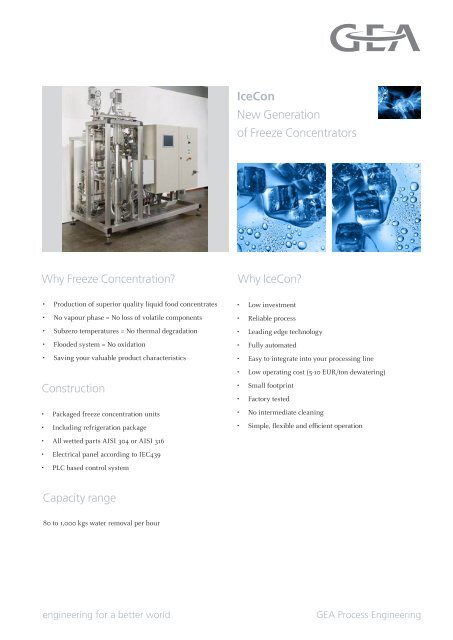

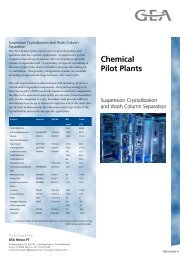

<strong>IceCon</strong><strong>New</strong> <strong>Generation</strong><strong>of</strong> <strong>Freeze</strong> <strong>Concentrators</strong>Why <strong>Freeze</strong> Concentration?Why <strong>IceCon</strong>?• Production <strong>of</strong> superior quality liquid food concentrates• No vapour phase = No loss <strong>of</strong> volatile components• Subzero temperatures = No thermal degradation• Flooded system = No oxidation• Saving your valuable product characteristicsConstruction• Packaged freeze concentration units• Including refrigeration package• All wetted parts AISI 304 or AISI 316• Electrical panel according to IEC439• PLC based control system• Low investment• Reliable process• Leading edge technology• Fully automated• Easy to integrate into your processing line• Low operating cost (5-10 EUR/ton dewatering)• Small footprint• Factory tested• No intermediate cleaning• Simple, flexible and efficient operationCapacity range80 to 1,000 kgs water removal per hourengineering for a better world<strong>GEA</strong> Process Engineering

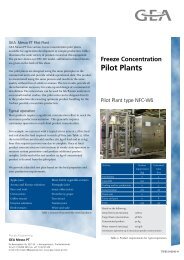

Concentration Processes<strong>Freeze</strong> ConcentrationWater removal is the key to concentration <strong>of</strong> all aqueousproducts. Various methods are available to remove water fromliquid food products. They can be divided into three maincategories:1. Vapour liquid separation Evaporation converts water(and other volatile components) into a vapour that can beseparated from the concentrated liquid.2. Liquid-liquid separationMembrane technology provides a barrier that allowswater (and all smaller molecules) to pass.3. Solid-liquid separationCrystallization converts the water into pure solid icecrystals. Solid-liquid separators are required to removethe ice.Evaporation is the most common and the most appliedtechnique for concentration. The limited selectivity and hightemperatures generally result in relatively poor retention <strong>of</strong> theoriginal product quality.Membranes can provide low operational costs but provide arelatively poor concentration factor and limited selectivity.Crystallization provides the highest selectivity toward waterremoval in that only water is included into the ice crystal. Thelow operating temperatures help to maintain the activity <strong>of</strong>sensitive nutritional and flavour components. Efficient solidliquidseparation technology is required and ensures that onlythe ice crystal (pure water) is removed from the product.Crystallization <strong>of</strong> water from liquid products has commonlybeen referred to as <strong>Freeze</strong> Concentration. The process hasbeen applied in various forms for centuries. In its earliest formit was as simple as leaving a barrel filled with product outsidein the winter and then draining the remaining liquid asconcentrated product. The ice is formed as pure water crystalsand everything else remains in the liquid. The early forms <strong>of</strong>freeze concentration generally had problems in efficientlyremoving the ice crystals as pure water. The concentratedproduct would stick to the ice surfaces resulting in undesirableproduct losses. <strong>GEA</strong> <strong>Messo</strong> <strong>PT</strong> has enhanced the freezeconcentration process with its unique solid-liquid separationinto a sophisticated process that effectively eliminates theselosses and fits perfectly into the modern processing plant. Theschematic illustrates a basic single-stage freeze concentrationprocess based on the patented <strong>GEA</strong> <strong>Messo</strong> <strong>PT</strong> process. Thistechnique creates the optimum growth conditions for anefficient separation <strong>of</strong> the ice crystals and provides the highestconcentration factor for most food liquids.Commercial systems are designed from standard componentsizes depending on your throughput requirements. Multistagesystems allow for any capacity from 10 to 10,000 kg/h.<strong>Freeze</strong> Concentration – precision water removal atfreezing temperatures ensuring product quality at its technicalbest.The feed product enters the scraped surfaceheat exchanger (crystallizer) where therefrigerant cools the product and producesvery small ice crystals (nuclei).These small crystals flow into therecrystallizer where they are allowed time togrow into large spherical ice crystals.Since these crystals are pure water the finalstep is removal in the <strong>GEA</strong> <strong>Messo</strong> <strong>PT</strong> washcolumn.The separation provided by this uniquedevice is so complete that the losses arebarely measurable.Next Steps – for more information regarding this technology and your specific configuration, please contact us at:info.niropt.nl@gea.com or phone +31.73 6390 390.<strong>GEA</strong> <strong>Messo</strong> <strong>PT</strong>De Beverspijken 7b, 5221 EE ‘s-Hertogenbosch, The NetherlandsTel +31 73 6390 390, Fax +31 73 6312 349info.niropt.nl@gea.com, www.gea-messo-pt.comTSF11.052012-H