The W6 Chemical pilot plant is used to provide ... - GEA Messo PT

The W6 Chemical pilot plant is used to provide ... - GEA Messo PT

The W6 Chemical pilot plant is used to provide ... - GEA Messo PT

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

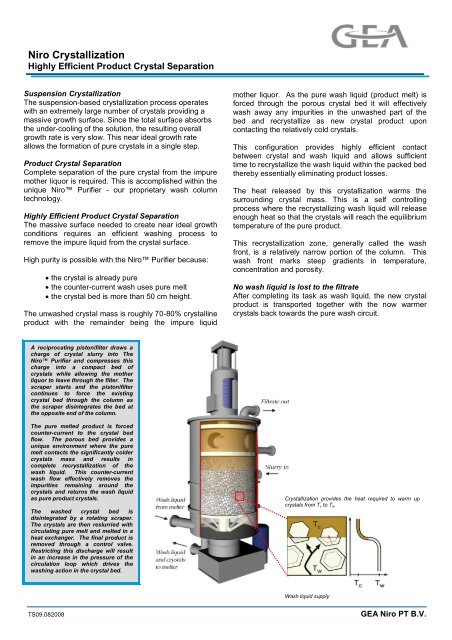

Niro CrystallizationHighly Efficient Product Crystal SeparationSuspension Crystallization<strong>The</strong> suspension-based crystallization process operateswith an extremely large number of crystals providing amassive growth surface. Since the <strong>to</strong>tal surface absorbsthe under-cooling of the solution, the resulting overallgrowth rate <strong>is</strong> very slow. Th<strong>is</strong> near ideal growth rateallows the formation of pure crystals in a single step.Product Crystal SeparationComplete separation of the pure crystal from the impuremother liquor <strong>is</strong> required. Th<strong>is</strong> <strong>is</strong> accompl<strong>is</strong>hed within theunique Niro Purifier - our proprietary wash columntechnology.Highly Efficient Product Crystal Separation<strong>The</strong> massive surface needed <strong>to</strong> create near ideal growthconditions requires an efficient washing process <strong>to</strong>remove the impure liquid from the crystal surface.High purity <strong>is</strong> possible with the Niro Purifier because: the crystal <strong>is</strong> already pure the counter-current wash uses pure melt the crystal bed <strong>is</strong> more than 50 cm height.<strong>The</strong> unwashed crystal mass <strong>is</strong> roughly 70-80% crystallineproduct with the remainder being the impure liquidmother liquor. As the pure wash liquid (product melt) <strong>is</strong>forced through the porous crystal bed it will effectivelywash away any impurities in the unwashed part of thebed and recrystallize as new crystal product uponcontacting the relatively cold crystals.Th<strong>is</strong> configuration <strong>provide</strong>s highly efficient contactbetween crystal and wash liquid and allows sufficienttime <strong>to</strong> recrystallize the wash liquid within the packed bedthereby essentially eliminating product losses.<strong>The</strong> heat released by th<strong>is</strong> crystallization warms thesurrounding crystal mass. Th<strong>is</strong> <strong>is</strong> a self controllingprocess where the recrystallizing wash liquid will releaseenough heat so that the crystals will reach the equilibriumtemperature of the pure product.Th<strong>is</strong> recrystallization zone, generally called the washfront, <strong>is</strong> a relatively narrow portion of the column. Th<strong>is</strong>wash front marks steep gradients in temperature,concentration and porosity.No wash liquid <strong>is</strong> lost <strong>to</strong> the filtrateAfter completing its task as wash liquid, the new crystalproduct <strong>is</strong> transported <strong>to</strong>gether with the now warmercrystals back <strong>to</strong>wards the pure wash circuit.A reciprocating p<strong>is</strong><strong>to</strong>n/filter draws acharge of crystal slurry in<strong>to</strong> <strong>The</strong>Niro Purifier and compresses th<strong>is</strong>charge in<strong>to</strong> a compact bed ofcrystals while allowing the motherliquor <strong>to</strong> leave through the filter. <strong>The</strong>scraper starts and the p<strong>is</strong><strong>to</strong>n/filtercontinues <strong>to</strong> force the ex<strong>is</strong>tingcrystal bed through the column asthe scraper d<strong>is</strong>integrates the bed atthe opposite end of the column.<strong>The</strong> pure melted product <strong>is</strong> forcedcounter-current <strong>to</strong> the crystal bedflow. <strong>The</strong> porous bed <strong>provide</strong>s aunique environment where the puremelt contacts the significantly coldercrystals mass and results incomplete recrystallization of thewash liquid. Th<strong>is</strong> counter-currentwash flow effectively removes theimpurities remaining around thecrystals and returns the wash liquidas pure product crystals.<strong>The</strong> washed crystal bed <strong>is</strong>d<strong>is</strong>integrated by a rotating scraper.<strong>The</strong> crystals are then reslurried withcirculating pure melt and melted in aheat exchanger. <strong>The</strong> final product <strong>is</strong>removed through a control valve.Restricting th<strong>is</strong> d<strong>is</strong>charge will resultin an increase in the pressure of thecirculation loop which drives thewashing action in the crystal bed.Crystallization <strong>provide</strong>s the heat required <strong>to</strong> warm upcrystals from T c <strong>to</strong> T wWash liquid supplyTS09.082008<strong>GEA</strong> Niro <strong>PT</strong> B.V.