Senior DCS/Instrument Engineer - thinkplusmanpower.com

Senior DCS/Instrument Engineer - thinkplusmanpower.com

Senior DCS/Instrument Engineer - thinkplusmanpower.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Function: Manufacturing<br />

Department: Maintenance<br />

Division: Methods Reliability<br />

Section: <strong>Instrument</strong>ation<br />

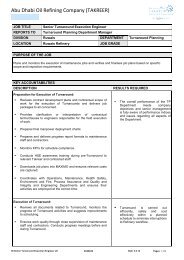

JOB TITLE<br />

Grade Code: 00<br />

SAP Job Code: 709<br />

Revision: 00<br />

SAUDI ARAMCO TOTAL Refining and Petrochemical Company<br />

JOB DESCRIPTION<br />

<strong>Senior</strong> <strong>DCS</strong>/<strong>Instrument</strong> <strong>Engineer</strong><br />

SITUATION IN ORGANIZATION (enclose a copy of your organization chart)<br />

BASIC FUNCTION<br />

Job Purpose:<br />

To lead the technical management, documentation and failure analysis on Digital Control Systems (<strong>DCS</strong>) and<br />

<strong>Instrument</strong>ation securing the inherent reliability and availability of such systems on the Refinery.<br />

Scope:<br />

Manage the <strong>DCS</strong> and <strong>Instrument</strong>ation team of <strong>Engineer</strong>s and technicians, providing technical support to the maintenance<br />

and operation of automation equipment on the Refinery. Ensure that all maintenance activities are carried out in<br />

accordance with SATORP’s quality and safety standards, specifications and reliability best practices.

MAIN ACTIVITIES<br />

Duties and Responsibilities:<br />

1. Provide functional Supervision to <strong>DCS</strong>/<strong>Instrument</strong>al personnel and support them in performing their assigned duties.<br />

2. Improve <strong>DCS</strong>/<strong>Instrument</strong>al reliability and availability through the implementation of Reliability <strong>Engineer</strong>ing principles,<br />

techniques and tools, such as Risk Based Maintenance (RBM) and Root Cause Failure Analysis (RCFA).<br />

3. Coordinate with other Maintenance Divisions and the Operations Department in SATORP to discuss, develop, review<br />

and manage <strong>DCS</strong>/<strong>Instrument</strong>al maintenance and reliability strategies.<br />

4. Contribute to the development of Predictive and Preventative Maintenance plans and procedures for all<br />

<strong>DCS</strong>/<strong>Instrument</strong>al equipment, and provide technical expertise for <strong>DCS</strong>/<strong>Instrument</strong>al maintenance activities, standards<br />

and procedures.<br />

5. Provide technical assistance and trouble-shooting support for all automation equipment, and ensure that all<br />

maintenance activities and procedures are aligned with reliability requirements.<br />

6. Lead and manage the <strong>DCS</strong> and <strong>Instrument</strong> equipment team, establishing clear goals and objectives related to the<br />

reliable performance of all automation equipment. Provide mentoring and coaching to assure development of<br />

personnel.<br />

7. Work closely with other Maintenance Divisions to determine and predict <strong>DCS</strong>/<strong>Instrument</strong>al <strong>com</strong>ponents’ life using<br />

appropriate reliability tools, such as Failure Modes and Effects Analysis (FMEA), Mean time between failures (MTBF)<br />

and Mean Time To Failure (MTTF), to ensure extended operating life of <strong>DCS</strong>/<strong>Instrument</strong>al equipment.<br />

8. Provide technical advice with regards to searching for and preparing new <strong>DCS</strong>/<strong>Instrument</strong>al proposals, and review<br />

equipment specifications, documents and drawings.<br />

9. Ensure keeping, maintaining and updating a database of all historical data pertaining to relevant equipment failures,<br />

and assist in analyzing failure data and preparing reliability test report.<br />

10. Define spare part requirements, employing Risk Based Maintenance and FMECA, perform regular audits to ensure<br />

working capital is optimised, stock levels are maintained and obsolete equipment are removed.<br />

11. Maximise automation equipment availability.<br />

12. Coordinate the training of <strong>DCS</strong> <strong>Engineer</strong>s, <strong>Instrument</strong> <strong>Engineer</strong>s and <strong>Instrument</strong> Technicians on general knowledge of<br />

<strong>DCS</strong> and instrumentation, performance monitoring technologies and awareness of safe working practices.<br />

13. Define, manage and review <strong>DCS</strong> and <strong>Instrument</strong> maintenance strategies. Develop maintenance procedures to<br />

support these strategies. Provide technical assistance and trouble-shooting support for all automation equipment.<br />

14. Develop ten-year renovation plans / budgets based on risk management of obsolescence equipment. Approve and<br />

supervise the engineering and design of modifications (technical) for all automation equipment and support systems.<br />

15. Perform other related duties as assigned by the Superintendent Methods Reliability.<br />

Expected Results:<br />

Safe and reliable operation of automation equipment, increased time between failures and reduced equipment<br />

maintenance costs. Applicable maintenance strategies and procedures in place and followed.<br />

Required Resources:<br />

PRINCIPAL CONTACTS (CONTEXT AND ENVIRONMENT)<br />

Internal:<br />

Superintendent Methods Reliability, Routine Maintenance Division, Operations Department, and other concerned<br />

SATORP’s Organizations.<br />

External:<br />

Equipment Manufacturers, Service Providers, and Maintenance Contractors.<br />

2/3

JOB PERFORMANCE DIMENSIONS<br />

• Manage a $10 million USD budget.<br />

MINIMUM REQUIREMENTS (QUALIFICATIONS / EXPERIENCE REQUIRED)<br />

Main Competencies and Qualities:<br />

• Ability to define maintenance strategies using FMECA and RBM methodologies.<br />

• Strong knowledge of <strong>Instrument</strong> Equipment functions from maintenance and reliability point of view.<br />

• Strong knowledge of Control Loop Tuning and Advanced Control schemes.<br />

• Strong knowledge of related health, safety and environmental regulations.<br />

• Capable of handling multiple tasks.<br />

• Strong interpersonal <strong>com</strong>munication skills.<br />

• Ability to continuously drive for process improvement.<br />

• Ability to work under pressure and meet tight deadlines.<br />

• Strong <strong>com</strong>mands of oral and written English.<br />

Education Background:<br />

Bachelor’s Degree in <strong>Engineer</strong>ing or equivalent.<br />

Experience:<br />

Eight (8) years of experience in <strong>Engineer</strong>ing and Maintenance of Electrical Equipment, of which at least Four (4) years in<br />

a similar position.<br />

Date: Approval: Fareed Kamfar, Manager Maintenance<br />

Job Holder:<br />

Signature:<br />

Date:<br />

Signature:<br />

3/3