Distinctively - CENTRIA

Distinctively - CENTRIA

Distinctively - CENTRIA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FormaBond®<br />

Metal Composite<br />

Wall System *<br />

<strong>Distinctively</strong> Superior.<br />

<strong>CENTRIA</strong> revolutionizes the thin aluminum composite panel<br />

industry with FormaBond. Unlike traditional ACM – that’s made<br />

through lamination, then fabricated into panels by a second<br />

party – FormaBond is manufactured entirely by <strong>CENTRIA</strong> using<br />

a proprietary reaction injection molding process. The result is a<br />

patented, stronger, flatter and finished ACM panel, complete with<br />

pressure-equalized joinery.<br />

Patented dry joinery eliminates wet seals and provides optimum<br />

venting to allow wall cavities to dry effectively while prohibiting<br />

the entry of rainwater, thus reducing the chance of entrapped<br />

moisture, material degradation and mold. Specify FormaBond and<br />

elevate the quality and integrity of your next ACM wall system.<br />

*Patent no: US 7,007,433 B2<br />

18 FormaBond<br />

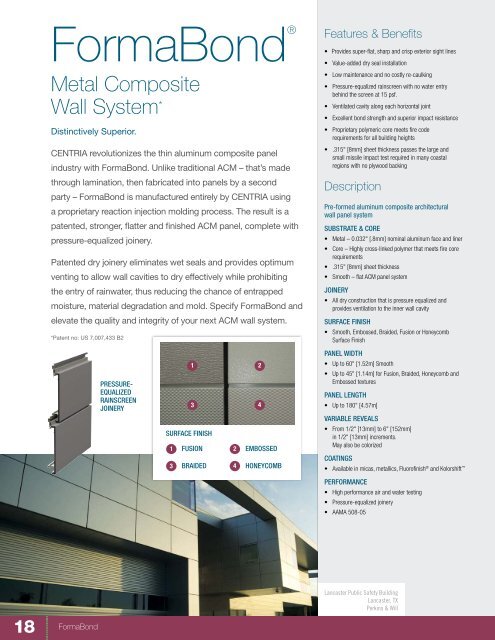

PRESSURE-<br />

EQUALIZED<br />

RAINSCREEN<br />

JOINERY<br />

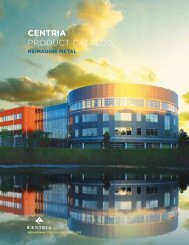

SURFACE FINISH<br />

1 2<br />

3 4<br />

1 FUSION 2 EmBOSSED<br />

3 BRAIDED 4 HONEYCOmB<br />

Features & Benefits<br />

• Provides super-flat, sharp and crisp exterior sight lines<br />

• Value-added dry seal installation<br />

• Low maintenance and no costly re-caulking<br />

• Pressure-equalized rainscreen with no water entry<br />

behind the screen at 15 psf.<br />

• Ventilated cavity along each horizontal joint<br />

• Excellent bond strength and superior impact resistance<br />

• Proprietary polymeric core meets fire code<br />

requirements for all building heights<br />

• .315" [8mm] sheet thickness passes the large and<br />

small missile impact test required in many coastal<br />

regions with no plywood backing<br />

Description<br />

Pre-formed aluminum composite architectural<br />

wall panel system<br />

SUBSTRATE & CORE<br />

• Metal – 0.032" [.8mm] nominal aluminum face and liner<br />

• Core – Highly cross-linked polymer that meets fire core<br />

requirements<br />

• .315" [8mm] sheet thickness<br />

• Smooth – flat ACM panel system<br />

JOINERY<br />

• All dry construction that is pressure equalized and<br />

provides ventilation to the inner wall cavity<br />

SURFACE FINISH<br />

• Smooth, Embossed, Braided, Fusion or Honeycomb<br />

Surface Finish<br />

PANEL WIDTH<br />

• Up to 60" [1.52m] Smooth<br />

• Up to 45" [1.14m] for Fusion, Braided, Honeycomb and<br />

Embossed textures<br />

PANEL LENGTH<br />

• Up to 180" [4.57m]<br />

VARIABLE REVEALS<br />

• From 1/2" [13mm] to 6" [152mm]<br />

in 1/2" [13mm] increments.<br />

May also be colorized<br />

COATINGS<br />

• Available in micas, metallics, Fluorofinish ® and Kolorshift PERFORmANCE<br />

• High performance air and water testing<br />

• Pressure-equalized joinery<br />

• AAMA 508-05<br />

Lancaster Public Safety Building<br />

Lancaster, TX<br />

Perkins & Will