Guide Extensive wastewater treatment process

Guide Extensive wastewater treatment process

Guide Extensive wastewater treatment process

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4<br />

An exception is made for lagooning. Indeed, analyses concerning discharges from this type of installation shall be carried<br />

out on filtered samples. However, the concentration of total suspended solids in unfiltered water samples must<br />

not exceed 150 mg/l.<br />

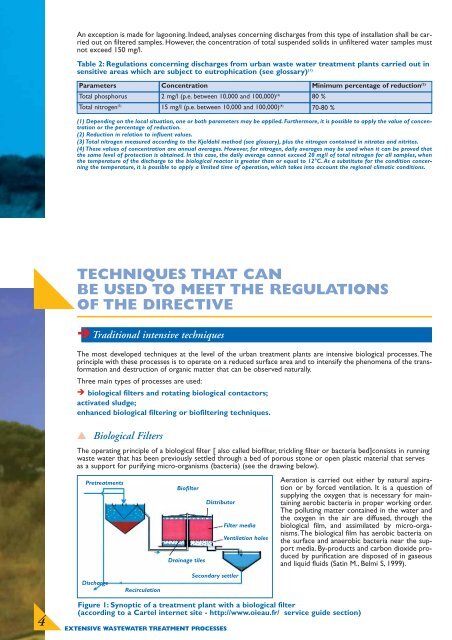

Table 2: Regulations concerning discharges from urban waste water <strong>treatment</strong> plants carried out in<br />

sensitive areas which are subject to eutrophication (see glossary) (1)<br />

Parameters Concentration Minimum percentage of reduction (2)<br />

Total phosphorus 2 mg/l (p.e. between 10,000 and 100,000) (4) 80 %<br />

Total nitrogen (3) 15 mg/l (p.e. between 10,000 and 100,000) (4)<br />

70-80 %<br />

(1) Depending on the local situation, one or both parameters may be applied. Furthermore, it is possible to apply the value of concentration<br />

or the percentage of reduction.<br />

(2) Reduction in relation to influent values.<br />

(3) Total nitrogen measured according to the Kjeldahl method (see glossary), plus the nitrogen contained in nitrates and nitrites.<br />

(4) These values of concentration are annual averages. However, for nitrogen, daily averages may be used when it can be proved that<br />

the same level of protection is obtained. In this case, the daily average cannot exceed 20 mg/l of total nitrogen for all samples, when<br />

the temperature of the discharge to the biological reactor is greater than or equal to 12°C. As a substitute for the condition concerning<br />

the temperature, it is possible to apply a limited time of operation, which takes into account the regional climatic conditions.<br />

TECHNIQUES THAT CAN<br />

BE USED TO MEET THE REGULATIONS<br />

OF THE DIRECTIVE<br />

�Traditional intensive techniques<br />

The most developed techniques at the level of the urban <strong>treatment</strong> plants are intensive biological <strong>process</strong>es. The<br />

principle with these <strong>process</strong>es is to operate on a reduced surface area and to intensify the phenomena of the transformation<br />

and destruction of organic matter that can be observed naturally.<br />

Three main types of <strong>process</strong>es are used:<br />

� biological filters and rotating biological contactors;<br />

activated sludge;<br />

enhanced biological filtering or biofiltering techniques.<br />

▲ Biological Filters<br />

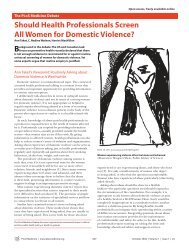

The operating principle of a biological filter [ also called biofilter, trickling filter or bacteria bed]consists in running<br />

waste water that has been previously settled through a bed of porous stone or open plastic material that serves<br />

as a support for purifying micro-organisms (bacteria) (see the drawing below).<br />

Pre<strong>treatment</strong>s<br />

Discharge<br />

Recirculation<br />

Biofilter<br />

Drainage tiles<br />

Distributor<br />

Secondary settler<br />

EXTENSIVE WASTEWATER TREATMENT PROCESSES<br />

Filter media<br />

Ventilation holes<br />

Aeration is carried out either by natural aspiration<br />

or by forced ventilation. It is a question of<br />

supplying the oxygen that is necessary for maintaining<br />

aerobic bacteria in proper working order.<br />

The polluting matter contained in the water and<br />

the oxygen in the air are diffused, through the<br />

biological film, and assimilated by micro-organisms.The<br />

biological film has aerobic bacteria on<br />

the surface and anaerobic bacteria near the support<br />

media. By-products and carbon dioxide produced<br />

by purification are disposed of in gaseous<br />

and liquid fluids (Satin M., Belmi S, 1999).<br />

Figure 1: Synoptic of a <strong>treatment</strong> plant with a biological filter<br />

(according to a Cartel internet site - http://www.oieau.fr/ service guide section)