Metal Lath Galvanized Junior™ Mesh (LAM) (P)* (O)* (S ...

Metal Lath Galvanized Junior™ Mesh (LAM) (P)* (O)* (S ...

Metal Lath Galvanized Junior™ Mesh (LAM) (P)* (O)* (S ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

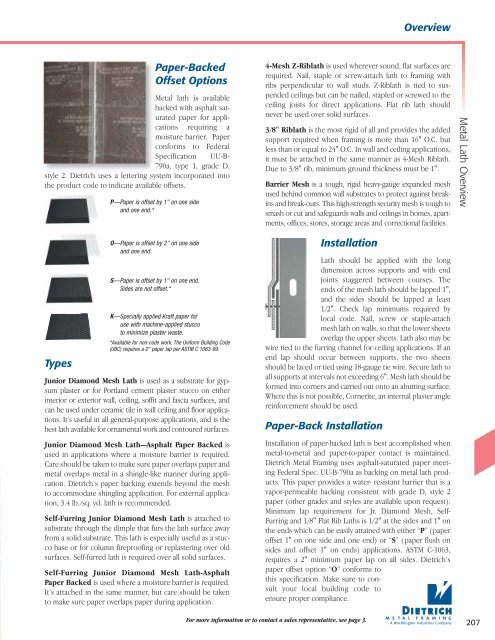

Paper-Backed<br />

Offset Options<br />

<strong>Metal</strong> lath is available<br />

backed with asphalt saturated<br />

paper for applications<br />

requiring a<br />

moisture barrier. Paper<br />

conforms to Federal<br />

Specification UU-B-<br />

790a, type 1, grade D,<br />

style 2. Dietrich uses a lettering system incorporated into<br />

the product code to indicate available offsets.<br />

Types<br />

P—Paper is offset by 1" on one side<br />

and one end.*<br />

O—Paper is offset by 2" on one side<br />

and one end.<br />

S—Paper is offset by 1" on one end.<br />

Sides are not offset.*<br />

K—Specially applied Kraft paper for<br />

use with machine-applied stucco<br />

to minimize plaster waste.<br />

*Available for non-code work. The Uniform Building Code<br />

(UBC) requires a 2" paper lap per ASTM C 1063-99.<br />

Junior Diamond <strong>Mesh</strong> <strong>Lath</strong> is used as a substrate for gypsum<br />

plaster or for Portland cement plaster stucco on either<br />

interior or exterior wall, ceiling, soffit and fascia surfaces, and<br />

can be used under ceramic tile in wall ceiling and floor applications.<br />

It’s useful in all general-purpose applications, and is the<br />

best lath available for ornamental work and contoured surfaces.<br />

Junior Diamond <strong>Mesh</strong> <strong>Lath</strong>—Asphalt Paper Backed is<br />

used in applications where a moisture barrier is required.<br />

Care should be taken to make sure paper overlaps paper and<br />

metal overlaps metal in a shingle-like manner during application.<br />

Dietrich’s paper backing extends beyond the mesh<br />

to accommodate shingling application. For external application,<br />

3.4 lb./sq. yd. lath is recommended.<br />

Self-Furring Junior Diamond <strong>Mesh</strong> <strong>Lath</strong> is attached to<br />

substrate through the dimple that furs the lath surface away<br />

from a solid substrate. This lath is especially useful as a stucco<br />

base or for column fireproofing or replastering over old<br />

surfaces. Self-furred lath is required over all solid surfaces.<br />

Self-Furring Junior Diamond <strong>Mesh</strong> <strong>Lath</strong>-Asphalt<br />

Paper Backed is used where a moisture barrier is required.<br />

It’s attached in the same manner, but care should be taken<br />

to make sure paper overlaps paper during application.<br />

For more information or to contact a sales representative, see page 3.<br />

Overview<br />

4-<strong>Mesh</strong> Z-Riblath is used wherever sound, flat surfaces are<br />

required. Nail, staple or screw-attach lath to framing with<br />

ribs perpendicular to wall studs. Z-Riblath is tied to suspended<br />

ceilings but can be nailed, stapled or screwed to the<br />

ceiling joists for direct applications. Flat rib lath should<br />

never be used over solid surfaces.<br />

3/8" Riblath is the most rigid of all and provides the added<br />

support required when framing is more than 16" O.C. but<br />

less than or equal to 24" O.C. In wall and ceiling applications,<br />

it must be attached in the same manner as 4-<strong>Mesh</strong> Riblath.<br />

Due to 3/8" rib, minimum ground thickness must be 1".<br />

Barrier <strong>Mesh</strong> is a tough, rigid heavy-gauge expanded mesh<br />

used behind common wall substrates to protect against breakins<br />

and break-outs. This high-strength security mesh is tough to<br />

smash or cut and safeguards walls and ceilings in homes, apartments,<br />

offices, stores, storage areas and correctional facilities.<br />

Installation<br />

<strong>Lath</strong> should be applied with the long<br />

dimension across supports and with end<br />

joints staggered between courses. The<br />

ends of the mesh lath should be lapped 1",<br />

and the sides should be lapped at least<br />

1/2". Check lap minimums required by<br />

local code. Nail, screw or staple-attach<br />

mesh lath on walls, so that the lower sheets<br />

overlap the upper sheets. <strong>Lath</strong> also may be<br />

wire tied to the furring channel for ceiling applications. If an<br />

end lap should occur between supports, the two sheets<br />

should be laced or tied using 18-gauge tie wire. Secure lath to<br />

all supports at intervals not exceeding 6". <strong>Mesh</strong> lath should be<br />

formed into corners and carried out onto an abutting surface.<br />

Where this is not possible, Cornerite, an internal plaster angle<br />

reinforcement should be used.<br />

Paper-Back Installation<br />

Installation of paper-backed lath is best accomplished when<br />

metal-to-metal and paper-to-paper contact is maintained.<br />

Dietrich <strong>Metal</strong> Framing uses asphalt-saturated paper meeting<br />

Federal Spec. UU-B-790a as backing on metal lath products.<br />

This paper provides a water- resistant barrier that is a<br />

vapor-permeable backing consistent with grade D, style 2<br />

paper (other grades and styles are available upon request).<br />

Minimum lap requirement for Jr. Diamond <strong>Mesh</strong>, Self-<br />

Furring and 1/8" Flat Rib <strong>Lath</strong>s is 1/2" at the sides and 1" on<br />

the ends which can be easily attained with either “P” (paper<br />

offset 1" on one side and one end) or “S” (paper flush on<br />

sides and offset 1" on ends) applications. ASTM C-1063,<br />

requires a 2" minimum paper lap on all sides. Dietrich’s<br />

paper offset option “O” conforms to<br />

this specification. Make sure to consult<br />

your local building code to<br />

ensure proper compliance.<br />

<strong>Metal</strong> <strong>Lath</strong> Overview<br />

207