Download MF6400 MF7400 HHP Brochure - Clarke and Pulman

Download MF6400 MF7400 HHP Brochure - Clarke and Pulman

Download MF6400 MF7400 HHP Brochure - Clarke and Pulman

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

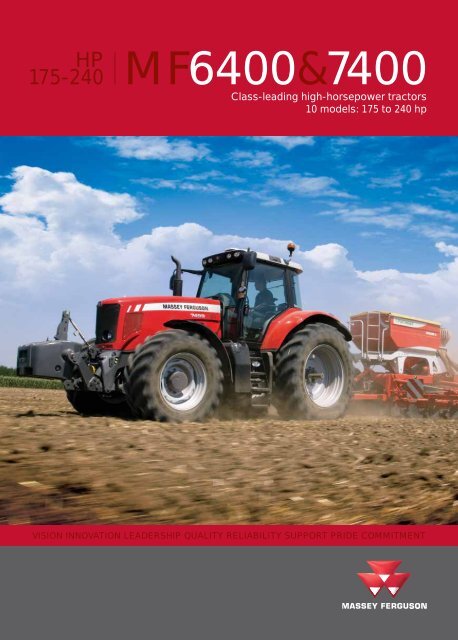

HP175-240 <strong>MF6400</strong>&7400Class-leading high-horsepower tractors10 models: 175 to 240 hpVISION INNOVATION LEADERSHIP QUALITY RELIABILITY SUPPORT PRIDE COMMITMENT

Unrivalled all-roundperformancePreferred by both farm managers, for economic reasons <strong>and</strong>by drivers for simply being a joy to operate, the latest MF 6400<strong>and</strong> MF 7400 Series tractors are rapidly becoming the newbenchmark in arable farming <strong>and</strong> contracting.So choose either MF 6400 Serieswith Dyna-6, the best semipowershifttransmission around,or MF 7400 Series, with Dyna-VT,Massey Ferguson’s unsurpassedCVT transmission, then start toenjoy the benefits of unrivalledoverall field efficiency.MF 6400 <strong>and</strong> MF 7400Series highlights• Two new models in the MF 7400Series range; The MF 7497<strong>and</strong> MF 7499 showcase biggerengines, higher torque <strong>and</strong>Dyna-VT transmissions whichnow include the Dynamic TractorManagement (DTM) systemfor complete engine <strong>and</strong>transmission control• Exceptionally low 70 d(B)A incabnoise level <strong>and</strong> automotivest<strong>and</strong>ards of comfort <strong>and</strong>controls reduce fatigue <strong>and</strong>increase productivity significantly• Latest generation AGCO SISUPOWER engines featuringcommon rail fuel injection <strong>and</strong>four-valve cylinder head designgive outst<strong>and</strong>ing power <strong>and</strong>torque delivery, excellent fueleconomy <strong>and</strong> lower emissions(Tier III compliant)• 50 km/h* maximum speed is nowavailable on all MF 6400 <strong>and</strong>MF 7400 models in this powerrange, reducing journeytimes <strong>and</strong> increasing haulageproductivity• Both transmissions featureclutchless operation, withleft-h<strong>and</strong> Power Control• The most comprehensive, yetsimple headl<strong>and</strong> managementsystems* reduce operatorworkload <strong>and</strong> increaseproductivity <strong>and</strong> work quality• Datatronic III is availablewith video capability <strong>and</strong>ISOBUS compatibilityMF 6485-99 <strong>and</strong> MF 7485-99models all have new-generationstyling, featuring:• A pivoting bonnet, giving easyaccess to the engine <strong>and</strong>cooling systems.• A new front axle support casting<strong>and</strong> ‘structural’ engine sumpthat enable fitment of theMassey Ferguson IFLS, fullyintegrated, factory-installed,front linkage <strong>and</strong> PTO.On MF 6400 models, the advancedDyna-6 transmission drivelineinteracts with the enginemanagement system to give evenmore power <strong>and</strong> torque for PTO<strong>and</strong> transport work.• All Dyna-6 models areavailable with the 50 km/h‘Eco’ transmission, givinghigh transport speeds withexceptionally low noise levels<strong>and</strong> reduced fuel consumption.*Specifications vary by model <strong>and</strong> market legislationThe MF 6400 <strong>and</strong> MF 7400 Model Line-UpModel Engine (AGCO SISU POWER) Capacity Rated hp 1 Max. hp 2 Max. PTO hp 3MF 6485 6 cyl. Turbo/intercooled 6.6 litre 160 175 160MF 6490 6 cyl. Turbo/intercooled 6.6 litre 170 185 170MF 6495 6 cyl. Turbo/intercooled 6.6 litre 185 198 180MF 6497 6 cyl. Turbo/intercooled 7.4 litre 200 215 195MF 6499 6 cyl. Turbo/intercooled 7.4 litre 215 230 205MF 7485 6 cyl. Turbo/intercooled 6.6 litre 165 180 160MF 7490 6 cyl. Turbo/intercooled 6.6 litre 175 190 170MF 7495 6 cyl. Turbo/intercooled 6.6 litre 190 203 180MF 7497 6 cyl. Turbo/intercooled 7.4 litre 205 225 195MF 7499 6 cyl. Turbo/intercooled 7.4 litre 220 240 2051ISO TR14396 (EG 97/68), at 2200 rpm.2ISO TR14396 (EG 97/68), at 2000 rpm.3OECD, at PTO shaft.0203

MF 6400 <strong>and</strong> MF 7400The driver’s choiceStraightforward ergonomic design, plenty of space, excellentvisibility <strong>and</strong> exceptionally low noise levels are the hallmarks ofthe MF 6400 <strong>and</strong> MF 7400 cab. Add to that, automotive industryquality materials <strong>and</strong> instrumentation, plus solid build quality <strong>and</strong>you have the ideal environment to spend a productive working day.01 MF 6400 Cab interior shown withDyna-6 transmission. Options showninclude AutoDrive, SMS <strong>and</strong> Datatronic III.02 MF 7400 cab interior (with optionalDatatronic III <strong>and</strong> fingertip spool valves).01Thoughtful designThe layout of the cab is spacious<strong>and</strong> well planned, with convenientlyplaced switches, superbinstrumentation <strong>and</strong> controlslogically grouped by function.All of the most frequently usedcontrols are mounted in theright-h<strong>and</strong> armrest, whichmoves with the seat so everythingalways falls readily to h<strong>and</strong>.Clarity at a glanceThe instruments display informationeither in digital, analogue or graphicform to present data in the mostappropriate way for optimum clarity.Quiet powerMF 6400 <strong>and</strong> MF 7400 tractorsare also exceptionally quiet, withsound levels inside the cab of70 dB(A) under load.The tone of the sound has alsobeen ‘tuned’ to further reduceany irritating noise, <strong>and</strong> levels ofvibration are minimised.The result is that working long,hard hours becomes far lessstressful <strong>and</strong> more productive. It’sa driving experience that really hasto be tried to be fully appreciated.A breath of fresh airThe heating <strong>and</strong> ventilationsystem has a large number ofadjustable outlets, providingexcellent air distribution <strong>and</strong>accurate temperature control.There is also a choice of eithermanually adjusted air conditioningor full climate control*, whichwill memorise your chosentemperature setting <strong>and</strong> return toit at start-up… automatically.Excellent visibilityA large area of tinted, heatreflectiveglass, narrow pillars<strong>and</strong> side-mounted exhaust allhelp to ensure excellent all-roundvisibility. Large telescopic rear viewmirrors - heated <strong>and</strong> electricallyadjustable on MF 7400 Series*,<strong>and</strong> optional on MF 6400 Series,are a further aid to safemanoeuvring <strong>and</strong> transport.The st<strong>and</strong>ard lighting givesexcellent night-time productivity,with Xenon lights available asan option for even higherdusk <strong>and</strong> evening productivity.* St<strong>and</strong>ard specifications vary by model<strong>and</strong> market040205

Quiet, comfortable<strong>and</strong> economical...whatever the taskThe st<strong>and</strong>ard seat provides exceptional comfortbut ride quality can be further enhanced...01 The high specification swivelling seat,featuring armrest-mounted controls <strong>and</strong> DynamicDamping System (DDS).02 Lumber adjustment switchon ‘super de-luxe’ seat.03 QuadLink <strong>and</strong> cabsuspension switches,giving full operator control.020304 - 05 Quadlink frontsuspension is integrated intothe design of the tractor.High specification seatsThe high specification, swivellingseat is fully adjustable includinglumbar support, pneumatic heightadjustment, plus height <strong>and</strong> fore<strong>and</strong> aft adjustment of the righth<strong>and</strong> armrest so that the armrestmountedcontrols can be perfectlypositioned. Options include a ‘lowfrequency’,super de-luxe seat*with double pneumatic lumbarsupport, heating <strong>and</strong> ‘activecarbon’ seat covering for greatercomfort in really hot conditions.QuadLink suspensionMF’s ‘QuadLink’ suspended frontaxle* further enhances ride comfort<strong>and</strong> control. It has a compact,simple design that automaticallymaintains a constant suspensionheight, regardless of axle load.The result is increased stability <strong>and</strong>a significant improvement in drivercomfort, productivity <strong>and</strong> safety...both on the road <strong>and</strong> in the field.Operator-controlledUnlike many other systems,QuadLink is operator-controlled soyou can choose whether to havethe system on or off.For example, when working in thefield with front linkage, where auniform depth of cultivation mustbe maintained, it is beneficial tobe able to deactivate the system.But when switched on, QuadLinkimproves comfort, safety <strong>and</strong>speed, especially in during loaderwork.Dual Stage suspended cabTo provide the ultimate in ridecomfort, MF’s cab suspensionsystem is available on allMF 6400 <strong>and</strong> MF 7400 Seriestractors. The design features ‘dualstage’ air suspension that can beadjusted at the flick of a switch,between two ride firmness settingsto suit field or road transportconditions. This unique operatorcontrolledsystem stabilises cabmovement more effectively <strong>and</strong>ensures a safer, more comfortableride in all conditions.Ride comfort improvementCompared to a ‘st<strong>and</strong>ard’ tractor,the overall effect of having a highspecification seat, QuadLinkfront axle suspension <strong>and</strong> cabsuspension can be a reduction invibration by up to 50% † .The result is greater comfort whenoperating for long periods, leadingto increased productivity, improvedwork quality <strong>and</strong> a more relaxingworking day.01 0406 ‘Dual stage’ cabsuspension system.06* St<strong>and</strong>ard specifications vary by model <strong>and</strong> market†Depending on speed <strong>and</strong> field or road conditions.050607

Plenty of power...<strong>and</strong> more in reserveAll models featured in this brochure are powered by AGCO SISUPOWER, Tier lll emissions compliant engines, featuring commonrail fuel injection <strong>and</strong> 4-valve cylinder head design. They deliverhigh power <strong>and</strong> torque <strong>and</strong> work in perfect harmony with the highlyefficient Dyna-6 <strong>and</strong> Dyna-VT transmissions to give superb field<strong>and</strong> transport capabilities, with excellent fuel economy.Power (PS)Power: MF 6485 - MF 6499BBAAPower increaseHigh power, with powerincrease as enginespeed falls between2200 <strong>and</strong> 2000 rpm.A:Normal power curve.B:Power Boost, availablewhen PTO is engagedor 3rd or 4th gearare selected.01 Common rail fuel injection: Morepower. More torque. Better fuel economy.Specific Fuel ConsumptionMore usable powerAll of the engines have significantlymore power at 2,000 rpm than at2,200 rpm (rated engine speed).This ‘power bulge’ gives incrediblelugging ability to pull throughdifficult conditions or to helphaul fully laden trailers on long,steep gradients.Also, with an increasedconstant power range of atleast 500 rpm, you can maintainwork rate at lower enginespeed, giving reduced noise<strong>and</strong> fuel consumption.Advanced ElectronicEngine ManagementThe Electronic Engine Managementsystem (EEM) controls not onlythe very precise common railfuel injection, but also enables arange of advanced engine controlfunctions, including Power Boost<strong>and</strong> Engine Speed Control*.Power boostDue to sophisticated interactionbetween the engine <strong>and</strong>transmission managementsystems, on MF 6400 modelswhen 3rd or 4th gear is selectedor when the PTO is engaged, EEMautomatically gives a significantpower <strong>and</strong> torque ‘boost’.Engine speed controlSwitches mounted convenientlyon the right-h<strong>and</strong> console enabletwo engine speeds to be pre-set<strong>and</strong> memorised.This enables one engine speed tobe set for work <strong>and</strong> the other foruse when turning at the headl<strong>and</strong>.The ability to return quickly <strong>and</strong>easily to precise engine speeds willboost productivity, improve workquality <strong>and</strong> simplify operation inalmost all of your daily tasks.Improved fuel economyElectronic engine managementconstantly monitors a wide rangeof parameters <strong>and</strong> makes continual<strong>and</strong> incredibly fine adjustments tofuel injection. Combined with fourvalvecylinder head design <strong>and</strong>Common Rail fuel injection, this hasgiven significant improvements inboth emissions <strong>and</strong> fuel economy.Whilst lowering the absoluteSpecific Fuel Consumption (SFC)figure is important, the graph (right)shows how the latest enginesachieve lower fuel consumptionover a much wider range ofoperating conditions.Common rail fuel injectionThe common rail fuel injectionsystem uses precise electroniccontrol to continuously monitoroperating conditions <strong>and</strong> engineload, <strong>and</strong> to regulate accordinglythe high-pressure fuel injection.The result is faster response tochanges in field conditions <strong>and</strong>engine load, more power <strong>and</strong>torque over a wider engine speedrange, excellent fuel economy <strong>and</strong>lower noise <strong>and</strong> emissions.Four valves per cylinderThe cylinder head design featurestwo inlet valves <strong>and</strong> two exhaustvalves per cylinder enablingthe fuel injectors to be centrallypositioned in the cylinder head.This design improves fuel/airmixture <strong>and</strong> gas flow, givingoptimum fuel combustion <strong>and</strong>reducing emissions <strong>and</strong> fuelconsumption, whilst also improvingengine reliability by reducing uppercylinder temperature. The moreefficient combustion also improvestorque characteristics throughoutthe whole working range.* St<strong>and</strong>ard specifications vary by model<strong>and</strong> marketTorque (Nm)Specific fuel consumption230 Optimum fueleconomy220210200190Engine rev/minTorque: MF 6485 - MF 6499BBAATorque reserveCompared to previousgeneration engines,MF’s electronicengine managementsystem broadens theoperating range withinwhich the tractor isoperating at optimumfuel efficiency.The torque curveshows how ‘pullingpower’ is maintainedas engine speed falls<strong>and</strong> how it increaseswith boost.A:Normal torque curve.B:Extra torque, availablewhen PTO is engagedor 3rd or 4th gear areselected.‘A/B’ memorise the engine speed,‘+/-’ adjust the memorised speeds (A/B)080109

: simply theNNeutralDe-clutchForward driveReverse driveChange up ratioChange down ratio01 Dyna-6 ‘T-h<strong>and</strong>le’ gearlever with Speedmatching<strong>and</strong> forward/reverse shuttle‘Comfort Control’.best semi-powershifttransmissionWith left-h<strong>and</strong> Power Control <strong>and</strong> smooth on-the-move clutchlesspowershift changes, it’s simply the best ‘semi-powershift’transmission in the field today.010202 & 04 Power Control providesthree functions on the one lever.03 The Autodrive Controller caneasily be adjusted to achieveideal transmission settings.10Simplicity <strong>and</strong> efficiencyDyna-6 uses four simplesynchromesh gears, each withsix Dynashift speeds. This widespread of speeds within eachrange means you can changeup or down under full load asconditions vary, to optimise output<strong>and</strong> minimise fuel consumption.Also, apart from starting the tractoror hitching an implement, there isnever any need to use the clutchpedal, so the seat can be swivelledfor field work, eliminating the effortof foot pedal operation. And witha choice of either left- or righth<strong>and</strong>control, there’s real operatingflexibility to suit any applicationor driver preference.Left-h<strong>and</strong> Power ControlThe left-h<strong>and</strong> Power Control leverprovides convenient forward/reverse shuttle, powershiftchanges, range changes* <strong>and</strong>fingertip de-clutching, leaving theright h<strong>and</strong> free to operate front<strong>and</strong> rear mounted implements.Shuttle operations are more efficienttoo, with programmable forward/reverse speeds, to reduce repetitivetasks <strong>and</strong> speed cycle times.Right-h<strong>and</strong> controlThe T-shaped gear lever ismounted in the adjustable armrest,so it’s always perfectly placed foreasy use. Simply ‘pulse’ the gearlever forwards or backwards tochange up or down throughthe six Dynashift ratios.To change range, simply pressthe range selection button asyou move the lever.Dyna-6 AutoDrive (optional)AutoDrive enables the operator toselect the engine speed at whichthe transmission will automaticallyupshift <strong>and</strong> will also downshiftautomatically according to load.The AutoDrive Controller hasthree main settings:• Manual, gives full manualcontrol with Speedmatchingswitched off.• Speedmatching, available withinboth Transport <strong>and</strong> Field sectors,provides automatic selection ofthe most appropriate Dynashiftratio after a range change hasbeen made.Gear changes can then be madeeither individually or rapidly, fromA to F range by holding the gearlever (or Power Control lever)forwards or backwards.In Transport, sequential changesalso include range changes,enabling 24 ratio changes, from1A to 4F, all at the touch of eitherthe left-h<strong>and</strong> PowerControl leveror the right-h<strong>and</strong> gear lever.• AutoDrive (see diagrams onright); in the Field sector, givesfully automatic upshifting <strong>and</strong>downshifting of Dynashiftchanges, <strong>and</strong> in the Transportsector, gives automatedDynashift <strong>and</strong> range changes.By adjusting the control, youcan pre-select the engine speedat which upshifting takes place,between 1600 <strong>and</strong> 2200 rpm.Downshifting takes place whenengine speed falls under loadby around 20%, maintaining fullcontrol <strong>and</strong> engine braking.AutoDrive gives you total controlof the transmission, with the exactlevel of automation you require forany application, simply by turningthe AutoDrive Controller.Creeper speedsThe (optional) creeper gearboxprovides a 4.0:1 speed reduction,giving additional 12 forward<strong>and</strong> 12 reverse creeper gearswith speeds down to around 400metres per hour at rated enginespeed.* In Autodrive transport mode0306Main Range0543210km/hAutoDrive Transport SectorAutoDrive Field Sector5Field workingrange102D1504CDAB1400 2200Engine SpeedForward/Reverse Speed4F 4F to 3C 3C to 4FHeavy Soil2D - 2CDynashift Range20EFAutomatic gear shifting302C - 2B - 2AAutomatic gear shifting40(MF 6495, 20.8R42 tyres)2A - 2F05 Dyna-6 offers 6 Dynashiftchanges in each range withmaximum speed at approx1900 rpm.06 AutoDrive - Field mode upshifts <strong>and</strong> downshiftsDyna-6 ratios. AutoDrive - Tansport mode upshifts<strong>and</strong> downshifts both Dyna-6 <strong>and</strong> range changes.11

: putting theMF 7400 Series aheadof the crowdDyna-VT gives infinitely variable speed control with optimumpower, engine speed <strong>and</strong> fuel efficiency, resulting in significantgains in output <strong>and</strong> productivity. And with the proven, familiar‘MF family’ control layout, operation is straightforward <strong>and</strong> intuitive.Stepless speed controlDyna-VT has two infinitely variablespeed ranges, 0-28 km/h for fieldapplications <strong>and</strong> 0-50 km/h* fortransport applications.To start work, simply move theleft-h<strong>and</strong> Power Control lever into‘forward’ or ‘reverse’ directionthen push the armrest-mountedDyna-VT lever. The further youpush the lever, the faster youaccelerate. No shifting of gears.No jerks. No breaks in tractionor power; just infinite speedcontrol from ‘supercreep’ tohigh transport speeds!To slow down, simply pull the leverback. When you’ve reached yourchosen speed, just release the lever.Left-h<strong>and</strong> Power ControlIf you prefer left-h<strong>and</strong> control, thePower Control lever adjusts groundspeed in a similar way, <strong>and</strong> alsogives convenient, left-h<strong>and</strong> controlof forward/reverse shuttle.Smooth forward/reverse shuttleMoving the Power Control leverfrom forward to reverse positiongives an incredibly smooth powershuttle, with the added benefitof being able to pre-set therelationship between forward<strong>and</strong> reverse speed.Pre-set speed controlTravel speed <strong>and</strong> rate ofacceleration can also be pre-set<strong>and</strong> memorised within each of tworanges ‘SV1’ <strong>and</strong> ‘SV2’.The memorised speed acts asa cruise control to maintain aspecified speed. It is activatedby pressing the SV1 or SV2 buttonlocated conveniently in the armrest<strong>and</strong> can be adjusted, during work,simply by turning the appropriateSV1/SV2 rotary switch on theright-h<strong>and</strong> console.The ‘Supervisor’Supervisor optimises therelationship between engineload <strong>and</strong> travel speed <strong>and</strong>, inconjunction with SV1/SV2 speedcontrol, can significantly increaseproductivity in all conditions.Supervisor reduces forward speedwhen load becomes excessive.The Supervisor can be adjustedfor different operational conditions,<strong>and</strong> SV1/SV2 will accelerate thetractor back to the desired forwardspeed as load decreases.As this process is happeningsmoothly, continuously <strong>and</strong>automatically, maximumoutput <strong>and</strong> fuel economy areeasily maintained.Dynamic Tractor Management(DTM) - Intelligent machinemanagement for optimumfuel efficiencyDynamic Tractor Management(DTM) is an electronic managementsystem which when activated,automatically controls the enginespeed according to the load on thetractor. It maintains the requiredforward speed whilst at the sametime minimising the engine revs inorder to keep fuel consumption toa minimum.For optimum convenience DTMcan be used in either pedal orlever mode.The combination of Dyna-VT<strong>and</strong> DTM will ensure maximumproductivity whilst minimising fuelconsumption <strong>and</strong> noise level.* Depending on market/legislation24km/h4030201001 002165301. SV1/SV2 speed memories.2. ‘Pedal’ or ‘Lever’operating modes.3. Speed range selection allin one convenient ‘pod’.4. Speed control lever.5. SV1/SV2 speed activation buttonsare conveniently located in theadjustable armrest.6. DTM button.As the load (red line) increases <strong>and</strong> decreases, the engine revs (grey line)rise <strong>and</strong> fall to maintain a constant speed, saving fuel <strong>and</strong> reducing noise.*Depending on market legislation*km/h5040302010001 Simple, infinite speed control,from creeper speeds to 50 km/h*.02 Dynamic Tractor Management (DTM) . 03 Effortless driving, with a choice of left- orright-h<strong>and</strong> speed control .120313

<strong>and</strong> precisionfor versatilityHere are just a few examples ofhow perfectly matched groundspeed, engine speed <strong>and</strong> powerrequirement can benefit a widerange of applications:With Dyna-VT there is no compromise. From ‘creep’ applicationsas low as 0.03 km/h to high-speed road transport, you set theparameters for power, economy <strong>and</strong> comfort so that you can easilyextract the maximum performance at the lowest operating cost.Low speed <strong>and</strong> lowerpower requirement.Harvesting <strong>and</strong> planting - withprecise ground speed control, toreduce engine speed, minimisein-cab noise <strong>and</strong> maximise fueleconomy.Maximum speed <strong>and</strong> highpower requirement.Transporting a fully laden trailerfrom the field at high speed - withmaximum engine power availableto maintain speed on hills.Low speed with a highpower requirement.Using a power harrow/seed drillcombination - with PTO power <strong>and</strong>productivity maximised <strong>and</strong> withthe ability to fine-tune travel speedto optimise work quality.Choice of operating modesIn addition to Lever Mode, wherethe Power Control lever or armrestmountedDyna-VT lever are used,Pedal Mode is also available.Pedal ModePedal Mode enables the tractorto be controlled by the use of theaccelerator pedal or the h<strong>and</strong>throttle. It is possible to set anengine rev range (minimum 1,400<strong>and</strong> maximum 2,260 revs) betweenwhich the engine is permitted tooperate. This enables the operatorto set the tractor precisely formaximum performance <strong>and</strong>economy for the prevailingconditions.Forager Mode, is ideal whenforaging or baling. This modemaintains pre-set engine speed<strong>and</strong> maximum power.So if a large lump of crop isencountered in the swath, just liftoff the pedal while the material isbaled or chopped. Ground speedis adjusted but engine speed <strong>and</strong>power is maintained.Once the problem has beentackled, simply press the pedal<strong>and</strong> you’re off again at normalworking speed.Maximum speed <strong>and</strong> lowpower requirement.Towing an empty trailer to thefield - at up to 50 km/h* with anengine speed of only 1600 rpm, tominimise in-cab noise <strong>and</strong> reducefuel consumption.* Depending on market/legislation1415

More power at thewheels <strong>and</strong> PTOThe light yet tremendously strong transaxle design <strong>and</strong> low powerlosses through the highly efficient transmissions give all MF 6400<strong>and</strong> MF 7400 Series tractors an outst<strong>and</strong>ing power-to-weight ratio.And with st<strong>and</strong>ard PTO speed coinciding with maximum enginepower <strong>and</strong> significant power boost available when the PTO isengaged*, there is always plenty of power in reserve.01 - 02 ConvenientPTO speed selection(01, MF 6400; 02, MF 7400).03 Fender-mountedPTO controls for addedconvenience <strong>and</strong> safety.04 PTO, engagement <strong>and</strong>‘Auto’ activation switches arewell placed <strong>and</strong> easy to operate.More PTO choiceA wide range of fully independentPTO speeds is available, including540/1000 rpm plus economy PTOsystems.Speed selection is controlledfrom the driver’s seat, plusexchangeable flanged shafts.The flanged PTO shaft is extremelystrong <strong>and</strong> provides a simple,‘oil-less’ shaft change.Control for front (optional) <strong>and</strong> rearsystems is grouped convenientlyto the right. Additional fendermountedengagement <strong>and</strong>emergency stop buttons also giveadded convenience <strong>and</strong> safety.Power with economy540 <strong>and</strong> 1000 rpm PTO speeds areachieved at or near to 2000 rpm,which is also maximum enginepower. With the ability to closelymatch ground speed at the chosenengine speed, you can alwaysmatch PTO speed, forward speed<strong>and</strong> power for optimum output<strong>and</strong> fuel economy.Economy PTOFor lighter duty work, ‘540 Eco’(750) PTO speed is at around1550 engine rpm, further improvingfuel economy <strong>and</strong> helping toreduce in-cab noise levels.Automated PTO controlIn ‘Auto’ mode, the PTO can beautomatically disengaged whenthe linkage is raised (or whentravelling at speeds above25 km/h) <strong>and</strong> re-engaged whenthe linkage is lowered.Further reducing the need foroperator input, the TransmissionController monitors <strong>and</strong> controlsPTO engagement depending onload. This gives a smoother‘take-up’, giving improved drivercomfort <strong>and</strong> also helping toprotect both implement <strong>and</strong>tractor from damage due toinappropriate engagement.Differential locks<strong>and</strong> 4-wheel driveThe Transmission Controller alsotakes care of many of the normallyrepetitive tasks of 4-wheel drive<strong>and</strong> differential lock operation.It ensures that you have 4-wheeldrive when you need it; whenbraking <strong>and</strong> when the differentiallock is engaged, <strong>and</strong> switches it offwhen you don’t; at over 14 km/h.The system also engages thedifferential lock when you need it(after initial manual engagement);when the implement is loweredinto work <strong>and</strong> disengages it whenyou don’t; when the linkage israised or when using independentbrakes <strong>and</strong> also when travelling atmore than 14 km/h.*See Page 8 <strong>and</strong> specifications for details031601020417

MF hydraulics:power with precisionThe MF Electronic Linkage Control system still maintains its positionas the industry leader in terms of accuracy, responsiveness, easeof use <strong>and</strong> reliability. And with high-capacity hydraulic systemsproviding excellent lift capacity <strong>and</strong> high oil flow for externalservices, you can be sure that you’ll get optimum performancefrom linkage-mounted <strong>and</strong> hydraulically-driven equipment.01 Natural layout of controls improvescomfort <strong>and</strong> productivity (Dyna-VT withnew Dynamic Tractor Management).02 Well-specifiedlinkage <strong>and</strong> hydraulics.03 Decompression couplersenable easier connection ofimplement hydraulic services.Accurate draft controlMassey Ferguson’s digital ELCsystem gives the highest st<strong>and</strong>ardsof draft <strong>and</strong> depth control. Thisoptimises weight transfer <strong>and</strong>traction, giving reduced wheelslip,tyre wear <strong>and</strong> fuel consumption<strong>and</strong> increased output.Simple ELC panelWith the more frequently-usedcontrols armrest-mounted <strong>and</strong> astraightforward ELC control panel,accurate operation is easy.The system also incorporatessensitivity, quick soil engagement<strong>and</strong> automatic drop speedas st<strong>and</strong>ard.The rear linkage can also beoperated from convenientlymounted push buttons oneach rear fender.Load sensing hydraulicsThe Closed Centre Load Sensing(CCLS) system provides high oilflow (up to 150 litre/min) for bothlinkage <strong>and</strong> external services, withvirtually instantaneous response.And as flow <strong>and</strong> pressure areautomatically regulated accordingto dem<strong>and</strong>, there’s no wastedpower - or fuel, used in pumpingoil that’s not required.Auxiliary spool valvesImplement hook-up is easy too,with ‘decompression couplers’that enable connection <strong>and</strong>disconnection under pressure.With a choice of mechanical orelectro-hydraulic spool valves,programmable SMS or fingertipswitches, complex equipmentcan be controlled more easily <strong>and</strong>effectively than ever.Rear axle <strong>and</strong> linkageThe rear axle <strong>and</strong> 3-point linkageare highly specified. Twin externallift rams, high visibility pick-uphitch <strong>and</strong> drawbar, externallinkage control on both rear fenders,twin variable float telescopicstabilisers <strong>and</strong> three spool valvesare all st<strong>and</strong>ard equipment.Active Transport Control (ATC)When driving across the headl<strong>and</strong>or transporting heavy mountedequipment, implement ‘bounce’can occur.Active Transport Control isintegrated into the ELC system asst<strong>and</strong>ard. It is a shock-absorbingsystem that minimises the‘pitching’ action - automaticallyadjusting for different implementweights. This gives smoother,safer, faster transport <strong>and</strong>, byreducing shock loads through thelift rams <strong>and</strong> hydraulic circuits, alsominimises the risk of damage tothe lift system.ATC is independent of the transportlock <strong>and</strong> can be controlled eithermanually or automatically, linked tothe ELC lift/lower switch. It is thenactivated when the implement israised <strong>and</strong> deactivated when theimplement is lowered.ATC <strong>and</strong> QuadLinkATC operates in conjunction withthe QuadLink suspended front axleto give exceptional stability whentransporting or operating mountedequipment at speed, giving greatercomfort, safety <strong>and</strong> productivity.QuadLink features:• Integration with the chassisdesign• Can be easily switched on or off• Fully adjustable toaccommodate weight of frontimplement attachment01020404 Integrated ActiveTransport Control gives faster,safer transport of mountedequipment.05 Front mounted hydraulic couplersenable easy hydraulic operation offront mounted implements.18 030519

Advanced Field <strong>and</strong>Headl<strong>and</strong> ManagementSystemsFrom the Spool Valve Management System(SMS) to fully programmed implementcontrol via Datatronic III <strong>and</strong> ISOBUS,MF 6400 <strong>and</strong> MF 7400 Series tractorshave among the most comprehensiveField <strong>and</strong> Headl<strong>and</strong> ManagementSystems available today.Whichever level you choose to meet yourbusiness needs, the result is simply a morerelaxing, more productive working day.Datatronic III has won aprestigious commendationat SIMA 2007 for datatransfer via the SD card,simplifying operation,control <strong>and</strong> traceability.01 02SMS Joystick control provides convenient<strong>and</strong> precise spool valve operation.Individual fingertip control of 4 spool valvesenables accurate control at the touch of a button.03 04Spool ValveManagement System (SMS)SMS* gives easier, more precise,memorised control of the electrohydraulic,proportionalspool valves.SMS: accuracy <strong>and</strong> simplicitySMS enables external hydraulic oilflow rates to be memorised <strong>and</strong>controlled via either an armrestmountedjoystick or fingertip toggleswitches*. Each time the samefunction <strong>and</strong> flow is required, asingle movement of the joystick orfingertip switch is all that is needed.Integrated TractorControl System (ITCS)ITCS (available as an option onall models <strong>and</strong> st<strong>and</strong>ard whenDatatronic III is specified) providesan entry level of field <strong>and</strong> headl<strong>and</strong>management that is ideal if all ofthe functions of Datatronic III arenot required.ITCS enables management of:Wheelslip control – toautomatically limit wheelslip toan operator-set maximum. Thisincreases traction, reduces tyrewear <strong>and</strong> protects soil structure.Headl<strong>and</strong> control – interactswith Engine Speed Control toautomatically change between A<strong>and</strong> B engine speeds as the linkageis raised <strong>and</strong> lowered.Engine speed change can bedelayed between 0 <strong>and</strong> 5 secondsfrom linkage lift/lower switchactivation.More information with ITCSITCS also gives a read-out of both‘trip’ <strong>and</strong> total fuel usage, <strong>and</strong>displays pre-set engine speeds,forward speed <strong>and</strong> PTO speed.Display <strong>and</strong> adjustment of additional automated functionsprovides efficient operator <strong>and</strong> machine control.Convenient touch pad enables quick <strong>and</strong>easy operation of ITCS.20The benefits of SMSMemorised flow rates <strong>and</strong> onetouchoperation greatly simplifyfield, <strong>and</strong> especially, headl<strong>and</strong>manoeuvres when operatingcomplex equipment or front <strong>and</strong>rear combinations.And, of course, SMS is idealfor faster, more efficient frontloader operation.Spool Valve Management –to set the flow <strong>and</strong> timing of thespool valves controlled by thejoystick or fingertip SMS switches.Linkage/external services oil flowpriority – to control, as aprecise percentage, the split ofoil flow to the linkage <strong>and</strong> spoolvalves to ensure optimum efficiencyfor different applications.Datatronic III: Information,control <strong>and</strong> easy operation.Two versions of Datatronic IIIare now available; with colourscreen, <strong>and</strong> with colour screenwith video capability <strong>and</strong>ISOBUS connectivity.* Options vary by model <strong>and</strong> market;see ‘Specifications’05 06Datatronic III provides comprehensive information <strong>and</strong>additional automation to improve the quality of work<strong>and</strong> reduce the operators’ workload.Data logging provides a valuable source of tractor <strong>and</strong>implement recording that can easily be viewed <strong>and</strong> analysedon a computer to improve profit <strong>and</strong> increase output.21

More than just a tractor.......more than just a headl<strong>and</strong> management system – Datatronic’sadvanced features that help you every step of the way.01 Navigation <strong>and</strong> selection of thefunctions either using the keys orthe encoder.02 - 03 Armrest-mounted buttonstarts or stops the pre-programmedheadl<strong>and</strong> sequence.Programmed headl<strong>and</strong><strong>and</strong> implement controlwith Datatronic IIIDatatronic III is controlled from amain screen with up to seven mainapplication menus, plus ‘Settings’for console set-up.Work menuThe work screen displays engine<strong>and</strong> PTO speed, travel speed <strong>and</strong>wheelslip information. A widerange of tractor functions canalso be displayed <strong>and</strong> controlled,including spool valves, memory,Dual Control <strong>and</strong> TIC.Headl<strong>and</strong> menuThe Headl<strong>and</strong> menu, quitesimply, gives access to themost comprehensive headl<strong>and</strong>management systemavailable today.It enables straightforwardprogramming of up to 35operations, activated at the touchof an armrest-mounted button.The sequence can be modifiedor over-ridden at any time.Memories menuSix independent sets of informationcan be stored, named <strong>and</strong>displayed. The data can also betransferred, via SD memory card,to the office computer for analysisor from tractor to tractor to speedupimplement setup.Recorded information includes:• tractor settings, includinggearbox, spool valves or arecorded headl<strong>and</strong> sequence;• implement width• information gathered duringfield operation, including hours<strong>and</strong> area worked, fuel usage,distance covered... <strong>and</strong> more.Electro-hydraulicspool valves menuThe EHS Valves menu is used toset the operating characteristics ofup to four electro-hydraulic spoolvalves. You can enable or disable‘float’ <strong>and</strong> accurately set ramextension <strong>and</strong> retraction, flowrates <strong>and</strong> kickout timing.ISOBUS compatibilityISOBUS, the industry-st<strong>and</strong>ardfor implement connectivity, meansthat all of your equipment can beeasily set up <strong>and</strong> operated viathe GTA Console.Remote cameraThe optional remote video cameracan be fitted anywhere on thetractor or on any front or rearmountedimplement.Used in conjunction with clear onscreenview (actual image shown)on the GTA Console when reversingenables faster, safer haulage workor, the operator to view any rear orside-mounted equipment.Dual Control menuThe Dual Control menu enablesfully programmed comm<strong>and</strong> offront <strong>and</strong> rear Dual Control <strong>and</strong>Trailed Implement Control, somaximum output <strong>and</strong> work qualitycan be achieved with a minimumof operator input.When using semi-mountedploughs, Dual Control automatesfurrow entry <strong>and</strong> exit, aids settingthe plough, improves evenness<strong>and</strong> control of work <strong>and</strong> gives thefull benefit of wheelslip control.When front linkage is fitted, frontDual Control gives automateddepth <strong>and</strong> entry <strong>and</strong> exit pointswith front <strong>and</strong> rear linkagemountedequipment.Trailed Implement Control (TIC)TIC uses wheelslip data toautomatically regulate workingdepth to optimise productivitywhen using trailed equipment.It is operated via the st<strong>and</strong>ardarmrest-mounted ELC controlswith set-up <strong>and</strong> monitoring viaeither ITCS or Datatronic III.For comprehensive information aboutMassey Ferguson advanced Field<strong>and</strong> Headl<strong>and</strong> Management systems,please ask your Dealer for the‘MF Technology’ brochure.0102 03ROTARY HARROW0405ON04 A typical Memory screen,showing fuel usage, hours worked,area worked <strong>and</strong> distance travelled.05 An example ofan ISOBUS function.06 ISOBUS implementconnection.07 - 08 Optional remote cameragives high quality image on thecolour/ISOBUS GTA Console.220607 0823

Tailored options forhigher productivity01 Ballast options include the 600 plus 900 kgmodular front weights.02 GTA200 software enables arange of reports to be produced.0103 A roof-mounted TopDock houses the Auto-Guide electronics, including the GPS receiver.Massey Ferguson IntegratedFront Linkage System (IFLS)A new front axle support castingenables factory-installation ofMassey Ferguson IntegratedFront Linkage System (IFLS) aneat, fully integrated front linkage<strong>and</strong> PTO system. Attached toan exceptionally strong structuralengine sump, this design meansthat no additional side rails arenecessary when specifying thefront linkage. So engine accessis further improved <strong>and</strong> a tightersteering lock is achieved, for fasterheadl<strong>and</strong> turns <strong>and</strong> manoeuvring.The integrated front linkage designalso has tremendous strength tocater for heavy, high-productivityfront-mounted equipment. Thenew front linkage also incorporatesa towing clevis, electrical connector<strong>and</strong> up to two spool valve couplers.GTA softwareData recorded using the DatatronicIII memory function (see page 20)can be displayed on the console,transferred via memory card fromtractor to tractor or to the officecomputer. This award-winningsystem can help improveproductivity, simplify day-to-dayoperation <strong>and</strong> also provide vital‘traceability’ data via PC-basedGTA software can be used for recordkeeping, analysis <strong>and</strong> mapping:GTA100 Communicator (st<strong>and</strong>ard)- enables machine use <strong>and</strong> jobdata to be managed, viewed<strong>and</strong> exported to third party farmmanagement programmes.GTA200 Record Keeping(optional) - allows machineperformance data to be allocatedto a specific job or field to producea range of reports, also enablingaccurate crop traceability.GTA300 Mapping (optional) -enables the user to create mapsfrom data containing GPSbasedpositioning informationgathered while working. Thisdata is recorded with other data,for example forward speed, fuelconsumption or yield.Auto-GuideFor faster, precision farming,the optional Auto-Guide satellitenavigation system* uses leadingGPS technology to guide yourtractor <strong>and</strong> implements at higherrates of speed <strong>and</strong> accuracy. Thisis especially valuable for moreaccurate operation at night, in lowvisibility or when working in preemergentcrops.Auto-Guide steers the tractor,without operator input, to makeparallel bouts avoiding overlap orunworked l<strong>and</strong>. This reducesdriver fatigue <strong>and</strong> fuel usage,eliminates unnecessary chemicalapplication <strong>and</strong> can significantlyincrease productivity.*For more information on Auto-Guide, pleaserefer to the MF Technology brochure.02240325

A joy to drive,a pleasure to own01 - 02 Easy access to airfilter <strong>and</strong> radiators encouragesregular maintenance.Built-in durabilityThe MF 6400 <strong>and</strong> MF 7400‘transaxle’ designs are extremelystrong yet give low overall weight,with an excellent power-toweightratio.This gives excellent loadcarryingcapacity <strong>and</strong> h<strong>and</strong>lingcharacteristics, while the immenserigidity reduces stress on components,reducing maintenance requirements<strong>and</strong> down-time.More style, more practicalityThe sleek bonnet on MF 6400<strong>and</strong> MF 7400 models is stylish<strong>and</strong> practical. Rear hinged, thelockable bonnet raises fully, givingcompletely clear access to theengine, radiator <strong>and</strong> re-designedcooling package.The radiators have a greatersurface area for improved cooling<strong>and</strong> also hinge <strong>and</strong> separate foreasy cleaning.Simple servicing <strong>and</strong>routine maintenanceThe conveniently placed engineoil dipsticks <strong>and</strong> fillers are safelypositioned on the ‘cold’ side of theengine, away from the hot exhaust.26And with convenient ground levelrefuelling, self-adjusting brakes<strong>and</strong> electronic protection of enginespeed, 4WD, differential locks,PTO <strong>and</strong> transmission, routinetasks are easy <strong>and</strong> servicingrequirements are minimised.01 0227

Individual carepackages for individualcircumstancesNothing is ever certain in life; this is especially true if you workwithin the agricultural sector. So imagine how much easier life wouldbe if you could experience true peace-of-mind where your farmmachinery is concerned; no more hidden costs or surprise invoices.01 Spacious, flat-floor platform 02 Screens help to protect the driverService <strong>and</strong> RepairContract* is a complete packageaimed at providing total care foryour tractor including routinemaintenance, repair cover <strong>and</strong>full AGCO backed warranty. Thisfully-backed contract will covercritical components such as:• Engine <strong>and</strong> transmission• Hydraulics• PTO• Steering• Electronics• Cab <strong>and</strong> controls• AxlesAssurance for thelife of the machineYou can be assured of ‘preventative’servicing using the latest technology<strong>and</strong> professionally trainedtechnicians. With years ofexperience they are on h<strong>and</strong> toensure that your machine runsat optimum performance.All of this will be carried outaccording to a strict maintenanceschedule supplied byMassey Ferguson.With acontract <strong>and</strong>through this ‘preventative’servicing, your machine willmaintain excellent productivitythroughout its long working life.The most important aspect of thispackage is that you will never incurany unexpected hidden costs.It is possible to cut the cost ofmaintaining your machine through‘preventative’ servicing <strong>and</strong>maintenance, thereby reducinglong term ownership costs <strong>and</strong>securing a productive future foryour business.Tailored to your needshas been designed tocater for your individual needs.Cover is available for up to 5years or 6,000 hours dependingon your requirements. Availableat initial point of sale or, for addedflexibility, you can choose to takeon acontract any timeup to 12 months after machineregistration.Your dealer will prepare theservicing contract <strong>and</strong> can tailorit to last up to a maximum of10,000 hours.By choosingService<strong>and</strong> Repair Contract, not only areyou assured of complete peaceof-mindfor you <strong>and</strong> your businessbut also a higher residual value foryour machinery, full dealer history<strong>and</strong> genuine AGCO Parts inside<strong>and</strong> out.For more information onService <strong>and</strong> RepairContracts speak to yourMassey Ferguson dealer.* Service <strong>and</strong> Repair Contractmay not be available or may be marketdependent. Please contact yourMassey Ferguson dealer to checkavailability in your area.28 29

Customer Support01 Ensuring thebest service support.02-04 Industry-leading partssupply from AGCO Parts.05 Lifetime support for allMassey Ferguson machines.AGCO CustomerSupport…providing localservice to theglobal br<strong>and</strong>Massey Ferguson is a true globalbr<strong>and</strong> with machines operating allover the world, from revolutionary“little grey fergie” tractors tothe latest high-tech tractors<strong>and</strong> combines. Have you everwondered how we continue toprovide industry-leading parts<strong>and</strong> service support to sucha vast array of machines <strong>and</strong>technologies across the globe?Behind every Massey Fergusonmachine is the powerful aftersalessupport of AGCO’s CustomerSupport organisation.Our main aim is to ensure thatevery machine - old or new - isfully supported locally, offeringevery Massey Ferguson owner:• The best service in the industry• Low cost of ownership• A reliable <strong>and</strong> durable machine• Minimum machine downtime• A high resale valueState-of-the-art warehousing<strong>and</strong> logistics from AGCO PartsOf course, every Massey Fergusondealer is fully backed-up bythe AGCO Customer Supportorganisation which providesindustry-leading parts supplythrough AGCO Parts’ state-ofthe-artwarehousing <strong>and</strong> logistics.With outst<strong>and</strong>ing service levels,overnight delivery <strong>and</strong> inventorycovering all Massey Fergusonmachines - even those over 10years old - we only ever supplygenuine parts, <strong>and</strong> we guaranteethe right fit, first time.The right aftersales solutionwhatever the age of machineWhatever the age ofMassey Ferguson machine,AGCO Customer Support hasthe right aftersales solution tosave time & money, providingappropriate, affordable <strong>and</strong>reliable servicing <strong>and</strong> maintenancesolutions in every situation.Practical local supportwhere you need itAGCO places great emphasis onproviding the best service to ourMassey Ferguson dealers <strong>and</strong> thisextends beyond the exceptionalservicing <strong>and</strong> maintenancesolutions <strong>and</strong> parts supply:• Expert training <strong>and</strong>specialist equipment• Advanced diagnostic techniques• Information retrieval technologyto communicate the very latestparts <strong>and</strong> service information• Highly skilled technicalsupport groupsWith aftersales support fromAGCO Customer Support, it’snot just about supplying a filteror doing an oil change. It’s aboutproviding the best solution to ourcustomers’ needs, wrapped upwith industry-leading parts <strong>and</strong>service support.0102033004 0531

Our promise to youOur mission at Massey Ferguson, since the company was founded,has been to design, engineer <strong>and</strong> manufacture reliable, trustworthy<strong>and</strong> innovative tractors. Tractors that people recognise the world over.VISIONOur vision for the world of agricultural machineryhas always been clear; to produce worthwhile<strong>and</strong> innovative solutions for professional farmersfeeding the world. Always recognisable, theMassey Ferguson br<strong>and</strong> of products signifiestechnological advancement, enhanced design,strict testing <strong>and</strong> quality manufacturing which isconsistently trustworthy <strong>and</strong> hardworking.INNOVATIONWe’ve always been one step ahead when it comes toinnovation. Our founder, Harry Ferguson is proof of that.Through continual questioning <strong>and</strong> analysis ofcustomers’ needs, our products are designed, tested<strong>and</strong> built to enhance productivity, efficiency <strong>and</strong>convenience, constantly pushing the boundariesof farm machinery.From the simplest push of a button to technologicalinnovations in engine <strong>and</strong> transmission efficiency, westrive to make life simpler for the operator.LEADERSHIPMassey Ferguson machinery is the most widely soldagricultural product in the world, making us the leadersin the agricultural arena. We’ve won awards for ourclass-leading technology <strong>and</strong> advancement in design<strong>and</strong> we’re already driving ahead, environmentally <strong>and</strong>economically.QUALITYIt takes certain distinctive attributes to make a qualityproduct. At Massey Ferguson, this distinction startsat the drawing board <strong>and</strong> doesn’t stop. Every stage ofmanufacturing, from the building <strong>and</strong> testing processto sourcing the best components, dem<strong>and</strong>sexcellence. Our products <strong>and</strong> services meet themost stringent st<strong>and</strong>ards allowing us to deliverour promises, confidently.RELIABILITYWe don’t let a Massey Ferguson machine out of oursight until we are 100% sure it will perform to thehigh st<strong>and</strong>ards you expect. Only after rigorous <strong>and</strong>painstaking testing both in simulations <strong>and</strong> in the field,will we allow our products to leave the factory. Whateveryou put your tractor through, day after day, season afterseason, we can guarantee we’ve already tested thoselimits <strong>and</strong> gone beyond them.SUPPORTAgriculture can be a tough business, that’s why wemake sure that you can get support whenever youneed it <strong>and</strong> at crucial times of the year. Be assured ofsustainability from more than 3,200 dealer outlets inover 140 countries <strong>and</strong> a comprehensive machinerydistribution network. You’ll be part of a dedicated familyof specialists who make it their business to give yougenuine, top quality service support.Equally, we won’t let an opportunity slip through yourfingers. If you have the commitment but not necessarilythe financial resources to compete in today’s marketdrivenclimate then AGCO Finance could have thesolution. Ask your local dealer for more information.Financial options are market specific but can includeleasing, hire purchase, contract hire <strong>and</strong> loan facilities.PRIDEPride means many things to us at Massey Ferguson.It’s in everything we do <strong>and</strong> it shows. It’s in our proudheritage, our unique product design <strong>and</strong> our ongoingsupport to our customers.COMMITMENTWe are deeply committed to delivering the highest ofexpectations <strong>and</strong> to build quality, reliable products withinnovative features that are backed by the best supportpackages. Ultimately, we are committed to continuousgrowth <strong>and</strong> profitability for all, whilst recognising theneeds of both large <strong>and</strong> small businesses throughprofessionalism <strong>and</strong> quality.32 33

SpecificationsEngine power, NominalMF 6485 MF 6490 MF 6495 MF 6497 MF 6499 MF 7485 MF 7490 MF 7495 MF 7497 MF 7499Rated hp @ 2200 rpm ISO hp (kW) 160 (118) 170 (125) 185 (136) 200 (147) 215 (158) 165 (121) 175 (129) 190 (140) 205 (151) 220 (162)Maximum hp @ 2000 rpm ISO hp (kW) 175 (129) 185 (136) 198 (146) 215 (158) 230 (169) 180 (132) 190 (140) 203 (149) 225 (166) 240 (177)Maximum torque Nm 750 796 841 883 928 836 880 904 928 970Engine power, in Transport/PTOMaximum hp @ 2000 rpm ISO hp (kW) 190 (140) 200 (147) 210 (155) 230 (169) 245 (180) - - - - -Maximum torque Nm 836 880 904 928 970 - - - - -Max. power available @ PTO shaftMaximum hp @ 1000 PTO rpmOECD hp (kW)(OECD, accuracy +/– 2%)160 (118) 170 (125) 180 (132) 195 (144) 205 (151) 160 (118) 170 (125) 180 (132) 195 (144) 205 (151)Specific fuel consumption † g/kWh 204 201 201 200 200 204 201 201 200 200EngineAGCO SISU POWERWater cooled, direct injection diesel. Tier lll compliant. Common rail electronic fuel injection.4 valves per cylinder.Type 66.CTA 66.CTA 66.CTA 74.CTA 74.CTA 66.CTA 66.CTA 66.CTA 74.CTA 74.CTACapacity/ no. of cylinders litre/no. 6.6/6 6.6/6 6.6/6 7.4/6 7.4/6 6.6/6 6.6/6 6.6/6 7.4/6 7.4/6AspirationTurbo/IntercooledClutchOperation <strong>and</strong> controlTransmissionDyna-6: Speedmatching(Up to 50 km/h max. speed )Dyna-6: AutoDrive(Up to 50 km/h max. speed )Forward <strong>and</strong> reverse, multi-plate, oil-cooled clutcheswith hydraulic actuation <strong>and</strong> electronic controlSemi-powershift gearbox with 6 Dynashift ratios ineach of 4 electro-hydraulically controlled ranges.Power Control <strong>and</strong> Speedmatching functions.As ‘Speedmatching’, plus AutoDrive, giving manual,semi- or fully-automated Dynashift changes- - - - -- - - - -- - - - -Creeper Speeds Additional 12F/12R Creeper Speeds - - - - -Dyna-VTField speed rangeRoad speed rangePower Take-Off (Rear)Operation <strong>and</strong> control- - - - -Stepless, continuously variable transmission0.03 – 28 km/h Forward <strong>and</strong>0.03 – 16 km/h Reverse0.03 – 50 km/h Forward <strong>and</strong>0.03 – 38 km/h ReverseIndependent, electro-hydraulic with rear fender-mounted start/stop control <strong>and</strong> headl<strong>and</strong> automation.In-cab control leverSpeed change:Shiftable, flanged shaft(6 <strong>and</strong> 21 spline) PTO speed @ engine rev/min540 rpm (6 spline shaft) rpm 1900 1900 1900 1900 1900 2060 2060 2060 2060 20601000 rpm (21 spline shaft) rpm 2000 2000 2000 1930 1930 2030 2030 2030 2030 2030Linkage <strong>and</strong> HydraulicsLinkage controlMax oil flow/pressureClosed Centre(load sensing)Lower linkslitre/min /bar/MF 6485 MF 6490 MF 6495 MF 6497 MF 6499 MF 7485 MF 7490 MF 7495 MF 7497 MF 7499Electronic control of draft, position, Intermix, height/depth, rate of drop,‘quick soil engagement’ <strong>and</strong> Active Transport Control110/150/200110/150/200110/150/200110/150/200110/150/200Quick-attach, hook end with Cat. 2/3 balls <strong>and</strong> cones110/150/200110/150/200110/150/200110/150/200Maximum lift capacity,kg 9100 9100 9100 9100 9100 9300 9300 9300 9300 9300at link endsAuxiliary spool valves (All Load Sensing. Other specifications are available. Please consult your Dealer)Spool valvesLarge choice of hydraulic combinations with up to 5 spoolvalves, with 110 or 150 litres flow <strong>and</strong> mechanical spoolvalves, or electrical (SMS joystick or fingertips) or combinationof both types.110/150/200Large choice of hydraulic combinations with up to 4 spoolvalves, with 110 or 150 litres flow <strong>and</strong> mechanical spoolvalves, or electrical (SMS joystick or fingertips) or combinationof both types.SteeringSteeringHydrostatic, balanced, with tilting telescopic steering columnBrakesOperation <strong>and</strong> controlOil-cooled, single plate discs with hydraulic actuation <strong>and</strong> power assistanceTrailer brakesHydraulic, pedal-operated4WD Front axleDifferential lockHydralock (full engagement/disengagement), with automated controlQuadLink suspended axle St<strong>and</strong>ard Wheels <strong>and</strong> Tyres (Full range available. Please consult your Dealer)FrontRear480/70R28580/70R38480/70R28580/70R38420/85R30520/85R42480/70R30620/70R42Track adjustments (with st<strong>and</strong>ard wheels <strong>and</strong> tyres)Front - 4WD/QuadLink m 1.64-2.13 1.64-2.13 1.64-2.13 1.65-2.13 1.65-2.13 1.64-2.13 1.64-2.13 1.64-2.13 1.65-2.13 1.65-2.13Rear m 1.86-2.08 1.86-2.08 1.90-2.11 1.72-2.32 1.72-2.32 1.86-2.08 1.86-2.08 1.90-2.11 1.72-2.32 1.72-2.32Weights <strong>and</strong> dimensions (approximate, with st<strong>and</strong>ard wheels <strong>and</strong> tyres, 4WD model, less fuel)Minimum, no ballast kg 6750 6800 7000 7300 7300 6950 7000 7200 7400 7400Dimensions (Less front weights)Overall length, to lowerlink endsm 5.00 5.00 5.00 5.00 5.00 5.00 5.00 5.00 5.00 5.00Overall height - over cab m 3.05 3.05 3.05 3.10 3.10 3.05 3.05 3.05 3.10 3.10Wheelbase m 3.00 3.00 3.00 3.00 3.00 3.00 3.00 3.00 3.00 3.00Turning circle, dia,less brakesm 10.3 10.3 10.3 10.3 10.3 10.3 10.3 10.3 10.3 10.3Fuel tank capacity litre 380 380 380 380 380 380 380 380 380 380480/70R30620/70R42480/70R28580/70R38480/70R28580/70R38420/85R30520/85R42480/70R30620/70R42480/70R30620/70R42Economy PTO @ engine rpm rpm /1520 /1520 /1520 /1520 /1520 /1600 /1600 /1600 /1600 /1600Shaft diameter35mm (1 3 /8in)Front Power Take-Off <strong>and</strong> LinkageMF IFLS -Integrated FrontLinkage Systemkg Linkage lift capacity kg 4000 4000 4000 4000 4000 4000 4000 4000 4000 4000Operation <strong>and</strong> controlIndependent, electro-hydraulic. 6 or 21 spline, 35mm (1 3 /8in) diameter PTO shaft. 1000 rpm @ 2040 engine rpm = St<strong>and</strong>ard = Optional– = Not applicable/available = Depending on market/legislation = ISO TR 14396 (EG 97/68 values arecomparable to ISO values +/- 0.5%)†= Optimum specific fuel consumption (Manufacturer’s test)* = Fender width complying with 50 km/h maximum road speedlegislationEvery effort has been made to ensure that the information contained in this publication is as accurate <strong>and</strong> current as possible. However, inaccuracies, errors oromissions may occur <strong>and</strong> details of the specifications may be changed at any time without notice. Therefore, all specifications should be confirmed with yourMassey Ferguson Dealer or Distributor prior to any purchase.

MF 6400 <strong>and</strong> MF 7400highlightsHere’s a quick reminder of some of the advanced features of theMF 6400 <strong>and</strong> MF 7400 Series tractors that further enhance theirplace firmly within the high horsepower sector.01 Two new models in the MF 7400 Series line-up 06make this range the superior choice in the highhorsepower sector.Available with Datatronic III, video capability<strong>and</strong> ISOBUS compatibility, together with themost comprehensive, yet simple headl<strong>and</strong>management system.02Highly efficient, powerful diesel engines, built usingthe latest technology to produce maximum torque,outst<strong>and</strong>ing fuel economy <strong>and</strong> lower emissions.07Smooth, modern styling in line with the newMassey Ferguson ‘family’ design.03 Choose from 10 models in the 175-240 hp08category to get precisely the right tractor foryour farming business.Transport boost on most models means50km/h can be achieved when undertakingtransport work, reducing journey times <strong>and</strong> raisingoperator productivity.04Spacious, exceptionally quiet cab, combineswith sector-leading levels of comfort to createa relaxing, stress-free working environment forthe operator.09New front axle support casting <strong>and</strong> ‘structural’engine sump to allow fitting of the fully integratedfront linkage <strong>and</strong> PTO system.05MF 6400 Series tractors have the renownedDyna-6 semi-powershift transmission, whilethe MF 7400s deliver the power via the unbeatableDyna-VT continuously variable transmission.Please also see MF 6400 <strong>and</strong> MF 7400medium horsepower brochure formodels from 100 to 170 hp.is a worldwide br<strong>and</strong> of AGCO.© AGCO Limited. 2009 | A-English/14887/1109/10m