customer information - Dillinger Hütte GTS

customer information - Dillinger Hütte GTS

customer information - Dillinger Hütte GTS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

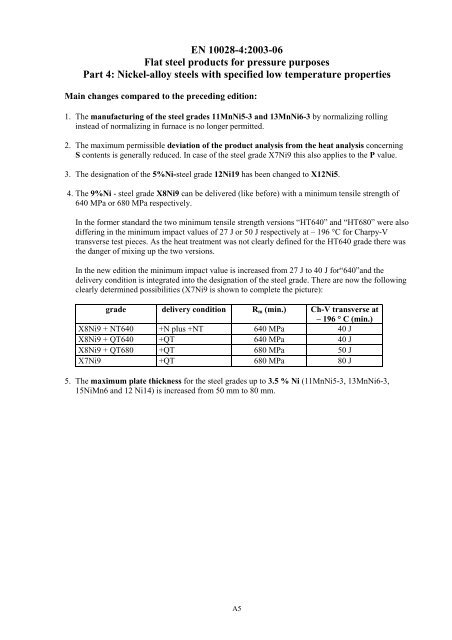

EN 10028-4:2003-06<br />

Flat steel products for pressure purposes<br />

Part 4: Nickel-alloy steels with specified low temperature properties<br />

Main changes compared to the preceding edition:<br />

1. The manufacturing of the steel grades 11MnNi5-3 and 13MnNi6-3 by normalizing rolling<br />

instead of normalizing in furnace is no longer permitted.<br />

2. The maximum permissible deviation of the product analysis from the heat analysis concerning<br />

S contents is generally reduced. In case of the steel grade X7Ni9 this also applies to the P value.<br />

3. The designation of the 5%Ni-steel grade 12Ni19 has been changed to X12Ni5.<br />

4. The 9%Ni - steel grade X8Ni9 can be delivered (like before) with a minimum tensile strength of<br />

640 MPa or 680 MPa respectively.<br />

In the former standard the two minimum tensile strength versions “HT640” and “HT680” were also<br />

differing in the minimum impact values of 27 J or 50 J respectively at – 196 °C for Charpy-V<br />

transverse test pieces. As the heat treatment was not clearly defined for the HT640 grade there was<br />

the danger of mixing up the two versions.<br />

In the new edition the minimum impact value is increased from 27 J to 40 J for“640”and the<br />

delivery condition is integrated into the designation of the steel grade. There are now the following<br />

clearly determined possibilities (X7Ni9 is shown to complete the picture):<br />

grade delivery condition Rm (min.) Ch-V transverse at<br />

– 196 ° C (min.)<br />

X8Ni9 + NT640 +N plus +NT 640 MPa 40 J<br />

X8Ni9 + QT640 +QT 640 MPa 40 J<br />

X8Ni9 + QT680 +QT 680 MPa 50 J<br />

X7Ni9 +QT 680 MPa 80 J<br />

5. The maximum plate thickness for the steel grades up to 3.5 % Ni (11MnNi5-3, 13MnNi6-3,<br />

15NiMn6 and 12 Ni14) is increased from 50 mm to 80 mm.<br />

A5