Tailor-made heavy plates for pressure vessels T - Dillinger Hütte GTS

Tailor-made heavy plates for pressure vessels T - Dillinger Hütte GTS

Tailor-made heavy plates for pressure vessels T - Dillinger Hütte GTS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PRODUCTION/PROCESSING/HANDLING 1<br />

<strong>Tailor</strong>-<strong>made</strong> <strong>heavy</strong> <strong>plates</strong> <strong>for</strong><br />

<strong>pressure</strong> <strong>vessels</strong><br />

F. Gottwalles, Dr. I. Detemple, Dr. P. Wolf<br />

<strong>Dillinger</strong> <strong>Hütte</strong> <strong>GTS</strong><br />

Introduction<br />

T<br />

echnical requirements <strong>for</strong> petrochemical<br />

reactor steels have proliferated in the last<br />

decade. The need to increase economic benefi<br />

ts together with higher operating temperatures<br />

and <strong>pressure</strong>s are leading to the construction of<br />

higher capacity reactors with thicker walls.<br />

Also, more severe requirements in these steel specifi -<br />

cations leave the steelmaker little scope to fi nd a good<br />

balance between all the infl uencing parameters, in<br />

order to achieve the best possible steel design.<br />

These two points can lead to a situation where the<br />

material’s physical limits are reached. It is not only<br />

the heat treatment, but also the chemical composition<br />

and thickness of the plate that strongly infl uence the<br />

steel’s mechanical properties.<br />

By taking the example of carbon manganese steel<br />

SA516-70 edition 2004 addendum 2006 [2], we will look<br />

at how the microstructure is modifi ed and thus the<br />

main mechanical properties.<br />

It may be noted that the 2007 edition of this standard<br />

provides <strong>for</strong> new possibilities − it now permits maximum<br />

manganese content of 1.50% as against 1.20% so<br />

long as the maximum carbon content is also reduced.<br />

However, this cannot be implemented if the reactor<br />

has to be constructed according to the 2004 edition<br />

addendum 2006 or previous editions.<br />

The hollomon parameter (HP) concept<br />

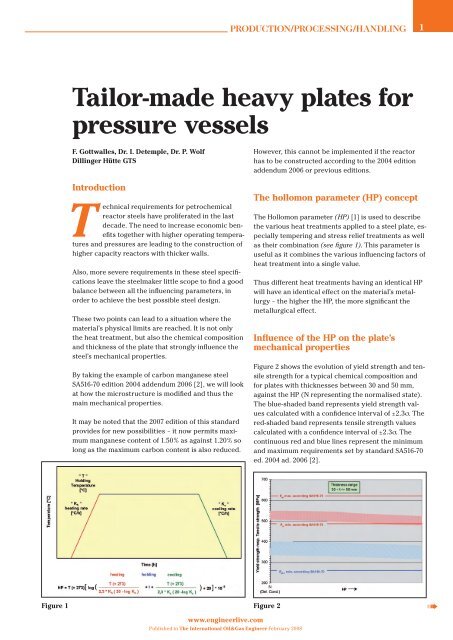

The Hollomon parameter (HP) [1] is used to describe<br />

the various heat treatments applied to a steel plate, especially<br />

tempering and stress relief treatments as well<br />

as their combination (see fi gure 1). This parameter is<br />

useful as it combines the various infl uencing factors of<br />

heat treatment into a single value.<br />

Thus different heat treatments having an identical HP<br />

will have an identical effect on the material’s metallurgy<br />

− the higher the HP, the more signifi cant the<br />

metallurgical effect.<br />

Infl uence of the HP on the plate’s<br />

mechanical properties<br />

Figure 2 shows the evolution of yield strength and tensile<br />

strength <strong>for</strong> a typical chemical composition and<br />

<strong>for</strong> <strong>plates</strong> with thicknesses between 30 and 50 mm,<br />

against the HP (N representing the normalised state).<br />

The blue-shaded band represents yield strength values<br />

calculated with a confi dence interval of ±2.3σ. The<br />

red-shaded band represents tensile strength values<br />

calculated with a confi dence interval of ±2.3σ. The<br />

continuous red and blue lines represent the minimum<br />

and maximum requirements set by standard SA516-70<br />

ed. 2004 ad. 2006 [2].<br />

Figure 1 Figure 2 D<br />

www.engineerlive.com<br />

Published in The International Oil&Gas Engineer February 2008

Figure 3<br />

Figure 4 and 5<br />

We can see that yield strength and tensile strength are<br />

affected by the heat treatment: the harsher the heat<br />

treatment, the more the material’s yield strength and<br />

tensile strength decrease.<br />

Figure 3 shows the evolution of toughness against HP.<br />

The coloured lines represent, <strong>for</strong> various test temperatures,<br />

the lower toughness limits calculated <strong>for</strong> a typical<br />

chemical composition and <strong>for</strong> <strong>plates</strong> with thicknesses<br />

between 30 and 50 mm. 99% of the results are<br />

thus found above this limit. The two horizontal black<br />

lines represent typical minimum values 25 J average<br />

(17 J lowest single value).<br />

We can see that the toughness is strongly affected by<br />

the heat treatment − the harsher the heat treatment,<br />

the more the material’s toughness decreases.<br />

There<strong>for</strong>e, by keeping the chemical composition<br />

constant whatever the HP, the requirements set by<br />

a standard or customer may no longer be complied<br />

with. To counter this effect, the steel’s carbon content<br />

www.engineerlive.com<br />

PRODUCTION/PROCESSING/HANDLING 2<br />

can be adjusted. Figures 4 and 5 are curves of the<br />

expected values of tensile strength and toughness at<br />

–29°C <strong>for</strong> plate thickness of 50 mm and typical chemical<br />

composition by only varying the carbon content<br />

and the HP.<br />

As fi gures 4 and 5 show, the carbon content has to<br />

be increased to ensure the minimum tensile strength<br />

requirement, and it has to be decreased to improve<br />

toughness. For certain carbon contents, and according<br />

to the heat treatment applied, it is no longer possible<br />

to ensure the product’s mechanical requirements<br />

without employing other solutions. These other solutions<br />

will be examined below.<br />

Infl uence of plate thickness on<br />

mechanical properties<br />

Figure 6 shows the evolution of yield strength and<br />

tensile strength, <strong>for</strong> a typical chemical composition<br />

and <strong>for</strong> normalised <strong>plates</strong>, against thickness.<br />

The blue-shaded band represents yield strength<br />

values calculated with a confi dence interval of ±2.3σ.<br />

Figure 6<br />

Published in The International Oil&Gas Engineer February 2008<br />

The red-shaded band represents<br />

tensile strength values calculated<br />

with a confi dence interval<br />

of ±2.3σ. The continuous red and<br />

blue lines represent the minimum<br />

and maximum requirements set<br />

by standard SA516-70 ed. 2004 ad.<br />

2006 [2].<br />

When plate thickness increases,<br />

the material’s yield strength and<br />

tensile strength decrease <strong>for</strong> a<br />

constant chemical composition.<br />

There<strong>for</strong>e, from a certain thickness,<br />

it is no longer possible to<br />

D

Figure 7<br />

ensure the minimum tensile strength requirements set<br />

by the standard by keeping the steel’s same chemical<br />

composition. Normally the carbon content has to be<br />

increased.<br />

Figure 7 shows the evolution of toughness against<br />

plate thickness. The coloured lines represent, <strong>for</strong><br />

various test temperatures, the lower toughness limits<br />

calculated <strong>for</strong> a typical chemical composition. 99% of<br />

the results are thus found above this limit. The two<br />

horizontal black lines represent typical minimum values<br />

25 J average (17 J lowest single value).<br />

For low plate thicknesses, the cooling rate (in air)<br />

is relatively high and can produce a ferritic-perlitic<br />

microstructure containing bainite. This negatively<br />

affects toughness in the untempered state. There<strong>for</strong>e<br />

the chemical composition and/or heat treatment<br />

requires adjustment.<br />

Above a certain thickness where toughness has<br />

reached a maximum, the material’s toughness de-<br />

Figure 8 and 9<br />

www.engineerlive.com<br />

Published in The International Oil&Gas Engineer February 2008<br />

PRODUCTION/PROCESSING/HANDLING 3<br />

creases with increased plate thickness, all other<br />

parameters remaining constant. This phenomenon is<br />

mainly due to increased grain size of the microstructure<br />

since the plate’s cooling rate decreases.<br />

There<strong>for</strong>e, to ensure the minimum requirements of the<br />

standard (or customer), <strong>for</strong> a given test temperature<br />

and thickness, it is necessary to modify the steel’s<br />

chemical composition and/or heat treatment.<br />

Let us look again at the solution of varying the carbon<br />

content to alleviate the negative effect of increasing<br />

the product’s thickness on the material’s mechanical<br />

properties. Figures 8 and 9 show the expected values<br />

of tensile strength and toughness at –29°C <strong>for</strong> a typical<br />

chemical composition of plate in normalised condition<br />

by varying the carbon content and plate thickness. As<br />

in the previous case, it appears necessary both <strong>for</strong> the<br />

carbon content to be increased to ensure the minimum<br />

tensile strength requirement, and to be reduced<br />

to improve toughness.<br />

Finally <strong>for</strong> certain combinations “product thickness –<br />

heat treatment – toughness test temperature – standard<br />

or customer specifi cation”, it can easily be seen<br />

that the single carbon content variation is no longer<br />

suffi cient. Furthermore, carbon negatively affects certain<br />

steel <strong>for</strong>ming properties, especially its suitability<br />

<strong>for</strong> oxycutting or its weldability.<br />

Finally, carbon comes directly into the calculation of<br />

the carbon equivalent which is often limited by the<br />

standards or customer specifi cations.<br />

There<strong>for</strong>e other methods have to be used to adjust the<br />

mechanical properties of the <strong>plates</strong>. However, these<br />

have to comply with the standard or be accepted by<br />

the customer.<br />

D

Alloying<br />

A reduction of carbon in the steel can be offset by<br />

adjusting the steel‘s chemistry using different alloying<br />

elements such as chromium, molybdenum, copper,<br />

nickel and/or niobium. Thus the alloying elements,<br />

by their effect, contribute directly to improving the<br />

steel‘s toughness, or allow to reduce the carbon content<br />

without reducing tensile strength and so indirectly<br />

improving the product‘s toughness.<br />

Figure 10<br />

Figure 10 shows the effect of alloying on the mechanical<br />

properties in the <strong>for</strong>m of zones. These zones<br />

are functions of the thickness and heat treatment<br />

depending on whether a „CMn“ concept or a<br />

„CMn + alloying“ concept is used. These zones represent<br />

(t; HP) combinations <strong>for</strong> which a plate can be<br />

produced according to standard SA516-70 ed. 2004<br />

ad. 2006 with minimum toughnesss in the transverse<br />

direction at quarter thickness of 25 J average<br />

(17 J lowest single value) at –29°C.<br />

However, this concept also has limits and certain<br />

„t; HP“ combinations cannot be reached. Standards<br />

and specifi cations restrict the alloying element content<br />

and these elements infl uence the carbon equivalent<br />

(the most commonly used <strong>for</strong>mula is:<br />

CE = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15). Furthermore,<br />

it should not be <strong>for</strong>gotten that the production<br />

cost of an alloyed plate is signifi cantly higher than<br />

that of a carbon-manganese plate.<br />

There<strong>for</strong>e, it is necessary to explore other avenues, <strong>for</strong><br />

example by directly adjusting the parameters of the<br />

<strong>heavy</strong> plate production process.<br />

PRODUCTION/PROCESSING/HANDLING 4<br />

www.engineerlive.com<br />

Accelerated cooling followed by<br />

tempering<br />

This solution consists in the accelerated cooling of<br />

the <strong>plates</strong> in order to produce a microstructure having<br />

a fi ner grain size and comprised of bainite and<br />

martensite. Nevertheless, to achieve good toughness<br />

on these <strong>plates</strong>, they have to receive a heat treatment<br />

(tempering) after quenching.<br />

However, certain standards or specifi cations do not<br />

permit this special treatment. Yet, according to standard<br />

SA516, <strong>for</strong> thick <strong>plates</strong> it is possible to reproduce<br />

cooling similar to that undergone by a thin plate after<br />

normalisation. This is not a matter of quenching but<br />

just the accelerated and controlled cooling of the thick<br />

<strong>plates</strong>. This accelerated cooling must be followed by<br />

tempering. The plate‘s delivery condition is no longer<br />

„N“ but „N + AC + T“.<br />

The goal is to produce the same microstructure as<br />

thin plate <strong>for</strong> thick plate. Grain size directly infl uences<br />

toughness. By acting on this parameter it is possible<br />

to satisfy the requirements in terms of toughness,<br />

while keeping enough carbon and alloying element<br />

content to reach the required levels of yield strength<br />

and tensile strength.<br />

Figure 11 shows typical plate microstructures obtained<br />

by means of these two types of process.<br />

Figure 11<br />

Published in The International Oil&Gas Engineer February 2008<br />

Figure 12, like fi gure 10, shows the effect of the<br />

„N + AC + T“ treatment on the mechanical properties.<br />

Here the zones also represent (t; HP) combinations <strong>for</strong><br />

which a plate can be produced according to standard<br />

SA516-70 ed. 2004 ad. 2006, with minimum toughness<br />

D

Figure 12<br />

in the transverse direction at quarter thickness of<br />

25 (17) J at –29°C, by the production method used.<br />

By implementing this type of process (when the<br />

standard or the customer specifi cation permits) the<br />

steelmaker can accept more severe requirements in<br />

terms of the (t; HP) combination or in terms of a pure<br />

requirement with constant (t; HP) combination.<br />

Conclusion<br />

By means of various examples we have seen that the<br />

mechanical properties of a <strong>heavy</strong> plate depend on<br />

many parameters. Not only the chemistry employed<br />

in preparing the steel in the steelplant, but also the<br />

thickness of the fi nished product and the type of process<br />

implemented strongly affect the characteristics of<br />

the fi nished product. Thus requirements that are too<br />

severe compared with those defi ned in the standard,<br />

especially when they only take account of part of<br />

the infl uencing parameters or when they are applied<br />

uni<strong>for</strong>mly to an entire range of thicknesses, limit the<br />

steelmaker‘s options to adjust the mechanical properties<br />

of <strong>heavy</strong> plate. For highly demanding specifi cations,<br />

as increasingly required by customers, it is<br />

there<strong>for</strong>e important to hold detail discussions with<br />

the steelmaker be<strong>for</strong>e ordering plate.<br />

PRODUCTION/PROCESSING/HANDLING 5<br />

BIBLIOGRAPHIC REFERENCES<br />

[1] HOLLOMON, John Herbert & JAFFE, L.D.<br />

Time-Temperature relations in Tempering<br />

Steel. Transaction of the AIME, 162, 1645,<br />

223-249<br />

[2] ASME Code Section II Part A, Edition 2004<br />

+ Addenda 2006, SA-516/SA-516M, Specifi -<br />

cation <strong>for</strong> <strong>pressure</strong> vessel <strong>plates</strong>, carbon<br />

steel, <strong>for</strong> moderate- and lower-temperature<br />

service<br />

[3] DETEMPLE Ingo, DEMMERATH Anja,<br />

The Effect of Heat Treatment, Hydrocarbon<br />

Engineering, November 1998, p. 67.<br />

[4] DETEMPLE Ingo, Alloying Concepts,<br />

Hydrocarbon Engineering, December 2003,<br />

p. 64.<br />

ABBREVIATIONS<br />

HP Hollomon Parameter<br />

t Thickness<br />

CE Carbon equivalent<br />

N Normalised<br />

AC Accelerated Cooling<br />

T Tempering<br />

Table 1: Table of abbreviations<br />

www.engineerlive.com<br />

Published in The International Oil&Gas Engineer February 2008

<strong>Dillinger</strong> HIC resistant <strong>pressure</strong> vessel <strong>plates</strong><br />

P.O. Box 1580<br />

66748 Dillingen<br />

Germany<br />

Phone: +49 6831 47-3453<br />

Fax: +49 6831 47-3089<br />

info@dillinger.biz • www.dillinger.de<br />

Statendamweg 81<br />

4905 AD Oosterhout, The Netherlands<br />

P.O. Box 190, 4900 AD Oosterhout,<br />

The Netherlands<br />

Phone: + 31 (0) 162 491500<br />

Fax. : + 31 (0) 162 429806<br />

john.roelands@aws.dillinger.biz<br />

hen.meesterman@aws.dillinger.biz<br />

www.ancoferwaldram.nl<br />

Road 1241, Between Junction 12 & 13<br />

Postfach: 17592, Jebel Ali,<br />

Dubai, United Arab Emirates<br />

Phone: +971 4 8 83 38 94<br />

Fax: +971 4 8 83 38 95<br />

randhir.venugopal@dme.dillinger.biz<br />

pjnarayanan@dme.dillinger.biz<br />

sales@dme.dillinger.biz<br />

www.dillingermiddleeast.com