USW@Work - National College Players Association - United ...

USW@Work - National College Players Association - United ...

USW@Work - National College Players Association - United ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

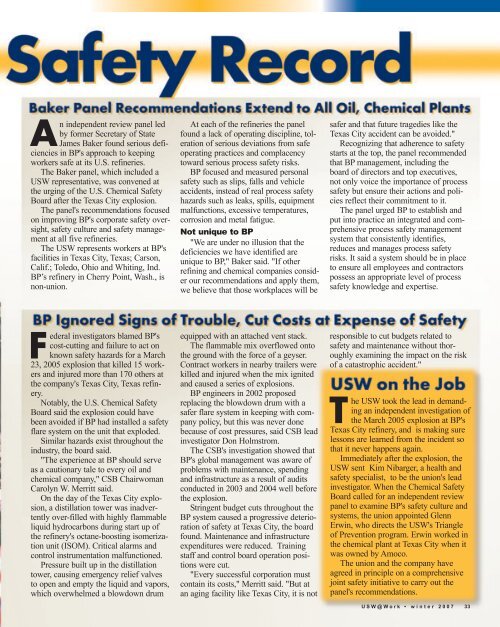

An independent review panel ledby former Secretary of StateJames Baker found serious deficienciesin BP's approach to keepingworkers safe at its U.S. refineries.The Baker panel, which included aUSW representative, was convened atthe urging of the U.S. Chemical SafetyBoard after the Texas City explosion.The panel's recommendations focusedon improving BP's corporate safety oversight,safety culture and safety managementat all five refineries.The USW represents workers at BP'sfacilities in Texas City, Texas; Carson,Calif.; Toledo, Ohio and Whiting, Ind.BP’s refinery in Cherry Point, Wash., isnon-union.At each of the refineries the panelfound a lack of operating discipline, tolerationof serious deviations from safeoperating practices and complacencytoward serious process safety risks.BP focused and measured personalsafety such as slips, falls and vehicleaccidents, instead of real process safetyhazards such as leaks, spills, equipmentmalfunctions, excessive temperatures,corrosion and metal fatigue.Not unique to BP"We are under no illusion that thedeficiencies we have identified areunique to BP," Baker said. "If otherrefining and chemical companies considerour recommendations and apply them,we believe that those workplaces will besafer and that future tragedies like theTexas City accident can be avoided."Recognizing that adherence to safetystarts at the top, the panel recommendedthat BP management, including theboard of directors and top executives,not only voice the importance of processsafety but ensure their actions and policiesreflect their commitment to it.The panel urged BP to establish andput into practice an integrated and comprehensiveprocess safety managementsystem that consistently identifies,reduces and manages process safetyrisks. It said a system should be in placeto ensure all employees and contractorspossess an appropriate level of processsafety knowledge and expertise.Federal investigators blamed BP'scost-cutting and failure to act onknown safety hazards for a March23, 2005 explosion that killed 15 workersand injured more than 170 others atthe company's Texas City, Texas refinery.Notably, the U.S. Chemical SafetyBoard said the explosion could havebeen avoided if BP had installed a safetyflare system on the unit that exploded.Similar hazards exist throughout theindustry, the board said."The experience at BP should serveas a cautionary tale to every oil andchemical company," CSB ChairwomanCarolyn W. Merritt said.On the day of the Texas City explosion,a distillation tower was inadvertentlyover-filled with highly flammableliquid hydrocarbons during start up ofthe refinery's octane-boosting isomerizationunit (ISOM). Critical alarms andcontrol instrumentation malfunctioned.Pressure built up in the distillationtower, causing emergency relief valvesto open and empty the liquid and vapors,which overwhelmed a blowdown drumequipped with an attached vent stack.The flammable mix overflowed ontothe ground with the force of a geyser.Contract workers in nearby trailers werekilled and injured when the mix ignitedand caused a series of explosions.BP engineers in 2002 proposedreplacing the blowdown drum with asafer flare system in keeping with companypolicy, but this was never donebecause of cost pressures, said CSB leadinvestigator Don Holmstrom.The CSB's investigation showed thatBP's global management was aware ofproblems with maintenance, spendingand infrastructure as a result of auditsconducted in 2003 and 2004 well beforethe explosion.Stringent budget cuts throughout theBP system caused a progressive deteriorationof safety at Texas City, the boardfound. Maintenance and infrastructureexpenditures were reduced. Trainingstaff and control board operation positionswere cut."Every successful corporation mustcontain its costs," Merritt said. "But atan aging facility like Texas City, it is notresponsible to cut budgets related tosafety and maintenance without thoroughlyexamining the impact on the riskof a catastrophic accident."The USW took the lead in demandingan independent investigation ofthe March 2005 explosion at BP'sTexas City refinery, and is making surelessons are learned from the incident sothat it never happens again.Immediately after the explosion, theUSW sent Kim Nibarger, a health andsafety specialist, to be the union's leadinvestigator. When the Chemical SafetyBoard called for an independent reviewpanel to examine BP's safety culture andsystems, the union appointed GlennErwin, who directs the USW's Triangleof Prevention program. Erwin worked inthe chemical plant at Texas City when itwas owned by Amoco.The union and the company haveagreed in principle on a comprehensivejoint safety initiative to carry out thepanel's recommendations.<strong>USW@Work</strong> • winter 2007 33