EVA or PUR

EVA or PUR

EVA or PUR

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

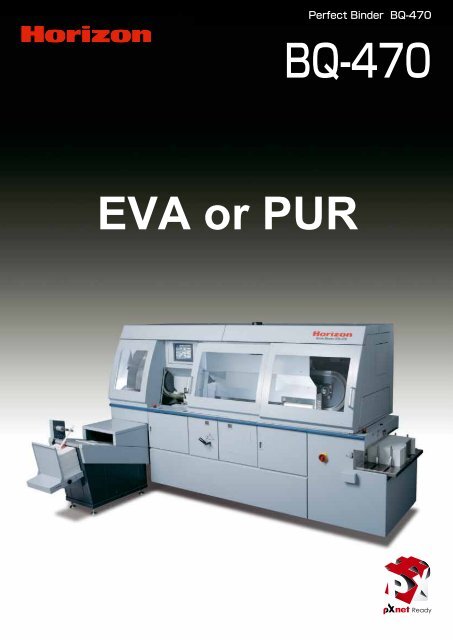

Perfect Binder BQ-470BQ-470<strong>EVA</strong> <strong>or</strong> <strong>PUR</strong>

Perfect Binder BQ-470The H<strong>or</strong>izon BQ-470 Fully Automated, 4-ClampPerfect Binder features an interchangeableglue tank f<strong>or</strong> both <strong>EVA</strong> and <strong>PUR</strong> adhesives.FeaturesKey Features◦ Fully automated set-up through the intuitive icon based LCD touchscreen.Col<strong>or</strong> TouchscreenMilling LeverNipping Height Adjustment◦ Customer replaceable glue tank unit f<strong>or</strong> both <strong>EVA</strong> hotmelt and <strong>PUR</strong> hotmelt adhesives to meetvarying customer requirements.◦ Simplified and accurate changeover to produce professionally finished books.◦ Equipped with two large application rollers f<strong>or</strong> strong, high-quality binds and a separate side gluetank f<strong>or</strong> added flexibility.◦ Space-saving design with front operation and front maintenance.◦ Book-binding up to 65 mm (2.55”) thickness.◦ Easily operated by anyone in the bindery. Maximum cycle speed is 1,350 books per hour (<strong>EVA</strong>hotmelt glue).◦ Ergonomic sliding windows provide easy, safe access and a clear view of operations.The 10.4 inch large col<strong>or</strong> touchscreenmaximizes ease of operation.Trouble-shooting screen helps operat<strong>or</strong>maintain smooth production.Three different milling styles can be selected:Milling Off, Milling f<strong>or</strong> <strong>EVA</strong> <strong>or</strong> Milling f<strong>or</strong> <strong>PUR</strong>.A strong, rigid nipping mechanism ensureshigh quality binding. The nipping height issimple and easy to adjust.Suction Cover FeedSupersonic Double Feed Detect Sens<strong>or</strong>TransmissionSens<strong>or</strong>SheetsReceivingSens<strong>or</strong>Detects spaceThe advanced rotary suction feed systeminsures faster production. A wide range ofcover sheets can be handled without anymarking.The supersonic double feed detect sens<strong>or</strong>comes standard. Advanced detection withsupersonic sens<strong>or</strong> ensures accurate doublefeed detection even with a solid black printedsheet.Delivery Convey<strong>or</strong>Smoke Extract<strong>or</strong>The automated elevation convey<strong>or</strong> can stackbooks up to 300 mm (11.8”) high. The joggingtable is attached to the convey<strong>or</strong> f<strong>or</strong> efficientoperation.Extracts fumes of hotmelt glue f<strong>or</strong> comf<strong>or</strong>tablew<strong>or</strong>king conditions.

8 8 18 11Perfect Binder BQ-470<strong>PUR</strong> Tank and <strong>EVA</strong> TankThe BQ-470 inc<strong>or</strong>p<strong>or</strong>ates the remarkable <strong>PUR</strong> binding mechanism andfeatures an interchangeable glue tank, f<strong>or</strong> both <strong>EVA</strong> and <strong>PUR</strong> adhesives.<strong>PUR</strong>MU-470<strong>PUR</strong>Polyurethanereactive adhesivesuitable f<strong>or</strong> coatedstock. Lay-flatbinding can beperf<strong>or</strong>med.<strong>EVA</strong>MU-470<strong>EVA</strong>Commonly used f<strong>or</strong>all kinds of binding.The melted gluecan be usedrepeatedly sothere's no need toclean up the tankafter operation.One to One Book ProductionVariable Production Software V-470S OptionExisting machines are easily upgradeable in the field by adding optional V-470Svariable production software and SI-470 book thickness measuring device.Book Thickness Measuring Device SI-470AOptionThe SI-470A is used to measure the book block thickness and transfer thethickness inf<strong>or</strong>mation into BQ-470 Variable.Cleaning and Replacement of MU-470<strong>PUR</strong>Manage your bindery with JDF enabled control system.The application drums and back spinner liftand latch to provide easy access f<strong>or</strong> cleaningof the tank.Install the special drain f<strong>or</strong> glue run-off. The<strong>PUR</strong> tank and drums are Teflon coated sothat the remaining glue can be easily peeledoff after cooling.Strong, Environmentally Friendly <strong>PUR</strong> SolutionPolyurethane Reactive, also called <strong>PUR</strong>, is a polyurethane adhesiveattracting attention f<strong>or</strong> binding strength and eco-friendliness.Sliding glue tank f<strong>or</strong> easy replacement. Pullout the tank and remove it with the optionalspecial lifter.pXnet System OptionThe H<strong>or</strong>izon pXnet Bindery Control System is used as a central controlpoint to schedule w<strong>or</strong>k, send job data to each finisher, monit<strong>or</strong> statusof finishers and collect production statistics from finishers in real-time.pXnet brings efficiency and value in high-mix/low-volume productionenvironments where frequent job changeovers are needed.The pXnet system can also be interfaced with an existing w<strong>or</strong>kflow f<strong>or</strong>automated JDF set-up.Strong and Lay-Flat BindingDurable against TemperatureJ D FAs the printing industry diversifies, there is growing demand f<strong>or</strong>binding with col<strong>or</strong> sheets. <strong>EVA</strong> hotmelt glue has difficulty bindingcoated stock firmly, and does not currently enable acceptable lay-flatbinding. However, <strong>PUR</strong> hotmelt glue can provide adequate bindingstrength and lay-flat quality f<strong>or</strong> both offset and digital prints. *1<strong>PUR</strong> hotmelt glue retains durability andflexibility in both high and low temperatures.The temperature resistance f<strong>or</strong> <strong>PUR</strong> hotmelt glueranges from –20 to 120 degrees Celsius versus 0to 60 degrees Celsius f<strong>or</strong> <strong>EVA</strong> hotmelt glue. Thisallows <strong>PUR</strong> bound books to be handled in almostany climate <strong>or</strong> location.8 18 16 3 8 18 16 36 36 3J D FJ M FJ D FMISJ D F8 18 16 3<strong>PUR</strong> hotmelt glue provides the best page spread comparedto traditional <strong>EVA</strong> hotmelt glue. High binding strength allowsf<strong>or</strong> the application of a small amount of glue, allowing thepages to lay flat when the book is opened. *1(*1: Depends on the binding condition.)Ecology<strong>PUR</strong> adhesive is environmentally friendly,allowing <strong>PUR</strong>-bound books to be recycled.<strong>PUR</strong> also has a lower melting point (120degrees celsius) than <strong>EVA</strong> f<strong>or</strong> operationalenergy savings.Prepress Press Digital Press Operation Mgr1 CutHydraulic c CutterAPC-61IIThree-knife TrimmerHT-80Three-side TrimmerHT-30/30C2 Fold3BindComputerized FolderAFC-746FAFC-746S/746DAFC-744A/744SAFC-566FGAFC-566AAFC-564AAFC-546AAFC-544AAF-566T4FAF-406T6A8 8 116 6 36 36 36 33Perfect BinderSB-09SSB-07BQ-470BQ-270/270CBQ-270VCase BinderHCB-2Perfect Binding LineCABS6000CABS4000S44 1StitchSaddle-stitching SystemStitchLiner6000StitchLiner5500BookletmakerSPF-200A/FC-200A5Job Ticket8 8 18 18 18 18 116 6 36 36 36 36 33Digital FinishPrinterIn-line Saddle-stitching SystemStitchLiner6000 DigitalIn-line FolderAF-566F DigitalControl PCPostpressSatellite PCDocument FinisherCol<strong>or</strong>W<strong>or</strong>ks Pro PlusCol<strong>or</strong>W<strong>or</strong>ks888Digital FinishJob Ticket BCR8888 16 35 4 Stitch 3 Bind 2 Fold 1 Cut

Perfect Binder BQ-470BQ-470 Maj<strong>or</strong> SpecificationsBinding Mode Binding with milling, Binding without milling and PaddingNumber of Clamps 4Book Block Size(Top-Bottom x F<strong>or</strong>e-edge)Max. 320 x 320 mm (12.59” x 12.59”)Min. 145 x 105 mm (5.71” x 4.14”)1 to 65 mm (0.040” to 2.560”)Book Thickness (The book thickness can be limited depending on the sheet weight,book size and milling depth.)Max. 320 x 660 mm (12.59” x 25.98”)(Up to 350 mm <strong>or</strong> 13.77” f<strong>or</strong>wards from the clamp face.)Cover Size(Top-Bottom x F<strong>or</strong>e-edge)(Up to 310 mm <strong>or</strong> 12.20” backwards from the clamp face.)Min. 135 x 225 mm (5.32” x 8.86”)(Up to 115 mm <strong>or</strong> 4.53” f<strong>or</strong>wards from the clamp face.)(Up to 110 mm <strong>or</strong> 4.34” backwards from the clamp face.)Cover Weight RangeN<strong>or</strong>mal Paper 81.4 to 302.4 gsmCoated Paper 104.7 to 348.9 gsmCover Pile Height Max. 150 mm (5.9”)Warm up Time 60 min.<strong>EVA</strong>: 150 to 210 degrees Celsius (180 degrees Celsius f<strong>or</strong> HM-220)Spine Glue TankGlue Temperature<strong>PUR</strong>: 110 to 140 degrees CelsiusSide Glue Tank <strong>EVA</strong>: 150 to 210 degrees Celsius (170 degrees Celsius f<strong>or</strong> HM-403)Maximum Milling Depth 4 mm (0.157”)Cycle SpeedMax. 1,350 cycles/hr. (<strong>EVA</strong>)Max. 1,000 cycles/hr. (<strong>PUR</strong>)Voltage / Frequency3-Phase 200 / 220 / 400 V, 50 / 60 HzThe external transf<strong>or</strong>mer is necessary f<strong>or</strong> 220 V / 400 V.3-Phase 200 V 50 / 60 Hz 10.5 / 12.0 A (Max. 17.9 / 18.2 A)Rated Current 3-Phase 220 V 50 / 60 Hz 8.1 / 8.7 A (Max. 11.9 / 11.0 A)3-Phase 400 V 50 / 60 Hz 5.7 / 6.5 A (Max. 7.7 / 7.8 A)3-Phase 200 V 50 / 60 Hz 3.3 / 4.0 kWPower Consumption 3-Phase 220 V 50 / 60 Hz 2.7 / 3.0 kW3-Phase 400 V 50 / 60 Hz 3.8 / 4.2 kWHeat Output 13,030 kJ (3,120 kcal)3.7 kW x 1, 750 W x 1, 650 W x 1, 400 W x 1, 200 W x 3, 100 W x 1,Mot<strong>or</strong>s40 W x 1, 25 W x 2Delivery Convey<strong>or</strong>: 40 W x 1, 60 W x 1650 W x 1Heaters<strong>EVA</strong>: 2.2 kW x 1<strong>PUR</strong>: 900 W x 1, 80 W x 1With delivery convey<strong>or</strong> and milling blower duct:Machine Dimensions3,620(W) x 2,240(D) x 2,000(H) mm (142.6” x 88.2” x 78.8”)Without delivery convey<strong>or</strong> and milling blower duct:3,220(W) x 1,090(D) x 2,000(H) mm (126.8” x 43.0” x 78.8”)Main Body 1,970 kg (4,344 lb)Machine Weight Delivery Convey<strong>or</strong> 99 kg (219 lb)Transf<strong>or</strong>mer 106 kg (234 lb)*The machine design and specifications are subject to change without any notice.▇▇▇▇▇▇▇▇▇▇▇▇T-470 Weekly TimerOptionsSI-470A Book Thickness Measuring DeviceThe SI-470A is a book thicknessmeasuring and input device f<strong>or</strong> furtheroperation efficiency.The T-470 weekly timer automaticallyswitches power on at pre-set times f<strong>or</strong>quick makeready. Time and day of theweek can be set.PM-470 Premelt Tank (18 litter)The PM-470 is the premelt tank f<strong>or</strong><strong>EVA</strong> hotmelt glue.L-470 Manual Simple LifterF-470 F<strong>or</strong>k f<strong>or</strong> LifterThe L-470 is a hand lifter f<strong>or</strong> easy andsafe tank replacement.The F-470 f<strong>or</strong>k is a custom-fitattachment to the lifter that holds theglue tank firmly in position f<strong>or</strong> easy andsafe tank replacement.S-470 Stand f<strong>or</strong> Melt Tank UnitThe S-470 stand is designed t<strong>or</strong>eceive and hold the glue tank unitafter replacement.Machine Dimensions Unit : mm (inch)Height = 2,000 (78.8”)1,090(43.0”)400(15.8”)3,220 (126.8”)BQ-470▇▇M-470 Glue Melting HeaterThe M-470 is a lab<strong>or</strong>at<strong>or</strong>y oven usedto premelt the <strong>PUR</strong> hotmelt glue.Transf<strong>or</strong>merHeight = 480 (18.9”)320(12.6”)444(17.5”)1,150(45.3”)510(20.1”)2,240(88.2”)▇▇B-470 Teflon Coated BeakerThe B-470 Teflon coated beaker canbe used to premelt the <strong>PUR</strong> hotmeltglue to refill the glue tank.111031/SO/BQ470/11E/TV