Gledhill High Efficiency Condensing Boiler - Gledhill Spare Parts

Gledhill High Efficiency Condensing Boiler - Gledhill Spare Parts

Gledhill High Efficiency Condensing Boiler - Gledhill Spare Parts

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

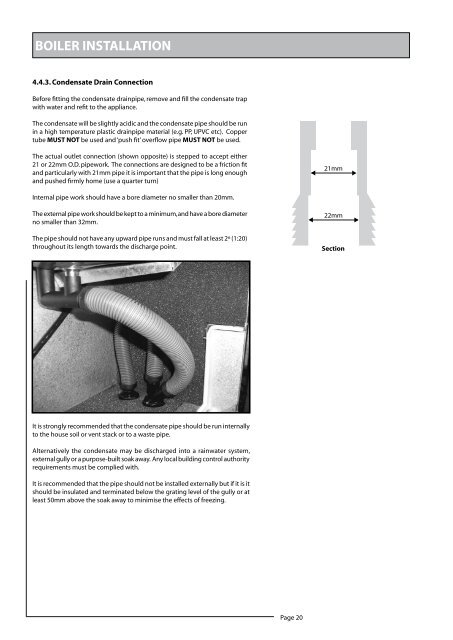

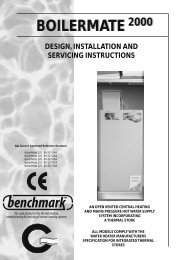

BOILER INSTALLATION4.4.3. Condensate Drain ConnectionBefore fitting the condensate drainpipe, remove and fill the condensate trapwith water and refit to the appliance.The condensate will be slightly acidic and the condensate pipe should be runin a high temperature plastic drainpipe material (e.g. PP, UPVC etc). Coppertube MUST NOT be used and ‘push fit’ overflow pipe MUST NOT be used.The actual outlet connection (shown opposite) is stepped to accept either21 or 22mm O.D. pipework. The connections are designed to be a friction fitand particularly with 21mm pipe it is important that the pipe is long enoughand pushed firmly home (use a quarter turn)21mmInternal pipe work should have a bore diameter no smaller than 20mm.The external pipe work should be kept to a minimum, and have a bore diameterno smaller than 32mm.The pipe should not have any upward pipe runs and must fall at least 2º (1:20)throughout its length towards the discharge point.22mmSectionIt is strongly recommended that the condensate pipe should be run internallyto the house soil or vent stack or to a waste pipe.Alternatively the condensate may be discharged into a rainwater system,external gully or a purpose-built soak away. Any local building control authorityrequirements must be complied with.It is recommended that the pipe should not be installed externally but if it is itshould be insulated and terminated below the grating level of the gully or atleast 50mm above the soak away to minimise the effects of freezing.Page 20