Download - Trade Garage Equipment

Download - Trade Garage Equipment

Download - Trade Garage Equipment

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

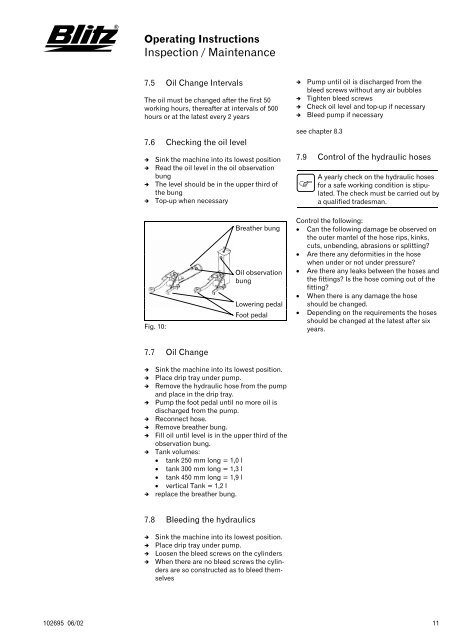

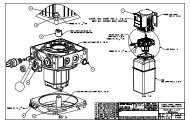

Operating InstructionsInspection / Maintenance7.5 Oil Change IntervalsThe oil must be changed after the first 50working hours, thereafter at intervals of 500hours or at the latest every 2 years7.6 Checking the oil level! Sink the machine into its lowest position! Read the oil level in the oil observationbung! The level should be in the upper third ofthe bung! Top-up when necessary! Pump until oil is discharged from thebleed screws without any air bubbles! Tighten bleed screws! Check oil level and top-up if necessary! Bleed pump if necessarysee chapter 8.37.9 Control of the hydraulic hosesA yearly check on the hydraulic hosesfor a safe working condition is stipulated.The check must be carried out bya qualified tradesman.Fig. 10:Breather bungOil observationbungLowering pedalFoot pedalControl the following:• Can the following damage be observed onthe outer mantel of the hose rips, kinks,cuts, unbending, abrasions or splitting?• Are there any deformities in the hosewhen under or not under pressure?• Are there any leaks between the hoses andthe fittings? Is the hose coming out of thefitting?• When there is any damage the hoseshould be changed.• Depending on the requirements the hosesshould be changed at the latest after sixyears.7.7 Oil Change! Sink the machine into its lowest position.! Place drip tray under pump.! Remove the hydraulic hose from the pumpand place in the drip tray.! Pump the foot pedal until no more oil isdischarged from the pump.! Reconnect hose.! Remove breather bung.! Fill oil until level is in the upper third of theobservation bung.! Tank volumes:• tank 250 mm long = 1,0 l• tank 300 mm long = 1,3 l• tank 450 mm long = 1,9 l• vertical Tank = 1,2 l! replace the breather bung.7.8 Bleeding the hydraulics! Sink the machine into its lowest position.! Place drip tray under pump.! Loosen the bleed screws on the cylinders! When there are no bleed screws the cylindersare so constructed as to bleed themselves102695 06/0211