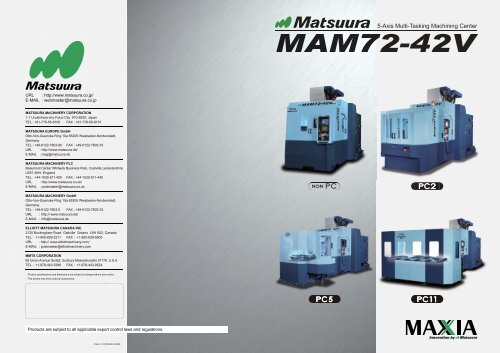

Matsuura mam72-42v

Matsuura mam72-42v

Matsuura mam72-42v

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

With the advent of globalization a new economic reality has dawned forWestern manufacturers, heralding a new era of competition from not onlyestablished markets, but also emerging economies such as China & India.The big question for CNC operations in the Western hemisphere is: "How dowe compete with low wage economies & a seemingly endless race to thebottom of the cost chain?"There is only one answer for these concerns: Unmanned multi pallet,multi axes CNC production processing.<strong>Matsuura</strong> lead the field in unmanned multi pallet CNC production solutions,in both 4 axes horizontals & 5 axis milling & mill turn configurations. OurMAM72 Series of 5 axis multi pallet machine tools have been the clearmarket leader for machines in their class for over a decade with in excessof 500 highly productive machines supplied to some of the worlds leadingOEM manufacturers & their tier one & tier two subcontractors.Completing our range of MAM72 5-axis products is the MAM72-42V for theproduction of small to medium sized complex geometric workpieces - inshort batches or for long periods of reliable lights out unmanned production.This formidable multi pallet 5 axis machine tool emerges from our rich &prestigious heritage in the design & manufacture of class leading productionprocesses & solutions, & incorporates many decades of <strong>Matsuura</strong>'s hardwon knowledge, expertise & total quality ethos.MAM72-25VMAM72-3VSMAM72-35VMAM72-3VMMAM72-42VMAM72-63V2 3

5-Axis Machining ExampleSample:W16 Engine BlockMaterial:A7075Tools:22CycleTime:52 hours 45 minutesBenefitThis complex W16 engine block wasmachined in just two operations. Byachieving a shorter tool overhang,greater rigidity is assured, s tool life isextended & metal removal rates areexceptionally high.FrontBackHigh Speed High Accuracy5-axis Mold Machining ExampleSample:Mold ExampleMaterial:CENA1(HRC40)Tools:5CycleTime:11 hourschoice for the cost effective "one hit machining" oftolerance critical, large & complex components in shortrun batches or long unattended production runsOne Hit Process, One Set UpBenefitBenefitBenefitThe concept behind 5-axis machining is tocomplete the component in "one hit, one loading",greatly reducing set up times. Because of thisprocess of "one hit, one oading", set up timesbetween different operations are eliminated. Inaddition to this, errors caused by set upchangeover & fixturing, usually between 2 or moredifferent machine tools, are also eliminated,adding assured precision to the process.By utilising the dynamics of the4th / 5th table, a short cutteroverhang can be applied to manyworkpieces in many materials,vastly improving surface finish.5 axis heel cutting is utilised for theouter machining of the workpiece.The outer curved surface ismachined using the bottom edge ofa square or radius end mill.Comparing this tool to a ball endmill the larger cutting volume of asquare or radius end mill fastermetal removal rates are achieved.TCPC (Tool Centre Point Control)aids simple set up & machining of aworkpiece. An "on machine"function, this allows users tochange aspects of the job at handwithout resorting to changing thepost processor.6 7

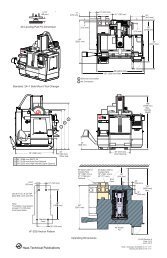

phas been designed as a fully fledged & integrated 5 axismachine tool not just a 3 axes machine tool with "bolt on"4th & 5th table. Due to the design integration at themachines inception, the MAM72-42V has an optimizedwork enclosure, offering maximum working envelopes andlimiting interference with the axes strokes.H350 mmØ 520mmH 350 mmoptionØ 420mmMaximum Work SizeLarger work sizes can be accommodated,with some restrictions. Please consult your<strong>Matsuura</strong> dealer for assessment of yourwork size.Robust & Compact A/C-Axis Table, In-House DesignThe A/C axes motors generate exceptionally highspeed rotation and high torque. Supplied asstandard, the B/ C axis are equipped with a provenscale feedback system, delivering superbrepeatability and many years of reliable, highlyaccurate operation.A/C-Axis Table SpecificationRotation Speed (A/C) 30 / 50 min -1Max. Acceleration (A/C) 1,730 / 4,054 deg/sec 2Max. Table Cutting Torque (A/C)Table Break Torque (A/C)Min. Indexing (A/C)Pallet* Clamping ForceIndexing Accuracy (A/C)Indexing Repeatability (A/C)Pallet is available on1,080 / 240 Nm2,152 / 1,610 NmMachine0.001 deg41.5 kN5/5 sec.2/ 2 sec.Optimized 5-Axis Machine StructureIntegrated into the design of the MAM72-42V, the<strong>Matsuura</strong> A/C-axis table has been designed in-houseusing FEM analysis. Configured with robust twin sidesupports, the table achieves maximum design rigidity.Both the APC & single table variant of the MAM72-42V achieve similar travels & offer superbmanoeuvrability. The diagram shown features thetwin pallet version.Optional TAILSTOCK isavailable for machining of longslender workpiecesOn conventional machines there is a dead space (shown as a hatched area)generated by the fixed nature of the APC arm mechanism. <strong>Matsuura</strong>'s provenFlip-Up Arm APC eliminates this dead space, utilizing the whole of the workingarea.X-Axis Travel : 520mm (20.47 in.)C-Axis Travel : 360degDeveloped & proven by <strong>Matsuura</strong> the Flip-Up Arm APCBy folding up the APC arm, we couldminimize the length of machine.Z-Axis Travel : 510mm (20.07 in.)A-Axis Travel -110 +110deg-110 +10degY-Axis Travel : 730mm (28.74 (28.74 in.) in.)Table Size : Ø300mmLoading Capacity : 235kgwith PC : 300mmLoading Capacity : 200kgThru Table Vacuum Clamping option6 Port Thru Table Clamping System is available as an option.8 9

Designed & Assembled "in-house"<strong>Matsuura</strong>'s SpindleEngineers work in adedicated Clean Roomcomplex to assure thehighest standards of buildquality & reliability. Ourultra precision spindlesare guaranteed to have arunout of less as an actual measured value than1pm (0.000039 in.) at the spindle nose.Vacuum Type Coolant Turu SpindleThis function prevents coolant from dripping &scattering in the machine enclosure & in the ATCduring tool change. A vacuum mechanismaspirates the remaining coolant in the circuit.optionEco-Friendly Grease LubricationThe Spindle bearing islubricated by an automatedgrease supply system. Lownoise operation, withminimum air requirement.Eco friendly &maintenance free.20,000 min -1 spindle provide withspindle grease auto supply systemSpindle Thermal DisplacementCompensationoption<strong>Matsuura</strong>'s own Thermal DisplacementCompensation function assures long periods ofaccurate machining performance.Spindle Specifications / Spindle Motor Power & Torque Diagrams<strong>Matsuura</strong><strong>Matsuura</strong>BT40 Spindle SpecificationMax. Rotation Speed 15,000 min -1Spindle Motor Power & Torque DiagramTorque (Nm)Power (kW)1000100Spindle Motor Power & Torque DiagramTorque (Nm)Power (kW)1000100FromMats<strong>Matsuura</strong> by<strong>Matsuura</strong>:Hi-Tech ura:Spindles toosuit avast array of industrial uses & a myriad of materialsMotor Power7.5 / 15 kW(10HP)Motor Torque 119.3 Nm / 1,200 min -1Motor Torque Oil-Air10010130%ED RatingContinuous Rating120010 50 1001000 1500 10000Spindle Speed (min-1)150001010.1100101119.3 Nm5 min. Rating10 min. RatingContinuous Rating120010 50 1001000 1500 10000Spindle Speed (min-1)150001010.1BT40 Spindle SpecificationMax. Rotation Speed 12,000 min -1Motor Power7.5 / 11 kWMotor Torque 167 Nm / 630 min -1Bearing Lubrication Grease<strong>Matsuura</strong> Hi-Tech Spindle<strong>Matsuura</strong><strong>Matsuura</strong>Spindle Motor Power & Torque DiagramSpindle Motor Power & Torque DiagramTorque (Nm)Power (kW) Torque (Nm)Power (kW)50050 5005010010 10010BT40 Spindle SpecificationMax. Rotation Speed 20,000 min -1Motor Power 7.5 / 11 kW(15HP)Motor Torque 70.7 Nm / 1,500 min -1Bearing Lubrication Spindle GreaseAuto Lubrication<strong>Matsuura</strong>Spindle Motor Power & Torque DiagramTorque (Nm)Power (kW)5001001050%ED RatingContinuous Rating110 40 1320 4500 6000 20000501010.1<strong>Matsuura</strong>Spindle Motor Power & Torque DiagramTorque (Nm)Power (kW)500501001010150%ED RatingContinuous Rating10.110 40 1320 4500 6000 200001025%ED Rating50%ED RatingContinuous Rating11050%ED RatingContinuous Rating1Optional BT40 30,000 min -1 is availableSpindle Speed (min-1)Spindle Speed (min-1)170010 40 630 1000Spindle Speed (min-1)0.14000 10000 12000170010 40 630 1000Spindle Speed (min-1)0.14000 10000 1200010 11

Swarf ManagementFeatured only on <strong>Matsuura</strong> products, ourproven X-Type APC door design eliminates allopportunities for swarf to become trapped &build up, eventually causing machinedowntimeX-Type APC door and W-Type coverDesigned around the operator to maximise theirproductivity, efficiency & comfort, the MAM72-42V offerssuperb ergonomic functionality.Both Side AccessibilityWide and capacious machineaccess at both the APC stationand enclosure door.Tempered glass in the mainenclosure window assuresclearer vision for longer periods.This exclusive <strong>Matsuura</strong> X-Type doordesign still maintains the MAM72-42V'slargest in class working envelope &workpiece accommodationLift-Up Chip ConveyorsoptionScraper TypeDrum FilterCoolant Tank Capacity 670Oily Coolant Applicable (less than 10 cSt)By integrating steep angled steel Z-Axis covers,swarf is efficiently directed into 2 gutters, wherestandard spiral chip conveyors rapidly transportwaste material out of the enclosure. Toaccommodate high volumes of metal removal ofall types, a wide variety of swarf managementsystem designs are available.Hinge TypeDrum FilterCoolant Tank Capacity 600Only Water Solution Coolant Applicable (less than 10 cSt)In case of using oily coolant,please consult <strong>Matsuura</strong>Front (Work Station Side)Operator Side12 13

<strong>Matsuura</strong>NC system is selectable from<strong>Matsuura</strong>or <strong>Matsuura</strong><strong>Matsuura</strong>Equipped with the latest highperformance CPU, Windows XPProfessional, graphical user interface,USB port.10.4 inch color LCD, soft keys verticallyarranged.Expanded media for data backup suchas PC card drive, USB Memory, USBHDD and so on.For High Speed and a Finer Surface FinishMachining for General Parts or Mold & DieAdvanced Zee LagY<strong>Matsuura</strong>Machining for more Complex, Precision PartsIZ-1/COMPMax.5,000 Block Look Ahead + Spline InterpolationAfter compressing a maximum of 50 blocks and engaging the100 Block Look Ahead function, IZ-1/COMP interpolates &applies to the B-Spline to the nearest point selected.Windows XP is a registered trademark of the Microsoft Corporation<strong>Matsuura</strong>High speed CPU and FSSB, internalCNC bus, optical fiber cables usedfor high speed data transfer.Nanometer resolution.10.4 inch color LCD, soft keysvertically arranged, Compact FlashPort, PC file management structureFor High Speed and a Finer Surface FinishMachining for General Parts or Mold & DieIZ-1/15FMachining for more Complex, Precision PartsIZ-1/30NF, IZ-2/150NFLook Ahead Linear Ace./dec.+ Nano interpolationExecuting the max. 200(IZ-1/30NF) or 600*(IZ-2/150NF) - block lookahead linear acc./dec. before interpolation achieves a smoothacc./dec. across the multiple blocks calculated by nano order.max.1,000 block available as option.Proven Software Performance for 5-Axis MachiningHandy ManHandy ManII providesmajor savings by reducingset-up, programming,operating & maintenancetimes.Handy ManHigh-Speed PrecisionMachining Program Support FunctionWhen utilizing this software,setting the required partaccuracy level is quick,simple and userfriendly, allowingyou to prioritizeprecision againstspeed.IPCEasy Programming (3+2-Axis)Cycle800Post Processor CAMplete TruePathl CAMPlete TruePath provides everythingyou need to analyze, edit, optimize andverify 5-axis toolpaths in a seamless 5 view3D environment. Take control of your postprocessing and reap the benefits from your<strong>Matsuura</strong> 5-axis machine.optionG-Tech 840DI offers, as standard feature,CYCLE800 which takes over necessarycalculations of coordinate values includingnecessary axes motions. When rotary axes aremoved, rather complex calculations, in line withmachine axes configuration, should be made forre-calculatingandestablishingsuitable workcoordinatesystem for thenew surface &its orientation.optionFollowing functions are available on theSimilar ones are available on theTool Diameter Interpolationsoptionon 5-AxisCUT3DC etc...CUT3DC sets the value oftool-off-sets automaticallyfor simultaneous 5-Axismachining according tothe pre-set value. Itenables the safe &automatic use of differentdiameter tools during 5-Axis machining with thetable tilted.NC Packageoption5-axis relatedOption PackageRTCP(TRAORI,CUT3DC,Cycle800,ect...)High SpeedHigh Precision PackageAutomatically Controlled Toolpathoption/ Tool Speed TRAORI5-Axis Transformation (TRAORI) is thekinematics transformation function of G-Tech840DI which realizes easy tool center pointprogramming for 5-Axis machining. The pathand path velocity of the tool center point, can beprogrammed based on the workpiececoordinate system, in the same way as that for3-Axis machine tools.Table RotationTable Tilt<strong>Matsuura</strong><strong>Matsuura</strong>Large Dia.Small Dia.ProgramCommandPackages of NC Software,tailored to your production,are available. Please consultyour <strong>Matsuura</strong> dealer for full details &assessment of your requirements.Program CommandTool center point moves according to the programcommand with table tilt/rotation.14 15

Main SpecificationsEquipment: Standard : OptionMovement & RangesX-Axis TravelY-Axis TravelZ-Axis TravelA-Axis TravelA-Axis TravelC-Axis TravelTable / PalletWorking SurfaceWorking SurfaceLoading CapacityLoading CapacityMax. Work SizeMax. Work SizeSpindle : BT40Spindle Speed RangeType of Spindle Taper HoleSpindle Bearing Inner DiameterMax. Spindle TorqueSpindle Motor (Low Speed:Continuous / 40%)Spindle Motor (High Speed:Continuous / 30 min.)FeedrateRapid Traverse (X/Y/Z)Rapid Traverse (A/C)Rapid Feed Acceleratio (X/Y/Z)Rapid Feed Acceleratio (A/C)Min.Movement Increment (X/Y/Z)Min.Movement Increment (A/C)Automatic Tool ChangerType of Tool ShankType of Retention KnobNumber of ToolsMax. Tool Diameterwhen the pockets onMax. Tool Diameter both sides are emptyMax. Tool LengthMax. Tool LengthMax. Tool WeightMethods of Tool SelectionTool Cahnge Arm520 mm (20.47 in.)730 mm (28.74 in.)510 mm (20.07 in.)-110 +110 deg-110 +10 deg360 degØ300 mm (Ø11.81 in.)300 300 mm (11.81 x 11.81 in.)235 kg (507 lb.)200 kg (440 lb.)Ø520 x H350 mm ( ÿ20.47 x H13.77î)Ø420 x H350 mm ( ÿ16.53 x H13.77î)40 12,000 min -1 (Grease Lubrication)7/24 Taper BT40Ø80 mm (Ø3.14 in.)167 Nm / 630 min -1AC 7.5 / 11 kWAC 7.5 / 11 kW50,000 mm/min (1,968.5 ipm)30/50 min -10.89 / 0.9 / 1.12 G1,730 / 4,054 deg/sec. 20.001 mm (0.000039 in.)0.001 degJIS B 6339 40TJIS B 6339 40P40 (Chain-Pot Type)300 mm (11.81 in.)350 mm (13.77 in.)10 kg (22 lb.)Memory randomDouble grip typePower SupplyInput PowerVoltage50 kVAAC 200/220 10% VFrequency50/60 1 HzAir Source0.54 0.93 MPaRequired Air Volume50 (max.300 N /min )Tank CapacityHydraulic oil tank capacityCoolant tank capacity40600Standard Accessories01.Total splash guard02.ATC Auto Door03.Synchronized Tapping04.AD-TAP Function05.IPC Function06.Spindle oil cooler07.Feed axis grease auto supply08.Coolant unit09.Spiral chip conveyor10.Chip flush system11.Movable manual pulse generator12.Spindle overload protect13.Workpiece counter (9 sorts of M function)14.Work Light (fluorescent)15.Standard mechanical tools & tool box16.Machine color paint17.Levelling plates and bolts (not utilised for the foundation)18.Scale feedback for A & C -axis19.Handy ManII Y/F20.CD-ROM for Memory Card Operation only for <strong>Matsuura</strong>21.<strong>Matsuura</strong> Safety SpecificationSpindle12,000 min -1 (L7.5/11 kW, H5.5/10 kW,Grease Lubrication)15,000 min -1 (L7.5/15 kW, H7.5/15 kW,Oil-Air Lubrication)20,000 min -1 (7.5/11 kW, Auto Grase Supply)30,000 min -1 (L13/17.5 kW, H18.5/22 kW,Oil-Air Lubrication)ATC40 (BT40 Chain Pot Type)320 (BT40 Matrix Type)80 (BT40 Chain Pot Type)360 (BT40 Matrix Type)120 (BT40 Matrix Type)400 (BT40 Matrix Type)150 (BT40 Matrix Type)440 (BT40 Matrix Type)180 (BT40 Matrix Type)480 (BT40 Matrix Type)210 (BT40 Matrix Type)520 (BT40 Matrix Type)240 (BT40 Matrix Type)High Accuracy ControlScale Feedback SystemXY-AxisScale Feedback SystemZ-AxisScale Feedback SystemXYZ-AxisScale Feedback SystemA-AxisScale Feedback SystemC-AxisSpindle Thermal Displacement ConpensationAPCNON-PCPC2PC5 (Floor Pallet System)PC11 (Floor Pallet System)PC24 (Tower Pallet System)PC17 (Linear Pallet System)CoolantCoolant UnitVacuum Type Coolant ThuruType AVacuum Type Coolant ThuruType BVacuum Type Coolant ThuruType C (2MPa)Vacuum Type Coolant ThuruType C (5MPa)Vacuum Type Coolant ThuruType C (7MPa)Coolant Flow CheckerMist Separator UnitMist Separator Unit with Fire Protect DamperCoolant Temperature ControllerTank 100Coolant Temperature ControllerTank 200Swarf ManegementTotal Enclosure GuradATC Auto DoorSpiral Chip ConveyorChip Flush SystemLift-Up Chip Conveyor (Hinge Type, Drum Filter)Chip BucketAir Blow For Chip/Swarf RemovalWorkpiece Cleaning Gun (Machine Side)Operation / MaintenanceAD-TAP FunctionIPC FunctionHandy ManII Y/FFeed-Axis Grease Auto SupplyWork Light8 Sets of Extra M FunctionSpindle Load Monitoring FunctionWeekly TimerSpindle Run Hour MeterRotary Wiper (Air Supply System)Rotary Wiper (Electrical System)Cumulative Run Hour Display UnitWork CounterExternal Manual Pulse GeneratorProgram End Announcement Light (Red,Yellow, Green)Safety Features<strong>Matsuura</strong> Safety SpecificationIn-Process Measurement / Broken Tool DetectionIn-Process Measurement / Auto Centerring (Touch Probe)Broken Tool Detection / Auto Tool Length (Touch Sensor)Broken Tool Detection / Auto Tool Length (Laser Sensor)In-Process Measurement (Touch Probe)+Broken Tool Detection(Touch Sensor)In-Process Measurement (Touch Probe)+Broken Tool Detection(Laser Sensor)TailstockTail Stock System300(1.18)Table Surface+0.02701424159+0.18014241590.025Ø99 0+0.025Ø50 0B(4 slots):1 st Glade C (4 parts):2 nd Glade Center Hole Details25BC45B74.5B8145CC90BPallet SyrfaceØ14(0.55)11(0.43)Ø20(0.78)A-A section120Ø16(0.62)M1222(0.86)30(1.18)Tapped HoleM12(1/2-13UNC)Ø70(2.75)+0.025 +0.001Ø25 0 (1) 015(0.59)Center Hole120(4.7)40(1.6)40(1.6)60(2.36)30(1.18)15(0.59)20(0.78)AA60(2.36)C20(0.78)20(0.78)125(5) 125(5)75(3) 75(5)25(1) 25(1)30(1.18)15(0.59)AA80(3.1)25(1) 25(1)75(5) 75(5)125(5) 125(5)300(1.18)Machine FrontUnit : mm (in.)16 17

Top View All Machines Height is same as 3,000 mm ( 118.1 in. )4911 (193.3)(280.5)7127(254.2)6457223840 toolsATC(88.1)520 toolsATC320 toolsATC240 toolsATC(214.9)545940 toolsATC(164.4) (126.7)(296.8)(274.6)(267.6)Incl. Optional Lift-Up Chip Conveyor(265.4)(97.5) (133.9)75396977679967422477 34034178 3220520 toolsATC320 toolsATC240 toolsATC6 Pallets4 tiresUnit : mm (in.)520 toolsATC320 toolsATC240 toolsATCSpindle Movement Interference[ X ] X-axis Stroke 520 mm (20.47 in.)[ Y ]Y-axis Stroke 790 mm (31.10 in.)[ Z ] Z-axis Stroke 510 mm (20.07 in.)[ A ] A-axis Stroke -110 ~ +110 deg[ C ] C-axis Stroke 360 degLoading Capacity 235 kg(518 lb.)Movable area shows movement of thespindle end (Gauge line).This diagram shows of the Y-axis travel as amovement of the spindle, however it is amovement of the table on the actual machine.A-Axis = 0 degMax. Work SizeATC Magazine SideSpindle Movement & RangeMax. Work SizeATC Magazine Side[ X ]260 260(10.23) (10.23)[ X ] X-axis Stroke 520 mm (20.47 in.)[ Y ]Y-axis Stroke 790 mm (31.10 in.)[ Z ] Z-axis Stroke 510 mm (20.07 in.)[ A ] A-axis Stroke -110 ~ +10 deg[ C ] C-axis Stroke 360 degLoading Capacity 200 kg(440 lb.)[ X ]260 260(10.23) (10.23)Center of C-Axis RotationCenter of A-Axis RotationMovable area shows movement of thespindle end (Gauge line).This diagram shows of the Y-axis travel as amovement of the spindle, however it is amovement of the table on the actual machine.A-Axis = 0 degOperator Panel SideCenter of C-Axis RotationCenter of A-Axis RotationOperator Panel SideFrom floor 1050 530 (20.86)From floor 1000 580 (22.83)(41.33)20 [ Z ](39.37)[ Z ] [ X ](0.78) 350 (13.77)70 350 (13.77)(13.77)Work StationSideWork StationSideWork StationSideWork StationSide325(12.79)[ A ][ Y ]405(15.94)(ÿ20.47)[ Y ]325 405(12.79) (15.94)Center of A-Axis Rotation(ÿ16.53)ATC Magazine SideOperator Panel SideATC Magazine SideOperator Panel Side[ A ]Center of A-Axis RotationA-axis = -90 deg / C-axis = -0,90,180,270 deg[ X ]Work StationSide(13.66)(10.59)347269Work StationSide[ X ](13.66)(10.59)347269325(12.79)302(11.88)[ Y ]405 (15.94)53(0.59)190(7.48)[ Y ]325(12.79)405 (15.94)302(11.88) 103(4.05)Spindle Diameter(ÿ7.48)Center of A-Axis RotationA-axis = -90 deg / C-axis = -0,90,180,270 degWork StationSideWork StationSide190(7.48)ATC Magazine SideOperator Panel Side[ Z ]ATC Magazine SideOperator Panel SideSpindle Diameter(ÿ7.48)[ Z ]Center of A-Axis RotationUnit : mm (in.)18 19