Brochure MultiSwiss 6x14 - Teximp SA

Brochure MultiSwiss 6x14 - Teximp SA

Brochure MultiSwiss 6x14 - Teximp SA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The efficient and economicsolution for manufacturing partsof moderate complexityAutomotiveMedicalElectronicsWatchmaking & Micromechanics2 <strong>MultiSwiss</strong> <strong>6x14</strong>

POWER AND FLEXIBILITY,A GUARANTEE OF FLAWLESS PRODUCTIONProductive■■Rapid barrel indexing made possible by thetorque motor.■■Ultra dynamic synchronous spindle drives.■■Independent speed for each position.Precise■■Exceptional rigidity through guide separation.■■Unsurpassed shock absorption with hydrostaticbearings.■■Thermal regulation of the entire machine.Outstanding performance■■■■■■■■■■■■■■■■■ ■Sliding headstock spindles with hydrostaticbushings.C axis at all positions.Polygon milling.14 linear axes, 7 C axes.Multi-tool design that allows the fitment of upto 18 tools on the machine.Up to 2 tools for second operation work.Optimal chip handling.Automatic regulation of machine temperature.“Plug & Play” system for attachments4 <strong>MultiSwiss</strong> <strong>6x14</strong>

PRODUCTIVITY AND PERFORMANCEBarrelThe barrel guarantees maximum precision at allpositions. The new indexing technology usinga torque motor allows for 0.3 sec indexing times,in complete silence.This system was tested for its reliability inover 40 million cycles before it received theTornos validation certificate.The independent spindles allow for ideal speedat each position and angular control for allmilling or radial drilling operations. With theC axis, combined operations (transmit) can alsobe performed through interpolation of thespindle and slide.SpindlesThe high-power synchronous drive spindles givethe machine great power. Acceleration timesare extremely short (0-8,000 rpm in less than onesecond). In addition to its own C axis, eachspindle has its own Z axis guided by hydrostaticbearings. This allows for increased shockabsorption and better lifespan of the tools andmachining surfaces.The <strong>MultiSwiss</strong> is extremely silent thanks toits torque motor driving the barrel as well asthe spindle drives and thus offers greater comfortof use for the operator.6 <strong>MultiSwiss</strong> <strong>6x14</strong>

GUARANTEED COST-EFFECTIVENESSModular multi-tool designUp to a maximum of 18 tools can be mountedto the machine, with up to 3 tools per position.It is also possible to mount various types ofattachments including : polygon milling attachments,standard or high-frequency drills formain and back work operations, thus expandingthe possible configurations of the <strong>MultiSwiss</strong>.Back workingThe independent back working slide withcapacity for 2 tools, combined with the secondoperation drive spindle, allow for complexturning or milling operations in masked time thatcan be oriented with respect to the operationsperformed.Frontal stationary drills (ESX-16)mounted on a dual support.Polygon milling attachment.1:1 radial drilling attachment.Stationary barfeeding deviceat position 1, stationary drillmounted on a dual support.Radial support forhigh-frequency spindle.2:1 radial drilling attachment.Turning toolholder and additionaldrilling toolholder.Basic turning toolholder (16x16).Frontal drilling attachment.<strong>MultiSwiss</strong> <strong>6x14</strong>7

producTiViTy and flexiBiliTy…ErgonomicsThe multiswiss was designed with the operatorin mind. With its excellent frontal access,it is user-friendly, ergonomic and innovative.The machining zone is completely open, allowingfor incomparable accessibility.chip removal is trouble-free thanks to thevertical slides that allow the chips to fall directlyinto the conveyor unit. The slides are equippedwith integrated cutting oil feed, thus limitingthe use of pipes that are often difficult to adjustand become traps for chips.Barfeeding : the choice of 1.5 m barsThis innovative design reduces logistics costs.loading is easier for the operator, thusallowing for increased machining quality thanksto reduced vibrations. This new barfeedingsystem also reduces chip length excess thicknessfor the face milling of each part.8 MultiSwiSS <strong>6x14</strong>

… guaranTeed ease of useWater / oil heat exchangerelectrical cabinetpart outletchilled waterproduction unitcutting oilfiltration device(50 µm)spindle oil filtrationdevice (5 µm)oil tank4 bar cutting oil pumpOptional 40 or 80 bar high-pressure pumploaderCompact all-in-one design !The multiswiss takes up less floor space :all peripheral units required for operations areintegrated at the back of the machine.The standard model of the multiswiss includesa loader and two-level filtration system.The container is equipped with an integratedwater / oil exchanger, making the machinecompatible with centralized water coolingnetworks. for customers without this type ofsystem, a chilled water production unit canbe added to the machine. in addition to the filter,cooling device and barfeeder, the machine’sbase is designed to include the chip conveyor,and the oil mist extraction device can be easilyconnected.This design makes it possible to installa multiswiss machine in replacement of singlespindlemachines with barfeeders or cam drivenmachines of similar capacity.ProgrammingThe TB-deco adV programming softwareallows for the creation of any multispindle componenttype :■■easy programming with icons for productiveand unproductive operations.■■Tool library.■■graphic synchronization of simultaneousoperations.■■calculation of actual machining time(gantt chart)■■control of the programme and tool trajectoriesthrough graphic simulation.■■Various machining macros for specific operations(thread chasing, drilling-roughing cycles,machining of complex forms, Torx, etc.).■■free update.■■Tornos software hotline.Integrated PC■■program editing on the machine.■■service instructions available on the machine.■■remote maintenance.■■possibility to control various peripheral units.■■large colour touch screen.■■usB.MultiSwiSS <strong>6x14</strong>9

KINEMATICS, PERSONALITYThanks to its multi-tool design, the <strong>MultiSwiss</strong>is highly flexible. The back work operationsallow for the installation of 2 back work tools.Various devices allow for additional machiningcapacity : polygon milling device, high-frequencydrilling /deburring systems for operations andback work. In all cases, the clearance forfalling chips is not obstructed during main orback work operations.Main advantages of <strong>MultiSwiss</strong> :■■Ergonomics : easy control.■■Accessibility : for single-spindle andmultispindle operators.■■Flexibility : Rapid set-up and change overs.■■Productivity : competitive price per part,excellent reactivity.■■Quality : homogeneity of productioncompared with the production of the samepart on several machines.X15X16X14X46S15S14Z11,12,13,14,15,16S46S16S13S11S12X11X13Z46X1210 <strong>MultiSwiss</strong> <strong>6x14</strong>

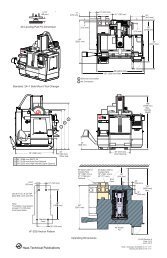

Technical specificaTionsTECHNICAL SPECIFICATIONSMULTISWISS 6X14Bar passage mm 4-14Max. part length mm 40Max. length mm 70Max. main spindle speed rpm 8,000Main spindle power kw 5.6Main spindle torque Nm 7.5Max. pickoff spindle speed rpm 8,000Pickoff spindle motor power kw 5Pickoff spindle motor torque Nm 6Spindle Z stroke mm 50Pickoff spindle Z stroke mm 150Number of linear axes 14Number of rotating axes7+1 (option)Number of cross slides during operation5+1 (cutting)X stroke of cross slides during operation mm 40Number of cross slides for back work 1X stroke of cross slides for back work mm 75Max. number of tools 18Max. number of tools for back work 2Spindle coolingwith oilCutting oil fi ltration mµ 50Oil tank capacity l 900Standard cutting oil pump : outlet pressure bars 4fl ow rate l / min 150High-pressure pump (options): a) outlet pressure bars 35fl ow rate l / min 40b) outlet pressure bars 80fl ow rate l / min 26weight kg 7,000installed power kw 59Numerical controlFanucProgramming systemtB-DECO ADV, integrated PC2,120 mm5,920 mm1,440 mmMultiSwiSS <strong>6x14</strong>11

Tornos S.A.Rue Industrielle 111CH - 2740 MoutierTel. +41 (0)32 494 44 44Fax +41 (0)32 494 49 03contact@tornos.comwww.tornos.comTornos TechnologiesDeutschland GmbHKarlsruher Str. 38D - 75179 PforzheimTel. +49 (0)7231 / 910 70Fax +49 (0)7231 / 910 750contact@tornos.deTornos TechnologiesFranceBoîte postale 330St-Pierre en FaucignyF - 74807 La Roches / Foron CedexTel. +33 (0)4 50 038 333Fax +33 (0)4 50 038 907contact@tornos.frTornos TechnologiesIbéricaPol. Ind. El CongostAvda. St Julià, 206 Nave 8E - 08403 GranollersTel. +34 93 846 59 43Fax +34 93 849 66 00comercial.tti@tornos.comTornos TechnologiesItalia SRLVia Cesare Pavese 21I - 20090 Opera / MITel. +39 02 57 68 15 01Fax +39 02 57 68 15 230italia.contact@tornos.comTornos TechnologiesUS Corporation840 Parkview BoulevardUS - Lombard, IL 60148Tel. +1 630 812 2040Fax +1 630 812 2039info-us@tornos.comwww.tornos.usTornos TechnologiesUK LtdTornos HouseWhitwick Business ParkCoalvilleUK - Leicestershire LE67 4JQTel. +44 (0) 1530 513100Fax +44 (0) 1530 814212sales@tornos.co.ukTornos Technologiespoland Sp. z o.o.Ul. Spółdzielcza 37-3955-080 Kąty WrocławskiePolandTel. +48 71 33 85 618Fax +48 71 33 85 617poland.contact@tornos.comTornos do brasil, LtdaAv. Dr. Cardoso de Melo,1470 Conj. 606CEP - 04548-004 Vila OlímpiaSão Paulo - BrasilTel. +55 11 3045 6695brazil.contact@tornos.comTORNOS technologies(Shanghai) LTDHui Feng Creativity GardenFeng Yu Building, 1-2FNo. 239, Xitai Rd, Xu Hui DistrictCN - Shanghai 200232Tel. +86 21 6235 1235Fax +86 21 6235 1938china.contact@tornos.comTornos Beijing OfficeRm.1706, Tower ADongyu Office BuildingJia #1 Shuguang XiliChaoyang DistrictCN - Beijing 100028Tel. +86 10 5979 8583Fax +86 10 5822 0483beijing.contact@tornos.comTornos TechnologiesAsia LTDUnit 4, Ground Floor, Transport CityBuilding1-7 Shing Wan RoadTai Wai, ShatinN.T., Hong KongTel. +852 2691 2633Fax +852 2691 2133asiapacific.contact@tornos.comTornos S.A. ThailandRepresentative Office7th Floor, 19, Bangna -Trad Soi 34,Bangna -Trad KM. 3 Road.Bangna, Bangkok, 10260ThailandTel. +66 2746 8840-1Fax +66 2746 8842thailand.contact@tornos.comTornos Technologies Asia LtdMalaysiaRepresentative OfficeK-7-1, Lorong Bayan Indah Dua,Bay Avenue, 11900 Pulau Pinang,MalaysiaTel. +6 04 642 6562 / 642 6563Fax +6 04 642 6561malaysia.contact@tornos.comConforms to the European CE / CEM Safety StandardsThis document is based on information available at the time of publication. While every effort has been made to be accurate, the information contained hereindoes not purport to cover all details or variations in hardware and software, nor to provide for every possible contingency in connection with installation, operationand maintenance. TORNOS S.A. assumes no obligation of notice to holders of this document with respect to changes subsequently made. TORNOS S.A. makes norepresentation or warranty, expressed, implied, or statutory with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency or usefulnessof the information contained herein. No warranties of merchantability nor fitness for purpose shall apply.Issue December/ AP – © Tornos 2011, all rights reserved