petro Chem ValVes - Premier Valves

petro Chem ValVes - Premier Valves

petro Chem ValVes - Premier Valves

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

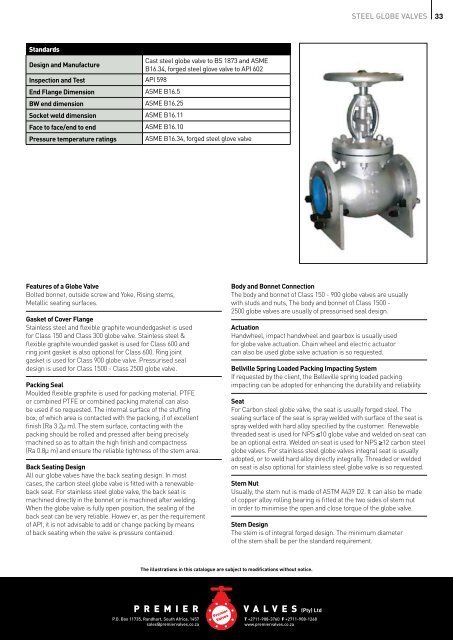

steel globe valves33StandardsDesign and ManufactureCast steel globe valve to BS 1873 and ASMEB16.34, forged steel glove valve to API 602Inspection and Test API 598End Flange Dimension ASME B16.5BW end dimension ASME B16.25Socket weld dimension ASME B16.11Face to face/end to end ASME B16.10Pressure temperature ratings ASME B16.34, forged steel glove valveFeatures of a Globe ValveBolted bonnet, outside screw and Yoke, Rising stems,Metallic seating surfaces.Gasket of Cover FlangeStainless steel and flexible graphite woundedgasket is usedfor Class 150 and Class 300 globe valve. Stainless steel &flexible graphite wounded gasket is used for Class 600 andring joint gasket is also optional for Class 600. Ring jointgasket is used for Class 900 globe valve. Pressurised sealdesign is used for Class 1500 - Class 2500 globe valve.Packing SealMoulded flexible graphite is used for packing material. PTFEor combined PTFE or combined packing material can alsobe used if so requested. The internal surface of the stuffingbox, of which area is contacted with the packing, if of excellentfinish (Ra 3.2µ m). The stem surface, contacting with thepacking should be rolled and pressed after being preciselymachined so as to attain the high finish and compactness(Ra 0.8µ m) and ensure the reliable tightness of the stem area.Back Seating DesignAll our globe valves have the back seating design. In mostcases, the carbon steel globe valve is fitted with a renewableback seat. For stainless steel globe valve, the back seat ismachined directly in the bonnet or is machined after welding.When the globe valve is fully open position, the sealing of theback seat can be very reliable. Howev er, as per the requirementof API, it is not advisable to add or change packing by meansof back seating when the valve is pressure contained.Body and Bonnet ConnectionThe body and bonnet of Class 150 - 900 globe valves are usuallywith studs and nuts, The body and bonnet of Class 1500 -2500 globe valves are usually of pressurised seal design.ActuationHandwheel, impact handwheel and gearbox is usually usedfor globe valve actuation. Chain wheel and electric actuatorcan also be used globe valve actuation is so requested.Bellville Spring Loaded Packing Impacting SystemIf requested by the client, the Belleville spring loaded packingimpacting can be adopted for enhancing the durability and reliability.SeatFor Carbon steel globe valve, the seat is usually forged steel. Thesealing surface of the seat is spray welded with surface of the seat isspray welded with hard alloy specified by the customer. Renewablethreaded seat is used for NPS ≤10 globe valve and welded on seat canbe an optional extra. Welded on seat is used for NPS ≥12 carbon steelglobe valves. For stainless steel globe valves integral seat is usuallyadopted, or to weld hard alloy directly integrally. Threaded or weldedon seat is also optional for stainless steel globe valve is so requested.Stem NutUsually, the stem nut is made of ASTM A439 D2. It can also be madeof copper alloy rolling bearing is fitted at the two sides of stem nutin order to minimise the open and close torque of the globe valve.Stem DesignThe stem is of integral forged design. The minimum diameterof the stem shall be per the standard requirement.The illustrations in this catalogue are subject to modifications without notice.premierP.O. Box 11735, Randhart, South Africa, 1457sales@premiervalves.co.zavalves (Pty) LtdT +2711-908-3760 F +2711-908-1268www.premiervalves.co.za