VSU SERIES 3-5403 PRESSURE SAFETY RELIEF VALVES - Parcol

VSU SERIES 3-5403 PRESSURE SAFETY RELIEF VALVES - Parcol

VSU SERIES 3-5403 PRESSURE SAFETY RELIEF VALVES - Parcol

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

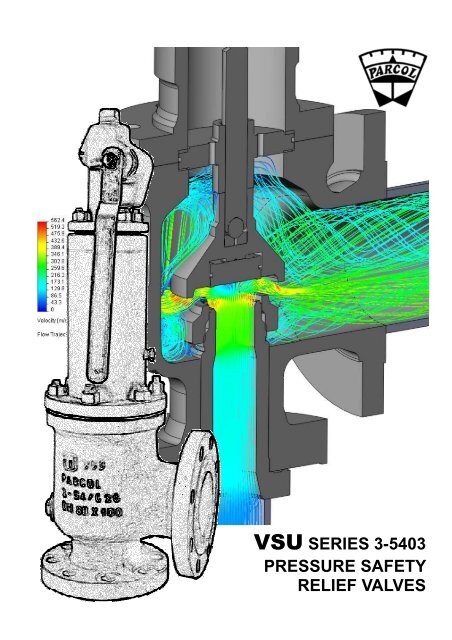

<strong>VSU</strong> <strong>SERIES</strong> 3-<strong>5403</strong><strong>PRESSURE</strong> <strong>SAFETY</strong><strong>RELIEF</strong> <strong>VALVES</strong>

<strong>VSU</strong> <strong>SERIES</strong> 3-<strong>5403</strong> <strong>PRESSURE</strong> <strong>SAFETY</strong> <strong>RELIEF</strong> <strong>VALVES</strong> PARCOLTECHNICAL DATAModel 3-5433 Conventional typeService Gas LiquidAlternatedischargeGas/liquidmixtureoverpressure (1) 10% 10% 10% 10%K (2) (3) (4) 0.967 0.751 0.967 / 0.751 (6)max back pressure(5)21% 14% 21% / 14% (6)Model 3-5483 Balanced bellows typeService Gas LiquidAlternatedischargeGas/liquidmixtureoverpressure (1) 10% 10% 10% 10%K (2) (3) (4) 0.980 0.789 0.980 / 0.789 (6)max back pressure(5)65% 60% 65% / 60% (6)(1) Minimum value = 0.1 bar according to standard ISO 4126-1(2) Coefficients of discharge K d for gas and K L for liquid(corresponds to K d of standard ISO 4126-1)(3) Value without back pressure. For corrected K values withback pressure refer to figures 1 and 2(4) For orifices D and E, K is, respectively for gas and liquid,0.964 and 0.780 for model 3-5433 and 0.952 and 0.810 formodel 3-5483(5) Evaluated as ratio between back pressure and relievingpressure (absolute values for gas; gauge values for liquid)(6) According to standard API 520 Part I, Annex CBlowdown values are within the limits of standards ISO4126-1 and API 520.Minimum set pressure for valves model 3-5433 is 0.5 bar;for valves model 3-5483 it depends by orifice size.TABLE of ORIFICESorifice flow flow thrust thrust valve minimum lifttype diameter area diameter area 3-5433 3-5483- mm cm 2 mm cm 2 mm mmD 10.2 0.82 11.5 1.04 4.0 -D(a1) 10.2 0.82 18.5 2.69 - 4.5E 13.6 1.45 15 1.77 5.0 -E(a) 13.6 1.45 18.5 2.69 - 4.5F 17 2.27 17.2 2.32 7.5 -F(a) 17 2.27 24.3 4.64 - 4.8G 23.5 4.34 24.3 4.64 10.3 12.3H 27.7 6.03 28.5 6.38 12.5 14.3J 36.3 10.3 37.5 11.0 16.1 18.5K 41.7 13.7 43.5 14.9 18.5 21.3L 51.9 21.2 54 22.9 23.0 26.5M 58.2 26.6 60.5 28.7 25.8 29.7N 63.9 32.1 66.5 34.7 28.3 32.6P 77.6 47.3 79 49.0 34.4 39.5Q 102 81.7 105 86.6 45.2 52.0R 123 118.8 125 122.7 54.6 62.7T 157 193.6 159 198.6 69.6 80.0U 175 240.5 181 257.3 77.6 89.2Pressure, velocity and Mach contours in a conventionalsafety valve during discharge simulation.Fig. 1 – Model 3-5433 – K D and K L versus built-up backpressureFig. 2 – Model 3-5483 – K D and K L versus superimposedand built-up back pressure- 3 -

<strong>VSU</strong> <strong>SERIES</strong> 3-<strong>5403</strong> <strong>PRESSURE</strong> <strong>SAFETY</strong> <strong>RELIEF</strong> <strong>VALVES</strong> PARCOL3-5433 CONVENTIONAL TYPE3-5483 BALANCED BELLOWS TYPEItem Part name1 Body2 Tight bonnet3 Cap4 Nozzle5 Disc6 Adjusting ring7 Stem assembly8 Guide9 Disc holder10 Spring11 Adjusting screw12 Lock nutItem Part name13 Pivoting bush14 Retaining ring15 Lower spring seat16 Upper spring seat23 Body stud24 Nut25 Plug26 Nut27 Adjusting ring set screw28 Plug (not shown on body)29 Bonnet stud30 NutItem Part name31 Plug40 Gasket41 Gasket42 Gasket43 Gasket44 Gasket45 Name plate (not shown)46 Name plate rivet (not shown)48 Auxiliary piston75 Bellows76 Bellows gasket- 4 -

<strong>VSU</strong> <strong>SERIES</strong> 3-<strong>5403</strong> <strong>PRESSURE</strong> <strong>SAFETY</strong> <strong>RELIEF</strong> <strong>VALVES</strong> PARCOLMAIN FEATURESBODYConstruction : cast.Sizes andrating: see tables. Series according to standardAPI 526 with ANSI and EN ratings.Connections : - flanged ANSI and EN. The nozzleraised face has a diameter matchingwith ANSI and EN standards but isgreater in height (see table of dimensions).- socket welding ends in accordancewith ANSI B 16.5 or screwed in accordancewith ANSI B 2.1 up to size1.1/2”x 3” included.- lug type, lens-type seal or other connectiontype according to Customer'sstandard available on request.JacketsWashingNOZZLE: for all valve bodies, jackets with ANSI150 and PN 16 are available.Inlet and outlet connections are NPTfemale screwed. Other types are optional(socket weld, flanged).: optionally, connections are supplied forthe washing of the disc and nozzleseating surfaces. Connection may bescrewed or socket weld.Construction : from bar stock or cast.MountingJacketsDISC: threaded and positively guided in thebody.: an inner jacket is provided for fluidswhich easily solidify.Connections consist of two tappedholes in the nozzle flanges which arethicker than the standard ones.Construction : from bar stock.Coating: Co-Cr hard facing; others on request.BONNETConstruction : from bar stock or cast.RealizationMountingCAP: usually tight. Open bonnet for high temperatureservice or on request.: flanged on body.Construction : from bar stock or cast.Two types: plain or with lifting lever.Mounting: the plain caps up to 2” x 3” size includedare screwed on the bonnet.Other caps are flanged.Accessories : test gag; open-valve limit switch; plumbing.DISC HOLDERConstruction : from bar stock or cast.Mounting: holds the disc by means of an elasticring in the lower side; holds an hardenedbush on which the ball of assembledstem pivots in the upper side.STAINLESS STEEL BELLOWSConstruction : the upper part of the bellows is weldedon a disc clamped between body andbonnet; the lower part of the bellows iswelded on a ring nut screwed on thedisc holder.DiametersApplicationlimits :: the bellows thrust area equals the orificethrust area listed in table.the maximum temperature for AISI 316Lconstruction is 350 °C.The maximum pressure values are thesame of standard API 526.Specific data are available on request.Accessories : bellows protection device; auxiliary piston.Supplied on request for particularlyheavy operating conditions.Soft seal: rubber ring. Materials and limitations ofuse supplied on request.- 5 -

<strong>VSU</strong> <strong>SERIES</strong> 3-<strong>5403</strong> <strong>PRESSURE</strong> <strong>SAFETY</strong> <strong>RELIEF</strong> <strong>VALVES</strong> PARCOLACCESSORIES and SPARE PARTSSOFT SEALTEST GAGItem Part name65 Test gag66 Nut67 Dowel68 Dowel69 Plug70 ChainItem5a5b5c5dPart nameDiscRing locking discSealing ringScrewLIFTING LEVERSTEM ASSEMBLYItem Part name51 Manual lift cap53 Stop disc54 Screw55 Fork56 Fork shaft57 Packing58 Packing end ring59 Lever60 Nut61 Packing glandNOZZLE FLUSHING DEVICEAUXILIARY PISTONBELLOWS PROTECTION DEVICEItem Part name17 Spindle18 Stem19 Ball- 6 -

<strong>VSU</strong> <strong>SERIES</strong> 3-<strong>5403</strong> <strong>PRESSURE</strong> <strong>SAFETY</strong> <strong>RELIEF</strong> <strong>VALVES</strong> PARCOLMATERIALS OF CONSTRUCTION<strong>Parcol</strong> <strong>VSU</strong>standard constructionwith lifting lever<strong>Parcol</strong> <strong>VSU</strong> withbody steam jacketing- 7 -

OVERALL DIMENSIONS and MASSESNOTE In case of 3-5483 type valve equipped with auxiliary piston, contact <strong>Parcol</strong> Technical Department for mass and dimensions1) When the outlet flange is RJ increase the dimension A of 6.5 mm for ANSI 150 and 8 mm for ANSI 3002) The dimension C is the same both with standard cap and lifting lever3) For 3-5483 type valve only05/2012 - ACA 0517