desuperheating control valve straight-way 1-5900 series - Parcol

desuperheating control valve straight-way 1-5900 series - Parcol

desuperheating control valve straight-way 1-5900 series - Parcol

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

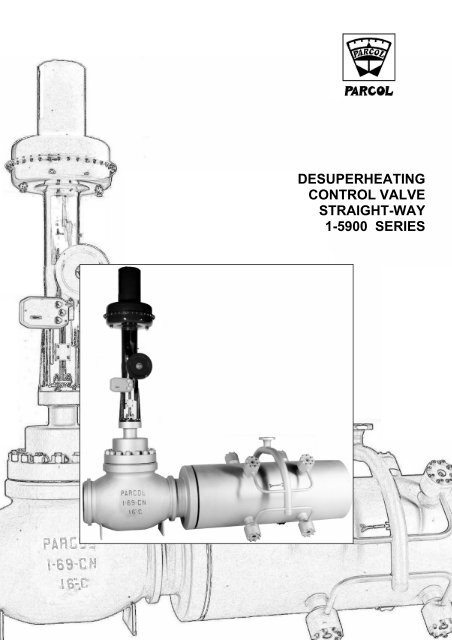

DESUPERHEATINGCONTROL VALVESTRAIGHT-WAY1-<strong>5900</strong> SERIESDescription1-<strong>5900</strong> <strong>valve</strong>, derived from 1-6933 <strong>series</strong>, is provided with <strong>straight</strong>-<strong>way</strong> globe body and cage trim.The pressure reduction is performed through two stages; the first one is intended for flow <strong>control</strong>,while the second one is a fixed throttling section.The <strong>valve</strong> may have different performances and applications, also depending on flow orientation,either over or under the plug.The 1 st stage is provided with single or multiple cage trim, same as 1-6933 <strong>series</strong>.The 2 nd stage may consist of a silencer installed on <strong>valve</strong> outlet, or, for less severe applications, ofa drilled basket mounted under the seat ring; such a basket also protects the body from theerosion when flow direction is over the seat.1-5990 model is provided both with the basket under the seat ring and the silencer at body outlet.The aforementioned silencer may be either single or multiple cage type (max 3), or consist of anintegral Limiphon disk stack welded to the outlet connection.For sizes over 12" the HAS high absorption silencer (reactive type) is also available.Only multistage models, mainly the ones provided with Limiphon stack, may be considered assilencers. As a matter of fact, in aforementioned cases, part of the noise generated by the pressurereduction in the first stage is absorbed and transformed into heat inside the silencer, independentlyfrom the flow rate.The steam coming out from the silencer enters the desuperheater injection chamber through anannular section where the velocity is kept at a suitable value to enhance the <strong>desuperheating</strong>efficiency.Performance of <strong>desuperheating</strong> system depends on the type of adopted devices and are describedin relevant technical pamphlets, where piping characteristics (size, velocities, <strong>straight</strong> lengths, etc.)and minimum probe distance for temperature <strong>control</strong> are shown.2

Applications− low/medium capacity pressure reduction/<strong>desuperheating</strong> processes - low/medium pressureturbine by-pass with operating temperature lower than 500°C− cogeneration plants, even for continuous <strong>control</strong> services requiring tight shut-off in closedposition− good performances under the acoustic view point, especially with limited turn-down− some limitations as far as p 1 /p 2 ratio is concerned, mainly in models provided with cage silencerCodification1 - 5 9XX034567Desuperheater typeundefinedLFP fixed area nozzleLVL, LVP or LVC spring type nozzleLVM multipleSpraysatsteam-assisted fixed nozzle0145689Downstream silencer typeundefinedwithout silencer (same as 1-6933 with outlet desuperheater)disk or drilled basket type silencer (max 3 stages)HAS reactive adsorption silencer (max 3+1 stages)Limiphon silencer (5 to about 20 stages)Basket under the seat without silencer - flow over the seatBasket under the seat + silencer - flow over the seatThe basket under the seat ring is sometime convenient when a low pressure drop silencer (e.g.single cage type) is provided; it is normally useless where multi-cage, HAS or Limiphon silencersare installed.WATERSTEAM1-5964 <strong>series</strong> <strong>valve</strong> - flow-to- close - piloted plug - Limiphon outlet silencer - injection chamberprovided with LVL spring nozzle type3

Technical featuresbody- <strong>straight</strong>-<strong>way</strong> globe same as 1-6933 <strong>series</strong> - cast construction with boltedbonnet- available sizes: 6", 8", 10", 12", 14", 16", 18", and 20"- ratings: up to ANSI 1500 from 6" to 12", up to ANSI 600 from 14" to 20"trim - 1 st stage consisting of single (std. GBR or GBRS) or double drilled cage -linear intrinsic characteristic- quick-change seat ring and plug are same as 1-6933 <strong>series</strong>- a removable drilled basket is fitted under the seat ring of 1-5980 and 90models; in 1-5980 model such a basket acts as 2 nd reduction stageexternal silencer - consists of a single or multi stage (max 3) drilled basket in 1-5940 and 90models and of a solid Limiphon disk stack in 1-5960 model- external silencer is al<strong>way</strong>s welded to outlet body connection; bigsilencers may be supported by baffles- <strong>valve</strong>s bigger than DN 10" may be equipped with HAS silencer (highconstructionmaterialsadsorption silencer)- body and bonnet normally in C and Cr-Mo steel according to steampressure and temperature- trim components in stellited and nitrided F6NM steel and 17-4PH fortemperature up to 350°C- silencer normally in Cr-Mo steel - Limiphon stack in X19CrMoVNbN11.1steel and in AISI 430 for temperature up to 400°Cleakage class (according to IEC 60534-4)- unbalanced plugs: V class or better- teflon or piloted balanced plugs: V class- balanced plugs provided with graphite inserts: IV S1 classV class only with special pneumatic, electric or hydraulic actuatorsSTEAMWATER1-5985 flow-to-close - quick-change design - removable seat ring and protecting basket - pilotedplug - tight shut-off - single cage silencer - injection chamber provided with liner and LVMdesuperheaterTypical application: LP by-pass - low p 1 /p 2 ratios - noise level up to 95 dB(A) for bare pipe4

Selection1- 5910 - high flow rate on low pressure services and not severe allowable pressure level - noturn-down limit1- 5940 - ideal solution for low pressure medium capacity turbine by-pass - combined cagearrangement of 1 st and 2 nd stage enables to perfectly meet such applicationrequirements as far as process <strong>control</strong> and generated noise are concerned1-5950 - low noise on low/medium pressure and high flow rate services - limited turndown1-5960 - some capacity and turn-down limits - suitable solution for low noise and high ∆p andp 1 /p 2 values applications1-5980 - mounting a basket just under the seat ring makes the design very compact andeconomic, suitable for limited p 1 /p 2 ratios (max 1:6 approximately) and only for flowover the plug - <strong>desuperheating</strong> efficiency of this model is basically worse then in othermodels; Spraysat injector (1-5986) is often preferable1-5990 - alternate 1-5940 design for higher p 1 /p 2 ratios or lower allowable noise.Aforementioned selection criteria are summarized in the table shown at page 5.flow-to-open / flow-to-close- flow-to-close direction (over the plug) is selected when a tight shut-off is required for hightemperature services- in such a case piloted plugs may be used also with conventional pneumatic actuators. Balancedplugs provided with special inserts available only with hydraulic, electric or special pneumaticactuators- the flow-to-open design has no particular limitation only when it is possible to use unbalancedplugs (low ∆p’s and seat diameters) or the temperature allows the use of Teflon seal rings.WATERSTEAM1-5986 flow-to-close - flow <strong>control</strong> by single cage - drilled basket under the seat - unbalancedplug - high temperature service and tight shut-off - actuator must be hydraulic or electrictype - injection chamber provided with Spraysat5

STEAMCONFIGURATION p P1/P2NOISETURNDOWNFLOWRATECONTROL10low lowveryexcellent poorhigh40moderate moderate moderatehighsatisfactory50highmoderatemoderatesatisfactoryverygood60veryhighveryhighmoderatelowexcellent80moderatelowhighhighpoor90highhighmoderatesatisfactorygood6

SizingModels provided either with internal or external cage silencer may be sized with good accuracy byIEC equations and by selecting DN and port according to the flow coefficient table.Models provided with downstream Limiphon stack must be instead sized by <strong>Parcol</strong> proprietarycriteria, also because in this case silencers are defined according to specific applicationrequirements.Also for noise pressure level prediction of 1-<strong>5900</strong> <strong>series</strong> <strong>valve</strong>, <strong>Parcol</strong> follows general principles of60534-8-3 IEC standard, but uses a proven proprietary method which takes into account thespecial configuration of <strong>valve</strong>+desuperheater assembly.For instance the acoustic benefit produced by downstream injected water is taken into account bya correction factor which is a function both of injector type and the ratio w between water andsteam flow rate. The acoustic benefit is maximum where injection is performed by LVM multiplenozzles; it can be calculated by the equation:∆L w = 38. w 1,5 .7

FLOW COEFFICIENTS1-5980Cv (1)DN port seat dia. travel 1-5940/50/601 st stage (2) (total)6 127 76 385 2886" 5 112 76 302 2254 95 60 235 1753 73.5 45 145 1088 162 100 610 4577 147 100 510 5828" 6 127 76 430 3005 112 76 307 2154 95 60 238 16610 216 100 975 7309 186 100 840 58810" 8 162 100 685 4807 147 100 537 3756 127 76 435 30512 244 100 1305 98010 216 100 1105 77312" 9 186 100 895 6268 162 100 695 4867 147 100 540 37814 293 150 1755 132013 266 150 1525 106714 12 244 100 1235 86510 216 100 1110 7709 186 100 900 63016 343 200 2310 173016 14 293 150 1850 130013 266 150 1635 114512 244 100 1245 87018 382 200 2650 200018 16 343 200 2420 168014 293 150 1900 135012 244 100 1245 88520 422 250 3600 270020 18 382 200 2800 196016 343 200 2500 175014 293 150 1960 1380(1) Linear characteristic - standard drilled cage.(2) General Cv of 1-5940 <strong>valve</strong> provided with external cage silencer is normally 70% of the one listedfor 1 st stage because Cv of 2 nd stage is normally equal to the one of 1 st stage.Different sizing is any<strong>way</strong> possible for special applications.PARCOL SpA - Via Isonzo, 2 - 20010 Canegrate (MI) - ITALYC.C.I.A.A. 554316 - Fiscal code & VAT no. (IT) 00688330158Telephone: +39 0331 413111 - Fax: +39 0331 404215e-mail: sales@parcol.com - http://www.parcol.comIssue 02-2002 ACA 05258