Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

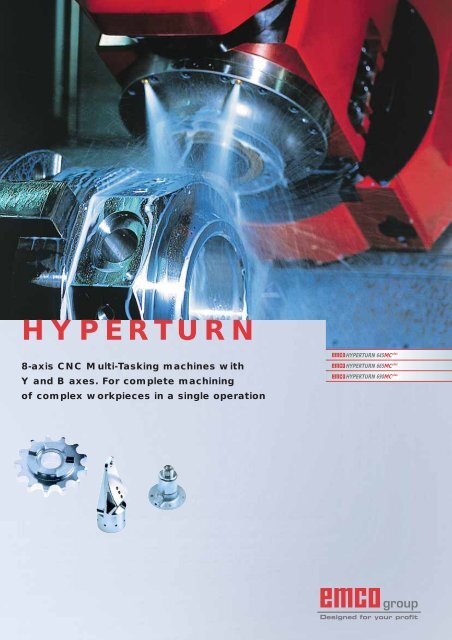

The HT 665MC plus inthe basic version with4 axes …… with optionalY axis for theupper turret …… with Y axis andB axis for the upperturret (QuickMill) …… with B axis millingspindle and toolmagazine (PowerMill).The HT 665MC withonly a B axis millingspindle: completemachining for smallbatch production.<strong>HYPERTURN</strong> QuickMillThis B axis configuration allows theupper turret to swivel to any positionwithin a 45 degree arc. The combinationof axial holder, radial holder, and745 degree holder makes it possible toreach any angle within a 180 degreerange. The advantage is a tool-changetime of a mere 0.2 seconds and anattractive price.24 -tool stationmagazineCAPTO-C4 (48 tool stationsoptional or HSK A50). Easy accessto tool magazine.77<strong>HYPERTURN</strong> PowerMillIn this design a milling spindle with hollow shaft motor takes the placeof the upper turret. The B axis travels 210 degrees and the tool carrier isa 24 station magazine with Capto-C4 holders (48 tool stations optional).These features make this machine the perfect balance of turning andmilling technology. Its versatility and stock-removal capability make thismachine ideal for the complete machining of complex workpieces thatneed high-grade milling.7CAPTO MultiheadA tool for roughing, finishing,threading, grooving and milling.Saves tool change time and freesup space in the tool magazine.<strong>HYPERTURN</strong> applicationsHydraulic sleeve(tempering steel)Bonnet flange(brass)7CAPTO MiniturretTriple slot tool holder for standardtools, shortens nonproductive timesand provides extra flexibility.Split taper socket(aluminium)Lug angle(brass)

199 GES HAVELLIAN KABAL SINGH 0 KHEMKARAN 0200 GES JHUGGIAN NOOR MOHMAD 0 KHEMKARAN 0201 GES JHUGGIAN PEER BAKSH 0 KHEMKARAN 0202 GES JUGIAN KALU 0 KHEMKARAN 0203 GES MUTJIAN WALA 318 KHEMKARAN DR.SUKHBIR SINGH SHC BHANGALA 5/012,12/12,16/12,19/12,23/12/08,2/1/09204 GES PREM NAGAR 0 KHEMKARAN 0-Jan205 GES RADHALKE 61 KHEMKARAN DR.GURBINDER SINGH SHC TOOT 5/1/2009206 GES RAM SINGH WALA 65 KHEMKARAN DR.SUKHBIR SINGH SHC BHANGALA 6/1/2009207 GES TOOT 140 KHEMKARAN DR.GURBINDER SINGH SHC TOOT 5/12,16/12,19/12/08208 GHS TOOT 62 KHEMKARAN DR.GURBINDER SINGH SHC TOOT 2/12/2008209 GES BAHADUR NAGAR 49 KHEMKARAN DR.SUKHBIR SINGH SHC BHANGALA 7-Nov210 GES DASSUWALA 125 KHEMKARAN DR.SUKHBIR SINGH SHC BHANGALA 11/11,14/11/08211 GES DASU WAL 70 KHEMKARAN DR.SUKHBIR SINGH SHC BHANGALA 18/11/08212 GES KHARA 110 KHEMKARAN DR.RAMAN KUMAR SHC VARNALA 6/10,9/10/08213 GES MAHNEKE 89 KHEMKARAN DR.SUKHBIR SINGH SHC BHANGALA 12/9,16/9/08214 GES PUNNIA 60 KHEMKARAN DR.RAMAN KUMAR SHC VARNALA 25/9/08215 GES VARNALA 185 KHEMKARAN DR.RAMAN KUMAR SHC VARNALA 1/9,4/9,8/9/08216 GH S VARNALA 63 KHEMKARAN DR.RAMAN KUMAR SHC VARNALA 11/9/2008217KHEMKARANGHS RAJOKE 64DR.GURMEET SINGH PHC RAJOKE 2/7/2008218KHEMKARAN DR.SUKHBIR SINGH SHC BHANGALAGES LAKHNA 15622/7/,25/7,29/7/0/8219KHEMKARAN DR.SUKHBIR SINGH SHC BHANGALAGMS LAKHNA 7019/8/08220KHEMKARAN DR.RAMAN KUMAR SHC VARNALAGES BHALLIAN WALA 607/7/2008221KHEMKARAN DR.RAMAN KUMAR SHC VARNALAGES DIBBIPURA 6324/7/08222KHEMKARANMAHARAJA RANJIT S.S RAJOKE 207DR.GURMEET SINGH PHC RAJOKE 3/9,10/9,17/9,24/9/08223KHEMKARAN DR.MONA SHC ASSAL UTTARSPRING DALE MODERN SC MADDAR 2468/7,11/7,15/7,18/7/0/8224KHEMKARAN DR.RAMAN KUMAR SHC VARNALADASHMESH SEN,SEC SCHOOL AMA 11618/8,21/8/08225KHEMKARAN DR.MONA SHC ASSAL UTTARSANT SOLIDER PUBLIC SCHOOL LA 3668/1,12/1,19/1,22/1,29/1/09226 BABA DEEP SINGH KHALSAKHEMKARAN DR.SUKHBIR SINGH SHC BHANGALASCHOOL LAKHANA 21422/7,25/7,19/7/08227 SH.GURU HARKRISHANKHEMKARAN DR.MONA SHC ASSAL UTTAR 19/9,3/10,7/10,10/1,17/10,21/10,24PUB.SCHOOL ASSAL 769/1031/104/11,11/11,14/11,18/11,21/228 KHEMKARAN DR.GURBINDER SINGH SHC TOOT 8/8,12/8,19/8,22/8,26/8,29/8,2/9,5/SAHEED BHAGAT SINGH SC VALTO 520 6,12/9,16/9,19/9/08229 KHEMKARAN DR.GURBINDER SINGH SHC TOOT 24/10,31/10,4/11,7/11,11/11,14/11,DASMESH SEN. SEC SCHOOL VALT 502 18/11,21/11,25/11,28/11/08230 KHEMKARAN DR.SUKHBIR SINGH SHC BHANGALAS.U.S SCHOOL BAHADUR NAGAR25519/9,3/10,7/10,10/10,17/10/08231KHEMKARAN DR.JATINDER KUMAR SCHSANT PARKASH SINGH BHURA KHO 280BHURAKOHNA 22/10,25/10,1/11,5/11,8/11/08232KHEMKARAN DR.MULAKH RAJ CHC KEMKARAN 17/7,21/7,24/7,28/7,4/8,17/8,11/8/0UNITED HIGH SCHOOL KHEMKARAN 3648233 G ES MARI SANT PURA 19 SUR SINGH DR. RAJESH BAGHAT CHC SURSINGH 5/8/2008234 GES BHIKHIWIDN PIND 160 SUR SINGH DR. SARTAJ SANDHU CHC SURSINGH 3/9,17/9,29/9/08235 GES BHIKHIWIND 120 SUR SINGH DR.SATNAM SINGH CHC SURSINGH 4/8,11/8/08236 GES BHIKHIWIND MANDI 228 SUR SINGH DR.SATNAM SINGH CHC SURSINGH 9/8,16/8,23/8,30/8/08237 GES BUA 38 SUR SINGH DR. GURSEWAK SINGH CHC SURSINGH 5/8,238 GES CHELA 50 SUR SINGH DR. RAJESH BAGHAT CHC SURSINGH 6/8/2008239 GES FARANDI PUR 55 SUR SINGH DR. RAJESH BAGHAT CHC SURSINGH 13/8/08240 GES KALE 96 SUR SINGH DR. RAJESH BAGHAT CHC SURSINGH 6/9/2008241 GES KOTLI SUR SINGH 59 SUR SINGH DR. RAJESH BAGHAT CHC SURSINGH 8-Oct242 GES MARI GAUR SINGH 56 SUR SINGH DR. GURSEWAK SINGH CHC SURSINGH 8/8/2008243 GES MARI SAMRA 41 SUR SINGH DR. GURSEWAK SINGH CHC SURSINGH 12/8/2008244 GES MARI THEH WALI 140 SUR SINGH DR. RAJESH BAGHAT CHC SURSINGH 24/9,30/9,17/9/08245 GES PHULA 54 SUR SINGH DR. GURSEWAK SINGH CHC SURSINGH 23/9/08246 GES SAND PURA 65 SUR SINGH DR.SATNAM SINGH CHC SURSINGH 7/08/08,14/8/08247 GES SANDHRA 95 SUR SINGH DR. RAJESH BAGHAT CHC SURSINGH 3/10,10/10,17/10/08Page 5 of 16

The Machines HYPERFlexibility/ESPRIT Automation<strong>HYPERTURN</strong> 690MC plusMulti-Tasking Machining CentersTechnical DataHT 690MC plusSpindle bore Ø 95/106 mm (3.74/4.17’’)Chuck diameter Ø 315 mm (12.4’’)Drive power37/54 kW (49.6/72.4 hp)Max. speed3200 rpmTurretsDrive power10,5 kW (14.08 hp)Torque40 Nm (28.57 ft/lbs)Max. speed3000 rpmMill. spindle (PowerMill)Drive power21,5 kW (28.8 hp)Torque128 Nm (94.3 ft/lbs)Max. speed (optional)7000 (12000) rpmB axis (swivel) 210°Y axis (travel) +/– 100 mm (3.9’’)The <strong>HYPERTURN</strong> 690MC plus is a modern turning/milling centrefor the complete machining of complex workpieces in one machine.It is extremely versatile thanks to its NC-controlled machining headwith tool changer. Robust machine construction and a high-performancemilling spindle with 21,5 kW (28.8hp) of power make anenormous cutting performance possible, even on large workpieces.main spindle- main drive with 54 kW (72.4 hp) power- high torque- wide speed range- bar capacity 94 (3.7“) or 105 mm (4.1”)- liquid-cooled headstock- rugged spindle bearing withtemperature-controlled oil-cooling systemB axis- large-dimensioned verticalmilling head- wide speed range- latest spindle motor technology- high torque- internal coolant supply- fast tool changes- wide programmable swivel rangecounter spindle- high-power drive unit- spindle nose as the main spindle- wide speed range- high torque- part hollow tension 95 mm (3.7”)- liquid-cooled headstock- rugged spindle bearing withtemperature controlledoil-cooling systemmachine enclosure- comprehensive operator protection- 100% coolant retention- excellent ergonomics- wide work area opening- suitable for top loading- chip conveyor in the basic machinecontrol unit:- SIEMENS SINUMERIK 840D- pivoting and positionable- function keys right whereyou want them- PC keyboard (optional)

OptionsTechnical dataProduct Range<strong>HYPERTURN</strong> applicationsTool turret disc(tempering steel)Cutter with indexableinserts (tempering steel)Carbide insert drill(tempering steel)Hydraulic part(steel)The TechnologyPreloaded linear guides in all axesensure the highest precision in the<strong>HYPERTURN</strong> 690. Built-in linear scalesare available as an option. Both spindlesare equipped with a direct measuringsystem. The position of the turretsalso permits the use of extended 3tools on both spindles. Optimum forcetransfer is achieved by the very widedistances between the bearing pointsof the carriages and both headstocks.Both the oil and cooling water cyclesof the headstocks are electronicallymonitored and kept at a constanttemperature.The modular conceptWhether barstock parts, shaft parts,flange parts or chucking parts – the<strong>HYPERTURN</strong> 690MC plus in its variousversions can take on any machiningtask. A wide range of automationsetting as well as options such aspart collection devices, steady restand much more round off thefeatures.The steady rest can be lowered (stroke 250 mm (9.8”)).Park position for flange parts.Lower turret, 12 positions VDI 40, withprocessing direction to the counter spindle.3Steady restA steady rest can be installed insteadof the lower turret. It can be loweredinto the park position for machiningflanges. The positioning is done viaa full controlable NC axis.B axis is clamped or indexed via a Hirth coupling.It can also be used as a NC axis in interpolation mode.Simple and safe tool changingsystem with short changing times.

Ingenious telescopic guideway covers for all axesFor the precise take over of semi-finished workpieces,the counterspindle moves to the work spindle as an NC axis.1<strong>HYPERTURN</strong> 690MC PowerMillThe machine is equipped with a high-power milling spindle with IntegratedSpindle Motor (ISM). The travel range of the B axis is 210°. A 30-tool-stationmagazine (48 or 80 tool stations optional) utilizing Capto-C5 or HSK 63 holders.Its high degree of flexibility and the high metal-cutting capacity make it particularlysuitable for completely machining complex workpieces that requireextensive milling.Model with steady rest and tailstock<strong>HYPERTURN</strong> 690MC plus as a turning centerDie <strong>HYPERTURN</strong> 690MC plus is available also as a pure turning center, with oneor two turrets, and with a tailstock or counter spindle. Both versions are availablewith optional Y axis on the upper turret. The machine is capable of turningsimultaneously on both spindles as well as performing true 4-axis machining.With dual tool holders, up to 48 tools are possible.5Fast Factsqoptimum thermal stabilitybecause all spindles areliquid-cooledqgood absorption of high cuttingforces by using oversizedspindle bearingsVersatile use of the tool systems on both spindles.qlarge chip volume due tomilling spindle with highdrive powerq large spindle bore ofØ 95 or 106 mm (3.7 or 4.2”)q tool magazine with up to 80positions (optional)qgood accessibility of toolsand clamps means shortset-up timesqqqqcast-iron bed with finitecomponent constructionboth tool systems can beused on both spindlesshaft machining with tailstockand steady restlarge swing for flangemachiningThe HT 690MC inthe basic version withor without Y axis …… the HT 690 MC plusin the 4 axis version …… with B axis millingspindle and 2nd toolturret …… only with B axismilling spindle …… with B axis millingspindle and tailstock.

4 5

The MachinesHYPER Flexibility/ESPRITAutomationHYPER FlexibilityThe <strong>HYPERTURN</strong> delivers flexibility without compromisingproductivity. With its powerful, adjustable milling spindleand nearly inexhaustible tool magazine, the <strong>HYPERTURN</strong>can do just about anything fast.Process options availableq milling surfaces,pockets, islandsand groovesq cam millingq thread millingq milling multiple cornersq turning multiple cornersq gear tooth millingq turning millingq drillingq thread turningq deep hole drillingq plung-cut turningq contour turningq profile milling▲▲Any number of contours can be programmedeasily with the transmit softwaresupport. The contour is describedin a milling center with X-, Y- andZ-coordinates and automatically convertedinto a C and X axis interpolation.A rigid C axis is the basic requirementfor accurate contour milling.With the help of the Y axis, it is possibleto manufacture circular pockets, rectangularpockets, islands and grooves – with theB axis, beveled surfaces are also possible.With the Y axis, it is possible to manufacturedrill holes. Standard cycles for contouring,drilling, and rigid tapping are also available.▲▲The precise synchronization of the tool drivewith the spindle drive make gear cuttingoperations on the front surface and peripherypossible. Gear teeth are manufacturedby hobbing.

OptionsTechnical dataProduct RangeProgramming with ESPRITThe sensational CAM solution for cuttingand cutting/milling. ESPRIT simplifiesthe programming of complex machiningprocesses enormously and drasticallyshortens fitting times.Fields of useqqqqcomplete CNC programming forup to 22 axis turningturning-milling for single spindlelathesturning-milling for multi-carriageturning centersturning-milling for multitaskingmachine tools including B axisCompletely modelled <strong>HYPERTURN</strong> 690MC plusValve body(steel)ToolsBonnet flange(brass)The machining and modelling of allpart geometries is supported byq Parasolid ®q ACIS ®q NURBS surface modellingq STLq 2D/3D wire grate modellingq 2D sketching, dimensioningand textsCollision monitoring on the <strong>HYPERTURN</strong> 665MC plus PowerMillwith milling spindle and tool turretSimulationsBracket pin(steel)qqqdry runs in a dynamicvolume viewshaded in the entire workingenvironment: machine tool,clamp, raw part and finishedworkpiececomplete collision recognition:tool, raw part, clamp and workpiece.Target/actual comparisonof the workpiece.Multi-axis complete machining on the counterspindleon the <strong>HYPERTURN</strong> 690MC plus.6 7

7OptionsTechnical dataProduct RangeWorkpiece magazinePallet attachments for all raw partsenable the positioned loading ofparts into the machine and raisethe number of loadable parts forunmanned production. Changeovertimes are reduced or eliminatedthanks to the perfect adjustmentto the customer's parts.4-piece pallet attachment for tees6-piece pallet attachment forarticulated bracketsMulti-piece pallet attachment fora family of parts4-piece pallet attachment for bonnets20-piece pallet magazinewith customer-specific pallets7 Pivoting B axisThe special thing about the <strong>HYPERTURN</strong> Gantry Loader is the integratedB axis of the gripper head. It enables raw parts to be loaded into devices atan angle and simultaneous pivoting and positioning. This means not onlyalmost unlimited flexibility when loading and unloading, it also dramaticallyreduces cycle times.Automatic machining of barmaterial up to 3, 4 and 6 meters7Short and to the pointFloorspace costs money. Making small machine footprints a necessity.Inanswer to this demand, EMCO has developed the market’s most compactshort loader: the EMCO LM1200. Tailored exactly for the <strong>HYPERTURN</strong>, itis the perfect solution for automatic feeding and loading of cut lengthbar stock.8 9

7The MachinesHYPERFlexibility/ESPRITAutomationMany options forunlimited possibilitiesNot every customer has the same needs. And so they don't needthe same solutions either. With our large range of options, we giveour customers the opportunity to fit their <strong>HYPERTURN</strong> accordingto their very own individual requirements.The optionsqqqqqqqqqqEMCO Tool monitoring systemtool measurementworkpiece measurementprogrammable clamping pressureturret restmoving windowunloading with the counter spindlefinished part conveyorhigh pressure and band filter unitand much, much moreA permanent eye on tool statusesProgrammable clamping pressureCoupling proportional valves with software makes fully automatic adjustmentof the clamping pressure possible on the work and counter spindles. This makes7 manual adjustment on the hydraulic unit a thing of the past.EMCO tool monitoring systemThe tool status is monitored by evaluating the load on the various axis drivemotors. Excessive loads point to extensive tool wear or broken tools. Too littleload means a tool is missing.7Tool eyeThe tool measurement sensor mounted in the working area of the <strong>HYPERTURN</strong>makes it possible to measure tools both in the upper and lower turret within themachine.

737Options Technical data Product RangeBand filter with high-pressurecoolant pumpsA coolant pressure of 25/40/60 or 80 bar can be set as needed. This enablescoolant fed drilling and milling tools to be used to their best advantage.7Integrated measurement station for producingprecision parts with low manpower.Measurement device with measurementgauge and integrated part remover. Rejectedparts are separated from accepted parts.The band filter ensures the best possible filtering of the cooling lubricant, especiallywhen machining short-cutting materials. This extends maintenance intervals and reducesthe downtimes they cause.Bull´s eyeThe rotating window gives you thebest possible view of the machine'sworking area, so you can observethe cutting process even whencoolants are being used.7An ingenious principle. The rotating window ensures that wateris removed immediately.A permanent steady rest is only availablefor the <strong>HYPERTURN</strong> 690.On the <strong>HYPERTURN</strong> 665 and 690 thesteady rest is mounted on the lower turretlike a tool.The Hyperturn 665/690 turret restThere are different rest solutions for our two <strong>HYPERTURN</strong> modelsfor supporting long, slender workpieces.Unloading through counter spindleLong, slender workpieces can be removed from the machine through the counterspindle. Finished pieces can be rolled simply onto an inclined surface or storedin a lateral magazine using a discontinuous belt.Finished part conveyorThe finished-part pick-up device puts the parts on an accumulating conveyor.A discontinuous belt ensures that the often very complex parts do not fall ontoeach other.10 11

The MachinesHYPERFlexibility/ESPRITAutomation<strong>HYPERTURN</strong> 645/665MC plusTechnical data, work areas, turret clearance,installation plans and performance diagramsWork areaSwing over bed 600 mm (23.6“) 600 mm (23.6“)Swing over slide 500 mm (19.7“) 500 mm (19.7“)Distance between spindle noses 1000 mm (39.4“) 975 mm (38.4“)Technical Data HT 645MC plus HT 665MC plus M (Nm)Maximum turning diameter 430 mm (16.9“) 430 mm (16.6“)Maximum part length 744 mm (29.3“) 744 mm (29.3“)Maximum bar-stock diameter Ø 45 mm (1.8“) Ø 65 mm (2.6“)TravelTravel in X/X2 280/205 mm (11/8.1“) 280/205 mm (11/8.1“)Travel in Z/Z2/Z3 900/750/750 mm (35.4/29.5/29.5“) 900/750/750 mm (35.4/29.5/29.5“)Travel in Y 100 (+/–50) mm (3.9 ( +/–2)“) 100 (+/–50) mm (3.9 (+/–2)“)Main spindleSpeed range 0–7000 rpm 0–5000 rpmMaximum torque 130 Nm (95.8 ft/lbs) 250 Nm (184.3 ft/lbs)Spindle nose (DIN 55026) A2-5 A2-6Spindle bearing (inside diameter) Ø 85 mm (3.4“) Ø 105 mm (4.1“)Spindle bore Ø 53 mm (2.1“) Ø 73 mm (2.9“)Counter spindleSpeed range 0–7000 rpm 0–7000 rpmMaximum torque 130 Nm (95.8 ft/lbs) 130 Nm (95.8 ft/lbs)Spindle nose (DIN 55026) A2-5 A2-6Spindle bearing (inside diameter) Ø 85 mm (3.4“) Ø 85 mm (3.4“)C axesResolution 0,001° 0,001°Rapid traverse 1000 rpm 1000 rpmDrive powerMain spindle (integrated spindle motor) 22 kW (29.5 hp) 29 kW (38.9 hp)Counter spindle (integrated spindle motor) 22 kW (29.5 hp) 22 kW (29.5 hp)Tool turret top and bottomNumber of tool stations 2 x 12 2 x 12VDI shaft (DIN 69880) 30/40 mm (1.2/1.6“) 30/40 mm (1.2/1.6“)Tool cross-section for square-shank tools 20 x 20 mm (0.8 x 0.8“) 20 x 20 mm (0.8 x 0.8“)Shank diameter for boring bars 32 mm (1.3“) 32 mm (1.3“)Turret indexing time 0.2 sec 0.2 secDriven toolsSpeed range 0–5000 rpm 0–5000 rpmTorque 25 Nm (18.4 ft/lbs) 25 Nm (18.4 ft/lbs)Drive power 6,7 kW (9 hp) 6,7 kW (9 hp)Number of driven stations 2 x 12 2 x 12B-QuickMill (with tool turret)Travel range (with interpolation) 45° 45°Holding torque of indexing (5°)/clamp (0.001°) 3000/600 Nm (2211/442 ft/lbs) 3000/600 Nm (2211/442 ft/lbs)B-PowerMill (with milling spindle)Travel range (with interpolation) 210° 210°Holding torque of indexing (5°)/clamp (0.001°) 3600/1300 Nm (2653/958 ft/lbs) 3600/1300 Nm (2653/958 ft/lbs)Number of tools 24/48 24/48Tool adapter CAPTO C4 (HSK A50) CAPTO C4 (HSK A50)Maximum torque 40 Nm (29.5 ft/lbs) 40 Nm (29.5 ft/lbs)Drive power 14,5 kW (19.4 hp) 14,5 kW (19.4 hp)Speed range 0–10000 rpm 0–10000 rpmTool-change time ( Tool - Tool) 1.3 sec 1.3 secFeed drivesRapid traverse in X/Z/Y/Z3 (counter spindle) 24/30/10/30 m/min 24/30/10/30 m/min(945/1181/394/1181 ipm) (945/1181/394/1181 ipm)Feed force in X/Z/Z3 (counter spindle) 5000/8000/9000 N 5000/8000/9000 N(1124/1798/2023 lbs) (1124/1798/2023 lbs)Coolant systemTank capacity 300 l (79 gal) 300 l (79 gal)Pump power 2 x 2,2 kW (2.7 x 3 hp) 2 x 2,2 kW (2.7 x 3 hp)Power consumptionConnected load 56 kVA 56 kVACompressed air 6 bar (87 PSI) 6 bar (87 PSI)DimensionsHeight of centers above floor 1200 mm (47.2“) 1200 mm (47.2“)Total height 2300 mm (90.6“) 2300 mm (90.6“)Footprint (without chip conveyor) W x D 3400 x 2550 mm (133.9 x 100.4”) 3400 x 2550 mm (133.9 x 100.4”)Total weight ca. 9500 kg (15432 lb) ca. 9500 kg (15432 lb)Safety devices CE-compliant CE-compliantMotor characteristic lines<strong>HYPERTURN</strong> 665 main spindle and<strong>HYPERTURN</strong> 645 main/counter spindle1501005030025020015010050M (Nm)150P (S6-40 % D.C.)P (S1-100 % D.C.)M (S1-100 % D.C.)M (S6-40 % D.C.)P (kW)30000 1000 2000 3000 4000 5000 6000P (S6-40 % D.C.)n (rpm)200 20P (S1-100 % D.C.)M (S1-100 % D.C.)000 1000 2000 3000 4000 5000 6000 7000n (rpm)M [Nm]4020100 1000 20003500M S6P S125201510M (S6-40 % D.C.)P S65P (kW)Motor characteristic lines <strong>HYPERTURN</strong>645/665 PowerMill milling spindle3000 4000 5000 6000 7000 8000 9000 100002515105P [kW]151430 650S1=100%S6=40% (at 1 min. D.C.)Motor characteristicsfor driven toolsM [Nm]2520151050M (S6-25%D.C.)P (S6-25%D.C.)11104M S13210n [rpm]P [kW]0 1000 2000 3000 4000 5000n [rpm]432113126,7650987

The MachinesHYPERFlexibility/ESPRITAutomationWork area and turret clearance <strong>HYPERTURN</strong> 645/665MC plus QuickMillWork area and turret clearance <strong>HYPERTURN</strong> 645/665MC plus PowerMill

OptionsTechnical dataProduct Range<strong>HYPERTURN</strong> 690MC plusTechnical data, work areas, installation plansand performance diagramsTechnical Data<strong>HYPERTURN</strong> 690MC plusWork areaSwing over bed 700 mm (27.6”)Maximum turning diameter 520 mm (20.5“)Distance between spindle noses 1500 mm (59.1“)Maximum bar-stock diameter 105 mm (4.2“)TravelTravel in X(B)/X2 490/280 mm (19.3/11“)Travel in Z/Z2/Z3 1055/1090/1100 mm (41.5/42.9/43.3“)Travel in Y 200 mm (+/–100 mm) (7.9“(+/–3.9“))Main spindleSpeed range0–3200 rpmSpindle nose (DIN 55026) A2-8Spindle bearing (inside diameter) 160 mm (6.3“)Maximum torque at spindle S1/S6 40 %470/687 Nm (346.4/506.3 ft/lbs)Spindle bore 106 mm (4.2“)Counter spindleSpeed range0–3200 rpmSpindle nose (DIN 55026) A2-8Spindle bearing (inside diameter) 160 mm (6.3“)Maximum torque at spindle S1/S6 40 %324/478 Nm (238.8/352.2 ft/lbs)C axesResolution 0.001°Rapid traverse1000 rpmDrive powerMain spindle S1/S6 40 %37/54 kW (49.5/72 hp)Counter spindle S1/S6 40 %17/25 kW (23/33.5 hp)Tool turret top and bottomNumber of tool stations 2 x 12VDI shaft (DIN 69880) 40 mm (1.6“)Tool cross-section for square-shank tools 25 x 25 mm (0.99 x 0.99“)Shank diameter for boring bars 40 mm (1.6“)Turret indexing time0.2 secDriven toolsSpeed range0–3000 rpmTorque S1/S3 40% D.C.27/40 Nm (20/29.5 ft/lbs)Drive power S1/S3 40% D.C.5,8/10,5 kW (7.8/14.1 hp)Number of driven stations 2 x 12B-PowerMillTravel range 210°Holding torque of indexing (5°)/clamp (0.1°) 3500/1000 Nm (2579/737 ft/lbs)Number of tools 30Tool adapterCAPTO C5Torque S1/S6 40% D.C.100/128 Nm (73.7/94 ft/lbs)Drive power S1/S6 40% D.C.17/21,5 kW (22.8/28.8 hp)Speed range0–7000 rpmTool-change time (tool – tool)2.2 secFeed drivesRapid traverse X/Z/Counter spindle30 m/min (1181 ipm)Rapid traverse Y15 m/min (590.5 ipm)Coolant systemTank capacity420 l (111 gal)Coolant pressure/delivery14 bar/10 l/min (203 PSI/37.8 gal/min)Power consumptionConnected load/with B axis78/86 kVADimensionsHeight of centers above floor 1292 mm (50.9“)Total height/with B axis 2650/2754 mm (104.3/108.4“)Footprint W x D (with B axis)7200 x 3124 (4324) mm(283.5 x 123 (170.2)“)Total weight/with B axis15000/15500 kg (33069/34171.3 lb)Safety devicesCE-compliantMain spindleM (Nm)800687 7006005004704003002001000M (Nm)60050047840032430012010020010014012880604020033,50M (Nm)45403530272522,42018,5151050S6 40% S6 40%S10 400 800 1200 1600 2000 2400 2800 3200Counter spindleS6 40%S1750 2500S6 40%0 400 800 1200 1600 2000 2400 28002120n (rpm)3200n (rpm)P (kW)60545040373020100P (kW)S1S1 17S1500Spindle PowerMillS6 (40%)500 1000 20001600M (Nm)S6 (40%)S13000 4000 5000 6000 7000Driven tools at tool turretNm (S3-40%)Nm (100K)Nm (60K)Kw (S3-40%)Kw (100K)Kw (60K)(rpm)P (kW)0 500 1000 1500 2000 2500 3000n (rpm)302520151050P (kW)1412108420302521,5201715105010,55,83,214 15

The MachinesHYPERFlexibility/ESPRITAutomationWork area <strong>HYPERTURN</strong> 690MCY plusWork area <strong>HYPERTURN</strong> 690MC plus with B axis

OptionsTechnical dataProduct RangeWork area <strong>HYPERTURN</strong> 690MC without B axis (all versions)283.6“123“104.3“100.4“194.1“ 58.9“103.1“60.6“Work area <strong>HYPERTURN</strong> 690 PowerMill with B axis (all versions)283.6“170.2“47.2“ 95.9“30.6“48.7“78“67.4“60.6“16 17

The MachinesHYPERFlexibility/ESPRITAutomationProduct RangeMECOFMulti-axis high-speed milling centersfor high dynamic and accucary in the fields of generalengeneering, moulds, dies, styling centers and aerospace.Axis travel from:1400 x 1650 x 800 mm (55.1 x 65 x 31,5“)FAMUPMECOF PERFORMAMECOF PRIMAMECOF AirOneMECOF AGILE CS 500CNC machining centerswith or without pallet changer, with top-quality spindle,linear drive system and 5-axis high-performance machiningcenter with water-cooled motor spindle.<strong>HYPERTURN</strong>FAMUP MC75-50FAMUP MC120-60FAMUP MCP70-50FAMUP MCP100-50FAMUP MMV LD-ReiheCNC turning-milling centersfor complete machining of complex workpiecesup to Ø 500 mm (19.69”).Workpiece diameters: Ø 45, 65, 95 and 106 mm(1.77, 2.56, 3.74, 4.17”)MAXXTURNHigh performanceCNC turning centersfor the versatile machining of chuck, shaft and rod parts.Part size up to 500 mm (19.7”) diameterBar stock capacity 45 (1,77") to 110 (4.3”) mm diameterTURNCNC turning centersModular CNC turning centers for the economical machiningof chuck, shaft and rod parts.Part size up to 1000 mm (39.37”) diameterBar stock capacity 25 (1”) to 206 (8.1”) mm diameterMATLathesUniversal manual lathes.Center height: 140 to 200 mm (5.51 to 7.87”)Center distance: 650 to 1 000 mm (25.59 to 39.37”)<strong>HYPERTURN</strong> 645MC <strong>HYPERTURN</strong> 665MC <strong>HYPERTURN</strong> 690MCMAXXTURN 45 MAXXTURN 65 MAXXTURN 95 MAXXTURN 110EMCOTURN E25EMCOTURN E45EMCOTURN E65EMCOTURN 332MCEMCOMAT-14 S/14 D EMCOMAT-17 S EMCOMAT-17 D EMCOMAT-20 DPrecision cycle controlled lathesSwing over cross slide: 160 to 510 mm (6.30 to 20.08”)Center distance: 1 000 to 6 000 mm (39.37 to 236.22”)MILLEMCOMAT-E160EMCOMAT-E300EMCOMAT-E360Milling machinesUniversal milling machines:Axis movements: 300/200/350 to 700/500/500 mm(11.81, 7.87, 13.78” to 27.56, 19.68, 19.68”)CONCEPTCNC turning-milling centerswith interchangeable control modules.EMCOMILL FB-3 EMCO C40 LINEAR EMCOMILL FB-5EMCOMILL FB-6Update: 11/2006CONCEPT TURN 55 CONCEPT MILL 55 CONCEPT TURN 105 CONCEPT MILL 105

Options Technical data Product RangeMECOF AGILE M MECOF LINEA DYNAMILL MECOF THE MACHINE MECOF MEC MILLFAMUP Linearmill 600 HDFAMUP Linearmill 600 EMFAMUP MCX750FAMUP MCX1200EMCOTURN 420MCEMCOTURN 900EMCOMAT-E400EMCOMAT-E480EMCOMILL FB-4 TNC 124/310 EMCOMILL FB-5 TNC 124/310 EMCOMILL FB-6 TNC 124/310CONCEPT TURN 155 CONCEPT MILL 155 CONCEPT TURN 450 CONCEPT MILL 30018 19

EN4336 . 06/07 © dassel & schumacher, munich. Subject to change due to technical progress. Errors and omissions excepted.Submitted by:HEADQUARTERS:EMCO MAIER Ges.m.b.H. . Salzburger Strasse 80 . A-5400 Hallein-TaxachPhone +43-62 45-8 91-0 . Fax +43-62 45-8 69 65 . email: info@emco.atEMCO has a global sales network. You can find the addresses at:www.emco.at