Split System 5-20 Tons

Split System 5-20 Tons

Split System 5-20 Tons

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Split</strong> <strong>System</strong> 5-<strong>20</strong> <strong>Tons</strong>Light CommercialTTA / TTH / TWESeries R407C, 50 Hz

ODYSSEY - with environmental friendly R407C refrigerant<strong>Split</strong> <strong>System</strong> Cooling Only UnitsCool You, Cool the EarthA new design of industrial airconditioner with non-ozone depletionrefrigerant R407C to provide steadycomfort with reliability and flexibilityfor all applications in split airconditioning system together with theeffort to cool down the earth andprotect our environment.Cool The EarthQuality and Reliability• Scroll compressors are availablefrom 6 to <strong>20</strong> tons with excellentreliability and high efficiency.• All units are 100 percent run testedprior to leaving the production line.Manifolding ScrollCompressors(TTA150-240)• The key to this system is an oilequalized line connecting the twocompressors. In addition, thedischarge lines are simplymanifolded togethers.• Efficiency and proven Technology.A manifolded set of compressors ismore efficient at part load than thecompressors with independentcircuits.• Manifolded to be single circuitprovides cost and time saving forinstallation.Maximum Efficiency• Lower noise operation and higherefficiency with the new generationhigher EER Scroll Compressor.• 64% fewer parts than a comparablecapacity reciprocating compressor.• Single rotating assembly minimizesthe friction and mechanical losses.• Smooth operation, similar to acentrifugal compressor, give lowtorque variation and extend motorlife, and minimal vibration reducingwear.• Solid mount with no internalsuspension to be worn out.• Integral inlet dirt separator removescontaminants.• Rolling element bearings for higherefficiency reduced friction. Nosuction or discharge valves forimproved efficiency compared to areciprocating compressor.FlexibilityTrane <strong>Split</strong> <strong>System</strong> offers single anddual compressors allowing the rightequipment to be matched to the jobapplication and save on operating cost.ConvertibilityTrane air handler (TWE Model) caneasily be converted for vertical orhorizontal airflow in free blow andducted applications.Ease of ServiceReduction of service time and costthrough• Single side access on condenser.• Multiple removable panels onair handlers.• Colored and numbered wiring.• Service valves.Trane <strong>Split</strong> <strong>System</strong> Units• A reputation for quality and reliability.• Improvements in efficiency,flexibility and installation.<strong>System</strong> Performance MatrixModel Evaporator Total Capacity Sensible CapacityOutdoor Indoor cfm MBH MBH2,000 72 45TTA075ED TTH075ED 2,500 75 493,000 78 522,700 96 62TTA100ED TTH100ED 3,400 100 684,100 103 723,<strong>20</strong>0 115 75TTA1<strong>20</strong>ED TWE1<strong>20</strong>ED 4,000 1<strong>20</strong> 824,800 124 884,300 145 103TTA150ED TWE160ED 5,300 150 1146,300 156 1<strong>20</strong>4,800 172 111TTA180ED TWE180ED 6,000 180 1217,<strong>20</strong>0 186 1315,600 193 135TTA<strong>20</strong>0ED TWE210ED 7,000 <strong>20</strong>0 1508,400 <strong>20</strong>7 1606,400 227 140TTA240ED TWE240ED 8,000 240 1519,600 250 161Note : Product design and specification are subject to change without notice.SSA5-SLB003-R407C-EN

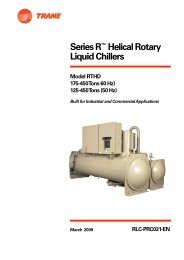

General Data-Air Handler UnitsDesigned With Your Needs In MindUNIT MODELS TTH075ED TTH100ED TWE1<strong>20</strong>ED TWE160ED TWE180ED TWE210ED TWE240EDPOWER CONNECTION V/ph/Hz 380-415/3/50 380-415/3/50 380-415/3/50 380-415/3/50 380-415/3/50 380-415/3/50 380-415/3/50MCA 1 A 2.5 4.6 4.6 4.6 6.4 6.4 10.0SYSTEM DATARefrigerant Type R407C R407C R407C R407C R407C R407C R407CNo. Refrigerant Circuits 1 1 1 2 2 2 2Refrigerant Connection Type BRAZE BRAZE BRAZE BRAZE BRAZE BRAZE BRAZESuction Line OD in (mm) 1 1/8 (28.57) 1 3/8 (34.93) 1 3/8 (34.93) 1 1/8 (28.57) 1 3/8 (34.93) 1 3/8 (34.93) 1 3/8 (34.93)Liquid Line OD in (mm) 1/2 (12.7) 1/2 (12.7) 1/2 (12.7) 1/2 (12.7) 1/2 (12.7) 1/2 (12.7) 1/2 (12.7)COILTube Size OD in (mm) 3/8 (9.53) 3/8 (9.53) 3/8 (9.53) 3/8 (9.53) 3/8 (9.53) 3/8 (9.53) 3/8 (9.53)Rows 3 3 3 3 3 3 3Fins per inch 15 15 14 14 12 15 15Refrigerant Flow Control EXPANSION VALVE EXPANSION VALVE EXPANSION VALVE EXPANSION VALVE EXPANSION VALVE EXPANSION VALVE EXPANSION VALVEDrain Connection Size in (mm) 1 (25.4) 1 (25.4) 1 (25.4) 1 (25.4) 1 (25.4) 1 (25.4) 1 (25.4)Drain Connection Type STEEL PIPE - MPT PLASTIC - FEMALE PIPEFANFan TypeDOUBLE INLET CENTRIFUGAL WITH FORWARD CURVED WHEELNo. used 1 2 1 1 1 2 2Drive TypeBELT - ADJUSTABLE DRIVEMOTORNo. of Motor 1 1 1 1 1 1 1Motor hp hp (kW) 1 (0.75) 2 (1.5) 2 (1.5) 2 (1.5) 3 (2.2) 3 (2.2) 5 (3.7)No. of Speed 1 1 1 1 1 1 1Motor Speed rpm 1400 1405 1405 1405 1425 1425 1440V/ph/Hz 380-415/3/50 380-415/3/50 380-415/3/50 380-415/3/50 380-415/3/50 380-415/3/50 380-415/3/50RLA / LRA 1.99 - 11.0 3.66 - 21.0 3.66 - 21.0 3.66 - 21.0 5.08 - 34.0 5.08 - 34.0 8.03 - 63.0FILTERTypeWASHABLE ALUMINIUM AIR FILTERNo. used 2 3 4 4 4 4 4Size (WxLxD) mm 440 x 600 x 25 440 x 5<strong>20</strong> x 25 355 x 635 x 25 400 x 927 x 25 400 x 927 x 25 555 x 727 x 25 555 x 727 x 25DIMENSION (HxWxD)Uncrated (Net) mm 5<strong>20</strong> x 1,312 x 841 5<strong>20</strong> x 1,680 x 841 1,523 x 1410 x 635 1,751 x 1,613 x 850 1,751 x 1,613 x 850 1,751 x 2,210 x 702 1,751 x 2,210 x 702WEIGHTUncrated (Net) kg 92 136 154 275 285 355 3651MCA - Minimum Circuit AmpacityNote : Product design and specification are subject to change without notice.General Data - Condensing UnitsUNIT MODELS TTA075ED TTA100ED TTA1<strong>20</strong>ED TTA150ED TTA180ED TTA<strong>20</strong>0ED TTA240EDPOWER CONNECTION V/ph/Hz 380-415/3/50MCA 1 A 18.06 27.29 29.95 32.72 35.00 49.22 54.17SYSTEM DATANo. Refrigerant Circuits 1 1 1 1* 1* 1* 1*Refrigerant Connection Type BRAZE BRAZE BRAZE BRAZE BRAZE BRAZE BRAZERefrigerant 2 R407C R407C R407C R407C R407C R407C R407CSuction Line OD 3 in (mm) 1 1/8 (28.6) 1 3/8 (34.9) 1 3/8 (34.9) 1 5/8 (41.3) 1 5/8 (41.3) 1 5/8 (41.3) 1 5/8 (41.3)Liquid line OD 3 in (mm) 1/2 (12.7) 1/2 (12.7) 1/2 (12.7) 5/8 (15.9) 5/8 (15.9) 5/8 (15.9) 5/8 (15.9)COMPRESSORCompressor TypeHermetic ScrollNo. Used 1 1 1 2 2 2 2V/ph/Hz 380/3/50 380/3/50 380/3/50 380/3/50 380/3/50 380/3/50 380/3/50RLA/LRA 13.6 / 98.0 <strong>20</strong>.7 / 130.0 22.9 / 145.0 13.6 / 98.0 14.3 / 130.0 <strong>20</strong>.7 / 130.0 22.9 / 145.0COILTube Size OD in (mm) 3/8 (9.53) 3/8 (9.53) 3/8 (9.53) 3/8 (9.53) 3/8 (9.53) 3/8 (9.53) 3/8 (9.53)Rows 2 2 2 2 2 2 2Fins per inch 16 16 16 16 16 16 16FANFan Type Propeller Propeller Propeller Propeller Propeller Propeller PropellerNo. used 1 1 1 2 2 2 2Drive Type Direct Direct Direct Direct Direct Direct DirectNominal Airflow cfm (cmh) 4885 (8300) 5768 (9800) 6828 (11600) 9770 (16600) 11536 (19600) 13537 (23000) 13537 (23000)MOTORNo. of Motor 1 1 1 2 2 2 2Motor Output Watt 290 4<strong>20</strong> 300 290 4<strong>20</strong> 300 300No. of Speed 1 1 1 1 1 1 1Motor Speed rpm 750 830 875 750 830 875 875V/ph/Hz 380/3/50 380/3/50 380/3/50 380/3/50 380/3/50 380/3/50 380/3/50RLA/LRA 1.06 / 2.27 1.41 / 3.53 1.32 / 2.80 1.06 / 2.27 1.41 / 3.53 1.32 / 2.80 1.32 / 2.80DIMENSION (HxWxD)Uncrated (Net) mm 1,050 x 950 x 1,060 1,050 x 950 x 1,060 1,050 x 950 x 1,060 1,050 x 2,<strong>20</strong>0 x 1,050 1,050 x 2,<strong>20</strong>0 x 1,050 1,050 x 2,<strong>20</strong>0 x 1,050 1,050 x 2,<strong>20</strong>0 x 1,050WEIGHTUncrated (Net) kg 164 180 192 382 415 428 4621MCA - Minimum Circuit Ampacity.2There is holding charge of refrigerant and N 2from factory. However, when install the unit, system must be vacuumed and recharged refrigerant in the field.* For TTA150-240, Dual refrigerant circuits are standard for Export.Note : Product design and specification are subject to change without notice.SSA5-SLB003-R407C-EN3

Features and BenefitsTTA075-1<strong>20</strong>EDTTA075-1<strong>20</strong>ED (Option)TTA150-240EDMirco processor controller(Option)TTH075-100EDTWE1<strong>20</strong>-240EDTTA Condensing UnitsStandard Feature• Powder paint finish.• Innovative cabinet design.• Refrigerant accessories as standard.• Single and dual compressorsOptional• Stainless casing / Copper fin /Blue fin / Aeris coating• Dual circuits (Thailand) or manifoldingsingle circuit (Export) for TTA150-240ED• Horizontal air discharge(for TTA075-1<strong>20</strong>)• Mirco Processor controller• Wire Guard.TTH/TWE Air Handler UnitsStandard Features• 500 mm in height (TTH075-100).• Excellent drain pan.• Belt drive.• Factory installed mounting channel(TTH075-100).• Quiet operation.• Convertible for horizontal or verticalconfiguration (TWE1<strong>20</strong>-240).• Thermal expansion valve.Optional• Discharge Plenum.• Return air grille (for TWE model only).• High static motor.• Stainless casing / Copper fin /Blue fin / Aeris coatingBenefits• Full covering of all edges and auniform paint finish for a smooth,attractive and durable cabinetexterior.• The most attractive light commercialcondensing unit available.• Each unit ships standard with theliquid and suction lines shut-off valve,hi-low pressure controls, liquid linefilter drier.• Optimized operation and reducedservice time.• Designed to provide corrosionprotection on sea coast application.• Dual circuits allow for comfortduring service time.• Flexible application when verticalspace limited.• Troubleshooting status displayhelps reduce service time.• Extend compressor life time bybalancing compressors loading.• Protect coil from delivery damage.Benefits• Designed to fit easily into tightceiling spaces.• Specially designed drain pan witha deep pitch to catch and drainwater safely away.• Fully adjustable airflow forapplication versatility and easeof servicing.• Supports the unit from below,and saves time and money forthe installer.• Well-insulated cabinet with fireretardant Polyethylene foam andwide forward curved fans.• Maximum application flexibilitywithout the extra inventory ofdedicated models.• For maximum application flexibilityand performance, capacitymodulation provides improvedcomfort and backup in the eventof a malfunction with one circuit.• Designed for free blow application.• For high static pressure applications.• Designed to provide corrosionprotection on sea coast application.Trane optimizes the performance of home and buildings around the world. A business of Ingersoll Rand, the leader in creating and sustaining safe, comfortable,and energy efficient environments, Trane offers a broad portfolio of advance controls and HVAC systems, comprehensive building services, and parts.For more information, visit www.tranethailand.com‡∑√π(ª√–‡∑»‰∑¬)‡≈¢∑’Ë 1126/2 —Èπ 30-31 Õ“§“√«“π‘ 2 ∂.‡æ√∫ÿ√’µ—¥„À¡à ·¢«ß¡—°°– —π ‡¢µ√“‡∑«’ °√ÿ߇∑æœ 10400‚∑√. 0-2704-9999@<strong>20</strong>10 Trane All rights reservedSSA5-SLB003-R407C-EN February 01, <strong>20</strong>11