b.tech. ceramic technology - Technicalsymposium

b.tech. ceramic technology - Technicalsymposium

b.tech. ceramic technology - Technicalsymposium

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

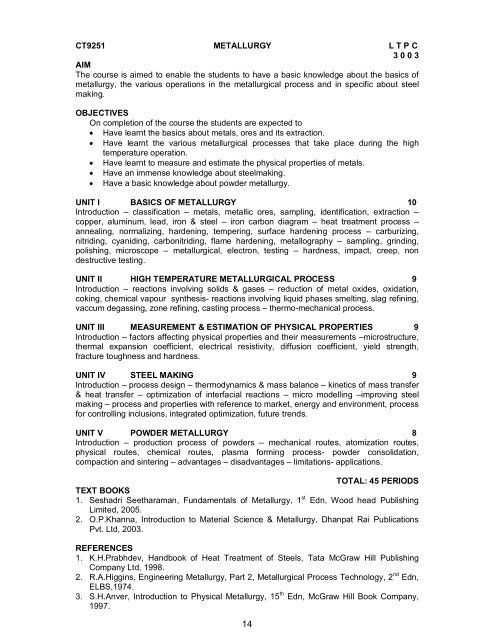

CT9251 METALLURGY L T P C3 0 0 3AIMThe course is aimed to enable the students to have a basic knowledge about the basics ofmetallurgy, the various operations in the metallurgical process and in specific about steelmaking.OBJECTIVESOn completion of the course the students are expected to Have learnt the basics about metals, ores and its extraction. Have learnt the various metallurgical processes that take place during the hightemperature operation. Have learnt to measure and estimate the physical properties of metals. Have an immense knowledge about steelmaking. Have a basic knowledge about powder metallurgy.UNIT I BASICS OF METALLURGY 10Introduction – classification – metals, metallic ores, sampling, identification, extraction –copper, aluminum, lead, iron & steel – iron carbon diagram – heat treatment process –annealing, normalizing, hardening, tempering, surface hardening process – carburizing,nitriding, cyaniding, carbonitriding, flame hardening, metallography – sampling, grinding,polishing, microscope – metallurgical, electron, testing – hardness, impact, creep, nondestructive testing.UNIT II HIGH TEMPERATURE METALLURGICAL PROCESS 9Introduction – reactions involving solids & gases – reduction of metal oxides, oxidation,coking, chemical vapour synthesis- reactions involving liquid phases smelting, slag refining,vaccum degassing, zone refining, casting process – thermo-mechanical process.UNIT III MEASUREMENT & ESTIMATION OF PHYSICAL PROPERTIES 9Introduction – factors affecting physical properties and their measurements –microstructure,thermal expansion coefficient, electrical resistivity, diffusion coefficient, yield strength,fracture toughness and hardness.UNIT IV STEEL MAKING 9Introduction – process design – thermodynamics & mass balance – kinetics of mass transfer& heat transfer – optimization of interfacial reactions – micro modelling –improving steelmaking – process and properties with reference to market, energy and environment, processfor controlling inclusions, integrated optimization, future trends.UNIT V POWDER METALLURGY 8Introduction – production process of powders – mechanical routes, atomization routes,physical routes, chemical routes, plasma forming process- powder consolidation,compaction and sintering – advantages – disadvantages – limitations- applications.TOTAL: 45 PERIODSTEXT BOOKS1. Seshadri Seetharaman, Fundamentals of Metallurgy, 1 st Edn, Wood head PublishingLimited, 2005.2. O.P.Khanna, Introduction to Material Science & Metallurgy, Dhanpat Rai PublicationsPvt. Ltd, 2003.REFERENCES1. K.H.Prabhdev, Handbook of Heat Treatment of Steels, Tata McGraw Hill PublishingCompany Ltd, 1998.2. R.A.Higgins, Engineering Metallurgy, Part 2, Metallurgical Process Technology, 2 nd Edn,ELBS,1974.3. S.H.Anver, Introduction to Physical Metallurgy, 15 th Edn, McGraw Hill Book Company,1997.14