b.tech. ceramic technology - Technicalsymposium

b.tech. ceramic technology - Technicalsymposium

b.tech. ceramic technology - Technicalsymposium

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

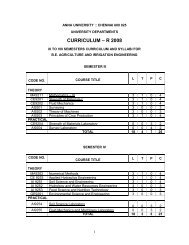

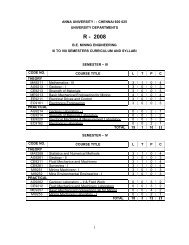

UNIT V MAGNETIC PROPERTIES 9Magnetic phenomena, origin of interactions in ferromagnetic materials, spinel ferrites, rareearth garnets, ortho ferrites and illmenites, hexagonal ferrites, polycrystalline ferrites,susceptibility, permeability, flux density, types of magnetism and their origin, electronicstructure and magnetic moment, exchange interaction and super exchange interaction,hysteresis loop and magnetic domain – domain structure.TOTAL: 45 PERIODSTEXT BOOKS1. Kingery W.D, Bowen H.K and Uhlmann D.R, Introduction to Ceramics, John Wiley &Sons, 1991.2. Barsoum M.W, Fundamentals of Ceramics, McGraw-Hill, 1997.REFERENCES1. David W.Richerson, Modern Ceramic Engineering, 3 rd Edn., Taylor and Francis, 2005.2. Moulson A.J and Herbert H. M, Electro<strong>ceramic</strong>s, Chapman and Hall, London, 1990.3. Allen Dinsdale, Pottery Science: Materials, Processes and Products, Ellis Horwood Ltd.,NY, 1986.CT9022 CERAMIC TESTING AND QUALITY CONTROL L T P C3 0 0 3AIMThe course is aimed to enable the students to have a basic knowledge about the varioustesting methods of <strong>ceramic</strong> raw materials and samples and also the basics about qualitycontrol.OBJECTIVESOn completion of the course the students are expected to Have learnt the basics about the testing methods for <strong>ceramic</strong> raw materials. Have learnt the various methods of testing the physical properties. Have learnt to test the various properties of glaze. Have an immense knowledge about testing of refractories. Have a basic knowledge about quality control.UNIT I TESTING OF RAW MATERIALS 9Conino and quartering of sample – sampling on delivery – measurement of moisture contentby IR moisture balance – speedy moisture test – particle size analysis – sieve test,sedimentation method –Stokes, Andreasen Pipette.UNIT II TESTING OF PHYSICAL PROPERTIES 9Determination of surface area by permeametry – plasticity – Perferkon test, Atterberg test,contraction – wet to dry, dry to fired, wet to fired, modulus of rupture – control of casting slips– fluidity – thixotrophy and specific gravity using torsion viscometer – vitrification – density –porosity – water absorption.UNIT III TESTING FOR GLAZE 9Measuring coherence parameter – pick up – testing of viscosity of glazes at lowtemperatures and high temperatures – test for the solubility of lead frits – glaze fit –hardnesstesting – glaze thickness – autoclave and crazing – thermal shock measurement.UNIT IV TESTING FOR REFRACTORIES 9Refractoriness – RUL – cold crushing strength – permanent linear change on reheating –spalling resistance – reversible thermal expansion – thermal conductivity – specific gravity –bulk density – slag resistance test.39