b.tech. ceramic technology - Technicalsymposium

b.tech. ceramic technology - Technicalsymposium

b.tech. ceramic technology - Technicalsymposium

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

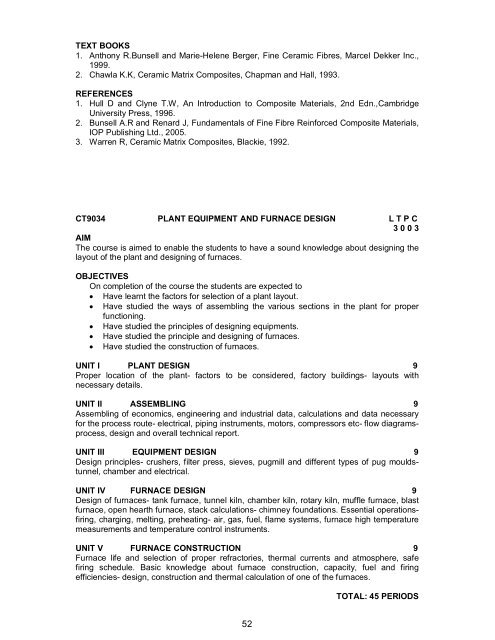

TEXT BOOKS1. Anthony R.Bunsell and Marie-Helene Berger, Fine Ceramic Fibres, Marcel Dekker Inc.,1999.2. Chawla K.K, Ceramic Matrix Composites, Chapman and Hall, 1993.REFERENCES1. Hull D and Clyne T.W, An Introduction to Composite Materials, 2nd Edn.,CambridgeUniversity Press, 1996.2. Bunsell A.R and Renard J, Fundamentals of Fine Fibre Reinforced Composite Materials,IOP Publishing Ltd., 2005.3. Warren R, Ceramic Matrix Composites, Blackie, 1992.CT9034 PLANT EQUIPMENT AND FURNACE DESIGN L T P C3 0 0 3AIMThe course is aimed to enable the students to have a sound knowledge about designing thelayout of the plant and designing of furnaces.OBJECTIVESOn completion of the course the students are expected to Have learnt the factors for selection of a plant layout. Have studied the ways of assembling the various sections in the plant for properfunctioning. Have studied the principles of designing equipments. Have studied the principle and designing of furnaces. Have studied the construction of furnaces.UNIT I PLANT DESIGN 9Proper location of the plant- factors to be considered, factory buildings- layouts withnecessary details.UNIT II ASSEMBLING 9Assembling of economics, engineering and industrial data, calculations and data necessaryfor the process route- electrical, piping instruments, motors, compressors etc- flow diagramsprocess,design and overall <strong>tech</strong>nical report.UNIT III EQUIPMENT DESIGN 9Design principles- crushers, filter press, sieves, pugmill and different types of pug mouldstunnel,chamber and electrical.UNIT IV FURNACE DESIGN 9Design of furnaces- tank furnace, tunnel kiln, chamber kiln, rotary kiln, muffle furnace, blastfurnace, open hearth furnace, stack calculations- chimney foundations. Essential operationsfiring,charging, melting, preheating- air, gas, fuel, flame systems, furnace high temperaturemeasurements and temperature control instruments.UNIT V FURNACE CONSTRUCTION 9Furnace life and selection of proper refractories, thermal currents and atmosphere, safefiring schedule. Basic knowledge about furnace construction, capacity, fuel and firingefficiencies- design, construction and thermal calculation of one of the furnaces.TOTAL: 45 PERIODS52