Water Bath Separator - FISSORE Agency

Water Bath Separator - FISSORE Agency

Water Bath Separator - FISSORE Agency

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

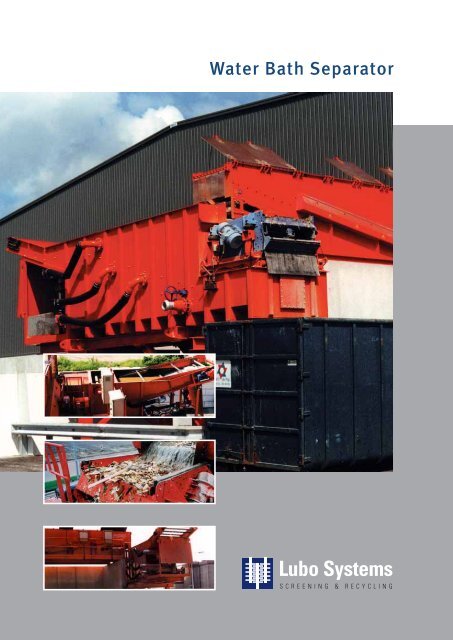

<strong>Water</strong> <strong>Bath</strong> <strong>Separator</strong>

T E C H N I C A L S P E C I F I C A T I O N S<strong>Water</strong> <strong>Bath</strong> <strong>Separator</strong>The principleThe basic principle is that floating materials are separated from the non floating materialsby its gravity difference. The water bath separator exists of a process-tank, executed with aStarScreen discharging the floating materials and a discharge conveyor for the non floatingmaterials. This combined with a water storage tank with slurry pump and a vibrating fines fluidscreen. The Lubo water bath separator has an integrated StarScreen that pulls out the floatingfraction, thus being able to extract a large amount of floating fraction and large floating pieces.A conventional water bath separator that uses a chain or a water flow for extracting, has alimited capacity to extract floating materials and large pieces.Process tankThe separation process takes place in the process tank. The heavy fraction sinks to the bottomof the tank on a conveyor belt that transports it out of the tank. The floating fraction is blowncross-flow towards the StarScreen that extracts it out of the process tank. The moment thefloating fraction hits the stars of the StarScreen the fraction is rapidly extracted from theprocess tank. The water drops through the StarScreen and drops on a vibrating (fluid) screenwith a very fine mesh to take the fines out of the water. The under-fraction (cleaned processingwater) from the fluid screen drops into the storage tank. The output of the floating fraction canbe designed to the left or right.<strong>Water</strong> Storage / Settling tankThe water from the process tank passes two settling compartments and flows into a pumpcompartment from where the water is circulated back to the process tank.Technical details:Total length10,000 mmWidth2,350 mmHeight2,500 mmSettling and cleaningDuring an installation-stop-period all water from the process tank will be drained automaticallyinto the storage tank and the slurry pump circulates only the water through the fines screenand the storage tank, this to prevent settling of the sludge in the tanks. After a defined periodthe process tank stops its circulation-washing process and the heavy fines in the water willsettle on the bottom of the settling compartments during this longer stop period. Emptying ofthese tank compartments can be done by an excavator. Optional Lubo supplies an integratedscrew auger for automatic discharge.Capacity and performanceThe input capacity of the water bath separator is approximately 40 tons per hour with amaximum of floating wood fraction of approx. 20 tons per hour. The maximum input sizematerial is approx. 1 metre and the maximum input weight from materials is approx. 80 kg. Forthe best performance the input material should be without fines < 10 mm and without foilsand paper.<strong>Water</strong> consumption and sludge production varies strongly depending on the input material.Lubo Screening & Recycling Systems B.V.Phileas Foggstraat 85, NL 7825 AW Emmen, P.O. Box 2222, NL 7801 CE Emmen, The NetherlandsTel.: +31(0)591 66 80 80, fax: +31(0)591 66 80 88, e-mail: info@lubo.nl, website: www.lubo.nl