- Page 3 and 4: ContentsMedical SuppliesSplinting 1

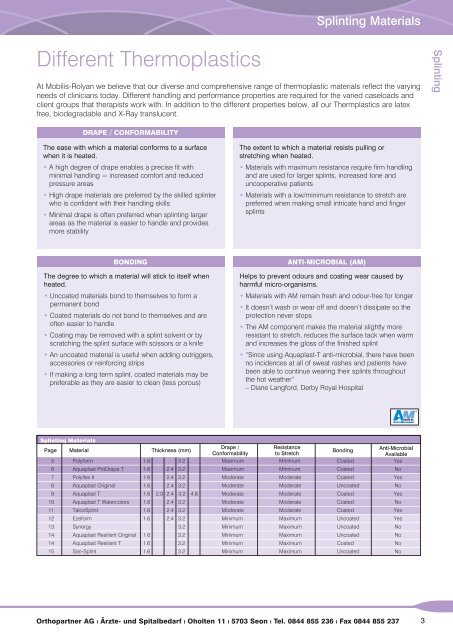

- Page 5: SplintingSplinting2 - 21 Splinting

- Page 9 and 10: Polyform & Polyform LightSplinting

- Page 11 and 12: Polyflex II & Polyflex II LightSpli

- Page 13 and 14: Aquaplast-TSplinting Materials2 Aqu

- Page 15 and 16: TailorSplintSplinting Materials1Tai

- Page 17 and 18: SynergySplinting Materials1SynergyM

- Page 19 and 20: San-Splint & San-Splint LightSplint

- Page 21 and 22: Anti-MicrobialSplinting Materials1

- Page 23 and 24: NeopreneSplinting Materials1 Neopre

- Page 25 and 26: Splinting Materials1 Adapt-It Therm

- Page 27 and 28: Pre-Cut Splints1 Wrist and Thumb Sp

- Page 29 and 30: Pre-Cut Splints1 Resting Pan Mitt S

- Page 31 and 32: Pre-Formed SplintsAnti-Spasticity S

- Page 33 and 34: Padding Materials1 100% Cotton Stoc

- Page 35 and 36: Padding Materials1 Contour FoamRoly

- Page 37 and 38: Strapping Materials1 Self-Adhesive

- Page 39 and 40: Strapping MaterialsSplinting1Velcro

- Page 41 and 42: Strapping Materials1SoftStrap Strap

- Page 43 and 44: Heat PansDigital version of our 9L

- Page 45 and 46: Tools & Accessories1 Splinting KitM

- Page 47 and 48: Tools & Accessories1 All-Purpose Sn

- Page 49 and 50: Tools & Accessories1 Nylon D-Rings2

- Page 51 and 52: Tools & Accessories1Rubber Band Ass

- Page 53 and 54: Tools & Accessories1 Starter KitInc

- Page 55 and 56: Saebo KitSaebo Stroke Rehabilitatio

- Page 57 and 58:

Dynamic Splinting Kits1 Phoenix Out

- Page 59 and 60:

Dynamic Splinting Kits1Adjustable E

- Page 61 and 62:

Finger Splints1 Sof•Stretch Finge

- Page 63 and 64:

Finger Splints1 P.I.P.E.Rolyan(Prox

- Page 65 and 66:

Finger Splints1 Murphy Ring Splints

- Page 67 and 68:

Finger Splints1Buddy StrapRolyanHol

- Page 69 and 70:

Therapy Consumables66 - 68 Rolyan B

- Page 71 and 72:

Rolyan Band - Resistive Exercise Ba

- Page 73 and 74:

Thera-Band ® Resistive Exercise Ba

- Page 75 and 76:

Therapeutic Putty1ROLYAN PROGRESSIV

- Page 77 and 78:

Therapeutic Putty1Therapy Consumabl

- Page 79 and 80:

Hand Exercisers1 BASIC ERGONOMIC HA

- Page 81 and 82:

Hand Exercisers1 R-LITE RESISTIVE F

- Page 83 and 84:

Hand Exercisers1 Xtensor Finger Ext

- Page 85 and 86:

Scar Management1 Mini MassagerCompa

- Page 87 and 88:

Rehab Supplies84 - 85 AIREX ® Exer

- Page 89 and 90:

AIREX ® Exercise MatsRehab Supplie

- Page 91 and 92:

Exercise Mats1 YOGA PILATES 190 MAT

- Page 93 and 94:

Therapy Balls1 GYMNIC CLASSIC PLUST

- Page 95 and 96:

Therapy Ball Accessories1 FASTER BL

- Page 97 and 98:

Weights & Resistance1 MEDICINE BALL

- Page 99 and 100:

Weights & Resistance1 NEOPRENE DUMB

- Page 101 and 102:

Balance1 DISC ‘O’ SIT AIR CUSHI

- Page 103 and 104:

Balance1 Balance HedgehogsPossible

- Page 105 and 106:

Balance1 TOGU Jumper ®• Choose t

- Page 107 and 108:

Rolls & WedgesTumble Forms 2 Rolls

- Page 109 and 110:

Upper Extremity Exercise1 Rolyan St

- Page 111 and 112:

Upper Extremity Exercise1 E-Z Exer

- Page 113 and 114:

Upper Extremity Exercise1Rehab Supp

- Page 115 and 116:

Upper Extremity Exercise1 Rolyan Re

- Page 117 and 118:

Lower Extremity Exercise1 Pedal Exe

- Page 119 and 120:

Hydrotherapy1 AIREX ® Hydro-BuoyHy

- Page 121 and 122:

Assessment Tools118 - 123 Strength1

- Page 123 and 124:

Strength1 JAMAR ® PLUS+ DIGITALHAN

- Page 125 and 126:

Strength1 Baseline ® Push/Pull Dyn

- Page 127 and 128:

Strength1 JAMAR ® HydraulicSammons

- Page 129 and 130:

MeasurementLATEXFREE1Assessment Too

- Page 131 and 132:

Measurement1Assessment Tools5 YEAR

- Page 133 and 134:

Sensation1 Taylor Percussion Hammer

- Page 135 and 136:

Sensation1 Jamar MonofilamentsAccur

- Page 137 and 138:

Range of Motion1 Finger/Toe Goniome

- Page 139 and 140:

Function, Perceptual & Cognitive As

- Page 141 and 142:

Function, Perceptual & Cognitive As

- Page 143 and 144:

140 Head & Neck141 Clavicle & Chest

- Page 145 and 146:

Clavicle & Chest1 Support RiteThis

- Page 147 and 148:

Back1 Neoprene Double Pull Lumbar B

- Page 149 and 150:

Shoulder & Slings1 Abduction SlingR

- Page 151 and 152:

Shoulder Supports1 MFC Unilateral S

- Page 153 and 154:

Elbow Supports1 Vulkan ® Si Elbow

- Page 155 and 156:

Wrist Supports & Wraps1 Neo-G Wrist

- Page 157 and 158:

Wrist Straps1 Vulkan Neoprene Wrist

- Page 159 and 160:

Wrist & Thumb1 Workhard D-RingRolya

- Page 161 and 162:

Thumb Supports1 3PP ThumSlingDesign

- Page 163 and 164:

Thumb Supports1 Upper Extremity Tap

- Page 165 and 166:

Arthritis & Hand Positioning Splint

- Page 167 and 168:

Hand Positioning Splints1 Kwik-Form

- Page 169 and 170:

Hand Positioning Splints1 Air Soft

- Page 171 and 172:

Inflatable Positioning Splints11Ort

- Page 173 and 174:

Knee Supports1 Neo-G Closed Knee Su

- Page 175 and 176:

Foot Splints1 Darco Toe Alignment S

- Page 177 and 178:

Ankle & Foot Orthoses1 Ankle Foot O

- Page 179 and 180:

Lower Extremity Positioning1 Comfi-

- Page 181 and 182:

FootwearOrthopaedicsPeg-Assist Inso

- Page 183 and 184:

Footwear1Darco APBDesigned to provi

- Page 185 and 186:

Oedema Supports1 Jobst Pre-Sized Gl

- Page 187 and 188:

Oedema Supports1 Ready-to-Wear Arm

- Page 189 and 190:

Ortho Upper Size GuideHelpful tips

- Page 191 and 192:

Footcare Appliances188 - 195 Applia

- Page 193 and 194:

Appliances1 Silipos Digital PadProt

- Page 195 and 196:

Appliances1 Silipos Ball of Foot Cu

- Page 197 and 198:

Appliances1 Silipos Heel/Elbow Slip

- Page 199 and 200:

AppliancesGelSmart M-Gel products a

- Page 201 and 202:

Household198 - 199 RevoReach200 - 2

- Page 203 and 204:

RevoReachHouseholdRevolving jaw hea

- Page 205 and 206:

Handi-ReacherBESTSELLER1HouseholdDI

- Page 207 and 208:

Reachers1Household1 Easireach IIHom

- Page 209 and 210:

Reachers1 Sure-Lock Reacher Sammons

- Page 211 and 212:

Plastic Grab Rails1 Moulded Fluted

- Page 213 and 214:

Plastic Grab Rails1 Prima Grab Rail

- Page 215 and 216:

Steel Grab RailsHomecraft Rails are

- Page 217 and 218:

Mobeli ® Suction Grab RailsMobeli

- Page 219 and 220:

Steps & Stools1 Step StoolA simple,

- Page 221 and 222:

Gripping & Turning Aids1 Three Key

- Page 223 and 224:

Gripping & Turning Aids3 The Functi

- Page 225 and 226:

®Non-Slip ProductsDycem coloured r

- Page 227 and 228:

Home Accessories1 Long Handled Dust

- Page 229 and 230:

Magnifiers1 Magnifying Viewer with

- Page 231 and 232:

Reading Aids1 Folding Book and Maga

- Page 233 and 234:

Scissors1 Easi-Grip Chiropodist Sci

- Page 235 and 236:

Medication Aids1 Opticare ® Eye Dr

- Page 237 and 238:

Kitchen & Dining234 - 236 Jar & Bot

- Page 239 and 240:

Jar & Bottle Openers1 Undo-It Jar a

- Page 241 and 242:

Bottle & Tin Openers1 Spillnot Jar

- Page 243 and 244:

Graters, Peelers & Slicers1 One Tou

- Page 245 and 246:

Food Preparation1 Clyde Grater,Home

- Page 247 and 248:

Food Preparation1 Bread BoardHomecr

- Page 249 and 250:

Homecraft Kitchen Utensils1 Reflex

- Page 251 and 252:

Newstead Cutlery1 Newstead Weighted

- Page 253 and 254:

Lightweight Foam Handled Cutlery1 L

- Page 255 and 256:

Kings Modular CutleryAA5535AA5534AA

- Page 257 and 258:

Kings Modular Cutlery1 Kings Standa

- Page 259 and 260:

Caring Cutlery1 Caring CutleryHomec

- Page 261 and 262:

Cutlery1 Sure Grip CutleryThese sta

- Page 263 and 264:

Paediatric Cutlery1 Paediatric Weig

- Page 265 and 266:

Cutlery Aids1 Plastazote Foam Tubin

- Page 267 and 268:

Plates & Dishes1 Suction Scoop Dish

- Page 269 and 270:

Plates & Dishes1 Hi-Lo DishUsers ca

- Page 271 and 272:

Cups & Mugs1 Sure Grip MugThis feed

- Page 273 and 274:

Cups & Mugs1 Caring MugHomecraftThi

- Page 275 and 276:

Cups & Mugs1 The Hydrant Drinking S

- Page 277 and 278:

Cups & Mugs1 Nosey Cutout CupDesign

- Page 279 and 280:

Cups & Straws1 Kennedy CupThis spil

- Page 281 and 282:

Kettles, Tippers & Holders1 Justy A

- Page 283 and 284:

Trays1 Bed MateHomecraftThis portab

- Page 285 and 286:

Trolleys1 Sherwood Folding Perching

- Page 287 and 288:

Trolleys1 Folding Walsall TrolleyHo

- Page 289 and 290:

Comfort & Dressing285 - 289 Sock &

- Page 291 and 292:

Sock & Stocking Aids1 Dorking Stock

- Page 293 and 294:

Sock & Stocking Aids11Comfort & Dre

- Page 295 and 296:

Dressing Aids1 SlipLift Pants AidUn

- Page 297 and 298:

ShoehornsNEW1NEW1Comfort & Dressing

- Page 299 and 300:

Posture Care1 Flexible Adjustable B

- Page 301 and 302:

Bedroom Equipment298 - 299 Bed & Ch

- Page 303 and 304:

Bed & Chair Tables1 Tea Time Bed an

- Page 305 and 306:

Bed & Chair Raisers1 Wooden Chair R

- Page 307 and 308:

ToiletingToileting304 - 305 Inconti

- Page 309 and 310:

Incontinence1 Lilbed Disposable Fur

- Page 311 and 312:

Devon Support Rails1 Devon Folding

- Page 313 and 314:

Devon Elite Support Rails1 22Toilet

- Page 315 and 316:

Support Rails1 Drop Down RailA high

- Page 317 and 318:

Raised Toilet Seats1 Savanah ® Rai

- Page 319 and 320:

Raised Toilet Seats1Raised Toilet S

- Page 321 and 322:

Toilet Seat with Arms1 Etac Cloo He

- Page 323 and 324:

Commodes1 Etac Swift CommodeDesign

- Page 325 and 326:

Folding Commodes1 Uni-Frame Folding

- Page 327 and 328:

Personal Care1 Buckingham EasywipeT

- Page 329 and 330:

Toileting Accessories1 Commode Pres

- Page 331 and 332:

Urinals1 Topper Male UrinalHomecraf

- Page 333 and 334:

Urinals1 Slipper UrinalA white plas

- Page 335 and 336:

BathingBathing332 - 334 Bath Boards

- Page 337 and 338:

Bath Boards1 Savanah Slatted Bath B

- Page 339 and 340:

Bath Boards & Bath Seats1 Farnham B

- Page 341 and 342:

Bath SeatsStatic bath seats are use

- Page 343 and 344:

Shower Stools1BathingA B C D E1 She

- Page 345 and 346:

Shower Stools1Sherwood Folding Perc

- Page 347 and 348:

Shower Stools1 Corner Shower StoolH

- Page 349 and 350:

Shower Stools1 Adjustable Height Sh

- Page 351 and 352:

The Ocean Range1 Deluxe Foldable Ch

- Page 353 and 354:

Etac ® Clean Wheeled Shower Commod

- Page 355 and 356:

Bath Mats1Sure Tread Bath and Showe

- Page 357 and 358:

Long Handled Bathing Accessories1 L

- Page 359 and 360:

Bathing Accessories1 Long Handled N

- Page 361 and 362:

Bathing Accessories1 Flannel Strap

- Page 363 and 364:

Bath Steps1 Savanah Modular Bath St

- Page 365 and 366:

Pressure Care362 - 369 Seating370 S

- Page 367 and 368:

Seating1 Visco Wave CushionHomecraf

- Page 369 and 370:

Seating1 Visco Care CushionHomecraf

- Page 371 and 372:

Seating1 Commode CushionClinically

- Page 373 and 374:

Seating1 Viola Alternating Cushion

- Page 375 and 376:

Elbow & Heel Protectors1 Fleece Hee

- Page 377 and 378:

Elbow & Heel Protectors1Waffle ® H

- Page 379 and 380:

Moving and Handling376 - 379 Transf

- Page 381 and 382:

Transfer Boards1 Curved Transfer Bo

- Page 383 and 384:

Transfer Boards1 Butterfly Board an

- Page 385 and 386:

Handling Belts1 Handling BeltsHomec

- Page 387 and 388:

Glide Sheets1 Lateral Transfer Glid

- Page 389 and 390:

Patient Turners1 Etac Patient Turne

- Page 391 and 392:

Turntables1 Swivel SeatThis high qu

- Page 393 and 394:

Turntables1 Rota CushionThe Rota Cu

- Page 395 and 396:

Bed Assists1Rope Ladder Bed HoistHo

- Page 397 and 398:

Patient Transfer1 Leg LifterHomecra

- Page 399 and 400:

Walking Aids396 Homecraft Tri-Wheel

- Page 401 and 402:

Tri Wheeled Accessories1 Three-Whee

- Page 403 and 404:

Walking Frame Accessories1Net Bag f

- Page 405 and 406:

Stick Seats1 Height Adjustable Stic

- Page 407 and 408:

Folding Walking Sticks1 Premium Fol

- Page 409 and 410:

Walking Sticks1 Bariatric Walking S

- Page 411 and 412:

Walking Stick Accessories1 Leather

- Page 413 and 414:

Elbow Crutches1 Shock Absorbing Cru

- Page 415 and 416:

Elbow Crutches1 Travel CrutchThe Tr

- Page 417 and 418:

Paediatrics414 Bathing415 Changing4

- Page 419 and 420:

ChangingSurfer Bather Child’s Bat

- Page 421 and 422:

Toileting1 Tumble Forms 2SammonsCar

- Page 423 and 424:

Toileting1 Svan Balance Toilet Fram

- Page 425 and 426:

Toileting1 Padded Toilet Seat Reduc

- Page 427 and 428:

Seating1 Zebra Positioning ChairThe

- Page 429 and 430:

Tumble Forms 2 Deluxe Floor Sitter1

- Page 431 and 432:

Seating1Tumble Forms 2Carrie Activi

- Page 433 and 434:

Positioning1 Tumble Forms 2SammonsA

- Page 435 and 436:

Positioning1Tumble Forms 2WedgesSam

- Page 437 and 438:

Positioning1 Tumble Forms 2 Univers

- Page 439 and 440:

PositioningVersa FormPositioning Pi

- Page 441 and 442:

Mobility1 Height AdjustableSammonsC

- Page 443 and 444:

Sensory Motor1 Tumble Forms 2Sammon

- Page 445 and 446:

Sensory Motor1 Slo-Mo Bump BallsMad

- Page 447 and 448:

Sensory Motor1 Dressing CubeA colou

- Page 449 and 450:

Sensory Motor1 Stereognosis KitRoly

- Page 451 and 452:

Therapeutic Resources - Games1 Noug

- Page 453 and 454:

Feeding1 EasieEaters Curved Utensil

- Page 455 and 456:

Feeding1 Caring MugHomecraftThis mu

- Page 457 and 458:

Scissors & Craftwork1 Easi-Grip Sci

- Page 459 and 460:

Writing Aids1 Pen and Pencil Holder

- Page 461 and 462:

BariatricsBariatrics458 Bathing459

- Page 463 and 464:

Bathing & ToiletingThe Mediatrics p

- Page 465 and 466:

Toileting1 Extra Wide CommodesConst

- Page 467 and 468:

Floor Recovery1 ELKThe ELK emergenc

- Page 469 and 470:

Alphabetical IndexDiscription Page

- Page 471 and 472:

Alphabetical IndexDiscription Page

- Page 473 and 474:

Alphabetical IndexDiscription Page

- Page 475 and 476:

Alphabetical IndexDiscription Page

- Page 477 and 478:

Numerical IndexProduct Code Page Pr

- Page 479 and 480:

Numerical IndexProduct Code Page Pr

- Page 481 and 482:

Numerical IndexProduct Code Page Pr

- Page 483 and 484:

Numerical IndexProduct Code Page Pr

- Page 485 and 486:

Numerical IndexProduct Code Page Pr

- Page 487 and 488:

Numerical IndexProduct Code Page Pr

- Page 489 and 490:

Numerical IndexProduct Code Page Pr

- Page 491 and 492:

Product Code Page Product Code Page

- Page 493:

Ärzte- und SpitalbedarfÄrzte- und