You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

12<br />

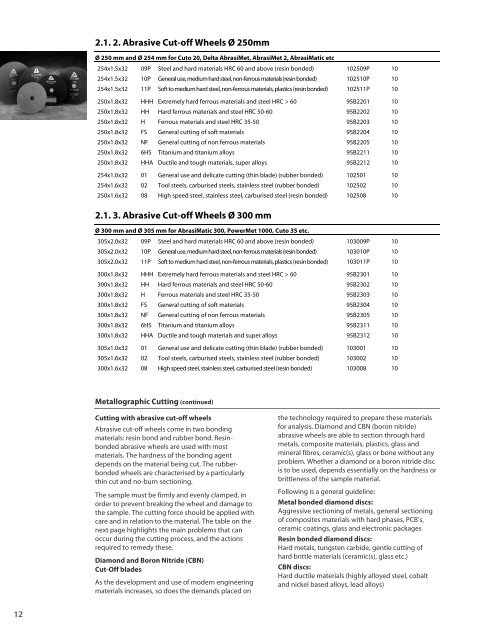

2.1. 2. Abrasive Cut-off Wheels Ø 250mm<br />

Ø 250 mm and Ø 254 mm for Cuto 20, Delta AbrasiMet, AbrasiMet 2, AbrasiMatic etc<br />

254x1.5x32 09P Steel and hard materials HRC 60 and above (resin bonded) 102509P 10 82.00<br />

254x1.5x32 10P General use, medium hard steel, non-ferrous materials (resin bonded) 102510P 10 82.00<br />

254x1.5x32 11P Soft to medium hard steel, non-ferrous materials, plastics (resin bonded) 102511P 10 82.00<br />

250x1.8x32 HHH Extremely hard ferrous materials and steel HRC > 60 95B2201 10 66.00<br />

250x1.8x32 HH Hard ferrous materials and steel HRC 50-60 95B2202 10 66.00<br />

250x1.8x32 H Ferrous materials and steel HRC 35-50 95B2203 10 66.00<br />

250x1.8x32 FS General cutting of soft materials 95B2204 10 66.00<br />

250x1.8x32 NF General cutting of non ferrous materials 95B2205 10 66.00<br />

250x1.8x32 6HS Titanium and titanium alloys 95B2211 10 101.00<br />

250x1.8x32 HHA Ductile and tough materials, super alloys 95B2212 10 66.00<br />

254x1.0x32 01 General use and delicate cutting (thin blade) (rubber bonded) 102501 10 134.00<br />

254x1.6x32 02 Tool steels, carburised steels, stainless steel (rubber bonded) 102502 10 134.00<br />

250x1.6x32 08 High speed steel, stainless steel, carburised steel (resin bonded) 102508 10 100.00<br />

2.1. 3. Abrasive Cut-off Wheels Ø 300 mm<br />

Ø 300 mm and Ø 305 mm for AbrasiMatic 300, PowerMet 1000, Cuto 35 etc.<br />

305x2.0x32 09P Steel and hard materials HRC 60 and above (resin bonded) 103009P 10 110.00<br />

305x2.0x32 10P General use, medium hard steel, non-ferrous materials (resin bonded) 103010P 10 110.00<br />

305x2.0x32 11P Soft to medium hard steel, non-ferrous materials, plastics (resin bonded) 103011P 10 110.00<br />

300x1.8x32 HHH Extremely hard ferrous materials and steel HRC > 60 95B2301 10 77.00<br />

300x1.8x32 HH Hard ferrous materials and steel HRC 50-60 95B2302 10 77.00<br />

300x1.8x32 H Ferrous materials and steel HRC 35-50 95B2303 10 77.00<br />

300x1.8x32 FS General cutting of soft materials 95B2304 10 77.00<br />

300x1.8x32 NF General cutting of non ferrous materials 95B2305 10 77.00<br />

300x1.8x32 6HS Titanium and titanium alloys 95B2311 10 130.00<br />

300x1.8x32 HHA Ductile and tough materials and super alloys 95B2312 10 77.00<br />

305x1.0x32 01 General use and delicate cutting (thin blade) (rubber bonded) 103001 10 151.00<br />

305x1.6x32 02 Tool steels, carburised steels, stainless steel (rubber bonded) 103002 10 151.00<br />

300x1.6x32 08 High speed steel, stainless steel, carburised steel (resin bonded) 103008 10 130.00<br />

Metallographic Cutting (continued)<br />

Cutting with abrasive cut-off wheels<br />

Abrasive cut-off wheels come in two bonding<br />

materials: resin bond and rubber bond. Resinbonded<br />

abrasive wheels are used with most<br />

materials. The hardness of the bonding agent<br />

depends on the material being cut. The rubberbonded<br />

wheels are characterised by a particularly<br />

thin cut and no-burn sectioning.<br />

The sample must be firmly and evenly clamped, in<br />

order to prevent breaking the wheel and damage to<br />

the sample. The cutting force should be applied with<br />

care and in relation to the material. The table on the<br />

next page highlights the main problems that can<br />

occur during the cutting process, and the actions<br />

required to remedy these.<br />

Diamond and Boron Nitride (CBN)<br />

Cut-Off blades<br />

As the development and use of modern engineering<br />

materials increases, so does the demands placed on<br />

the technology required to prepare these materials<br />

for analysis. Diamond and CBN (boron nitride)<br />

abrasive wheels are able to section through hard<br />

metals, composite materials, plastics, glass and<br />

mineral fibres, ceramic(s), glass or bone without any<br />

problem. Whether a diamond or a boron nitride disc<br />

is to be used, depends essentially on the hardness or<br />

brittleness of the sample material.<br />

Following is a general guideline:<br />

Metal bonded diamond discs:<br />

Aggressive sectioning of metals, general sectioning<br />

of composites materials with hard phases, PCB’s,<br />

ceramic coatings, glass and electronic packages<br />

Resin bonded diamond discs:<br />

Hard metals, tungsten carbide, gentle cutting of<br />

hard brittle materials (ceramic(s), glass etc.)<br />

CBN discs:<br />

Hard ductile materials (highly alloyed steel, cobalt<br />

and nickel based alloys, lead alloys)