cobra nc 0400 b - Busch Vacuum Technics

cobra nc 0400 b - Busch Vacuum Technics

cobra nc 0400 b - Busch Vacuum Technics

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

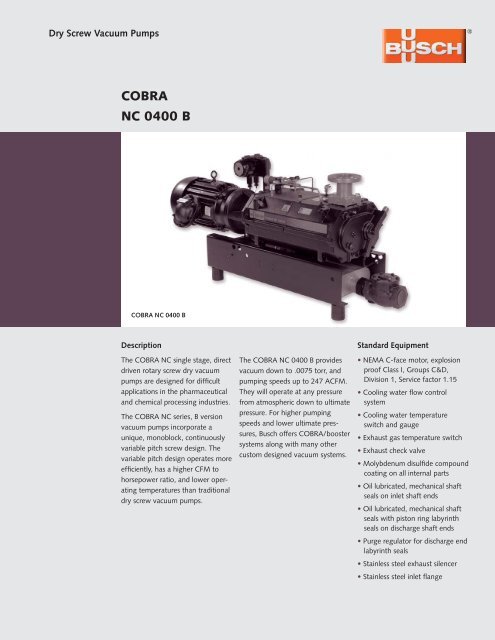

Dry Screw <strong>Vacuum</strong> Pumps®COBRANC <strong>0400</strong> BCOBRA NC <strong>0400</strong> BDescriptionThe COBRA NC single stage, directdriven rotary screw dry vacuumpumps are designed for difficultapplications in the pharmaceuticaland chemical processing industries.The COBRA NC series, B versionvacuum pumps i<strong>nc</strong>orporate aunique, monoblock, continuouslyvariable pitch screw design. Thevariable pitch design operates moreefficiently, has a higher CFM tohorsepower ratio, and lower operatingtemperatures than traditionaldry screw vacuum pumps.The COBRA NC <strong>0400</strong> B providesvacuum down to .0075 torr, andpumping speeds up to 247 ACFM.They will operate at any pressurefrom atmospheric down to ultimatepressure. For higher pumpingspeeds and lower ultimate pressures,<strong>Busch</strong> offers COBRA/boostersystems along with many othercustom designed vacuum systems.Standard Equipment• NEMA C-face motor, explosionproof Class I, Groups C&D,Division 1, Service factor 1.15• Cooling water flow controlsystem• Cooling water temperatureswitch and gauge• Exhaust gas temperature switch• Exhaust check valve• Molybdenum disulfide compoundcoating on all internal parts• Oil lubricated, mechanical shaftseals on inlet shaft ends• Oil lubricated, mechanical shaftseals with piston ring labyrinthseals on discharge shaft ends• Purge regulator for discharge endlabyrinth seals• Stainless steel exhaust sile<strong>nc</strong>er• Stainless steel inlet flange

Dry Screw <strong>Vacuum</strong> PumpsOperating Pri<strong>nc</strong>iple15578648321 Inlet2 Exhaust3 Water Jacket4 ScrewOperating Pri<strong>nc</strong>ipleTwo counter rotating screw shapedrotors rotate inside of a commo<strong>nc</strong>ylinder. As the screws rotate, theytrap a volume of gas at the inlet ofthe vacuum pump, and conveythat gas towards the vacuum pumpdischarge.The variable pitch design causesan internal compression within thepumping chamber prior to dischargingthe gas. This pri<strong>nc</strong>iple createsup to 50% higher efficie<strong>nc</strong>y (CFMper horsepower), and reduces thetemperature rise by up to 50% i<strong>nc</strong>omparison with traditional screwdesigns.5 Oil6 Gas Path7 Timing Gears8 Bearings/SealsThe screws do not contact eachother or the cylinder/end plates dueto precision manufacturing andgears that maintain rotor timing.Therefore, no lubricant is requiredin the pumping chamber.Lubricants for the bearings andgears are sealed from the pumpingchamber by mechanical shaft seals.Cooling is achieved by a direct(o<strong>nc</strong>e-through) water cooling systemwhich utilizes an integral coolantpump and flow controlling valve.Applications• Drying processes in the pharmaceuticalindustry demanding special product purity• Recovery of solvents, from drying, filtration,crystallization, and distillation processes• Degassing processes in the furnace, metaland coating industry• Degassing processes in the food industry• Impregnation processes• Crystal growing for semiconductor andsolar industries• Extruder degassing• Recycling of process gases without addingcontamination• Industrial furnaces• Evacuation of gas bottles prior to fillingwith high-purity gases• Leak testing• Central vacuum for laboratory andpilot plants• Sinter processes• Coating technology• <strong>Vacuum</strong> processes in all applicationswhere oil-free vacuum is required

®Pumping Speed vs. Inlet PressureNC <strong>0400</strong> BBrake Horsepower vs. Inlet PressureNC <strong>0400</strong> B260240220Pumping Speed (ACFM)15141312Brake Horsepower200111801601401201008010987654604020032100.001 0.01 0.1 1 10 100 1000 0.001 0.01 0.1 1 10 100 1000Inlet Pressure (Torr)Inlet Pressure (Torr)Technical DataNC <strong>0400</strong> BNominal pumping speed ACFM 247Ultimate pressure Torr .0075Motor size HP 15Motor rotational speed RPM 3600Sound level rating* dbA 69Approximate oil sump capacity Qts. 1Average water usage rate GPM 1.3Approximate weight (as shown) Lbs 1433All performa<strong>nc</strong>e data is based on ambient conditions of 14.7 PSIA and 70º F, and has a tolera<strong>nc</strong>e of + /- 10%.*DIN EN ISO 2151

Dry Screw <strong>Vacuum</strong> Pumps®DimensionsCOBRA NC <strong>0400</strong> B10”6 1 /8”Inlet 3”ANSI flange26 1 /2”31 1 /2”30 5 /8”Discharge3” NPT12 3 /8”6 1 /8”8 3 /4”7”13 7 /8”17”28 5 /8”3”12” 4”40 3 /8”44 7 /8”68 1 /4”All dimensions in i<strong>nc</strong>hes unless otherwise noted.<strong>Busch</strong> - all over the world in industryISO 9001-2000 Registered Company<strong>Busch</strong>, I<strong>nc</strong>. 516 Viking Drive Virginia Beach, VA 23452Phone (757) 463-7800 FAX (757) 463-7407www.buschpump.com1-800-USA-PUMPAmsterdam Barcelona Birmingham Basel Brussels Dublin Göteborg Helsinki Istanbul Copenhagen Kuala Lumpur Milan Maulburg Melbourne Montreal MoscowNew York New Plymouth Oslo Paris San Jose São Paulo Seoul Singapore Taipei Tokyo ViennaModels and specifications are subject to change without notice 01-9/07