Jim Kellett Takes the Lead at ECAO 2011 ECAO Industry Conference

Jim Kellett Takes the Lead at ECAO 2011 ECAO Industry Conference

Jim Kellett Takes the Lead at ECAO 2011 ECAO Industry Conference

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

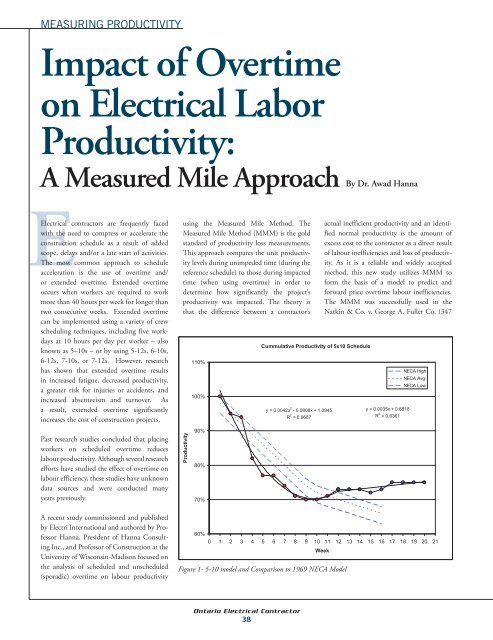

MEASURING PRODUCTIVITYImpact of Overtimeon Electrical LaborProductivity:A Measured Mile Approach By Dr. Awad HannaElectrical contractors are frequently facedwith <strong>the</strong> need to compress or acceler<strong>at</strong>e <strong>the</strong>construction schedule as a result of addedscope, delays and/or a l<strong>at</strong>e start of activities.The most common approach to scheduleacceler<strong>at</strong>ion is <strong>the</strong> use of overtime and/or extended overtime. Extended overtimeoccurs when workers are required to workmore than 40 hours per week for longer thantwo consecutive weeks. Extended overtimecan be implemented using a variety of crewscheduling techniques, including five workdays<strong>at</strong> 10 hours per day per worker – alsoknown as 5–10s – or by using 5-12s, 6-10s,6-12s, 7-10s, or 7-12s. However, researchhas shown th<strong>at</strong> extended overtime resultsin increased f<strong>at</strong>igue, decreased productivity,a gre<strong>at</strong>er risk for injuries or accidents, andincreased absenteeism and turnover. Asa result, extended overtime significantlyincreases <strong>the</strong> cost of construction projects.Past research studies concluded th<strong>at</strong> placingworkers on scheduled overtime reduceslabour productivity. Although several researchefforts have studied <strong>the</strong> effect of overtime onlabour efficiency, <strong>the</strong>se studies have unknownd<strong>at</strong>a sources and were conducted manyyears previously.A recent study commissioned and publishedby Electri Intern<strong>at</strong>ional and authored by ProfessorHanna, President of Hanna ConsultingInc., and Professor of Construction <strong>at</strong> <strong>the</strong>University of Wisconsin-Madison focused on<strong>the</strong> analysis of scheduled and unscheduled(sporadic) overtime on labour productivityusing <strong>the</strong> Measured Mile Method. TheMeasured Mile Method (MMM) is <strong>the</strong> goldstandard of productivity loss measurements.This approach compares <strong>the</strong> unit productivitylevels during unimpeded time (during <strong>the</strong>reference schedule) to those during impactedtime (when using overtime) in order todetermine how significantly <strong>the</strong> project’sproductivity was impacted. The <strong>the</strong>ory isth<strong>at</strong> <strong>the</strong> difference between a contractor’sProductivity110%100%90%80%70%Cummul<strong>at</strong>ive Productivity of 5x10 Scheduley = 0.0042x 2 - 0.0808x + 1.0945R 2 = 0.9687actual inefficient productivity and an identifiednormal productivity is <strong>the</strong> amount ofexcess cost to <strong>the</strong> contractor as a direct resultof labour inefficiencies and loss of productivity.As it is a reliable and widely acceptedmethod, this new study utilizes MMM toform <strong>the</strong> basis of a model to predict andforward price overtime labour inefficiencies.The MMM was successfully used in <strong>the</strong>N<strong>at</strong>kin & Co. v. George A. Fuller Co. (347y = 0.0035x + 0.6818R 2 = 0.636160%0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21WeekFigure 1- 5-10 model and Comparison to 1969 NECA ModelNECA HighNECA AvgNECA LowOntario Electrical Contractor38