Product Features and Specifications - Ingersoll Rand

Product Features and Specifications - Ingersoll Rand

Product Features and Specifications - Ingersoll Rand

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

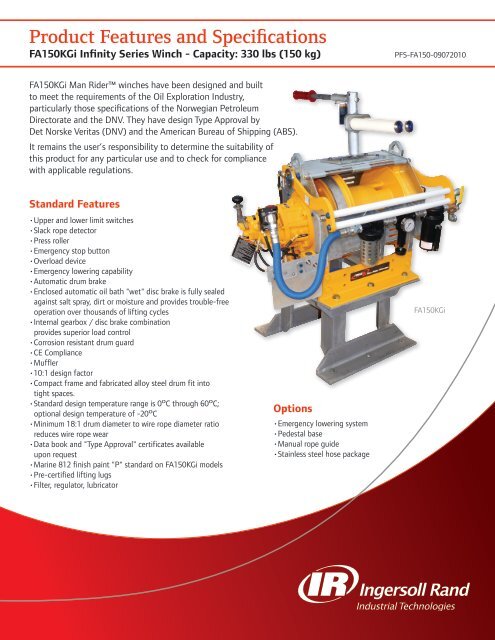

<strong>Product</strong> <strong>Features</strong> <strong>and</strong> <strong>Specifications</strong>FA150KGi Infinity Series Winch - Capacity: 330 lbs (150 kg)PFS-FA150-09072010FA150KGi Man Rider winches have been designed <strong>and</strong> builtto meet the requirements of the Oil Exploration Industry,particularly those specifications of the Norwegian PetroleumDirectorate <strong>and</strong> the DNV. They have design Type Approval byDet Norske Veritas (DNV) <strong>and</strong> the American Bureau of Shipping (ABS).It remains the user’s responsibility to determine the suitability ofthis product for any particular use <strong>and</strong> to check for compliancewith applicable regulations.St<strong>and</strong>ard <strong>Features</strong>• Upper <strong>and</strong> lower limit switches• Slack rope detector• Press roller• Emergency stop button• Overload device• Emergency lowering capability• Automatic drum brake• Enclosed automatic oil bath "wet" disc brake is fully sealedagainst salt spray, dirt or moisture <strong>and</strong> provides trouble-freeoperation over thous<strong>and</strong>s of lifting cycles• Internal gearbox / disc brake combinationprovides superior load control• Corrosion resistant drum guard• CE Compliance• Muffler• 10:1 design factor• Compact frame <strong>and</strong> fabricated alloy steel drum fit intotight spaces.• St<strong>and</strong>ard design temperature range is 0o C through 60 o C;optional design temperature of -20 o C• Minimum 18:1 drum diameter to wire rope diameter ratioreduces wire rope wear• Data book <strong>and</strong> "Type Approval" certificates availableupon request• Marine 812 finish paint "P" st<strong>and</strong>ard on FA150KGi models• Pre-certified lifting lugs• Filter, regulator, lubricatorOptions• Emergency lowering system• Pedestal base• Manual rope guide• Stainless steel hose packageFA150KGi

<strong>Product</strong> <strong>Features</strong> <strong>and</strong> <strong>Specifications</strong>FA150KGi Infinity Series Winch - Capacity: 330 lbs (150 kg)PFS-FA150-0907201043.5 [1105]12.0 [305]40.2[1021]AIR INLET1/2” NPTLIMITSWITCHMOTOREXHAUST3/4” NPT33.0[839]ø 10.75[273]ø 19.0[483]ø 14.0[356]FA150KGiø .69 [17]22.8 [579].50 [13]2.0 [51]10.0 [254]20.0 [508]24.0 [610] 7.1[125]Dimensions shown are inches.Dimensions in Brackets [ ] are mm.Dimensions are subject to change.Contact factory for certified drawings.Dimensions: FA150KGi-MR <strong>and</strong> Bolt Down PatternDrum Length 12” [305 mm]Both Brakesin mmOverall Length 43.6 1107‘A’ 20 508‘B’ 9.00 229‘C’ 0.69 18Total # Holes 6Bolt Down PatternB B BCDRUMA‘C’ = Bolt Hole Inside DiameterMan Rider Lift Ratings at 10:1 Design Factor (Performance at 6.3 Bar - 90 PSI at air inlet when winch is operating)Top LayerFirst LayerRated Speed at Average Air Sound Inlet Exhaust NetCapacity Speed Rated Capacity Stall Pull Consumption (1) Level (2) Size Size WeightModel # hp lbs kg ft/min m/min ft/min m/min lbs kg f 3 /min m 3 /min db(A) NPT NPT lbs kgFA150KGi-MR12-1-E 2 330 150 89 27 82 25 622 283 50 14 89 1/2” 3/4” 750 340(1) Average Air Consumption is at rated load <strong>and</strong> speed at top layer (2) With optional mufflerDrum Wire Rope Storage Capacity - Imperial - Man RiderRated Rope Min Req Breakcapacity Diameter Strength* Accumulated rope capacity in feet / number of layersSeries lbs in lbs 1 2 3 4 5 6 7 8 9 10 11 12 13 14FA150KGi-12 330 3/8 3,300 90 186 288 396 509 628 753 884 1,021 1,163 1,311Drum Wire Rope Storage Capacity - Metric - Man RiderRated Rope Min Req Breakcapacity Diameter Strength* Accumulated rope capacity in meters / number of layersSeries kg mm kg 1 2 3 4 5 6 7 8 9 10 11 12 13 14FA150KGi-12 150 10 1497 26 54 84 115 148 183 220 259 299 341 385* Note: The Minimum Required Breaking Strength for the wire rope needs to be the Rated Capacity multiplied by the Design Factor.Example: for the FA150KGi-12 (with a 10:1 Design Factor) 330 x 10 = 3,300 lbs.

<strong>Product</strong> <strong>Features</strong> <strong>and</strong> <strong>Specifications</strong>FA2i-MR Infinity Series Winch - Capacity: 3,180 lbs (1 445 kg)PFS-FA2i-MR-09292010<strong>Ingersoll</strong> R<strong>and</strong>’s offering of dedicated <strong>and</strong> dual purpose(utility & personnel lifting) Man Rider winchesare known worldwide as the st<strong>and</strong>ard formeeting the toughest personnel liftingrequirements in the industry.These rugged, oilfield tough wincheshave Type Approval or IndependentReview certificates issued by theclassification societies of ABS or DNV.<strong>Features</strong>Meeting world st<strong>and</strong>ards.Certified to those st<strong>and</strong>ards.Drilling rigs <strong>and</strong> platforms are used all over the world <strong>and</strong>come under numerous <strong>and</strong> diverse regulations. <strong>Ingersoll</strong>R<strong>and</strong> builds to regional <strong>and</strong> global specifications <strong>and</strong> ourwinches are certified by Det Norske Veritas (DNV), <strong>and</strong>the American Bureau of Shipping (ABS).Type ApprovalA comprehensive design review by a third party addressesintended service, applications, ratings, design calculations,load bearing components, product specifications,<strong>and</strong> service restrictions or limitations. Plant surveys verifyquality control procedures. A Type Approval certificate isthen issued.FA2i-MR with optionalAir Preparation PackageWhat makes a winch a Man RiderMinimum design factors of 8:1. Dual Brakes.Drum Guards. Type Approval Certs <strong>and</strong> DataBooks upon request (when requested at time oforder). And, depending on where in the worldit will be used, may include additional optionssuch as: - CE certification, overload device,slack wire detector, limit switch, emergencyshut-off, emergency lowering device <strong>and</strong>spooling device.

<strong>Product</strong> <strong>Features</strong> <strong>and</strong> <strong>Specifications</strong>FA2i-MR Infinity Series Winch - Capacity: 3,180 lbs (1 445 kg)PFS-FA2i-MR-09292010AIR INLET1-1/4”NPTOverall LengthDrum LengthLIMITSWITCHMOTOREXHAUST1-1/4”NPT 28.4[723]ø .69 [17]FA2i-MR12MK1GFA2i-MR24MK1Gwith disc <strong>and</strong> manual brakeBase Length8.4 [213].5 [13]ø 10.75[273]ø 19.0[483]ø 14.0[356]2.0 [51]10.0[254]20.0 [508]24.0 [610]4.9[125]Dimensions shown are inches.Dimensions in Brackets [ ] are mm.FA2i - MK1GDimensions are subject to change.Contact factory for certified drawings.Dimensions: FA2i-MR <strong>and</strong> Bolt Down PatternDrum Length 12” [305 mm]Drum Length 24” [610 mm]Drum & Disc BrakesDrum & Disc Brakesin mm in mmOverall Length 40.8 1036 52.8 1341Base Length 22.8 579 34.8 884‘A’ 20.0 508 20.0 508‘B’ 9.0 229 10.0 254‘C’ 0.69 18 0.69 18Total # Holes 6 8Bolt Down PatternB B BCDRUMA‘C’ = Bolt Hole Inside DiameterMan Rider Lift Ratings at 8:1 Design Factor (Performance at 6.3 Bar - 90 PSI at air inlet when winch is operating)Top LayerFirst LayerRated Speed at Average Air Sound Inlet Exhaust NetCapacity Speed Rated Capacity Stall Pull Consumption (1) Level (2) Size Size WeightModel # hp lbs kg ft/min m/min ft/min m/min lbs kg f 3 /min m 3 /min db(A) NPT NPT lbs kgFA2i-MR24MK1 9 3,180 1445 75 23 68 21 9,139 4154 280 8 87 1-1/4” 1-1/4” 925 420Utility Lift Ratings at 5:1 Design Factor (Performance at 6.3 Bar - 90 PSI at air inlet when winch is operating)FA2i-MR24MK1 8 4,400 2000 51 16 55 17 9,139 4154 280 8 87 1-1/4” 1-1/4” 850 386(1) Average Air Consumption is at rated load <strong>and</strong> speed at top layer (2) With optional mufflerDrum Wire Rope Storage Capacity - Imperial - Man RiderRated Rope Min Req Breakcapacity Diameter Strength* Accumulated rope capacity in feet / number of layersSeries lbs in lbs 1 2 3 4 5 6 7 8 9 10 11 12 13 14FA2i-MR12 3,180 1/2 25,440 66 141 220 305 396 492 594 702FA2i-MR24 3,180 1/2 25,440 138 289 450 624 809 1,006 1,214 1,435Drum Wire Rope Storage Capacity - Metric - Man RiderRated Ropecapacity DiameterMin Req BreakStrength* Accumulated rope capacity in meters / number of layersSeries kg mm kg 1 2 3 4 5 6 7 8 9 10 11 12 13 14FA2i-MR12 1445 13 11539 20 42 66 91 119 147 178 210FA2i-MR24 1445 13 11539 41 86 135 187 242 301 364 430* Note: The Minimum Required Breaking Strength for the wire rope needs to be the Rated Capacity multiplied by the Design Factor.Example: for the FA2i-MR12 (with a 8:1 Design Factor) 3,180 x 8 = 25,440 lbs.

<strong>Product</strong> <strong>Features</strong> <strong>and</strong> <strong>Specifications</strong>FA2.5i-MR Infinity Series Winch - Capacity: 3,180 lbs (1 445 kg)PFS-FA2.5i-MR-09292010<strong>Ingersoll</strong> R<strong>and</strong>’s offering of dedicated <strong>and</strong> dual purpose(utility & personnel lifting) Man Rider winchesare known worldwide as the st<strong>and</strong>ard formeeting the toughest personnel liftingrequirements in the industry.These rugged, oilfield tough winches haveType Approval or Independent Reviewcertificates issued by the classificationsocieties of ABS or DNV.<strong>Features</strong>Meeting world st<strong>and</strong>ards.Certified to those st<strong>and</strong>ards.Drilling rigs <strong>and</strong> platforms are used all over the world <strong>and</strong>come under numerous <strong>and</strong> diverse regulations. <strong>Ingersoll</strong>R<strong>and</strong> builds to regional <strong>and</strong> global specifications <strong>and</strong> ourwinches are certified by Det Norske Veritas (DNV), <strong>and</strong>the American Bureau of Shipping (ABS).Type ApprovalA comprehensive design review by a third party addressesintended service, applications, ratings, design calculations,load bearing components, product specifications,<strong>and</strong> service restrictions or limitations. Plant surveys verifyquality control procedures. A Type Approval certificate isthen issued.FA2.5i-MR withoptional -CE PackageWhat makes a winch a Man RiderMinimum design factors of 8:1. Dual Brakes.Drum Guards. Type Approval Certs <strong>and</strong> DataBooks upon request (when requested at time oforder). And, depending on where in the worldit will be used, may include additional optionssuch as: - CE certification, overload device,slack wire detector, limit switch, emergencyshut-off, emergency lowering device <strong>and</strong>spooling device.

<strong>Product</strong> <strong>Features</strong> <strong>and</strong> <strong>Specifications</strong>FA2.5i-MR Infinity Series Winch - Capacity: 3,180 lbs (1 445 kg)PFS-FA2.5i-MR-09292010AIR INLET1-1/4” NPTOverall LengthDrum LengthLIMITSWITCHMOTOREXHAUST2-1/2” NPT33.0[839]FA2.5i-MR12MK1GFA2.5i-MR24MK1Gwith disc <strong>and</strong> manual brakeø .69 [17]Base LengthDimensions: FA2.5i-MR <strong>and</strong> Bolt Down Pattern8.4 [213].5 [13]Drum Length 12” [305 mm]Drum Length 24” [610 mm]Drum & Disc BrakesDrum & Disc Brakesin mm in mmOverall Length 45.8 1163 58.0 1473Base Length 22.8 579 34.8 884‘A’ 20.0 508 20.0 508‘B’ 9.0 229 10.0 254‘C’ 0.69 18 0.69 18Total # Holes 6 8ø 10.75[273]ø 19.0[483]2.0 [51]ø 14.0[356]B10.0[254]20.0 [508]24.0 [610]4.9[125]Dimensions shown are inches.Dimensions in Brackets [ ] are mm.FA2.5i - MR-MK1Dimensions are subject to change.Contact factory for certified drawings.Bolt Down PatternBDRUM‘C’ = Bolt Hole Inside DiameterBCAMan Rider Lift Ratings at 8:1 Design Factor (Performance at 6.3 Bar - 90 PSI at air inlet when winch is operating)Top LayerFirst LayerRated Speed at Average Air Sound Inlet Exhaust NetCapacity Speed Rated Capacity Stall Pull Consumption (1) Level (2) Size Size WeightModel # hp lbs kg ft/min m/min ft/min m/min lbs kg f 3 /min m 3 /min db(A) NPT NPT lbs kgFA2.5i-MR24MK1G 25 3,180 1445 173 53 145 44 10,277 4671 700 20 97 1-1/4” 2-1/2” 1,265 574Utility Lift Ratings at 5:1 Design Factor (Performance at 6.3 Bar - 90 PSI at air inlet when winch is operating)FA2.5i-MR24MK1G 25 5,000 2273 132 40 128 39 10,277 4671 700 20 97 1-1/4” 2-1/2” 1,061 481(1) Average Air Consumption is at rated load <strong>and</strong> speed at top layer (2) With optional mufflerDrum Wire Rope Storage Capacity - Imperial - Man RiderRated Rope Min Req Breakcapacity Diameter Strength* Accumulated rope capacity in feet / number of layersSeries lbs in lbs 1 2 3 4 5 6 7 8 9 10 11 12 13 14FA2.5i-MR12 3,180 1/2 25,440 68 141 220 305 396 492 594 702FA2.5i-MR24 3,180 1/2 25,440 138 289 450 624 809 1,006 1,214 1,435Drum Wire Rope Storage Capacity - Metric - Man RiderRated Ropecapacity DiameterMin Req BreakStrength* Accumulated rope capacity in meters / number of layersSeries kg mm kg 1 2 3 4 5 6 7 8 9 10 11 12 13 14FA2.5i-MR12 1445 13 11539 20 42 66 91 119 147 178 210FA2.5i-MR24 1445 13 11539 41 86 135 187 242 301 364 430* Note: The Minimum Required Breaking Strength for the wire rope needs to be the Rated Capacity multiplied by the Design Factor.Example: for the FA2.5i-MR12 (with a 8:1 Design Factor) 3,180 x 8 = 25,440 lbs.

<strong>Product</strong> <strong>Features</strong> <strong>and</strong> <strong>Specifications</strong>FA5i-MR Infinity Series Winch - Capacity: 6,875 lbs (3 125 kg)PFS-FA5i-MR-09292010<strong>Ingersoll</strong> R<strong>and</strong>’s offering of dedicated <strong>and</strong> dual purpose (utility & personnel lifting) Man Rider winchesare known worldwide as the st<strong>and</strong>ard for meeting the toughestpersonnel lifting requirements in the industry.These rugged, oilfield tough winches haveType Approval or Independent Reviewcertificates issued by the classificationsocieties of ABS or DNV.<strong>Features</strong>Meeting world st<strong>and</strong>ards.Certified to those st<strong>and</strong>ards.Drilling rigs <strong>and</strong> platforms are used all over theworld <strong>and</strong> come under numerous <strong>and</strong> diverseregulations. <strong>Ingersoll</strong> R<strong>and</strong> builds to regional <strong>and</strong>global specifications <strong>and</strong> our winches are certifiedby Det Norske Veritas (DNV), <strong>and</strong> the AmericanBureau of Shipping (ABS).Type ApprovalA comprehensive design review by a third party addressesintended service, applications, ratings, design calculations,load bearing components, product specifications,<strong>and</strong> service restrictions or limitations. Plant surveys verifyquality control procedures. A Type Approval certificate isthen issued.FA5i-MR with optional Overload,E-stop & Air Preparation PackageWhat makes a winch a Man RiderMinimum design factors of 8:1. Dual Brakes.Drum Guards. Type Approval Certs <strong>and</strong> DataBooks upon request (when requested at time oforder). And, depending on where in the worldit will be used, may include additional optionssuch as: - CE certification, overload device,slack wire detector, limit switch, emergencyshut-off, emergency lowering device <strong>and</strong>spooling device.

<strong>Product</strong> <strong>Features</strong> <strong>and</strong> <strong>Specifications</strong>FA5i-MR Infinity Series Winch - Capacity: 6,875 lbs (3 125 kg)PFS-FA5i-MR-09292010AIR INLET1-1/4” NPTOverall LengthDrum LengthMOTOREXHAUST2-1/2” NPT36.5[928]8.4 [213]LIMITSWITCHø 15.0[381] ø 27.0[686]ø 17.5[444]ø .81 [21]FA5i-MR16MK1GFA5i-MR24MK1Gwith disc <strong>and</strong> manual brakeBase Length.75 [19]1.9 [47]15.6 [397]31.26 [794]35.0 [889]Dimensions shown are inches.Dimensions in FA5i Brackets - MR-MK1G [ ] are mm.2.7 [68]Dimensions are subject to change.Contact factory for certified drawings.Dimensions: FA5i-MR <strong>and</strong> Bolt Down PatternDrum Length 16” [406 mm]Drum Length 24” [610 mm]Drum & Disc BrakesDrum & Disc Brakesin mm in mmOverall Length 51.6 1311 59.6 1514Base Length 28.34 720 36.34 923‘A’ 31.25 794 31.25 794‘B’ 9.0 229 10.5 267‘C’ 0.81 21 0.81 21Total # Holes 6 8Bolt Down PatternB B BCDRUMA‘C’ = Bolt Hole Inside DiameterMan Rider Lift Ratings at 8:1 Design Factor (Performance at 6.3 Bar - 90 PSI at air inlet when winch is operating)Top LayerFirst LayerRated Speed at Average Air Sound Inlet Exhaust NetCapacity Speed Rated Capacity Stall Pull Consumption (1) Level (2) Size Size WeightModel # hp lbs kg ft/min m/min ft/min m/min lbs kg f 3 /min m 3 /min db(A) NPT NPT lbs kgFA5i-MR24MK1G 25 6,870 3123 75 23 61 19 23,594 10725 700 20 97 1-1/4” 2-1/2” 2,000 907Utility Lift Ratings at 5:1 Design Factor (Performance at 6.3 Bar - 90 PSI at air inlet when winch is operating)FA5i-MR24MK1G 25 11,000 5000 54 16 51 16 23,594 10725 700 20 97 1-1/4” 2-1/2” 1,872 849(1) Average Air Consumption is at rated load <strong>and</strong> speed at top layer (2) With optional mufflerDrum Wire Rope Storage Capacity - Imperial - Man RiderRated Rope Min Req Breakcapacity Diameter Strength* Accumulated rope capacity in feet / number of layersSeries lbs in lbs 1 2 3 4 5 6 7 8 9 10 11 12 13 14FA5i-MR16 6,870 3/4 54,960 84 175 274 381 495 617 746 883FA5i-MR24 6,870 3/4 54,960 128 267 418 581 755 940 1,138 1,346Drum Wire Rope Storage Capacity - Metric - Man RiderRated Ropecapacity DiameterMin Req BreakStrength* Accumulated rope capacity in meters / number of layersSeries kg mm kg 1 2 3 4 5 6 7 8 9 10 11 12 13 14FA5i-MR16 3123 19 24929 26 53 84 116 151 188 227 269FA5i-MR24 3123 19 24929 39 81 127 177 230 287 347 410* Note: The Minimum Required Breaking Strength for the wire rope needs to be the Rated Capacity multiplied by the Design Factor.Example: for the FA5i-MR16 (with a 8:1 Design Factor) 6,870 x 8 = 54,960 lbs.

Force 5“Offshore” Man RiderSeries3180 to 6870 lb (1445 to 3117 kg) capacityKnown worldwide as the st<strong>and</strong>ard for meeting thetoughest personnel lifting requirements in theoffshore industry.Dual rated for personnel <strong>and</strong> utility lifting applications, these wincheshave Type Approval or Independent Review certificates issued by theclassification societies of ABS, DNV or LRS. Meet NPD, NMD <strong>and</strong> UKHSE regulations for personnel lifting operations. Oil field tough toweather the harsh environments in marine applications.Definitions■ Third party: An independent certifying agency that offersformalized review <strong>and</strong> approval programs for Man Rider winchesaccepted for suitability to lift personnel. Recognized third partyagencies are:• American Bureau of Shipping (ABS)• Det Norske Veritas (DNV)• Lloyd’s Register of Shipping (LRS)■ Type Approval: A comprehensive design review by anindependent third party which examines the intended service <strong>and</strong>application, winch ratings, design calculations of load bearingcomponents, product specifications <strong>and</strong> service restrictions orlimitations. A plant survey is also conducted to verify that qualitycontrol procedures <strong>and</strong> features are adequate <strong>and</strong> consistent. Uponsuccessful completion, a Type Approval certificate is issued.■ Third Party Certification: A review process of quality by anindependent third party requested by the customer. Includes:1. Type Approval certificate (design)2. Third party survey during manufacturing (quality)3. Third party witness of performance testing (quality)4. Issuance of certificates as required by regulatory agencyacknowledging compliance.■ St<strong>and</strong>ard features:• Enclosed automatic oil bath “wet” disc brake is fully sealed againstsalt spray, dirt or moisture <strong>and</strong> provides trouble-free operation overthous<strong>and</strong>s of lifting cycles.• Manual drum mounted b<strong>and</strong> brake for additional braking by operator• Internal gearbox / disc brake combination for superior load control• Corrosion resistant drum guard supports the weight of a 200 lb/91 kg person.FA150KGMR• Dual rated 8:1 design factor for manrider rating; 5:1 design factorfor utility rating• Compact, frame <strong>and</strong> fabricated alloy steel drum fit into tight spaces• St<strong>and</strong>ard operating temperature range is 0°C through 60°C; optionaldesign temperature of -10°C or -20°C• Minimum 18:1 drum diameter to wire rope diameter ratio reduceswire rope wear.• Data book <strong>and</strong> “Type Approval” certificates available upon request.• Marine 812 paint system on FA150KGMR models.■ Options <strong>and</strong> accessories:• Automatic b<strong>and</strong> brakes• Variable drum lengths• Grooved drums• Drum divider flange• Upper <strong>and</strong> lower limit switches• Corrosion resistant marine grade coating system: s<strong>and</strong>blast towhite metal finish <strong>and</strong> carbozinc primer with a Marine 812 finish• Remote controls• Air prep package: filter, lubricator, strainer, liquidator <strong>and</strong> regulator• Muffler• Hydraulic models• Electric-Over-Air remote control pendent for unlimited pendentlength• Third party certifications for low temperature applications<strong>Specifications</strong>: performance is based on 90 psi (6.3 bar) air inlet pressure with motor runningModel no. Force 5 MR ratings at top layer Personnel rating Maximum Average air Pipe Hose ShippingPersonnel (1) Utility (2) avg line speed stall pull consumption inlet size size weightlbs kg lbs kg fpm m/min lbs kg scfm m 3 /min in. mm in. mm lbs kgFA2MR24MK1G 3180 1445 4400 2000 75 23 9000 4090 335 9.5 1 1 ⁄4 32 1 1 ⁄4 32 906 411FA2.5MR24MK1G 3180 1445 5000 2273 159 48 10000 4545 700 19.9 1 1 ⁄4 32 1 1 ⁄ 2 38 1178 534FA5MR24MK1G 6870 3123 11000 5000 69 21 24000 10909 700 19.9 1 1 ⁄4 32 1 1 ⁄ 2 38 2020 916Force 5 Third Generation Man Rider Series ratings at mid layer (4)FA2BMR-MK1G 2500 1136 4000 1818 168 51 6800 3084 380 10.8 1 1 ⁄4 32 1 1 ⁄ 2 38 786 357FA2.5AMR-MK1G 3125 1420 5000 2273 173 53 10400 4727 560 15.9 1 1 ⁄4 32 1 1 ⁄ 2 38 905 411FA5AMR-MK1G 6250 2841 10000 4545 102 31 17000 7727 600 17.0 1 1 ⁄4 32 1 1 ⁄ 2 38 1842 837(1) “-E” models for European Union allow one lift capacity rating only; i.e., only personnel lift rating is allowed for both personnel <strong>and</strong> utility applications.(2) Utility rating only for those countries that allow dual ratings, e.g. USA.(3) Per NPD regulations(4) Third Generation Man Riders are not available in CE format.37

Force 5“Offshore” Man RiderSeries3180 to 6870 lb (1445 to 3117 kg) capacityRope storage for personnel lifting (1)Model Rope diameter Model Rope diameternumber Drum length 10mm 1 ⁄2" 13mm 3 ⁄4" 19mm number Drum length 10mm 1 ⁄2" 13mm 3 ⁄4" 19mmin. mm ft m ft m ft m in. mm ft m ft m ft mFA5MR8 203 – – – – 235 7212 305 – – – – 365 11116 406 – – – – 495 15124 610 – – – – 755 2308 203 – – 321 97 – – FA2BMRS 7 178 – – 198 60 – –FA2MR12 305 – – 492 150 – – <strong>and</strong>M 13.5 343 – – 396 120 – –<strong>and</strong>16 406 – – 663 202 – – FA2.5AMRL 20 508 – – 595 181 – –FA2.5MR24 610 – – 1006 306 – – R 24 610 – – 717 218 – –(1) Based on UK HSE st<strong>and</strong>ards requiring top layer to be 2 1 ⁄2 times the wire ropeFA5AMRS 12 305 – – – – 321 98diameter below drum flange.L 24 610 – – – – 663 202Rope speed at mid drum at 90 psiWinch series at 330 lbs (150 kg) at personnel rating at utility ratingUp Down Up Down Up Downfpm m/min fpm m/min fpm m/min fpm m/min fpm m/min fpm m/minΦFA2MR 121 37 60 18 72 22 125 38 53 16 140 43FA2.5MR 235 71 125 38 160 49 155 47 113 34 190 58FA5MR 94 29 60 18 69 21 55 17 54 16 70 21FA2BMR 253 77 – – 160 49 – – 102 31 – –FA2.5AMR 257 78 – – 173 53 – – 117 36 – –FA5AMR 177 54 – – 102 31 – – 50 15 – –38

Force 5“Offshore” Man RiderSeries3180 to 6870 lb (1445 to 3117 kg) capacityDimensionsFA2MR24MK1G with disc <strong>and</strong> manual brake in inches (mm)Inlet 1 1 ⁄4 NPT24 (610)4.13 (105)Cabletake offCable anchor14.69(297)28.63 (727)22.75 (578)ValveExhaust1 1 ⁄4 NPTMotorExhaust1 1 ⁄4 NPTø11 ⁄16(17.5) 8 pl.ø 10 3 ⁄4(273)ø 19(483)23.50 (597)8.13 (206)14 (356)20.31 (516).50 (12.7)1.63 (41)10 (254) 10 (254) 10 (254)33.25 (845)48.50 (1232)50.88 (1292) with disc brake13.13 (333)1.63 (41)10 (254)2 (51) 20 (508) 2 (51)24 (610)FA2.5MR24MK1G with disc <strong>and</strong> manual brake in inches (mm)32.79 (833)ValveExhaust1 1 ⁄2 NPT27.38 (695)MotorExhaust2 1 ⁄2 NPTAir inlet 1 1 /4 NPTø11 /16 ( ø 17.5)8 places2.31 (59)52.19 (1326)24 (610)12.69(322)10 (254) 10 (254) 10 (254)34.38 (873)56.25 (1429) w/disc brake4.13 (105)ø 10.75( ø 273).5(13)ø 19 ( ø 483)2.06 (52)Cabletake off23.5 (597)8.13(206)14 (356)2(51)Cableanchor10 (254)20 (508)24 (610)14.69 (297)20.31 (516)2(51)FA5MR24MK1G with disc <strong>and</strong> manual brake in inches (mm)Valve Exhaust 1 1 /2 NPTAir inlet 1 1 /4 NPT24 (610)6 (152)Cable anchorCable take off19.19 (487)38.79 (985)33.38 (848)ø13/16 ( ø 21)8 placesø 15 (381)ø 27 ( ø 686)11.63(295)31 (787)17.5 (445)Top layer28.81 (732)MotorExhaust2 1 ⁄2 NPT13.5 (343).75 (19)15.63 (397)1.8831.25 (794) 1.8810.5 10.5 10.53 (76) 3 (76) (48)35 (889)(48)(267) (267) (267)17.5 (445) w/disc37.5 (953)14.5 (368) w/o discDimensions are subject to change. Contact factory for certified prints59.06 (1500) w/disc; 56.06 (1424) w/o disc39

Force 5“Offshore” Man RiderSeries3180 to 6870 lb (1445 to 3117 kg) capacityDimensionsModel A B C Dno. in. mm in. mm in. mm in. mmFA2BMR-SMK1G 7.0 178 37.4 950 12.3 312 7.5 191FA2BMR-MMK1G 13.5 343 43.9 1115 18.8 478 10.81 274FA2BMR-LMK1G 20.0 508 50.4 1280 25.3 643 14.0 356FA2BMR-RMK1G 24.0 610 54.4 1382 29.3 744 16.0 406FA2BMR in inches (mm)15.94 (405)Cabletake-offFA2B27.59(701)3.87 (98)DimensionsModel A B C Dno. in. mm in. mm in. mm in. mmFA2.5AMR-SMK1G 7.0 178 41.19 1046 12.31 313 7.50 191FA2.5AMR-MMK1G 13.5 343 47.69 1211 18.81 478 10.81 274FA2.5AMR-LMK1G 20.0 508 54.19 1376 25.31 643 14.00 356FA2.5AMR-RMK1G 24.0 610 58.19 1478 29.31 744 16.00 406FA5AMR-SMK1G 12.0 305 46.50 1181 17.89 454 10.50 266FA5AMR-LMK1G 24.0 610 58.13 1486 29.89 759 16.50 419AAir inlet1-1/4" NPTValve exhaust1-1/2" NPT17.54(445)HU40A23.0(584)17.00(432)9.25(235)10.50(267)16.88(423)7.50(191)15.00 (381)22.11 (562)0.63 (16)4 x 0.81 (21)w/disc brake7.27 (185)w/o disc brake3.73 (95)BCDMotor exhaust1" NPTFA2.5AMR in inches (mm)22.11 (562)Cabletake-off17.54(445)Gearboxoil fill29.30(744)ø17.00(ø432)Aø9.25(ø235)3.87 (98)Motoroil drain1Air inlet (1 ⁄4" NPT)1Valve exhaust (1 ⁄2" NPT)9.25(235)10.50(267)23.88(607)Gearboxoil level7.50(190.5)15.00 (381)4 X ø.81(ø21)Gearbox oil drain7.27(185)CDBMotor oil levelMotor oil drain.63(16)Motor exhaust (21⁄2" NPT)FA5AMR in inches (mm)Cabletake-off28.04 (712)Dimensions are subject to change. Contact factory for certified printsCable anchorpocket withwedgeDrum length A5.75 (146)Motoroil fill3.79 (96)Air inlet1 1 ⁄4" NPTValve exhaust11 ⁄2" NPT4024.81(630)12.56(319)Gearbox/disc oillevelGearboxoil drain22.00 (559)Disc brakeoil drainGearboxoil fill81 (21)mounting2 per side(4 total)7.14(181)12.75(324)CDBMotor oil drainMotor oil levelfarsideMotorexhaust12 ⁄2" NPT21.81(554)25.94(659)31.35(796)

Force 5“Offshore” Man RiderSeries3180 to 6870 lb (1445 to 3117 kg) capacityHow To Order:Specify complete model code as shown. To order options, use the option code in the option table <strong>and</strong> add as a suffix to the model code. To order a Force Five airwinch with a non-st<strong>and</strong>ard drum length, refer to the available drum lengths provided in the drum length table below. Enter the desired drum length for each winch inthe drum length section of the model code. To order accessories such as filters <strong>and</strong> lubricators, enter these as separate accessory items by the part number in theair winch accessories table. Example: FA2.5MR24MK1GPSeriesFA1(σ2BPersonnel cap.2.5= 2500 lbs (1136 kg)2.5A = 3125 lbs (1420 kg)2 = 3180 lbs (1445 kg)2.5 = 3180 lbs (1445 kg)5A = 6250 lbs (2841 kg)5 = 6870 lbs (3111 kg)Force FiveFA = Air poweredFH = Hydraulic poweredMan Rider cap.MRMR = ManRiderDrum length2424 = 24" (610 mm)between flanges.See drum lengthcharts below.Notes:All Force 5 units come with st<strong>and</strong>ard six (6) str<strong>and</strong> wire rope anchor <strong>and</strong>winding directions for right h<strong>and</strong> overwind.Option Notes:(1) With remote pilot control option, line speeds will decrease.(2) Number designates drum grooving. Number equals wire rope size insixteenths. The st<strong>and</strong>ard will be based on a right h<strong>and</strong> overwind rotation <strong>and</strong>spiral grooving for the recommended size of wire rope for the st<strong>and</strong>ard lengthof drum only. Grooving involving longer or shorter drums, or drums equippedwith a divider flange will be an engineered item with longer lead time.(3) D = drum divider flange. The st<strong>and</strong>ard will be based on right h<strong>and</strong> over windrotation. Two steel flanges are welded to the center of the drum. This providesthe motor side of the drum (half) with a rope anchor. Anchor locations mustbe specified by the customer.(4) Documentation, witness testing <strong>and</strong> material traceability available; must berequested at time of order. Specify options or contact factory or your nearestIR distributor for information.Drum brakeDisc brakeKK = Auto disc (std)A = Auto drum brakeM = Manual drum brake (std)1 = St<strong>and</strong>ard winch mounted throttle2XX = Remote full flow lever throttle (max 20 ft/6 m)3XX = Remote pilot pendent throttle (std = 6 ft/1.8 m;max 66 ft/20 m) (1)4XX = Remote pilot lever throttle (std = 6 ft/1.8 m;max 66 ft/20 m) (1)5XX = Remote electric over air throttleXX = Specify hose length or pendent cord in feetM1 Material traceability certificates according to EN 10204 (Ex DIN 50049) 2.2 on load bearing parts. This conformitydocument affirms (by the manufacturer) that parts are in compliance with the requirements of the order based on nonspecificinspection <strong>and</strong> testing (i.e. results are typical material properties for these parts.)M2 Material traceability certificates according to EN 10204 (Ex DIN 50049) 3.1b on load bearing parts. These documentsaffirm (by a department independent of the manufacturing department) that the actual parts used in the product are incompliance with the order based on specific inspection <strong>and</strong> testing (i.e. results are actual material properties for thoseparts.)M3 Material traceability certificates according to EN 10204 (Ex DIN 50049) 3.1b on load bearing parts. These documentsaffirm (by a department independent of the manufacturing department) that the actual parts used in the product are incompliance with the order based on specific inspection <strong>and</strong> testing (i.e. results are actual material properties for thoseparts in a finished, as delivered condition.)(5) Not available on Third Generation SeriesMDrum lengthsFA2B & FA2.5A in. mmFA5AS 7 178M 13 1 ⁄2 343L 20 508R 24 610S 12 305L 24 610Control brake1Options (see notes below)GP7 = Drum grooving (specify rope size insixteenths, e.g. 7 = 7 ⁄16") (2)C = Low temperature; please specify intext: -10˚ C or -20˚ CD = Drum divider flange <strong>and</strong> additionalcable anchor (3)G = Drum guardL = Drum locking pin (5)M1 = Per DIN 50049/En10204 Para 2.2“Typicals” (4)M2 = Per DIN 50049/En10204 Para 3.1bactual per product as purchased (4)M3 = Per DIN 50049/En10204 Para 3.1bactual per product as delivered infinal condition (4)N = Type approval; please specify intext: DNV, ABS or LloydsP = Corrosion resistant marine gradecoating system: s<strong>and</strong>blast to whitemetal finish <strong>and</strong> carbozinc primerwith a Marine 812 finishQ = Special paint; please specifyS = Limit switch (upper <strong>and</strong> lower) (5)U = Underwound (available only withautodisc brake XK)V = Press rollerW = Witness; please specifyX = Special testing; please specifyZ = S<strong>and</strong>blast <strong>and</strong> carbozinc primeronly-E = Compliance with EuropeanMachinery Directive (insert atend of model code) (5)Drum lengths available in. (mm)Model 8 12 16 24 30 36(203) (305) (406) (610) (762) (914)ΦFA2 yes yes yes Std yes* yes*FA2.5 yes yes yes Std yes yesFA5 no yes yes Std yes yesContact factory for lengths other than shown.* Special orderSpecial optional requirements for offshore complianceare available (see codes above where applicable):• Material traceability• Charpy testing• Certificate of compliance• Third party witness• Customer witness• Special documentation• Regulatory agency certification• Low temperature materialsMan Rider winches have been designed <strong>and</strong> built tomeet the requirements of the Offshore Oil Industry,particularly those specifications of the NorwegianMaritime Directorate, the Norwegian PetroleumDirectorate <strong>and</strong> the UK HSE. They are Type Approvedby Lloyds Register of Shipping, Det Norske Veritas(DNV) <strong>and</strong> the American Bureau of Shipping (ABS).There is no st<strong>and</strong>ard covering the use of these ManRiders in other than the offshore environment. It is,therefore, the user’s responsibility to determine thesuitability of this product for any particular use <strong>and</strong> tocheck for compliance with applicable regulations.41

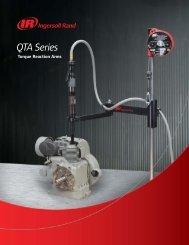

Liftstar TM Pneumatic ManRider Winch150 kg (330 lbs) CapacityModel: LS2-150RLP-L-EThe LS2-150RLP-L-E pneumaticManRiding winch is specially designedfor safe <strong>and</strong> reliable personnel liftingoperations by means of a safety harnesson offshore rigs <strong>and</strong> platforms in aheavy duty <strong>and</strong> critical offshore workingenvironment.It is designed to meet the latest NPD <strong>and</strong>European Machinery Directives <strong>and</strong> istype approved by DNV.It is delivered with the CE mark <strong>and</strong> an ECdeclaration of conformity.St<strong>and</strong>ard <strong>Features</strong>:• Compact modular construction : Save space on the drill floors — Easy inspection <strong>and</strong> maintenance.• Design factor 10:1 on main load bearing parts.• Gear type air motor : Simple rotary motor with two moving parts ony (rotors) — Rotors made from composite material — Ability toaccept contaminated air — High starting torque — Good spotting capability.• High efficiency planetary gear box : Totally enclosed within the drum for better space saving — Planetary type for betterefficiency.• Internal automatic multi-disc brake : Fully enclosed for better protection <strong>and</strong> better corrosion resistance.• External automatic b<strong>and</strong> brake (directly acting onto the drum for total safety) : Activated by fail safeautomatic brake cylinder (spring applied) — The b<strong>and</strong> brake is manufactured from stainless steel for superior corrosion protection.Note: In case of power failure, both the b<strong>and</strong> brake <strong>and</strong> the disc brake will automatically apply.• Overload protection device : Automatically stops the winch from lifting in case of overload exceeding 130% SWL,both brakes are applied automatically.• Main power emergency stop device : Allows the operator to quickly <strong>and</strong> safely stop the winch in caseof an emergency situation.• Slack wire detector : Automatically stops the winch from paying out in case of slack wire — Designedfor vertical rope entry — Composite rollers <strong>and</strong> stainless steel guides offer maximum protectionagainst wear <strong>and</strong> corrosion — “Window” type design to avoid wire rope from getting out of the roller.• Top <strong>and</strong> Bottom limit switches : Automatically stops the winch when the travelexceeds the pre-determined working distance — Simple adjustment method requiresonly a screwdriver.Continued on back pageEx

St<strong>and</strong>ard <strong>Features</strong> (continued)• Assisting spooling device : Presses the wire rope onto the drum toimprove winding, specially at no load condition — Composite rollers ongalvanized steel guides for maximum wear <strong>and</strong> corrosion resistance.• Total drum guarding system : Operator is fully protected frommoving parts — Rigged stainless steel construction — Meets stringentEuropean st<strong>and</strong>ard EN953 for machine guarding.• Helical grooved drum : Ensure better rope spooling than plaindrum — Allows greater fleet angle up to 2° — Specially designed for10 mm wire rope — St<strong>and</strong>ard under wound configuration.• Wedge style cable anchor : Simplifies wire rope change-out<strong>and</strong> installation.• Local lever throttle control : Precise spotting control withinfinitely variable speed — "Press <strong>and</strong> shift" throttle lever preventsaccidental throttle movements — Throttle h<strong>and</strong>le is located on the right h<strong>and</strong>side of the winch (operator st<strong>and</strong>ing behind the winch).• Pre-equipped Emergency lifting <strong>and</strong> lowering device :Allows both lifting <strong>and</strong> lowering of the ManRider in case of main powerfailure — Includes a 3 way / 2 position valve with a secondary air inlet( 3 /4 inch BSP) which must be connected on site to a nitrogen bottle.Note : Pressurised nitrogen bottle is not supplied.• Lifting lugs : Easily accessible lifting points — Accommodate slings or hooks.• Filter, regulator & lubricator : FRL package mounted directly on the operator side of the winch.• Marine paint for corrosion protection.• Design temperature TD = -20°C.• Suitable for Zone 1 <strong>and</strong> 2 as per ATEX directive 94/9/EC.• FEM Classification 4m.Option:• Pilot pendent control version available on request.• 3rd party certification by DNV.• Offshore paint with s<strong>and</strong>blasting.<strong>Specifications</strong> at 90 psi (6.2 bar)Rated capacityLifting speed (at rated load)Free air consumptionWorking pressure rangeRecommended rope diameterWorking rope capacityStorage rope capacityOverall dimensions (L x W x H)Estimated weight (without wire rope)150 kg0 to 30 m/min.0 to 2.2 m 3 /min.5 to 7 bar10 mm54 m on 2 layers154 m on 5 layers779 x 697 x 585 mm210 kg aboutSafety is ourNo.1 PriorityEurope - Middle East & Africa<strong>Ingersoll</strong>-R<strong>and</strong> Equipements de <strong>Product</strong>ion S.A.<strong>Product</strong>ivity Solutions529 Avenue R. Salengro59450 Sin le NobleFranceTel: +33 (0)3 27 93 08 08Fax: +33 (0)3 27 93 08 19E-mail: dou_irep@eu.irco.comUSA & Canada<strong>Ingersoll</strong>-R<strong>and</strong><strong>Product</strong>ivity Solutions2724 Sixth Avenue SouthSeattle, WA 98134USATel: (206) 624-0466Fax: (206) 624-6265E-mail: Winch<strong>and</strong>HoistSolutions@irco.comwww.Winch<strong>and</strong>HoistSolutions.com© 2006 <strong>Ingersoll</strong>-R<strong>and</strong> Company.Form No. E42005

BP 5959450 SIN LE NOBLEFRANCETEL: +33 (0)3 27 93 08 08FAX: +33 (0)3 27 93 08 00Copyright © 2003All Rights Reserved805 maxi585295Lifting lugO35F.R.L blockUPDOWN= 560 =4 holes O 18Winch mounting384LS2-150RLP-L-EAIR POWEREDMAN-RIDING WINCH313Ropeentry28°Slack wiredetectorAir inletO3/4"BSPLimitswitches3 waysvalveEmergencyinletO3/4"BSPPress rollerLifting lugO35779420 183300 86INTERNAL IR REFERENCE76470001DOCUMENT NUMBER0 5 / 0 4 / 0 4 D 1/1Faillon JLENGINEERING MANAGERO 342O 450<strong>Specifications</strong> :- Rated working load : 150 kg- Lifting speed (with rated load) : 0 to 30 m/min at6.3bar/90PSI- Free air consumption : 0 to 2.5 Nm3/min- Working pressure range : 5 to 7 bar- Recommended rope diameter : 10 mm- Weight without rope : about 210 kg- Working rope capacity : 54 m on 2 layers- Total rope storage capacity : 154 m on 5 layersSt<strong>and</strong>ard <strong>Features</strong> / Equipment :- Two independent auto brakes: an internal multidiscbrake <strong>and</strong> external drum b<strong>and</strong> brake.- Throttle lever returns to off position <strong>and</strong> locks whenreleased- High efficiency planetary gearing is inside drum forbetter protection <strong>and</strong> minimum overall dimensions- Overload protection device (torque limiter)- Main air emergency stop- Pre-equipped emergency lifting or lowering device(pressurised nitrogen bottle not supplied)- Slack wire detector- Upper & lower limit switches (accuracy : ± 10 cm)- Assisting spooling device – for better rope windingat no load- Drum guard- Grooved drum (for wire rope ∅ 10 mm)- Filter – Regulator – Lubricator- S<strong>and</strong>blasting <strong>and</strong> offshore paint 290 µ- Installation <strong>and</strong> operation manual- DNV type approved <strong>and</strong> CE certification- Design temperature TD = -20° COn Request :(Dwg.D6470639)- 3.1b material traceability certificates according toDIN 50049 (EN 10204) for load bearing parts- Witness test by Third Party (DNV, Lloyd’s, ABS,etc)The equipment described on this sheet is subject to the general sales <strong>and</strong> warranty conditions of INGERSOLL-RAND company. Because of the constantevolution of technology INGERSOLL-RAND company reserves the right to modify without notice the specifications contained in this document.