Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

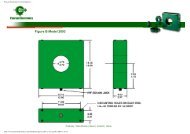

Monolithic Assemblies with λ/20 TWDApplicationsWe routinely produce optically bonded assemblies withless than 0.05 waves of transmitted wavefront distortion(TWD) peak-to-valley. λ/10 wavefronts are fairly commonon single optical components, but when you buildmulti-element optic assemblies, these distortions cancompound, resulting in much higher levels of distortion.With our nanometer-level tolerances, IBS coatings, andunique zero-bond-length adhesive-free CADB ® bondingprocess, our monolithic optical assemblies consistentlyexceed even the most stringent specificationsincluding λ/20 peak-to-valley TWD, beam deviation < 30arcseconds and optical path lengths matched to betterthan 10 microns.YAG chip laser with cladding on all sidesBuilt in collaboration with the Engineering Research Center for Extreme Ultraviolet(EUV) Science and Technology and Colorado State University.This high-power yttrium aluminum garnet (YAG or Y 3 Al 5 O 12 ) chip laseris a completely epoxy-free assembly comprised of several doped YAGand sapphire components. Manufactured using our patent-pendingCADB ® bonding process and advanced polishing techniques, thispart required several iterative processing steps, thus highlighting theimportance of robust, durable bonds and meticulous cleaning andhandling techniques. From the raw material specifications through thefinal metrology, we worked together with the customer to meet theirbudgetary requirements and performance expectations for the final,coated assembly.Superpolished Sapphire to < 1Å RMSOnce our customers found out that we can polish andmeasure fused silica surfaces to < 1 angstrom in RMSsurface roughness, they immediately asked us if wecould do the same thing on sapphire. Within just a fewweeks we were able to refine our polishing and cleaningprocesses to achieve similar surface quality on not justsapphire (shown here), but Ti:sapphire and TGG crystalas well.Super-polished or laser quality polished substrates andassemblies are ideal for use as low-loss laser mirrors,high energy waveguides and in cavity ring-down spectroscopy(CRDS) where thermal stability, surface scatterand high laser damage thresholds are key requirements.precisionphotonics.com19