- Page 1 and 2: Amirkabir Univ. Tech., IranApplicat

- Page 3 and 4: PAM/COPPE/UFRJSynthesis and Charact

- Page 7 and 8: UFSCUFSCUFSCUFSCUFSCUFSCarUFSCarUFS

- Page 9: Maximizing Hydrocarbon Liquids Reco

- Page 14 and 15: Synthesis and Gas permeation proper

- Page 17: Synthesis and characterization of F

- Page 20 and 21: [1] M. R. Kosseva (2009), Processin

- Page 22 and 23: Electrodialysis as desalting or pur

- Page 24 and 25: average permeate BOD 5 and NH 3 con

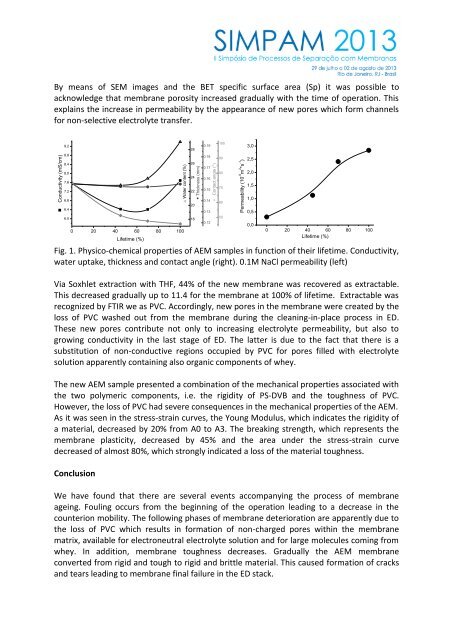

- Page 28 and 29: References[1] R. Ghalloussi, W. Gar

- Page 30 and 31: Development of Sulfonated Polysulfo

- Page 32 and 33: Selectivity of Nanofiltration Membr

- Page 34 and 35: Clarification of RED Beetroot Juice

- Page 36 and 37: Definition Of The Limiting Flux Con

- Page 38 and 39: Evaluation Of Reverse Osmosis And N

- Page 40: New Polyamide Membranes from PAMAM

- Page 43 and 44: The output variables in this study

- Page 45 and 46: In-module chemical modification and

- Page 48 and 49: Catalytic Microfiltration Membranes

- Page 50 and 51: Table 1 shows the results of permea

- Page 52 and 53: Newly Developed Composite Hollow Fi

- Page 54: Antimicrobial polyvinyl alcohol fil

- Page 59 and 60: Polycaprolactone membranes by phase

- Page 61 and 62: [5] A. P. Harvey, M. R. Mackley, an

- Page 63 and 64: Use of Membrane Contactor to Improv

- Page 65 and 66: Recovery and concentration of efflu

- Page 67 and 68: Synthesis and Characterization of M

- Page 69 and 70: Superficial Characterization and Lo

- Page 71 and 72: Membrane Adsorber Process for Decon

- Page 74 and 75: Study of PVC Membranes Prepared Via

- Page 76 and 77:

Polyvinyl Alcohol / Activated Carbo

- Page 78 and 79:

Facilitated Transport of Polypropyl

- Page 80 and 81:

Preparation of Chlorine-Resistant N

- Page 82 and 83:

Direct Osmosis Process for Power Ge

- Page 84 and 85:

Bio-Lubricant Production by Pervapo

- Page 86 and 87:

Application of Ceramic Membranes fo

- Page 89 and 90:

Polyurethane Membranes to Remove Su

- Page 91 and 92:

Mixed Matrix Membranes for Gas Sepa

- Page 93 and 94:

Oily Wastewater Treatment by Membra

- Page 95 and 96:

Concentration of Copper (ppm)Percen

- Page 97 and 98:

sections of membranes were observed

- Page 100 and 101:

CO 2 Separation from Natural Gas wi

- Page 102 and 103:

CO 2 Removal Systems with Membranes

- Page 104 and 105:

[6] V. Alekseev (2010), Mar. Poll.

- Page 107 and 108:

Submitted to SIMPAM 2013www.peq.cop

- Page 109 and 110:

Characterization of the Pore Size o

- Page 111 and 112:

Volume Fraction (φ)Volume Fraction

- Page 113 and 114:

Flux (kg/m 2 .hr) Flux (kg/m 2 .hr)

- Page 115 and 116:

Characterization of ionic liquid an

- Page 117 and 118:

Permeability [Barrer]7x10 46x10 45x

- Page 119 and 120:

Characteristic and Applications of

- Page 121 and 122:

Remoção de Cor (%)Remoção de Tu

- Page 123:

Removal of Trihalometanes Precursor

- Page 127 and 128:

eutilization for domestic purposes.

- Page 129 and 130:

Comparative Analysis of electrodial

- Page 132 and 133:

Intensidade (u.a.)Preparation and c

- Page 134 and 135:

THE PERFORMANCE OF A SYSTEM OF WATE

- Page 137 and 138:

Evaluating the Quality of treated w

- Page 139 and 140:

To determine the permeate flux used

- Page 141 and 142:

ConclusionsAt the present time, bas

- Page 143 and 144:

Analysis of Polymer Membranes Obtai

- Page 145:

Performance and selectivity of LLDP

- Page 148 and 149:

IntensityIntensityFigure 1. Effect

- Page 150 and 151:

Sol-gel Processing of Titania Membr

- Page 152 and 153:

All curves presented linear shape a

- Page 154 and 155:

Figure 2 - Box-Plot - Coefficient o

- Page 156 and 157:

Toxicity removal on leachate treatm

- Page 158 and 159:

Poly(vinyl alcohol) and Chitosan Bl

- Page 160 and 161:

Pressure / TorrPressure / TorrThis

- Page 162 and 163:

Vinasse Treatment by Anaerobic Memb

- Page 164 and 165:

Preparation and characterization of

- Page 166 and 167:

Microfiltration for Indigo Blue Dye

- Page 168 and 169:

PLGA Nanoparticles Containing Dexam

- Page 170 and 171:

As can be seen in Table 1, the syst

- Page 172 and 173:

231Figure 2 - Photograph of the pil

- Page 174 and 175:

AcknowledgementsThe authors acknowl

- Page 176 and 177:

Table 2 - NF feed and permeate qual

- Page 178 and 179:

COD Feed (mg/L)COD Feed (mg/L)COD P

- Page 180 and 181:

[4] RESOLUTION Nº 430, OF MAY 13,

- Page 182 and 183:

Synthesis and characterization of m

- Page 184 and 185:

Ultrafiltration/Nanofiltration for

- Page 186 and 187:

Preparation of Electrodialysis Memb

- Page 188 and 189:

[4] E. Sgreccia; M.L. Di Vona; P. K

- Page 190 and 191:

Table 1. Evaluation of solutions ob

- Page 192 and 193:

Concentration of ovine cheese whey

- Page 194 and 195:

[11] A. Chollangi; M. Hossain (2007

- Page 196 and 197:

Biofilm Formation on Laboratory Nan

- Page 198 and 199:

Removal of nitrate in aqueous efflu

- Page 200 and 201:

(aFigura 2. Difratograma das alumin

- Page 202 and 203:

AcknowledgementsReferencesWe gratef

- Page 204:

[1] COTE, P.; BUISSON, H.; PRADERIE

- Page 207 and 208:

[1] Larminie, J., Dicks, A. Fuel ce

- Page 209 and 210:

Magnetic Field Influence on Cleanin

- Page 211 and 212:

Influence Of Pretreatment On The Pe

- Page 213 and 214:

[3] Shukla, R., Cheryan, M. (2002)

- Page 215 and 216:

Separation of Mixtures of Soybean O

- Page 217 and 218:

Effect of Dense CO 2 on Polymeric C

- Page 219 and 220:

Whey VRF1,5 VRF2 VRF 2,5 VRF 3 VRF

- Page 221 and 222:

A Study of the Resistances During P

- Page 223 and 224:

Characterization of Cellulose Aceta

- Page 225 and 226:

Characterization of Cellulose Aceta

- Page 227 and 228:

Monitoring the Shelf Life of Microf

- Page 229 and 230:

Clarification of Artichoke By-produ

- Page 231 and 232:

WATER TREATMENT TO HEALTH CLINICSAn

- Page 233 and 234:

PAPER TITLE: ULTRAFILTRATION AS PRE

- Page 235 and 236:

Continuous Production of Biodiesel

- Page 237 and 238:

Performance of Liquid Membranes in

- Page 239 and 240:

Performance of Batch Pervaporation

- Page 241 and 242:

Demineralization of waste waters co

- Page 243 and 244:

Electrodialysis for food and enviro

- Page 245 and 246:

Optimizing Cobalt (II) Removal from

- Page 247 and 248:

The permeability of the material sh

- Page 249 and 250:

1D and 2D Approach for Modelling Ho

- Page 251 and 252:

Multi-stage Design for Carbon Captu

- Page 253 and 254:

Membrane Fouling Control using High

- Page 255:

AcknowledgmentsL.C. Tomé is gratef

- Page 258 and 259:

Treatment of Kraft Pulp Mill (EPO)

- Page 260 and 261:

Comparison of the Performance of Me

- Page 262 and 263:

These novel membranes are potential

- Page 264 and 265:

Polycarbonate Modified Membranes Wi

- Page 266 and 267:

Industrial Application of Membranes

- Page 268 and 269:

Production of Filtrating Membranes

- Page 270 and 271:

the high contact area provided by h

- Page 272 and 273:

of the retentate must be closely co

- Page 274 and 275:

Polymeric nanofiltration Membranes

- Page 276 and 277:

Diffusion of Monovalent Cations thr

- Page 278 and 279:

Effect of the UF-Membrane Cut-off o

- Page 280 and 281:

Saxitoxins Removal by NF270 e NF90

- Page 282:

Effect of Plasma Activation on Poly