Abstracts - peq / coppe / ufrj

Abstracts - peq / coppe / ufrj

Abstracts - peq / coppe / ufrj

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

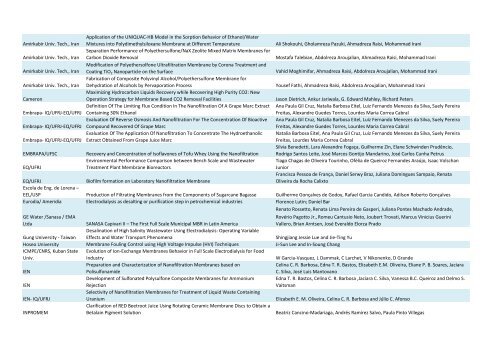

Amirkabir Univ. Tech., IranApplication of the UNIQUAC-HB Model in the Sorption Behavior of Ethanol/WaterMixtures into Polydimethylsiloxane Membrane at Different TemperatureAli Shokouhi, Gholamreza Pazuki, Ahmadreza Raisi, Mohammad IraniAmirkabir Univ. Tech., IranSeparation Performance of Polyethersulfone/NaX Zeolite Mixed Matrix Membranes forCarbon Dioxide RemovalMostafa Talebian, Abdolreza Aroujalian, Ahmadreza Raisi, Mohammad IraniAmirkabir Univ. Tech., IranModification of Polyethersolfone Ultrafiltration Membrane by Corona Treatment andCoating TiO 2 Nanoparticle on the SurfaceVahid Moghimifar, Ahmadreza Raisi, Abdolreza Aroujalian, Mohammad IraniAmirkabir Univ. Tech., IranFabrication of Composite Polyvinyl Alcohol/Polyethersulfone Membrane forDehydration of Alcohols by Pervaporation ProcessYousef Fathi, Ahmadreza Raisi, Abdolreza Aroujalian, Mohammad IraniCameronMaximizing Hydrocarbon Liquids Recovery while Recovering High Purity CO2: NewOperation Strategy for Membrane Based CO2 Removal FacilitiesJason Dietrich, Ankur Jariwala, G. Edward Mahley, Richard PetersEmbrapa- IQ/UFRJ-EQ/UFRJDefinition Of The Limiting Flux Condition In The Nanofiltration Of A Grape Marc ExtractContaining 30% EthanolAna Paula Gil Cruz, Natalia Barbosa Eitel, Luiz Fernando Menezes da Silva, Suely PereiraFreitas, Alexandre Guedes Torres, Lourdes Maria Correa CabralEmbrapa- IQ/UFRJ-EQ/UFRJEvaluation Of Reverse Osmosis And Nanofiltration For The Concentration Of BioactiveCompound Recovered Of Grape MarcAna Paula Gil Cruz, Natalia Barbosa Eitel, Luiz Fernando Menezes da Silva, Suely PereiraFreitas, Alexandre Guedes Torres, Lourdes Maria Correa CabralEmbrapa- IQ/UFRJ-EQ/UFRJEvaluation Of The Application Of Nanofiltration To Concentrate The HydroethanolicExtract Obtained From Grape Juice MarcNatalia Barbosa Eitel, Ana Paula Gil Cruz, Luiz Fernando Menezes da Silva, Suely PereiraFreitas, Lourdes Maria Correa CabralEMBRAPA/UFSCRecovery and Concentration of Isoflavones of Tofu Whey Using the NanofiltrationSilvia Benedetti, Lara Alexandre Fogaça, Guilherme Zin, Elane Schwinden Prudêncio,Rodrigo Santos Leite, José Marcos Gontijo Mandarino, José Carlos Cunha PetrusEQ/UFRJEnvironmental Performance Comparison between Bench Scale and WastewaterTreatment Plant Membrane BioreactorsTiago Chagas de Oliveira Tourinho, Ofélia de Queiroz Fernandes Araújo, Isaac VolschanJuniorEQ/UFRJBiofilm formation on Laboratory Nanofiltration MembraneFrancisca Pessoa de França, Daniel Serwy Braz, Juliana Domingues Sampaio, RenataOliveira da Rocha CalixtoEscola de Eng. de Lorena –EEL/USP Production of Filtrating Membranes from the Components of Sugarcane Bagasse Guilherme Gonçalves de Godoy, Rafael Garcia Candido, Adilson Roberto GonçalvesEurodia/ Ameridia Electrodialysis as desalting or purification step in petrochemical industries Florence Lutin; Daniel BarGE Water /Sanasa / EMALtdaSANASA Capivari II – The First Full Scale Municipal MBR in Latin AmericaRenato Rossetto, Renata Lima Pereira de Gasperi, Juliana Pontes Machado Andrade,Rovério Pagotto Jr., Romeu Cantusio Neto, Joubert Trovati, Marcus Vinicius GueriniVallero, Brian Arntsen, José Everaldo Elorza PradoGung University - TaiwanDesalination of High Salinity Wastewater Using Electrodialysis: Operating VariableEffects and Water Transport PhenomenaShingjiang Jessie Lue and Jie-Ting YuHoseo University Membrane Fouling Control using High Voltage Impulse (HVI) Techniques Ji-Sun Lee and In-Soung ChangICMPE/CNRS, Kuban StateUniv.Evolution of Ion-Exchange Membranes Behavior in Full Scale Electrodialysis for FoodIndustryW Garcia-Vasquez, L Dammak, C Larchet, V Nikonenko, D GrandeIENPreparation and Characterization of Nanofiltration Membranes based onPolisulfonamideCelina C. R. Barbosa, Edna T. R. Bastos, Elizabeth E.M. Oliveira, Eliane P. B. Soares, JaciaraC. Silva, José Luis MantovanoIENDevelopment of Sulfonated Polysulfone Composite Membranes for AmmoniumRejectionEdna T. R. Bastos, Celina C. R. Barbosa ,Jaciara C. Silva, Vanessa B.C. Queiroz and Delmo S.VaitsmanIEN- IQ/UFRJSelectivity of Nanofiltration Membranes for Treatment of Liquid Waste ContainingUraniumElizabeth E. M. Oliveira, Celina C. R. Barbosa and Júlio C. AfonsoINPROMEMClarification of RED Beetroot Juice Using Rotating Ceramic Membrane Discs to Obtain aBetalain Pigment SolutionBeatriz Cancino-Madariaga, Andrés Ramírez Salvo, Paula Pinto Villegas

Inst. Inf. Tech. /Faculty ofBios. Eng.Gas separation properties of Mixed Matrix Membranes comprising of Matrimid andFuntionalized Mesoporous MCM-41Asim Laeeq Khan, Chalida Klaysom, Amit Gahlaut, Ivo VankelecomInst. Inf. Tech. /Faculty ofBios. Eng.Synthesis and Gas permeation properties of Mixed Matrix Membranes comprised ofAcrylate derivitized PSf and Amine functionalized Mesorporous MCM-41 for CO 2separationAsim Laeeq Khan, Chalida Klaysom, Amit Gahlaut, Ivo VankelecomInst. Inf. Tech. /Faculty ofBioscience Eng.Synthesis and characterization of Fluorinated and Sulfonated Aromatic PEEKmembranes; Application in CO 2 separationAsim Laeeq Khan, Chalida Klaysom, Amit Gahlaut, Ivo VankelecomInst. Tecn.de Buenos Aires Simulating Pressure Retarded Osmosis Using UniSim Design Guillermina Gentile, Paula Llano, María Fidalgo de CortalezziINT/UFRJStudy of Parameters on Preparation of Composite Membranes Based on ActivatedCarbonKarla Patricia Macedo Licona, Marcello Pojucan Magaldi Santos, Amal Elzubair Eltom andJosé Carlos da RochaKoch Memb. / Águas doBrasil Drinking water: Single step Ultrafiltration treatment of high turbid River Water Kevin Phillips, Isadora Argentoni Nagaoka, Manny Singh, André Lermontov, Alberto CostaMintekIn-module chemical modification and assessment of polyethersulfone capillaryultrafiltration membranesK. Philemon Matabola, Banele Vatsha and Richard M. MoutloaliMintekCatalytic Microfiltration Membranes containing Fe/Ni Bimetallic Nanoparticles for theReductive Degradation of Azo Dyes and Organochlorines in WaterKeneiloe Sikhwivhilu, Richard M. MoutloaliPAM/COPPE/UFRJAdhesion between Layers of composite Membranes in a Hollow Fiber ShapeSynthesized by Simultaneous Extrusion for Reverse OsmosisFelipe Coelho Cunha, Frederico de Araujo Kronemberger e Cristiano Piacsek BorgesPAM/COPPE/UFRJ Membrane Adsorber Process for Decontamination of Injectable Solutions Almeida, K. M., Ferraz, H. C. e Almeida, M. MPAM/COPPE/UFRJMixed Matrix Membranes for Gas Separation: Morphological Characterization andTransport Properties for O2/N2Sandro Eugenio da Silva, Bruno da Silva Gonçalves Alves, Helen Conceição Ferraz, CristianoPiacsek BorgesPAM/COPPE/UFRJEvaluation of Solubility of Propylene and Propane gas in Facilitated TransportMembranes Containing Silver as Carrier AgentCarolina Guedes Fioravante Rezende, Cristiano Piacsek borgesBorges, Alberto ClaudioHabertPAM/COPPE/UFRJ Development membranes for osmotic power generation Jader Conceição da Silva, Cristiano Piacsek BorgesPAM/COPPE/UFRJDevelopment of Functionalized Poly(etherimide) Membrane for Application inHemodialysisAlana Melo dos Santos, Alberto Claudio Habert e Helen Conceição FerrazPAM/COPPE/UFRJ -Univ.Nova de LisboaSuperficial Characterization and Long-term Test of Reverse Osmosis Membranes Coatedwith PVA and Natural BiocidesJuliana A. Guimarães, Claudia Galinha, Helen C. Ferraz, Cristiano P. Borges, João Paulo S. G.CrespoPAM/COPPE/UFRJ Bio-Lubricant Production by Pervaporation-Assisted Reaction Paola Andrea Borda Díaz, Frederico Kronemberger, Alberto Claudio HabertPAM/COPPE/UFRJSuccinic Acid Liquid-Liquid Extraction with Membrane ContactorsLuciana de Souza Moraes, Frederico de Araujo Kronemberger, Helen Conceição Ferraz andAlberto Claudio HabertPAM/COPPE/UFRJStudy of PVC Membranes Prepared Via Non Solvent Induced Phase Separation ProcessLiana Franco Padilha, Cristiano Piacsek BorgesPAM/COPPE/UFRJDirect Osmosis Process for Power Generation using Salinity Gradient: FO/PRO PrototypeInvestigation using Hollow Fiber ModulesNicolas Roger Jean-Daniel Mermier, Cristiano Piacsek BorgesPAM/COPPE/UFRJSystems for composite hollow fibers synthesis combining simultaneous phase inversionand interfacial polymerizationNicolas Roger Jean-Daniel Mermier, Cristiano P. BorgesPAM/COPPE/UFRJ Feasibility and Metodology for the Reuse of Reverse Osmosis Modules Paula Werneck Teixeira Reuther, Cristiano Piacsek Borges, Frederico KronembergerPAM/COPPE/UFRJPolyurethane Membranes to Remove Sulfur Compounds from Naphtha byPervaporation ProcessRafael Aislan Amaral, Alberto Cláudio Habert, Cristiano Piacsek BorgesPAM/COPPE/UFRJ Antimicrobial polyvinyl alcohol films with in situ synthesized silver nanoparticle Beatriz Thompson Binoto Ferreira, Helen C. Ferraz, Liliane D. Pollo

PAM/COPPE/UFRJSynthesis and Characterization of Polyvinyl Alcohol Containing Carbon Nanoparticles forthe Separation of Olefin/Paraffin MixtureJuliana Jatobá, Luíza Martins de Almeida, Jane Hitomi Fujiyama-Novak, Alberto CláudioHabertPAM/COPPE/UFRJ Study from Hydrodynamics Aiming to Reduce Fouling in MBR Thaissa P. Silva, Cristiano P. Borges, Frederico A. KronenberguerMarina N. Souza, Jéssica Schner, Jane H. Fujiyama-Novak, Maria E. F. Garcia, Maria EugêniaPAM/COPPE/UFRJPreparation of Chlorine-Resistant NF Membrane Fabricated by Interfacial Polymerization Sena, Alberto C. Habert, Cristiano Borges, Mônica O. PennaPAM/COPPE/UFRJ Study of New Permeators for Membrane Bioreactors (MBR) Aiming at Fouling Control Robson Rodrigues Mororó, Cristiano Piacsek Borges, Frederico de Araujo KronembergerPAM/COPPE/UFRJDevelopment of Poly(ethylene oxide) Membranes for Desulfurization of Gasoline byPervaporationMaria Elizabeth Ferreira Garcia, Sandra Renata Rossi, Carlos Alberto de Araujo Monteiro,Cristiano Piacsek BorgesPAM/COPPE/UFRJCoagulation, Flocculation and Microfiltration processes for wastewater reuse inSugarcane IndustryGisele Mattedi, Cristiano P. Borges, Lidia YokoyamaPAM/COPPE/UFRJRecovery and concentration of effluent from the delignification stage in the productionprocess of lignocellulosic ethanolAna C. M. Costa, Gisele Mattedi, Cristiano P. Borges, Lidia Maria Melo Santa AnnaAna C. M. Costa, Gabriela M. dos Ramos, Gisele Mattedi, Cristiano P. Borges, Rodrigo S. deThe use of different types of antiscalants to prevent barium sulphate precipitationPAM/COPPE/UFRJSouza, Vânia M. J. SantiagoPAM/COPPE/UFRJ Membrane Reactors for Transesterification of Triglycerides Dilson da Costa Maia Filho, Vera Maria Martin Salim, Cristiano Piacsek Borges.PAM/COPPE/UFRJ Polycaprolactone membranes by phase inversion process Cristina Cardoso Pereira and Cristiano Piacsek BorgesPAM MembranasPerformance of Cartridge Filters as Pre-Treatment of Pressurized MicrofiltrationJocarla da Silva Rogerio, Walter Bom Braga Junior, Gabriela Marques dos Ramos, RobertoBentes de CarvalhoAna C. M. Costa, Gabriela M. dos Ramos, Gisele Mattedi, Paula W. T. Reuther, Cristiano P.PAM/COPPE/UFRJ-Petrobras Evaluation of Reversal Electrodialysis Process to Treat Refinery WastewaterBorges, Rodrigo S. de Souza, Vânia M. J. SantiagoPAM/COPPE/UFRJ-Petrobras - UFBAOily Wastewater Treatment by Membrane Separation Processes Aiming Reuse:Considerations Based on Experimental DataAlbérico Ricardo Passos da Motta, Cristiano Piacsek Borges, Karla Patricia de OliveiraEsquerre, Asher Kiperstok, Rafaela Oliveira FloresPAM/COPPE/UFRJ-Univ.ColômbiaContinuous Production of Biodiesel using a Liquid-Liquid Film Reactor packed withHollow Fiber MembranesAderson Imbachi, Nevardo Bello Yaya, Luz Dary Carreño Pineda, Juan Guillermo CadavidEstrada, Alberto Claudio Habert , Paulo César Narváez RincónPAM/COPPE/UFRJ-EQ/UFRJ Use of Membrane Contactor to Improve the Ozone Transport in Gas-Liquid SystemFelipe Rodrigues Alves dos Santos, Fabiana Valéria da Fonseca Araújo, Cristiano PiacsekBorgesPolyvinyl Alcohol / Activated Carbon Composite Thin Layer to Improve ChlorinePAM/COPPE/UFRJ-IMA/UFRJ Resistance of Commercial RO Polyamide MembranesLucinda F. Silva , Ricardo C. Michel, Cristiano P. BorgesPAM/COPPE/UFRJ-IQ/UFRJ New Polyamide Membranes from PAMAM and GlutaraldehydeHilenio da Silva Monteiro, Liana Camboin, Mylene Fernandes, Alberto Claudio Habert,Vanessa Rodrigues FurtadoPAM/COPPE/UFRJ -IQ/UFRJSynthesis and Characterization of Mixed Matrix Membranes Containing MOFs for CO 2CaptureJéssica de S. Ribeiro , Talita O C. Leite, Elisângela S. Costa, Alberto Claudio Habert, HelenConceição Ferraz, Bruno da S. Gonçalves Alves, Jussara L. de MirandaPAM/Pam memb. Characterization of National Hollow FiberMembranesfor Use in Hemodialysis Nascimento, C. R. F.,Ferraz, H. C., Almeida, K. M. .e Borges, C. P.PAM/COPPE/UFRJ-PetrobrasFacilitated Transport of Propylene Through a Membrane Containing Silver Salt asCarrierLuíza M. de Almeida, Douglas V. Fernandes, Felipe C. Cunha, Jane H. Fujiyama-Novak,Liliane Pollo, Cristiano Borges, Alberto C. Habert, Carlos R. K. RabelloPAM/COPPE/UFRJ-Petrobras-EQ/UFRJApplication of Ceramic Membranes for Oilfield Produced Water Treatment in OffshorePlatformsSilvio Edegar Weschenfelder, Ana Maria Travalloni Louvisse, Cristiano Piacseck Borges,Juacyara Carboneli CamposPAM-COPPE/UNIFAP/ UFPACopper Waste Recovery from Hydrometallurgical Industry by Membrane ContactorSystemKleber Bittencourt Oliveira; Helen Conceição Ferraz; Emanuel Negrão Macêdo

PAM-COPPE/UNSAEthanol dehydration through crosslinked PVA/PES composite membranes with plasmatreated asymmetric supportBetina Villagra Di Carlo ,Elza Castro Vidaurre, Alberto Claudio HabertPAM-COPPE/PetrobrasNewly Developed Composite Hollow Fiber Membrane by Interfacial Polymerization ofHydrazineAna C. M. Costa, Paula W. Teixeira, Maria E. F. Garcia, Jane H. Fujiyama-Novak, Gabriela M.Ramos, Alberto C. Habert, Cristiano Borges, Mônica O. PennaPAM-COPPE/Univ. Nac.ColombiaModeling and Simulation of Membrane Reactor for Biodiesel ProductionMario Noriega, Anderson Imbachi, Nevardo Bello Yaya, Luz Dary Carreño Pineda, JairoErnesto Perilla Perilla, Juan Guillermo Cadavid Estrada, Alberto Claudio Habert, PauloCésar Narváez RincónPetrobras Assessment of Membranes Potential for Ballast Water Treatment Rafael Ferreira de Jesus, Ana Maria Travalloni Louvisse, Celso Alleluia MauroPetrobrasCO 2 Removal Systems with Membranes at Petrobras Offshore UnitsLeandro Fernandes Nolasco Quintanilha, Paulo Roberto de Jesus, Rafael Henrique PecoraGomesPetrobras Sulphate Removal Units Monitoring Martins Jr, Elpidio CorreaPetrobras/ EQ-UFRJ CO 2 Separation from Natural Gas with Membrane Permeators and Gas-Liquid Contactors José Luiz de Medeiros, Ofélia de Queiroz Fernandes Araújo e Wilson M. GravaPolymem AS - FranceGigamem® : An Innovative Ultrafiltration Membrane Process Application To SeawaterFiltration For Injection On Large 250,000 bpd (10 Mgd) Oil PlatformsOlivier Lorain / Jean Michel EspenanPoroGen Corporation, USAAdvances in polymeric membrane material technology open new options for naturalgas treatingBen Bikson, and Yong DingPorometerCharacterization of the Pore Size of Polymeric Membranes by Capillary Flow Porometryand Comparison with other Characterization TechniquesLuc Stoops, Chris Dotremont, Danny Pattyn and Angels Cano-OdenaSolvaySolvay Materials for UF/MF Membranes and Development TrendsAnna Maria Bertasa, Pasquale Campanelli, Emanuele Dinicolo, Thomas Kohnert, TheodoreMoore, Aldo SanguinetiUBE Industries Polyimide Hollow Fiber Membranes which contribute to Energy Creation Nozomu TANIHARA1, Nobuhiko FUKUDA, Tomohide NAKAMURA, Tetsuo NAKAYASUUBE Industries Characteristic and Applications of Polyimide Hollow Fiber Membrane Tetsuo NAKAYASU, Nozomu TANIHARA and Tomohide NAKAMURAUCSMicrofiltration and Ultrafiltration applied to Concentration of Pectinases Produced bySolid-State FermentationPatrícia Poletto, Eloane Malvessi, Mára Zeni, Mauricio Moura da SilveiraUCS/ UFRGS Characterization of Poly (ether imide) Microfiltration Membrane Carine Pertile, Camila Baldasso, Mara Zeni, Isabel C.TessaroUCS/UFU/UFESCharacterization of Cellulose Acetate Membranes Produced from Recycling Corn Huskfor Application in UltrafiltrationElaine Angélica Mundim Ribeiro, Carla da Silva Meireles, Guimes Rodrigues Filho, JuliaGraciele Vieira, Rosana Maria Nascimento Assunção, Jocelei Duarte, Mara ZeniUCS/UFU/Univ. Genova Characterization of Cellulose Acetate Membranes Produced from Mango SeedCarla S.Meireles, Sabrina D. Ribeiro, Elaine A. Mundim, Guimes Rodrigues Filho, JoyceRover Rosa, Rosana M.N.Assunção, Mara Zeni, Aldo Bottino, Gustavo CappanelliUEMPurification of Protein Coagulant from Moringa oleifera SeedAline Takaoka Alves Baptista; Pedro Henrique Freitas Cardines; Carole Silveira; MarianaOliveira Silva, Marcelo Fernandes Vieira; Rosângela Bergamasco; Angélica MarquetottiSalcedo VieiraUEMRemoval of Trihalometanes Precursors by Combined ProcessCoagulation/Flocculation/Membranes in water treatmentMilene Carvalho Bongiovani, Franciele Pereira Camacho, Letícia Nishi, Karina CardosoValverde, Livia de Oliveira Ruiz Moreti, Driano Rezende, Carlos Henrique Furlan, AngélicaMarquetotti Salcedo Vieira, Rosângela BergamascoUEM - UNINGA -PAM MembranasFuture of Membranes for Greywater ReuseTaísa Machado de Oliveira, Cláudia Telles Benatti, Célia Regina Granhen Tavares, RobertoBentes de Carvalho, Rafael Alberto NishimuraUERJElectroflocculation and Reverse Osmosis in the Treatment of Oily WastewaterLeonardo Firmino da Silva, Patrícia Braz Ximango, Alexandre Andrade Cerqueira, MônicaRegina da Costa Marques, Fábio Merçon

UFSCUFSCUFSCUFSCUFSCUFSCarUFSCarUFSJ-UFUPretreatment Influence on Hexane Permeability in Nanofiltration and Reverse OsmosisCommercial Polymeric MembranesEffect of Dense CO 2 on Polymeric Commercial MembranesMagnetic Field Influence on Cleaning of Ultrafiltration Membranes Applied to Treatmentof Textile WastewaterUse of Precipitation and Ultrafiltration to Purify Inulinase Obtained by Solid StateFermentation of Sugarcane BagasseSeparation of Mixtures of Soybean Oil and Organic Solvents by Ceramic MembranesPEI/PEIS blends reinforced with sepiolite Clay for fuel cell polymeric electrolytes:evaluation of applicabilityPC/PCS blends reinforced with sepiolite clay for polymeric PEMFC electrolyte:Evaluation of applicabilityA Study of the Resistances During Permeate Flux Decline in Crossflow Microfiltration ofPassion Fruit JuiceKatia Rezzadori, Frederico M. Penha, Mariane C. Proner, Lara Fogaça, José C. C. Petrus,Marco Di LuccioKatia Rezzadori, Josamaique G. Veneral, Lucas Pires, J. Vladimir Oliveira, José C. C. Petrus,Marco Di LuccioFranciele Carlesso, Selene M. A. G. U. Souza, Antônio A. U. Souza, J. Vladimir de Oliveira,Marco Di LuccioSimone Maria Golunski, Helen Treichel, Marco Di LuccioJonas R. M. de Melo, Ricardo Verlindo, Ana Paula Picolo, Diane Rigo, Débora Z. Flôres,Marcus V. Tres, Juliana Steffens; J. Vladimir Oliveira, Marco Di LuccioAna C. O. Gomes, Fernando N. S. Monteiro, Caio M. Paranhos, L. A. PessanAna C. O. Gomes, Eduardo Backes, Caio M. Paranhos, L. A. PessanRui Carlos Castro Domingues,Miria Hespanhol Miranda Reis,Vicelma Luiz CardosoUFVTreatment of Kraft Pulp Mill (EPO) Bleaching Plant Filtrates Using Membrane Technology Rafael Quezada Reyes, Claudio Mudado SilvaUFVMonitoring the Shelf Life of Microfiltered WheyMaura Pinheiro Alves, Renam de Oliveira Moreira, Guilherme Mendes da Silva, RafaelOliveira Bento, Cláudia Lúcia de Oliveira Pinto, Antônio Fernandes de CarvalhoUNICAMPParametric Analysis of a Ethylbenzene Dehydrogenation Model carried on a MembraneReactor with heat and mass transferGermano Possani, Roger J. Zemp.UNICAMPClarification of Artichoke By-product Extract by Membrane Process: MembraneSelection Criteria and Fouling Mechanism Modeling During FiltrationMariana Teixeira da Costa Machado, Miriam Dupas HubingerUNIRIO Water treatment to health clinics Anna Lecticia Martinez Toledo, Maria Eugênia SenaUnitek Ultrafiltration as pretreatment in river water desmineralization by reverse osmosis Manuel García de la MataUniv. Cartagena /Univ.MurciaOptimizing Cobalt (II) Removal from Aqueous Solution by Bulk Liquid MembranesContaining D2EHPA. Study of Transport ParametersG. León, A. Hidalgo, M. Gómez, M.D. Murcia, B. Miguel, M.A. GuzmánUniv. Cartagena /Univ.MurciaCharacterization of RO90 membrane using saline solutions. Application of Spiegler-Kedem-Kachalsky modelA. Hidalgo, G. León, M. Gómez, M.D. Murcia, M.A. Guzmán, C. GuardiolaUniv. ChileExtraction of the light lanthanide metal ions by means of emulsified liquid membranesusing several kinds of organophosphorus extractants as carrier C. Basualto F., F. Valenzuela L., L. Molina C., J. Sapag H.Univ. Chile Effect of Particle Diameter on the Permeability of Polypropylene/Silica Nanocomposites Diego Bracho, Moisés Gómez, Humberto Palza, Raul QuijadaUniv. EdinburghMulti-stage Design for Carbon Capture from Coal-fired Power Plants: From ProcessDesign to Economic AnalysisDavide Bocciardo, Maria-Chiara Ferrari, Stefano BrandaniUniv. Edinburgh1D and 2D Approach for Modelling Hollow-fiber and Spiral-wound Permeators For GasSeparationDavide Bocciardo, Maria-Chiara Ferrari, Stefano BrandaniUniv. L’Aquila/ USP Effect of the UF-Membrane Cut-off on the Invertase Activity Francesco Di Addezio, Ester Junko Yoriyaz, Maria Cantarella and Michele VitoloUniv. Nac. Colombia Performance of Batch Pervaporation Membrane Reactor for Isoamyl Acetate SynthesisWilmar Osorio-Viana, Jesús David Quintero-Arias, Javier Fontalvo,Izabela Dobrosz-Gómez,Miguel Ángel Gómez-García

Univ. Nac. Colombia Isoamyl Acetate Production - Membrane Reactor Design GuidelinesWilmar Osorio-Viana, Jesús David Quintero-Arias, Javier Fontalvo,Izabela Dobrosz-Gómez,Miguel Ángel Gómez-GarcíaUniv. Nac. Colombia Measurement of the solubility of water - ethanol mixtures in PDMS membranes Andrea Fuertes, Mario Noriega, Miguel Ángel Gómez García, Javier FontalvoUniv. Nac. Colombia Performance of Liquid Membranes in the Taylor Flow regimeJuan David García-Mahecha, Alan Didier Pérez-Ávila, Miguel Ángel Gómez-García, JavierFontalvo-AlzateUniv. Passo FundoProduction of Whey Protein Concentrated (WPC) by Ultrafiltration followed by dialysisCaroline Dalcin Zanon, Gabriela Viganó, Juliane Mosmann, Vera Maria Rodrigues, VandréBarbosa BriãoUniv. Tolouse/CNRSElectrodialysis for food and environmental applications. Scientific targets and industrialrealizationsHélène Roux-de BalmannUniv. Tolouse/CNRS USP Demineralization of waste waters containing phenol by electrodialysis H. Roux-de Balmann , F.J. Borges, R. GuardaniUniversidade Nova deLisboa, Universidade deLiliana C. Tomé, Luís P.N. Rebelo, Carmen S.R. Freire, David Mecerreyes, Isabel M.Ionic Liquids and Polymeric Ionic Liquids Membranes for COAveiro, University of the2 SeparationMarruchoBasque CountryUniversidade Nova deLisboa, Universidade deAveiro, University of theBasque CountryLight Olefin/Paraffin Separation Using Polymeric Ionic Liquid Membranes Containing Ag + -IL as CarrierLiliana C. Tomé, David Mecerreyes, Carmen S.R. Freire, Luís P.N. Rebelo, Isabel M.MarruchoUNSAComparison of the Performance of Membranes in Treatment from Industry TanneryWastewaters.Estela María Romero-Dondiz, Jorge Emilio Almazán, Verónica Beatriz Rajal and Elza FaniCastro-Vidaurre.UNSAPreparation and evaluation of ciprofloxacin delivery from poly(3-hidroxybutirate)membranesJosé M. Bermudez, Analía I. Romero, Mercedes Villegas, M. Florencia Dib Ashur, Mónica L.Parentis y Elza F. Castro VidaurreUNSA/UFSCarPolycarbonate Modified Membranes With Silanized Clays For Use In Ethanol / WaterPervaporationL. Dada, M. Toro, C. Carrera, E. Erdmann, C. Paranhos, L. Pessan, H. DestéfanisUNSA/Univ California atDavisUltrafiltration Membranes Modified by Plasma and Its Application in The Viral RemovalIn Water TreatmentMercedes L. Méndez, Verónica Rajal, Elza F. CastroUOP Honeywell Industrial Application of Membranes for CO 2 Removal from Natural Gas William I. EchtUSPMembrane Distillation Process Design Applied to Highly Concentrated Brines:Mathematical Model and Operating Conditions AnalysisCarlos Eduardo Pantoja, Marcelo Martins Seckler, Yuri NariyoshiUSPPolymeric nanofiltration Membranes based on PVC and C-butyl Pyrogallol[4]arene or C-butyl Resorcin[4]areneSilvânia Marilene de Lima and Grégoire Jean-François DemetsUSPStudy of integrated use of Coagulation / Flocculation and Membrane SeparationProcesses Microfiltration and Ultrafiltration in WheyPaulo Ricardo Amador Mendes, Júlia de Goes Monteiro Antônio, Luís Fernando FigueiredoFariaUSPDiffusion of Monovalent Cations through Membranes Based on Polymers andcucurbituril IonophoresTiago Mateus B. Teodósio, Gregoire Jean-Françóis DemetsUTFPRRiver Water Treatment by Microfiltration with Sedimentation Pretreatment with anAlternative CoagulantAline Neher, Lucila Adriani Coral, Fatima de Jesus BassettiUTFPR/UFSC Saxitoxins Removal by NF270 e NF90 Nanofiltration Membranes Lucila Adriani Coral, Fatima de Jesus Bassetti, Flávio Rubens LapolliVictoria University / DeakinUniversityEffect of Plasma Activation on Polyamide Reverse Osmosis Membrane for ImprovedChlorine ToleranceRackel REIS, Ludovic Dumée, Mary She, John ORBELL, Mikel DUKE

Maximizing Hydrocarbon Liquids Recovery while Recovering High Purity CO 2 :New Operation Strategy for Membrane Based CO 2 Removal FacilitiesJason Dietrich * , Ankur Jariwala, G. Edward Mahley, Richard PetersCameron International, Jason.Dietrich@c-a-m.comCameron Cynara® CO 2 removal membranes have been successful and very well proven in theonshore as well as offshore markets for over 25 years. In recent years, there is a significant emphasisfrom Oil and Gas producers to maximize hydrocarbon liquids recovery while removing CO 2 fromnatural gas.Cameron operates the Cynara® membrane facility at SACROC in West Texas – owned by Kinder-Morgan – which processes 750 MMSCFD of natural gas by removing CO 2 from 90 mol% in the feedgas to 10 mol% in the product gas. Traditionally this facility was focused on maximizing natural gasrecovery while recovering high purity CO 2 using membranes. With growing demand of natural gasliquids in last couple of years, Kinder-Morgan is maximizing the advantage of Cynara® membranes towithstand and recover hydrocarbon liquids while removing CO 2 from natural gas. This was achievedby implementing several improvements in the existing facility including targeted membranereplacement, feed flow optimization, temperature increase, and improved temperature stability.The recent improvements in temperature control and increased heat capacity, along with membranereplacements, have resulted in large performance gains in certain parts of the facility. Combined withthe consistent monitoring of plant performance data in real-time, these changes have had a directresult in terms of hydrocarbon recovery gain, without negative effects to the CO 2 permeate purity.

Gas separation properties of Mixed Matrix Membranes comprising of Matrimid andFuntionalized Mesoporous MCM-41Asim Laeeq Khan a *, Chalida Klaysom b , Amit Gahlaut b , Ivo Vankelecom ba Department of Chemical Engineering, COMSATS Institute of Information Technology, Lahore,Pakistanb Center of Surface Chemistry and Catalysis, Faculty of Bioscience Engineering, KU Leuven, Belgiumalaeeqkhan@ciitlahore.edu.pkMixed matrix membranes (MMMs) can potentially improve the separation performance oftraditional polymeric membranes while still maintaining their processing advantages and lower costs.In this work, MMMs composed of Matrimid and SO 3 functionalized mesoporous silica spheres wereprepared by the solution casting method. Matrimid was chosen as the polymer matrix due to itsseveral inherent properties such as good processability, easy commercial availability, goodseparation properties, and good mechanical and thermal stability. The filler particles werefunctionalized with sulfonic acid (-SO 3 H) groups to increase the separation performance of themembranes by increasing the CO 2 solubility. The fast diffusion of gases through the mesoporousmaterials, accompanied by this increased CO 2 solubility, resulted in the simultaneous increase of gaspermeability and selectivity. CO2 permeation data and SEM images of the synthesized MMMssuggest that the fillers adhered well to the polymer matrix. DSC analysis of the membranes showsthat incorporation of unmodified MCM-41 particles into the Matrimid matrix has very little effect onthe T g , indicating the absence of interaction between the inorganic and polymeric phases. On theother hand and somehow surprising, the addition of SO 3 H - MCM-41 increased the T g of MMMs. Thispoints toward an increased interaction between the Matrimid and the filler particles, the nature ofwhich is not really clear. The comparison of DSC results suggest that the incorporation of the SO3Hfunctionalizedfillers in MMMs can be used as an effective tool to tailor the structure and propertiesof the membranes. Gas permeation tests indicated that the addition of functionalized MCM-41 topolymer matrix increases both the gas permeability and selectivity.The highest ideal selectivitiesobtained here for CO 2 /N 2 and CO 2 /CH 4 were 32.97 and 31.48 (CO 2 permeability = 9.13 Barrer),respectively. In order to evaluate the practical commercial viability of these membranes, they weretested under different operating pressures and temperatures and the results were plotted on theRobeson trade-off upper-bound.Fig. 1 TEM image of as-synthesized MCM-41Fig.2. SEM images of cross-sections of Matrimid membranescontaining 30% loading of (a-c) MCM-41

Synthesis and Gas permeation properties of Mixed Matrix Membranes comprisedof Acrylate derivitized PSf and Amine functionalized Mesorporous MCM-41 for CO 2separationAsim Laeeq Khan a *, Chalida Klaysom b , Amit Gahlaut b , Ivo Vankelecom ba Department of Chemical Engineering, COMSATS Institute of Information Technology, Lahore,Pakistanb Center of Surface Chemistry and Catalysis, Faculty of Bioscience Engineering, KU Leuven, Belgiumalaeeqkhan@ciitlahore.edu.pkMixed matrix membranes (MMMs) can potentially improve the separation performance oftraditional polymeric membranes while still maintaining their processing advantages and lower costs.In this work, MMMs composed of acrylate derivatized polysulfone and mesoporous MCM-41 wereprepared by solution casting. MCM-41 is a hexagonal member of the family of mesoporous silicamaterials, and possesses well-ordered one-dimensional pores. It is a promising material for MMMsbecause of several inherent advantages, such as high specific surface area, high CO 2 adsorption, highmechanical and thermal stability and easy surface modification. The high porosity of MCM-41facilitates faster gas diffusion through the pores compared to zeolites. The voids at the polymer-fillerinterface were removed by the introduction of covalent linkages between the modified polymer andthe functionalized fillers. Amino functional groups were deposited on the surface of as-preparedMCM-41 via a grafting method. Mesoporous silica MCM-41 with 100–150 nm in diameter wassuccessfully prepared. The as-prepared MCM-41 showed a highly ordered structure as can beconfirmed by the TEM image. Gas permeation results and SEM images of the synthesized MMMsconfirmed a good adhesion and dispersion of the fillers within the polymer matrix. In comparison toMMMs with unmodified MCM-41, covalently linked MCM-41 fillers rendered the MMMs significantlyhigher CO 2 /CH 4 and CO 2 /N 2 selectivities due to the presence of a covalent link between the -NH 2group of the filler and the acrylate of the polymer. The highest ideal selectivities obtained here forCO 2 /N 2 and CO 2 /CH 4 were 32.97 and 31.48 (CO 2 permeability = 9.13 Barrer), respectively. Theperformance of membranes under mixed gas feeds and different operating temperatures was alsostudied. The performance of MMMs was further investigated by varying the feed temperature. Theresults were in agreement with the expected trends for gas transport via solution–diffusionmechanism in glassy polymers. The higher temperature increases the CO 2 permeability due to theincrease in flexibility and free volume within the polymer matrix. However, the flux of the nondesirablegas (CH 4 and N 2 ) increases slightly more with the increase in temperature, resulting in anoverall decrease in selectivity with increasing temperature.abFig. 1. SEM images ofcross-sections of MMMs containing a 30% loading of (a) PSfAc-MCM-41 and(b)PSfAc-NH2-MCM-41.

Fig. 2 Pure gas (CO 2 ) permeabilities and ideal selectivities for PSfAc-MCM41 and covalently linkedMMMs (10 bar and 25 o C).

Synthesis and characterization of Fluorinated and Sulfonated Aromatic PEEKmembranes; Application in CO 2 separationAsim Laeeq Khan a *, Chalida Klaysom b , Amit Gahlaut b , Ivo Vankelecom ba Department of Chemical Engineering, COMSATS Institute of Information Technology, Lahore,Pakistanb Center of Surface Chemistry and Catalysis, Faculty of Bioscience Engineering, KU Leuven, Belgiumalaeeqkhan@ciitlahore.edu.pkThis paper describes the performance of fluorinated and sulfonated aromatic poly(ether etherketone) (FS-PEEK) membranes, directly prepared from the sulfonated monomer, for CO 2 separationfrom gas mixtures containing N 2 or CH 4 . Dense membranes with different degrees of sulfonationwere prepared via solvent evaporation. Increasing degree of sulfonation simultaneously improvesthe permeability and selectivity of both gas pairs. The effect of counterions was investigated byconverting FS-PEEK membranes from the Na + -form in which they are prepared, to the H + andmultivalent cationic forms. Gas permeability and selectivity for polymers with divalent and trivalentcounterions were higher than those for polymers in the monovalent and H + -forms. In order to studythe stability and potential industrial application of these membranes, they were tested at differentconditions of feed pressure, temperature and CO 2 feed concentration.

Evaluation Of The Application Of Nanofiltration To Concentrate TheHydroethanolic Extract Obtained From Grape Juice MarcNatalia Barbosa Eitel* 1 , Ana Paula Gil Cruz 2 , Luiz Fernando Menezes da Silva 3 , Suely PereiraFreitas 1 , Lourdes Maria Correa Cabral 31 Universidade Federal do Rio de Janeiro - Escola de Química/UFRJ, Rio de Janeiro, Brasil.2 Universidade Federal do Rio de Janeiro - Instituto de Química/UFRJ, Rio de Janeiro, Brasil.3 Embrapa Agroindústria de Alimentos, Rio de Janeiro, Brasil.*e-mail: natalia.eitel@poli.<strong>ufrj</strong>.brSome environmental problems followed the rapid industrialization of the past decades. In the case ofthe food industry, particularly the ones processing vegetables and fruits, the main problem observedis the inadequate disposal of its wastes. When it comes to grape juice industries, the main wastegenerated and also of the highest volume is the marc, basically consisting of skins and seeds. Thisresidue has a large recovery potential and a high cost of treatment due to its high biochemical andchemical oxygen demand (BOD and COD) [1, 2]. Because of its rich phenolic composition and greatantioxidant potential, several works have been conducted to evaluate its use as an alcoholic extract[3-6]. It is known, however, that these bioactive compounds are thermolabile. The aim of this study,therefore, is to evaluate the application of nanofiltration to concentrate the hydroethanolic extractobtained from grape juice marc. The nanofiltration was chosen due to its characteristics: energysavings, selectivity, separation of thermolabile compounds and simplicity of operation [7].The bagasse, previously hydrated during 1 hour at 30°C, suffered a hydroethanol extraction with 30%ethanol, pH 4.0 adjusted with citric acid, in proportion of 9:1 solvent: substrate during 120 min at50°C under a mechanical stirring of 48RPM. The nanofiltration was carried out in spiral woundpolyamide membrane modules system with a filter area of 2,5m 2 . The process was conducted during61min at 40°C with applied pressure of 12 bar in the system, which was previously determined byevaluation of the limiting flux at 20°C, 30°C and 40°C, under a fed batch until a volumetricconcentration factor of at least 10 was reached. The permeate stream was fully collected and its fluxmeasured in kg.h -1 m -2 every 5 minutes. Samples of the streams were collected and submitted foranalyzes of antioxidant activity (AA) [8, 9], total phenolics (TP) [10 modified by 11] and total (TA) andmonomeric (MA) anthocyanins [12]. The results are shown in Table 1 below.Table 1 – Analytical Results Obtained For The Different Process StreamsStream AA 1 TP 2 TA 3 MA 3Feed 4,32 ± 0,13 55,40 ± 2,77 13,71 ± 0,07 10,90 ± 0,06Permeate N/D N/D N/D N/DRetentate 49,02± 6,72 593,17 ± 25,64 155,23 ± 3,48 119,42 ± 4,131-μmol Trolox∙g -1 ; 2-mg Gallic acid∙100g -1 ; 3-mg malvidin-3,5-diglucoside∙100g -1 ); N/D- Not DetectedThe nanofiltration process proved itself as an attractive alternative for the concentration of bioactivecompounds recovered from the grape marc through a hydroethanol extraction. However other testsshould be performed to confirm these results and determine the influence of other processparameters on its concentration and its permeate flux.

[1] M. R. Kosseva (2009), Processing of food wastes, Adv. Food Nutr. Res., 58, 57-136.[2] A. C. Habert et al. (2006), In: Processos de Separação por Membranas, Rio de Janeiro, E-papers.[3] M. A Bustamante et al. (2008), Waste Management, 28, 372–380.[4] D. Amendola et al. (2010), J. of Food Engineering, 97, 384-392.[5] J. M. Luque-Rodríguez et al. (2007), Bioresource Technology, 98, 2705-2713.[6] G. Spigno et al. (2007), J. of Food Engineering, 81, 200-208.[7] Y. Yilmaza et al. (2006), J. of Food Composition and Analysis, 19, 41-48.[8] V. L. Singleton et al. (1965), Am. J. Enol. Vitic., 16, 144-168.[9] R. Re et al. (1999), Free Radic. Biol. Med., 26, 1231-1237.[10] S. Georgé et al. (2005), J. of Agricultural and Food Chemistry, 53, 1370-1373.[11] M. M. Giusti et al. (2001), Characterization and mesasurement of anthocyanins by UV-visible pectroscopy,In: Current Protocols in Food Analytical Chemistry, New York: Wiley.[12] M. S. Rufino et al. (2007), Metodologia Científica: Determinação da atividade antioxidante total em frutaspela captura do radical ABTS + , Comunicado Técnico Embrapa Agroindústria Tropical, 128.

Environmental Performance Comparison between Bench Scale andWastewater Treatment Plant Membrane BioreactorsTiago Chagas de Oliveira Tourinho (1)*Ofélia de Queiroz Fernandes Araújo (1)Isaac Volschan Junior (1)(1) Universidade Federal do Rio de Janeiro – tiago_tourinho2@yahoo.com.brWastewater treatment with membrane bioreactor (MBR) combines biological process with amembrane separation process. It is increasingly adopted to treat municipal wastewaters, producinghigh-quality effluent with a small footprint [1], and is one of the most outstanding and up to datetechnologies applied to wastewater treatment. However, it presents some disadvantages, like highenergy consumption (0.4–1 kWh/m 3 compared to conventional activated sludge process (CASP),values ranging from 0.3 to 0.4 kWh/m 3 ) [2], and the necessity of chemical cleaning to prevent fouling.All these features have to be considered in the decision-making process of MBRs implementation,not only on the economic but also on the environmental point of view, aiming a holistic evaluation.Aiming at a better understanding of the environmental impact differences between CASP and MBRprocesses, this study evaluates the environmental performance of MBRs in two scales: MBR benchexperiments (BE) and MBR wastewater treatment plants (WwTPs). In this direction, the study intendsto 1) investigate energy consumption (assumed hydropower), sodium hypochlorite (NaClO) forchemical cleaning, and permeated pollutants, expected to exhibit biggest potential impact; 2)identify which impact category is the most relevant; 3) compare the impacts of MBR-BE to MBR-WwTPs to identify scale effects; 4) discuss correlations between operational conditions andenvironmental effects [3][4]. SimaPro 7.2, a life cycle analysis software, was used as a tool for theevaluation of the overall environmental impacts. The results indicated, for all investigated cases, thatelectricity was the most impacting aspect. The most relevant impact category, for NaClO andelectricity, was human toxicity, while for the permeated pollutants the category freshwatereutrophication showed highest impact. A reduction of impact with an increase in process scale wasobserved: 98.4% for energy; 30.4% for NaClO, and 98.3% reduction for overall impact. Last, it wasobserved that when the NaClO(g)/kWh ratio is greater than or equal to 2.595, NaClO will be moreenvironmentally impacting than energy consumption.References[1] J.-H. Choi, H. Y. Ng (2008), Chemosphere, 71, 853–859.[2] A. Hospido et al. (2012), Desalination, 285, 263–270.[3] M. Gander et al. (2000), Separation and Purification Technology, 18, 119–130.[4] S. Judd (2011), The MBR Book: principles and applications of membrane bioreactors for water andwastewater treatment. 2nd ed. Oxford: Elsevier.

Electrodialysis as desalting or purification step in petrochemical industriesFlorence Lutin* ; Daniel Bar**(*) Eurodia Industrie S.A. (Fr) florence.lutin@eurodia.com(**) Ameridia (US) dbar@ameridia.comOn offshore platforms for gas production, Natural gas is dehydrated to avoid corrosion or pipelineplugging due to ice or hydrate formation. The traditional way to dehydrate the gas is by absorption inTriethylene Glycol (TEG) or Diethylene Glycol. This glycol solution is recycled but it becomes loadedwith (sea)salt. To avoid pipeline plugging due to the precipitation of salt, the Ethylene Glycolsolutions must be treated. The conventional process to regenerate Glycol solutions are vacuumdistillation and ion exchange resins. Electrodialysis (ED) technology can be applied to remove saltsfrom Glycol solution. Compared to vacuum distillation, the ED process is more economical. The mainbenefit compared to ion exchange resins is to avoid the huge consumption of chemicals forregeneration.Another application of ED is amine purification/regeneration in flue gas scrubbing processes inindustries such as chemical, sulphur smelters, or oil refineries. The goal is to clean the flue gasses andobtain a regenerable Sulfur Dioxide (SO 2 ) stream. This technology uses an aqueous amine solution toachieve a high efficiency selective absorption of Sulfur Dioxide from a large variety of gas streams.The process is similar to conventional amine-based gas treating units in refineries and natural gasprocessing. ED is applied to purify the amine solution from heat-stable salts. Regenerating theabsorbent eliminates the high cost of consumables, while its high capacity and selectivity reducecapital costs. Effluents from the process are minimal compare to ion exchange; as a result, it can beconsidered as an “eco-friendly” process.EURODIA has developed a three-compartment EUR40 ED stack for these customers. The amine isneutralized or substituted by another anion inside the stack. Alternate processes require thedemineralization of the amine solution with conventional two-compartment ED stacks.During the last few years, Eurodia Industrie has developed new types of electrodialysis (ED) stacks toachieve high one-pass desalination rates of up to 80 % and allow for very compact systems. Thesesystems are very well suited to process brackish waters or salted solution with low salt levels(between 1 and 5 g/l). These compact ED systems can also easily be paired with reverse osmosisunits to increase the water recovery rate from ~75% to 95%. In addition, Eurodia is very interested inthe Capacitive Deionization (CDI) Technology, because of the great process simplifications that canbe achieved, still with high recovery rates (90% with desalination rates of up to 90%). To developapplications for CDI, Eurodia is working in partnership with Enpar Technologies (Guelph, Ontario,Canada). Overall, the main objective of Eurodia for water treatment applications is to develop small,compact, and simple units, consuming low energy (potentially powered by solar energy), and thatcan be installed in batteries for larger capacities.In the agro-food industries, EURODIA proposes complete process line for desalination andpurification of products such as whey, speciality sugars (Inuline, FOS, etc.), starches, and wine. Allthese processes combine several membrane technologies: such as ED, NF, and RO to propose themost cost effective processes with an “eco-friendly” strategy while obtaining the highest qualityend-products. In Brazil several plants are in operation for whey demineralization (DM90) and winemuststabilization.

SANASA Capivari II – The First Full Scale Municipal MBR in Latin AmericaRenato Rossetto 1 , Renata Lima Pereira de Gasperi 1 *, Juliana Pontes Machado Andrade 1 ,Rovério Pagotto Jr. 1 , Romeu Cantusio Neto 1 , Joubert Trovati 2 , Marcus Vinicius GueriniVallero 2 , Brian Arntsen 2 , José Everaldo Elorza Prado³1 Sociedade de Abastecimento de Água e Saneamento S/A - SANASA, 2 GE Water and ProcessTechnologies, ³E.M.A. Engenharia de Meio Ambiente Ltda,* tratamento.esgoto@sanasa.com.brThe macro region of Campinas (Brazil) is rapidly evolving with new housing developments andindustries, with the challenge of finding new ways to treat wastewater to a quality that can bereused in order to overcome water scarcity problems. To address this challenge, SANASA (publiclyowned water & wastewater concessionaire from Campinas) has recently constructed the “EPAR(Water Reuse Production Plant) Capivari II with the GE ZeeWeed 500D ® UF membrane system. This isthe first large scale MBR system in Latin America with biological tertiary treatment capability(nitrogen and phosphorus removal), being able to treat an average flow of 182 L/s in its first phase ofconstruction (Figure 1). The filtration system is composed of 3 membrane trains with more than36.000 m 2 of total membrane filtration area.Figure 1: Aerial view of the SANASA Capivari II Wastewater Treatment and Reuse Facility inCampinas, Brazil.The MBR plant was commissioned in April, 2012 and during the first year of operation permeatequality has exceeded expectations. COD removal rates are above 95% on a consistent basis. The

average permeate BOD 5 and NH 3 concentrations were respectively 0,92 mg/L and 0,15 mg/L, with aturbidity lower than 0,3 NTU (Table 1).Table 1 Summary of feed and effluent quality for the SANASA Capivari II MBR plant.ParameterFeed(raw sewage)Permeate(treated effluent)AverageRemovalRange Average Range Average (%)COD (mg/L) 650 – 770 725 17 – 30 23,4 96,9BOD 5 (mg/L) 324 – 390 360 0,5 – 2 0,92 99,8TKN (mg/L) 66 – 96 83 0,01 – 1,80 0,74 98,6NH 3 -N (mg/L) 32 – 69 54 0,01 – 0,29 0,15 99,7TN-N (mg/L) 68 – 97 85 4,5 – 6,9 5,3 93,8TP (mg/L) 8,2 – 10,0 9,1 0,98 – 7,35 3,05 73,0TSS (mg/L) 276 – 332 307 0,6 – 2,0 1,1 99,7Turbidity (NTU) - - 0,18 – 0,28 0,23 -Treated effluent is sent to a water reuse accumulation tank (from where in future reuse water will bepumped to potential customers) and currently it is being discharged to the Capivari River.This paper will present key information related to the MBR system design, start-up and operation,giving special attention to design recommendations for the generation of high quality effluent forpotential reuse. The procedures for the successful start-up of the MBR system will be discussed andthe performance data (biology performance and membrane performance) from the first year ofoperation will be presented.

Desalination of High Salinity Wastewater Using Electrodialysis: OperatingVariable Effects and Water Transport PhenomenaShingjiang Jessie Lue* and Jie-Ting YuDepartment of Chemical and Materials Engineering and Green Technology Research Center, ChangGung University, Kwei-shan 333, Taoyuan, TaiwanEmail: jessie@mail.cgu.edu.twThe objective of this study is to establish desalination efficiency for wastewater using electrodialysis(ED) technology. The effects of applied current density and process time on electrical efficiency,power consumption, salt rejection, and water recovery were investigated for industrial high-salinitywastewater from polycarbonate industry. In the electrodialysis of 6 % NaCl solution, the salt rejectioncould achieve 99.95 % with 60 % water recovery at 4 A (7.81 mA/cm 2 ). The power consumption was46.04 kWh/m 3 and average current efficiency was 47.09 % during the operation for 11 hours. Whenprocessing the industrial wastewater at the same current density, the rejection was 99.98 % with52.63 % water recovery. The power consumption was 131.18 kWh/m 3 and average current efficiencywas 20.08 % during the 13-hour operation. For industrial wastewater, the power consumption andoperating time were higher than that for the model NaCl solution to obtain similar desalination level.The water recovery in the ED process was studied and the water transports across the membranewere determined and ascribed to ion hydration and osmotic pressure effects. Water transport withhydrated ions was mainly affected by the salt reduction level. It was assumed that water loss for theindustrial wastewater due to ion hydration was the same as the model NaCl solution at thecomparable salt removal level. The water loss due to osmotic pressure was higher for the industrialwastewater than that of the model NaCl solution. The water loss could be as high as 2.55 L from 10-Lfeed in the former case. The water quality was evaluated before and after the ED process. Theconcentration of total dissolved solids, total organic compounds, ionic species, and conductivity werereduced by 99.77 %. This study demonstrates that ED is an effective way to recover and reclaimpurified water from high salinity wastewater.Fig. 1. Permeate conductivity decreased withoperating time at different applied voltages(12 and 20 V) on wastewater.Fig. 2. Permeate water loss in electrodializedwastewater due to hydration and osmosis as afunction of salt reduction level using differentdifferent applied voltages (12V and 20V).

Evolution of Ion-Exchange Membranes Behavior in Full Scale Electrodialysisfor Food IndustryW Garcia-Vasquez 1* , L Dammak 1 , C Larchet 1 , V Nikonenko 2 , D Grande 1 ,1 Institut de Chimie et des Matériaux Paris-Est (ICMPE) UMR 7182 CNRS, Thiais, France.2 Kuban State University, Krasnodar, Russia.* garcia-vasquez@icmpe.cnrs.frIn this communication, physico-chemical, structural and mechanical properties of ionexchangemembranes (IEMs) were investigated throughout their lifetime in a full scaleelectrodialysis (ED) stack used for whey demineralization, to get a deeper insight into theunderstanding of IEM degradation. This fundamental investigation reveals significant issuesconcerning IEMs properties and their long-term behavior. The approach is based upon theinterpretation of the membranes characterization in actual ED for whey demineralization bymeans of a systematic analysis of new samples and samples used at different times.Samples of a cation-exchange membrane (CEM) and an anion-exchange membrane (AEM),CMX-SB and AMX-SB respectively, were taken from an industrial ED stack at 45%, 70% and100% of their lifetime in whey demineralization (several thousands of h). To take out everysample it was necessary to stop the production and disassembly the ED stack; a fresh samplewas also studied to compare a new membrane with the used ones and to establish theevolution of membrane characteristics with time. This kind of membranes are made offunctionalized polystyrene crosslinked with DVB (PS-DVB) and finely powdered poly vinylchloride (PVC), all of this coated onto a PVC cloth used as reinforcing material. Membraneswere characterized by its physicochemical properties: conductivity, permeability, exchangecapacity, thickness, water uptake, contact angle; structural and elemental properties: SEM,EDX, FTIR, ICP, nitrogen sorption porosimetry, etc.; mechanical by the tensile strength test.The microheterogeneous model was applied to describe the samples structure/propertiesrelations.After characterization, it was seen that CEM samples were more robust and resistant thanthe AEM counterparts, which were more unstable. Furthermore, CEM samples were stillfunctional while AEM had to be replaced from the ED stack. The same phenomenon wasobserved previously when the same kind of membranes were studied for anotherapplication in ED for the food industry [1-3]. The results of AEM will be explained in furtherdetail to get a deeper insight into the understanding of AEM degradation.With increasing time of operation, the membranes became darker and more fragile. Therewas not a significant loss of the ion-exchange capacity or degradation of the functionalpoly(styrene-co-divinylbenzene). However, fouling (observed by FTIR) causes a decrease inthe counter-ion mobility within the membrane which produces a reduction of the electricalconductivity (Fig 1).

Conductivity (mS/cm)Contact angle (°)Permeability (10 -9 m 2 *s -1 )By means of SEM images and the BET specific surface area (Sp) it was possible toacknowledge that membrane porosity increased gradually with the time of operation. Thisexplains the increase in permeability by the appearance of new pores which form channelsfor non-selective electrolyte transfer.9.28.88.48.07.67.26.86.46.00 20 40 60 80 100Lifetime (%) Water content (%)282624222018• Thickness (mm)0.190.180.170.160.150.140.130.1210090807060503,02,52,01,51,00,50,00 20 40 60 80 100Lifetime (%)Fig. 1. Physico-chemical properties of AEM samples in function of their lifetime. Conductivity,water uptake, thickness and contact angle (right). 0.1M NaCl permeability (left)Via Soxhlet extraction with THF, 44% of the new membrane was recovered as extractable.This decreased gradually up to 11.4 for the membrane at 100% of lifetime. Extractable wasrecognized by FTIR we as PVC. Accordingly, new pores in the membrane were created by theloss of PVC washed out from the membrane during the cleaning-in-place process in ED.These new pores contribute not only to increasing electrolyte permeability, but also togrowing conductivity in the last stage of ED. The latter is due to the fact that there is asubstitution of non-conductive regions occupied by PVC for pores filled with electrolytesolution apparently containing also organic components of whey.The new AEM sample presented a combination of the mechanical properties associated withthe two polymeric components, i.e. the rigidity of PS-DVB and the toughness of PVC.However, the loss of PVC had severe consequences in the mechanical properties of the AEM.As it was seen in the stress-strain curves, the Young Modulus, which indicates the rigidity ofa material, decreased by 20% from A0 to A3. The breaking strength, which represents themembrane plasticity, decreased by 45% and the area under the stress-strain curvedecreased of almost 80%, which strongly indicated a loss of the material toughness.ConclusionWe have found that there are several events accompanying the process of membraneageing. Fouling occurs from the beginning of the operation leading to a decrease in thecounterion mobility. The following phases of membrane deterioration are apparently due tothe loss of PVC which results in formation of non-charged pores within the membranematrix, available for electroneutral electrolyte solution and for large molecules coming fromwhey. In addition, membrane toughness decreases. Gradually the AEM membraneconverted from rigid and tough to rigid and brittle material. This caused formation of cracksand tears leading to membrane final failure in the ED stack.

References[1] R. Ghalloussi, W. Garcia-Vasquez, N. Bellakhal, C. Larchet, L. Dammak, P. Huguet, D.Grande, Ageing of ion-exchange membranes used in electrodialysis: Investigation of staticparameters, electrolyte permeability and tensile strength, Sep. Purif. Technol., 80 (2011)270-275.[2] R. Ghalloussi, W. Garcia-Vasquez, L. Chaabane, L. Dammak, C. Larchet, N. Bellakhal,Decline of ion-exchange membranes after utilization in electrodialysis for food applications,Phys. Chem. News, 65 (2012) 66-72.[3] R. Ghalloussi, W. Garcia-Vasquez, L. Chaabane, L. Dammak, C. Larchet, S. Deabate, E.Nevakshenova, V. Nikonenko, D. Grande, Ageing of ion-exchange membranes inelectrodialysis: A structural and physicochemical investigation, J. Membr. Sci., In press(2013).AcknowledgementsThe study was realized within French-Russian laboratory "Ion-exchange membranes andrelated processes". We are grateful to CNRS, France, and to RFBR (grants 11-08-93107_CNRSL, 12-08-00188_CNRSL, 13-08-96508r_yug) Russia, and to FP7 Marie CurieActions "CoTraPhen" project PIRSES-GA-2010-269135 for financial support.

Preparation and Characterization of Nanofiltration Membranes based onPolisulfonamideCelina C. R. Barbosa 1 , Edna T. R. Bastos 1* , Elizabeth E.M. Oliveira 1 , Eliane P. B. Soares 1 ,Jaciara C. Silva 1 José Luis Mantovano 21Instituto de Engenharia Nuclear (IEN / CNEN)Rua Hélio de Almeida 75 – 21941-906 - Rio de Janeiro – Brasil* ednaruas@ien.gov.brAbstract. The membrane separation processes are becoming an increasingly important alternativepurification of the products and in water treatment in general. One such process is nanofiltration(NF), an intermediate process between reverse osmosis and ultrafiltration membranes. The NFmembranes have the property of separate molecules of low molecular weight and multipurpose ion[1]. NF membranes are obtained mainly by interfacial polymerization between a diamine and an acidchloride. The performance of NF membranes is dependent on several factors such as type and ratioof monomers used, preparation and condition of post-treatment. The piperazine (PIP) is a monomerwidely used for interfacial polymerization, which reacts with trimesoíla chloride (TMC), leading toformation of NF membranes poly (piperazinamida) [2] .This work aims to synthesize, characterize and evaluate NF membranes with selective layerpolisulfonamide obtained through the reaction between diamines: PIP/4,4diaminodiphenylsulfone(DDS) and the acid chloride (TMC) using as support the commercial membrane UF of poly (ethersulfone) (PES). The membranes were characterized as transport properties and content of DDSincorporated in the selective layer for the following analyzes: Infrared (IR) and X-ray diffraction.Experiments to determine the transport properties: permeate flux and rejection of sulphate ionswere performed using a permeation system with displacement tangential flow with operatingpressure of 15 bar. The concentration of sulfate in the solutions permeated and feeding weredetermined in ICS-1000 ion chromatograph and the rejection of the membranes calculated accordingto the equation:R (%) = (1-Cp/Ca) x100Regarding the results it can be concluded that the rejection of sulphate ions decreases withincreasing content of DDS, probably due to the larger size pores of the selective layer. Through X-raydiffraction was confirmed incorporation of the DDS in every synthesized membrane.Keywords: nanolfiltration,polisulfonamide, interfacial polymerizationReferences[1] W. J. Lau, A. F. Ismail, N. Midsdan, M. A. Kassim. A recent progress in thin film composite membrane: areview, Desalination. (2011) 1-10.[2] M. Jahanshahi, A. Rahimpour, M. Peryavi. Developing thin film composite poly (piperazine-amide) and poly(vinyl-alcohol) nanofiltration membranes, Desalination 257 (2010) 129-136.

Development of Sulfonated Polysulfone Composite Membranes forAmmonium RejectionEdna T. R. Bastos *1 , Celina C. R. Barbosa 1 ,Jaciara C. Silva 2 , Vanessa B.C. Queiroz 2 and DelmoS. Vaitsman 31Instituto de Engenharia Nuclear (IEN / CNEN)Rua Hélio de Almeida 75 – 21941-906 - Rio de Janeiro – Brazil2 Bolsista CT/Petro3Departamento de Química Analítica, Instituto de Química, Universidade Federal do Rio deJaneiro,Av. Athos da Silveira Ramos, 149, room A-519 – 21941-909 - Rio de Janeiro – Brazil* ednaruas@ien.gov.brAbstract. In the present investigation, were synthesized compositemembranes prepared by simultaneous casting of two polymersolutions using the technique of phase inversion by immersion /precipitation [1,2]. The support layer was prepared usingpolyethersulfone and polysulfone as base polymer and for the toplayer was used sulfonated polysulfone (SPSU) with 50% sulfonationdegree [3,4] . The morphology of the resulting membranes wascharacterized by scanning electron microscopy (SEM). The finalresults showed that it is possible to prepare composite membranesby simultaneous casting of two polymer solutions with adherencebetween the two layers. Regarding the permeation tests, thedeveloped membranes presented values of hydraulic permeabilitywithin the range of commercial nanofiltration (NF) membranes [5,6](Table 1). Values rejection of 80% ammonium ions can be increasedby using a SPSU with a greater degree of sulfonation [7].

CodeMembraneTable - Transport Properties of the compositemembranes synthesized and commercialPermeateflux(L/m 2 . h)Hydraulicpermeability(L/m 2 h. bar)(NH 4 ) 2 SO 4(%) R NH4+NH 4 ClM-12 18 2.0 71 4M-15 2 1.2 80 4M-22 24 4.1 78 4M-23 29 8.0 15 3M-30 131 22.1 < 1 < 1M-32 123 19.1 < 1 < 1*DK 12 2.4 99 3*DL 11 2.0 92 3*commercialKeywords: polysulfone sulfonated; composite membrane; ammoniumrejection.References[1] Bastos, E.T.R. (2006), “Development and application of polymericmembranes in the removal ammonium in wastewater" Universidade Federaldo Rio de Janeiro, Brazil.[2] Chen, S.H., Liou, R.M., Lin, Y.Y., Lai, C.L., Lai, J.Y. (2009), "Preparation andcharacterizations of asymmetric sulfonated polysulfone membranes by wetphase inversion method", European Polymer. J., 45, 1293-1301.[3] Ding, Y., Bikson, B. (2010), "Preparation and characterization of semicrystallinepoly (ether ketone) hollow fiber membranes", Journal ofMembrane Science, 357, 192–198.[4] Lufrano, F., Baglio, V., Staiti, P., Arico, A. S., Antonucci, V. (2006),"Development and characterization of sulfonated polysulfone membranesfor direct methanol fuel cells" Desalination, 199, 283- 285.[5] Mulder, M. (2000), Basic principles of membrane technology, 2 nd ed.,Kluwer Academic Publishers, Dordrecht.[6] Schafer, A.I., Fane, A.G. and Waite, T.D. (2005), Nanofiltration: principlesand applications, Elsevier, Oxford.[7] Mashallah, R., Saeed, S., Sayed, N.A. (2012), “Simulation of ammoniaremoval from industrial wastewater streams by means of a hollow - fibermembrane contactor" Desalination, 285, 383-392

Selectivity of Nanofiltration Membranes for Treatment of Liquid WasteContaining UraniumElizabeth E. M. Oliveira 1* , Celina C. R. Barbosa 1 and Júlio C. Afonso 21Instituto de Engenharia Nuclear (IEN / CNEN)eemoju.gmail.com2Departamento de Química Analítica, Instituto de Química,Universidade Federal do Rio de JaneiroThe Nuclear Fuel Factory of INB is one of the most modern industry for the production of nuclear fuelfor the light water reactors PWRs (Pressurized Water Reactor), adopted by Brazil for the generationof nuclear-electricity. These reactors use enriched uranium in the isotope 235, which to the undergofission generates thermal energy in the reactor core. The production of uranium dioxide (UO 2 ) fromthe reconversion of uranium hexafluoride gas (UF 6 ) is the most important step in the cycle of nuclearfuel. The UF 6 (g) is heated in an autoclave and vaporized into a tank containing demineralized waterto 100 º C, where it is mixed with other two gases: carbon dioxide (CO 2 ) to prevent clogging of thenozzle of UF 6 and ammonia gas (NH 3 ) [1]. The chemical reaction between these compounds producesuranato tricarbonate (VI) ammonium known as (TCAU), yellow solid water insoluble. Theregenerating streams of waste liquid containing uranium, one of these waste streams is called"carbonated water" due to the presence of high concentration of CO 3 2- in its composition, this wasteis originated from washing of the gases generated in the thermal hydrolysis of the uranato thetricarbonate (VI) and ammonia is generated a volume of approximately 2.5 m 3 per tonne of uraniumoxide. This type of waste can contain up to 0.050 g L -1 of uranium in solution. The goal is recover theuranium, which may return to the productive process of UO2 pellets. The application of PSM in thetreatment of radioactive waste is relatively recent, only in recent years membrane technology hasbeen gradually introduced in the nuclear area for the treatment of radioactive waste of low andmedium activity (

References*1+ “Indústrias Nucleares do Brasil, http://www.inb.gov.br (2009).*2+ Z.T. Grażyna, H. Marian and, G.C. Andrzej (2001), Separation and Purification Technology., 22-23, 617-625.[3] Z.T. Grażyna, Journal of Membrane Science 225, (2003), p 25-39[4], S.J. Macnaughton, J.K. McCulloch, K. Marshall and, R.J. Ring (2002), in Technologies for the treatment ofeffluents from uranium mines, mills and tailings, IAEA, Vienna, pp. 55-65.[5] CONAMA - National Brazilian Environmental Council (2005), Directory 357, March 17, 2005, Official Journal,March 18 (in Portuguese).[6] CNEN - Directory 6.05 (1985), Radioactive wastes management in nuclear installations, CNEN, Brasília (inPortuguese).[7] M. Dulama, N. Deneanu, E. Dumitru, I.V. Popescu and M. Pavelescu (2008), Proceedings of NUCLEAR 2008annual international conference on sustainable development through nuclear research and education,Pitesti, May, pp. 426-433.[8] L. Kwang-Lung, Chu, Min-Lin and Shieh, Mu-Chang (1987), Desalination, 61, 125-136.[9], A.I. Schäfer, A.G. Fane and, T.D. Waite (2005), Nanofiltration: principles and applications, Elsevier, Oxford,2005.

Clarification of RED Beetroot Juice Using Rotating Ceramic Membrane Discs toObtain a Betalain Pigment SolutionBeatriz Cancino-Madariaga*, Andrés Ramírez Salvo, Paula Pinto VillegasINPROMEM E.I.R.L. (Research in membrane Process) Address: Carrera 241, Villa Alemana, CHILE.bcancinomadariaga@gmail.comRed beetroot (Beta vulgaris) is one of the most important sources of betalains used in food coloring.Betalains have healthy properties and can be used as additives in desserts, baked foods, dry mixes,dairy products and meat products. Common betalain extraction from red beetroot is generallyperformed using water mixed with organic solvents such as methanol or ethanol. However,nowadays there is an increased preference for natural extraction methods without the addition ofsolvents. Thus, the use of membranes and warm water extraction is an alternative for juiceclarification. The clarified pigment solution can then be concentrated by other membrane processes,such as Nanofiltration. The aims of this work we present the use of rotating ceramic membrane discs(RCMD), to clarify a red beetroot juice to obtain a betalain pigment solution free of turbidity.Methods. To obtain the betalain solution, fresh beetroot was processed. The steps in the operationwere peeling, milling, warm water extraction and centrifugation. The liquid phase was used as theprocess fluid for microfiltration. An RCMD with an area of 0.1 m2 and a pore size of 0.2 µm was used.Since the turbulence of the membrane leads to fouling, permeability and membrane foulingresistance were studied. The RCMD was tested at 15 °C with water at different rotation frequenciesbetween 0 and 30 Hz and between 0 and 1.4 bar obtaining a model function. The RCMD with theprocess fluid was also studied at the same temperature and rotating frequency, and with twotransmembrane pressure levels (TMP), 0.6 and 0.8 bar. Turbidity, sugar and betalains weredetermined. Turbulence was measured in terms of Reynold and shear stress (SS). The influence ofthe feed flow was also studied using two different pumps.Results. The model function to describe the behavior of the water was obtained. The behavior for theprocess fluid at different frequencies was also developed for TMP levels of 0.6 and 0.8 bar. For bothTMPs the turbidity in the permeate was 0; however, there are differences in the flux. The best fluxfor 0.6 bar, was 1.55 •10 -5 m³/m²s at 20 Hz. The flux was optimal at this frequency. There was noinfluence from the pumps on the behavior of betalain permeation or on permeate flux. The SS of theRCMD depends on the rotation frequency, with less than 1 s -1 not relevant.Conclusions: SS produced by RCMD is not relevant for betalain properties, as structure andcharacteristics are maintained. The betalain transmission is over 80% depending on rotationfrequency and TMP. The clarification of the red beet juice using RCMD is complete, producing apermeate with 0 NTU of turbidity.

Study of Parameters on Preparation of Composite Membranes Based onActivated CarbonKarla Patricia Macedo Licona*, Marcello Pojucan Magaldi Santos*, Amal Elzubair Eltom**and José Carlos da Rocha** National Institute of Technology** Metallurgical and Materials Engineering Program, COPPE/UFRJIn this work, membranes based on activated carbons have been studied, and because of thelarge surface area and, consequently, adsorption capacity of pores, has a wide use forpurification of liquids or gases in its fullness. The basic idea is the sophistication oftechnologic domain to obtain composite membranes based on organic resin – activatedcarbons that have apparent porosity as UF membranes. The membranes were prepared with40% epoxy resin and 60% commercial activated carbon MADECARBO® micro and mesaporous, raw state and dried at 100° C, analyzing three types of solvents (toluene, ethylacetate and ethyl alcohol). The physical properties, as Arquimedes density, showed apparentporosity between 47%-70% to raw carbon and 49%-62% to dried carbon. The microstructureof the specimens was evaluated by scanning electron microscopy, indicating goodhomogeneity of the resin-carbon interaction for both formulations with raw and driedcarbons. The flow tests were performed in a cell test for tubular membranes that simulatesparallel flow type filter. For the flow, the formulation that presented lowest results of thisproperty was the carbon dried in ethyl acetate. As for the raw carbon, the lowest flow resultobtained was the same dried carbon but dried in ethyl alcohol. From the results, it wasconcluded that this filtration systems are strongly influenced by the formulation obtainingprocess and, consequently, the microstructure plays an important role for the type offiltration obtained.

Definition Of The Limiting Flux Condition In The Nanofiltration Of A GrapeMarc Extract Containing 30% EthanolAna Paula Gil Cruz¹*, Natalia Barbosa Eitel², Luiz Fernando Menezes da Silva³, Suely PereiraFreitas², Alexandre Guedes Torres¹, Lourdes Maria Correa Cabral³¹Universidade Federal do Rio de Janeiro/UFRJ, Instituto de Química, Rio de Janeiro, Brasil. -ana_gil@uol.com.br.²Universidade Federal do Rio de Janeiro/UFRJ, Escola de Química, Rio de Janeiro, Brasil.³ Embrapa Agroindústria de Alimentos, Rio de Janeiro, Brasil.Grape marc, being composed of skins and seeds, presents an interesting composition in phenoliccompounds, whose recovery has aroused the interest of research and productive sectors [1]. Extractsrich in natural antioxidant compounds are being tested as ingredients in food formulations to inhibitthe creation of free radicals and / or interrupt the auto oxidation, allowing a reduced use of artificialadditives in ready for consumption food preparation [2].However these compounds are more efficiently extracted using solvents, which often hinder theirconcentration by membrane separation processes [3]. The ethanol content in the feed fraction maybe a limiting factor for membrane processes [4]. On the other hand, the temperature and pressureapplied to the system can also influence the permeate flux. The objective of this study was,therefore, to determine the limiting flux in the nanofiltration of a Pinot noir grape marc extractcontaining 30% ethanol. Thus, the extract was obtained as by [5] and the limiting flux determined atdifferent temperatures. The nanofiltration system used was composed of a polyamide spiral woundmembranes with maximum working temperature of 45°C.As the extraction was carried out at 50°C, this temperature didn’t damage the bioactive compounds.The limiting flux was determined at 20, 30 and 40°C temperatures at a flow rate of 700 L h -1 . Asexpected, increasing temperature had a positive influence in the permeate flux (Fig. 1). However, thiseffect wasn’t linear, i.e. the increase observed from 20 to 30°C wasn’t the same as from 30 to 40°C.Higher temperatures increase the permeate flow. As concluded the rheological study of the extractperformed by [6], this is a non-Newtonian, shear thinning and temperature dependent fluid. Thepressure also had a positively action on the permeate flux. The limiting flux was reached at 20°C and30°C with pressure of 16 bar, while the 40°C limiting flow has been reached at a transmembranepressure of 12 bar. Thus, the best condition for the nanofiltration of grape marc extract containing30% ethanol was 40°C with a 12 bar pressure applied to the system.

Fluxo de Permeado (L.h-¹.m²)15010020°C30°C40°C5000 5 10 15 20 25P (Bar)Figure 1 – Limiting fluxReferences:[1] C. BRAZINHA and J. CRESPO (2010), Filtration + Separation (2010).[2] M. S. BREWER (2011), Comprehensive Reviews in Food Science and Food Safety (2011) 221-242.[3] M. TSUI and M. CHERYAN (2004), Journal of Membrane Science, 237, 61-69.[4] N. LEIDENS (2011), UFRGS, 37p.[5] A. P. G. CRUZ et al. (2012), XXII Congresso Brasileiro de Fruticultura, 5059-5062.[6] C. C. B. HIGTINO (2012), UFRJ, 87p.

Evaluation Of Reverse Osmosis And Nanofiltration For The Concentration OfBioactive Compound Recovered Of Grape MarcAna Paula Gil Cruz¹*, Natalia Barbosa Eitel², Luiz Fernando Menezes da Silva³, Suely PereiraFreitas², Alexandre Guedes Torres¹, Lourdes Maria Correa Cabral³¹Universidade Federal do Rio de Janeiro/UFRJ, Instituto de Química, Rio de Janeiro, Brasil. -ana_gil@uol.com.br.²Universidade Federal do Rio de Janeiro/UFRJ, Escola de Química, Rio de Janeiro, Brasil.³ Embrapa Agroindústria de Alimentos, Rio de Janeiro, Brasil.In the food industry, especially in the ones of fruit and vegetable processing, it’s estimated that 10 to60% of the feedstock turn into waste [1]. In Brazil, about 57% of the grape crop is destined forprocessing. Grape marc is the generated residue in greater volume, 16% of the processed grapes [2].The disposal of this waste presents serious environmental constraints, caused by high chemical andbiochemical oxygen demand, which increases the need for treatments with higher costs associated.However, this co-product stands out for its rich composition in bioactive compounds, which may berecovered. This recovery increases its value and can reduce the costs of its treatment to a properenvironmental disposal.The membrane separation processes, particularly the ultra- and nanofiltration and reverse osmosis,have been studied as a technology with great potential to concentrate and to achieve a betterstability of phenolic compounds [3], which are easily degraded in the presence of inadequate oxygenconcentrations, pH, temperature and other inadequate conditions [4]. However, the extraction ofthese compounds is more efficient with the use of solvents instead of water [5]. On the other hand,the presence of a solvent may impair the concentration in polymeric membranes, since those caninteract with the membrane material, in such a way the membranes could lose their permeabilityand selectivity characteristics or also their integrity [6].Thus the aim of this study was to evaluate the use of a reverse osmosis membrane and nanofiltrationsystems for the concentration of bioactive compounds from a grape marc extract containing 70%ethanol. A reverse osmosis polyamide membrane has been tested on a plate and frame system withtotal filtering area of 0.288 m². The nanofiltration membranes tested were the ceramic, α-alumina, atubular type with 0.023 m² and a polymer polyamide-spiral type with a total area of 2.5 m². Theethanol present in the extract interacted strongly with the reverse osmosis membrane, whoseintegrity was lost after the second process. The ceramic membrane was not efficient for theconcentration of the compounds of interest, which have permeated. The nanofiltration membranewas the most efficient system for concentrating these compounds. The retention coefficient reached98% for phenolic compounds and 100% for anthocyanins.

a b cFigure 1 – Nanofiltration streams of a 70% hidroethanolic extract obtained from a white winegrape marca- Feed Stream; b- Retentate; c- PermeateReferences:[1] W. E. EIPESON and R. S. RAMTEKE (2003), In: H. S. Ramaswamy, et al. Handbook of Postharvest TechnologyCereals, Fruits, Vegetables, Tea, and Spices, cap. 28 , 819-844.[2] M. A. BUSTAMANTE et al. (2008), Waste Management, 28, 372-380.[3] B. DÍAZ-REINOSO et al. (2009), J. of Food Eng., 91, 587-593.[4] M. NAZCK and F. SHAHIDHI (2004), J. Chromatography A, 1054, 95–111.[5] J. CHANDRASEKHAR et al (2012), Food and Bioproducts Processing, 90, 615-623.[6] E. M. TSUI and M. CHERYAN (2004), Journal of Membrane Science, 237, 61-69.

New Polyamide Membranes from PAMAM and Glutaraldehyde1 Hilenio da Silva Monteiro, 1 Liana Camboin, 1 Mylene Fernandes, 2 Alberto Claudio Habert,3 Vanessa Rodrigues Furtado *1 Escola de Química/UFRJ, 2 COPPE/UFRJ, 3 Instituto de Química/UFRJvanessa@iq.<strong>ufrj</strong>.brNew polyamide membranes have been prepared from PAMAM G4 dendrimer and glutaraldehyde byinterfacial polymerization over a polyethersulphone microporous support [1], followed by crosslinkof the polymer clusters with glutaraldehyde. PAMAM G4 is a globular polymer with a highlyfunctionalized surface (64 primary amines) and inner voids with controlled size. Synthesisparameters explored included glutaraldehyde/PAMAM molar ratios (ranging from 8 to 64), thePAMAM G4 solution concentration, in addition to polymerization and crosslinking reaction times.Membrane characterization was evaluated measuring surface roughness, permeability and molecularweight cut-off for several standards organic and inorganic solutes.The membranes were resistant to acidic and slightly alkaline pH (pH 8) and their performance werestable in extended runs experiments, with excellent reproducibility. The best performances wereachieved with membranes prepared with glutaraldehyde/PAMAM molar ratios between 16 and 32and PAMAM concentrations between 10 and 25 mg/mL. Measured fluxes ranges from 7 to 20 L/h.m²for operating pressures of 12 to 20 bars. Typical rejection values from 90 up to 100% were obtainedfor polyethyleneglicol (MW 1,000 to 20,000), while ionic solutes such as for NaCl and MgSO 4 showedresults from 80 to 95 %. No fouling effects were observed.As the PAMAM dendrimer polyamide membranes allow inner void size control by changing thereaction variables, and a further surface modification, conveniently achieved due to the reactivity ofthe PAMAM surface amines, the results indicate good prospects of this material for nanofiltrationapplications.[1] L.M. Jin, S.L. Yu, W.X. Shi, X.S. Yi, N. Sun, Y.L. Ge, C. Ma (2012), Polymer 53 (2012) 5295e5303