Standard Details for Metal Roofing & Siding - Best Materials

Standard Details for Metal Roofing & Siding - Best Materials

Standard Details for Metal Roofing & Siding - Best Materials

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

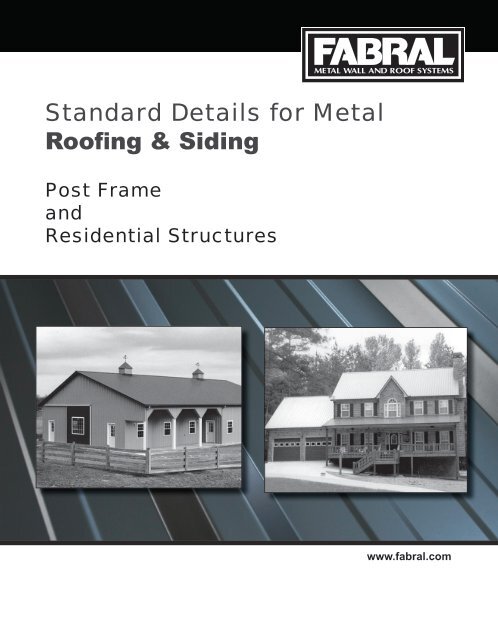

<strong>Standard</strong> <strong>Details</strong> <strong>for</strong> <strong>Metal</strong><strong>Roofing</strong> & <strong>Siding</strong>Post FrameandResidential Structureswww.fabral.com

Table of ContentsInstallation Instructions 2 - 3Paint System & Warranties 4Steel Panel Profiles 5 - 6Aluminum Panel Profiles 7Post Frame Estimating & Roof Types 8Post Frame Building <strong>Details</strong> 9Post FrameFlashings/Trim 10 - 13Post Frame Trim <strong>Details</strong>: 13 - 30Box Gable - 13Endlap & Rain Carrying Table - 14Eaves - 15-16Ridges - 16-18Gables - 18-19Flying Gable - 20Endwall - 21Sidewall & Valley - 22Gambrel & Transition - 23Outside Corner - 24Inside Corner & Base Guard - 25Door Jambs & Headers - 26-29Translucent Panels - 29Window <strong>Details</strong> - 30Residential Building <strong>Details</strong> 31Residential Load Tables & Profiles 32Residential Flashings/Trim 33Residential Trim <strong>Details</strong>: 34 - 43Ridges - 34Eaves - 35Gable & Endwall - 36Sidewall & Gambrel - 37Transition & Pipe Boot - 38Skylight & Chimney - 39-41Dormer <strong>Details</strong> - 42-43Accessories 44**Due to Product improvements, changes and other factors, Fabral reserves the right to change or delete in<strong>for</strong>mationherein without prior notice or obligation to make changes in products previously purchased.

Installation InstructionsBuilding Design and ConstructionIn order to ensure the anticipated per<strong>for</strong>mance and longevity,protect metal panels from potentially corrosive situations and materials.When treated lumber will be in direct contact with metal panels or flashingsplease note the following: Galvanized steel is compatible with theCCA (Chromated Copper Arsenate) pressure-treated lumber that waspredominantly used be<strong>for</strong>e 2004, but not with the older Penta treatedlumber or the new ACQ (Alkaline Copper Quartenary), CA (CopperAzole), or CBA (Copper Boron Azole). Stainless steel or other specialtreated fasteners should be used into these non-compatible pressuretreated lumbers. Aluminum must be separated from contact with alltreated wood since the soluble copper in the preservative is corrosive toaluminum. Likewise, dissimilar metals also require a protective barrierbetween them to prevent galvanic corrosion. Request FABRAL TechnicalBulletins #803, 106, and 107 <strong>for</strong> more in<strong>for</strong>mation on treated lumberand dissimilar metals.Plastic, builders’ felt, bituminous paint, caulking, or gasketmaterial may be used to separate panels from treated woodand dissimilar metals. When using aluminum panels in direct contactwith steel, use a separator as described above and fasten with StainlessSteel screws.Fertilizer, lime, acids, feeds, manure, soils, and many othercompounds also cause corrosion in metal panels. Contact betweenmetal panels and any potentially corrosive materials should be prevented.Porous insulation materials may absorb and retain moisture,and should not be used in direct contact with metal panels. Use a vaporbarrier such as polyethylene plastic or 30-lb felt to prevent moisturefrom contacting both the insulation and the metal panel.FABRAL’s translucent panels are intended <strong>for</strong> siding applicationsonly. In all situations, foot traffic should be avoided on translucentpanels. Translucent panels used in roofing applications will break downin a short time and cause staining and premature corrosion of the metalpanels below. If used on roofs, apply butyl caulking to separate thefiberglass panels from the metal. Translucent panels should be cleanedand sealed regularly, as recommended by the translucent panel manufacturer.Purlins, Girts and Roof DeckThe substructure to which the metal panels are fastened mustbe properly spaced and sufficiently thick to provide a roof or wall systemable to meet required design loads.A 2” nominal lumber thickness provides the maximum pulloutvalues <strong>for</strong> both screws and nails when the fasteners penetrate aminimum of 1” into the wood. Since 1” nominal lumber and solid deckingare thinner, they provide somewhat lower pullout values. When usingpurlins, FABRAL recommends a maximum spacing of 24” on-center(note that 5V requires solid decking). Pullout values decrease if thefasteners protrude completely through the purlins. Kiln-dried softwoodis recommended <strong>for</strong> purlins or decking (pine, fir, hemlock, and spruce).Hardwoods are difficult to fasten into without splitting and contain tannicacids that are corrosive to metal panels. Green (non-kiln-dried) lumbermay warp, twist, and shrink as the wood seasons fully, causing wavinessin the panels as well as loosening and leaking of the fasteners.Solid decking is highly recommended <strong>for</strong> all residential applications.When usingsolid decking or sheathing, always use 30-lb feltor underlayment and plan on using closerfastener spacing and larger diameter #14 screws. (Refer to the tableson page 31).On re-roofing projects where the condition of the old deckingis in question, or where existing shingles will be left in place, new 2x4purlins should be fastened through the decking and into the rafters. Thiswill provide a solid framework <strong>for</strong> attaching the metal panels. For moredetailed in<strong>for</strong>mation on Re-roofing applications, consult FABRAL TechnicalBulletin #721, Re-<strong>Roofing</strong> With <strong>Metal</strong>. Load tables are available <strong>for</strong>all FABRAL panels; contact FABRAL <strong>for</strong> additional in<strong>for</strong>mation.<strong>Roofing</strong>Panel sidelaps should face away from wind driven rain. Toaccomplish this, begin by installing the first sheet square with theeave and gable at the down wind end of the roof, farthest away fromthe source of prevailing winds.In applications requiring a panel endlap, please refer to thedetailed instructions in this booklet. For best results, lap panels asshown and install in the indicated sequence. All endlaps require sealant.When weather-tightness is critical, use sealant tape in all sidelaps.To provide a drip edge, allow an overhang of 1 to 2 inches atthe eave. At the gable edge, use a gable or sidewall flashing. This willkeep weather out, prevent lifting in high winds, and provide a neat, finishedappearance. The trim and roofing sheet should be fastened every12 to 24 inches along the gable edge.Roof PitchThe metal roofing panels shown in this manual require a minimumslope of 2½” per foot to ensure proper drainage. Refer to the raincarryingtable in this booklet <strong>for</strong> the maximum allowable panel length perslope that will provide adequate drainage. For longer slopes and lowerroof pitches, contact FABRAL <strong>for</strong> other suitable profiles.Bending and BowingAluminum roofing and siding sheets are roll<strong>for</strong>med from hardened,tempered metal <strong>for</strong> maximum strength. If a sheet must be bent,a gentle 90-degree bend is the maximum recommended. <strong>Metal</strong> shouldnot be re-bent once it has been <strong>for</strong>med, nor should it be folded back onitself. When a metal roofing sheet must be installed on a curved roof,screws should be installed at every overlapping rib at the sheet endsto resist the natural tendency of the metal to spring back. The standardfastening pattern is permitted over the rest of the sheet. When installingthe metal panels shown in this booklet over a curved arch, the minimumradius of the arch is 18’ <strong>for</strong> aluminum panels and 24’ <strong>for</strong> steel panels.Use sealant tape or butyl caulking at all sidelaps and endlaps.Additional care and fasteners must be provided when securing the topand bottom purlins on an arched rafter building to prevent the curvedpanels from pulling the purlins loose from the rafters. Ring-shank polebarn nails, heavy wood screws, lag screws, or bolts are often used <strong>for</strong>attaching these purlins.<strong>Siding</strong><strong>Siding</strong> should be installed using the standard fastening andoverlap patterns to ensure optimum per<strong>for</strong>mance. For strong, neat cornersuse hemmed corner flashings. Do not run siding sheets all theway to the ground. Instead, provide a protective base of concrete,masonry, treated wood, or similar material and terminate the sidingsheets 6” above grade.2

Installation InstructionsIf siding sheets are installed horizontally, use sealant tape orbutyl caulking at the vertical laps to ensure weather-tight joints. Installpanels from the bottom up so that water is directed away from, and notinto, the lap joints.FasteningFABRAL can supply either screws or nails <strong>for</strong> fastening intodimension lumber, with screws offering better pullout values. Alwaysuse screws with solid sheathing. Screws <strong>for</strong> use with steel panels aregalvanized and then coated with an organic polymer <strong>for</strong> optimum corrosionresistance. For best results with aluminum panels, use #300series stainless steel screws.The FabrOseal® galvanized ring-shank nail, with its premiumlong-life silicone rubber gasket, assures a lasting seal and is the bestnail available <strong>for</strong> steel panels when screws are not desired.The correct way to fasten steel panels with nails is to drivethe nail through the top of the rib so the washer is compressed securelyagainst the metal. Nail placement must be in the ribs <strong>for</strong> roofing applicationsto minimize the potential <strong>for</strong> roof leaks. Over-driving the nailcan split the washer and dimple the metal, causing leaks.Correct Under-Driven Over-DrivenWood screws with combination metal and neoprene washersshould be installed in the flat area of the panel adjacent to the ribs, andtightened such that the washer is compressed as illustrated above. Thiswill ensure a lasting, leak-proof seal. Remove any metal filings createdby the drilling action of the screws to avoid rust staining on the panelsurface. Refer to the fastening schedules in this booklet <strong>for</strong> the correctfastener locations.Flashing and TrimAlways begin flashing installation from the bottom and workup, so that upper flashings are lapped on top of lower flashings. This willprevent moisture from leaking under the flashings and into the structure.Endlap flashings a minimum of 6” and seal the lap joints with sealant.Extend flashings 4-6” beyond the building, cut along the bend lines, applysealant, and fold the side flaps in and the top flaps down to cap offthe ends. Secure with pop-rivets or stitch screws.Some roof conditions, such as valleys, may require a longerendlap and/or a larger flashing to properly drain moisture from the roof.Factors that influence flashing size, shape, and endlap requirementsinclude roof pitch, roof geometry, slope length, and climatic factors (suchas heavy snowfall or rainfall).Whenever possible, begin trim installation at the downwindend of the roof, farthest away from the source of prevailing winds, to allowflashing laps to face away from wind-driven rain. Refer to the detailsin this book <strong>for</strong> the proper location of fasteners and sealants.The flashings and trims shown in this book are standard parts.Custom trims are available to meet your specific design needs. If youneed a special trim, please furnish a drawing of the desired shape, includingdimensions and angles, to your Fabral dealer to obtain pricingand availability.Refer to the SMACNA Architectural Sheet <strong>Metal</strong> Manual<strong>for</strong> additional in<strong>for</strong>mation about detailing and installingflashings.SafetyAlways work safely when installing metal products and useextreme caution on the roof at all times. Wear gloves and safety glassesto reduce the risk of injury, and use hearing protection when operatingpower tools. Always be sure that ladders are safely positioned andproperly secured. Safety harnesses or other special equipment maybe required; be sure to Consult OSHA guidelines <strong>for</strong> compliance withall safety requirements.Do Not walk on panels until all the fasteners are installed.<strong>Metal</strong> roofing panels are slippery when wet, dusty, frosty, or oily -- DoNot attempt to walk on a metal roof under these conditions. Wear softsoledshoes to improve traction and to minimize damage to the paintfinish. Always be aware of your position on the roof relative to any roofopenings, roof edges, co-workers, and penetrations. Installing metalpanels or flashings on a windy day can be dangerous and should beavoided if possible.Cutting Aluminum PanelsTo make a cut parallel to the ribs, score the panel deeply witha sharp utility knife and bend back-and-<strong>for</strong>th along the score, breakingthe metal off cleanly. For cuts across the ribs, use straight-cut snips,electric or pneumatic shears, a portable profile shear, or an electricnibbler. Some installers prefer using a circular saw with a metal cuttingblade (a fine-tooth hardwood blade, or a standard combination bladereversed in the saw works also). Light oil or soap on the blade willmake cutting easier.Cutting and Drilling Steel PanelsSteel panels may be cut with metal snips, electric or pneumaticshears, a portable profile shear, or an electric nibbler. Someinstallers prefer using a circular saw to cut metal panels. Do Not useself-consuming abrasive blades because of the following: 1. Abrasiveblades burn the paint and galvanizing at the cut edge, leaving edgesthat are jagged and unsightly and rust more quickly 2. Abrasiveblades produce hot metal filings that embed in the paint and cause rustmarks on the face of the panel 3. All saw cut panels must be turnedface down and cut in a location down-wind and well away from thebuilding and other panels to avoid embedment of metal filings on otherpanels 4. All saw cut panels must be thoroughly wiped to ensure theremoval of all metal filings. If saw cutting cannot be avoided, select acarbide-tipped blade specially designed <strong>for</strong> cutting light-gage ferrousmetal panels. These blades are now available at many home centersand lumber yards. Pre-drilling wall panels gives uni<strong>for</strong>m alignment ofscrew rows. Be sure to remove drill filings once panels are installed toavoid rust marks from the filings.Building MaintenanceA metal roof should be inspected annually and cleaned as necessaryto maintain its beauty and per<strong>for</strong>mance. Any debris or residue, includingleaves, twigs, and dust should be cleaned off promptly to preventmoisture entrapment against the metal, which may lead to finish deteriorationor premature corrosion. Flashings may need to be re-sealedperiodically in order to maintain optimum weathertightness.3

Paint System & WarrantiesEnduracote is a paint system that takes per<strong>for</strong>mance to the next level. Based oncutting edge resin technology, this system offers unbeatable durability and superiorlong-term per<strong>for</strong>mance against the elements.The Enduracote Warranty• Lifetime film integrity <strong>for</strong> walls & roofs• 30-year against fade & chalk• 10-year edge rust against acid rainFor profiles: Grand Rib 3®, Alu-Tuff II, 5V Crimp, ProClad,StrongClad, Mighti-Rib®The Enduracote PLUS Warranty• Lifetime film integrity <strong>for</strong> walls & roofs• 30-year against fade & chalk• 15-year edge rust against acid rain• 25-year non-per<strong>for</strong>ation against acid rain<strong>for</strong> walls; 20-years <strong>for</strong> roofsFor profiles: Grand Rib 3® PLUS, Alu-Tuff, 1 1//2” SSR,ClimaguardGRANDRIB 3 ® , ALU-TUFF II, 5V, PRIME RIB, STRONGCLAD TM26 GAGE MIGHTI-RIB & ULTRA-RIB PANELSLIMITED LIFETIME ENDURACOTE TM PAINT WARRANTYPERFORMANCE GUARANTEEFabral, a Euramax Company, Lancaster, PA, hereinafter referred to as "Fabral" or "Seller," guarantees that within the continental United Statesnormal outdoor atmospheric conditions (which term excludes corrosive or aggressive atmospheres including, but not limited to those contaminatedwith chemical fumes or salt spray) will not cause the exterior side paint on the ENDURACOTE TM galvanized steel roofing and siding panels sold toyou under this guarantee to:1. Crack, check, or peel <strong>for</strong> the lifetime of the building <strong>for</strong> sidewall panels and roofing panels.NOTE: A crack is a break in the coating sufficiently deep that the underlying surface is visible. Checking refers to shallow breaks in the coatingwhich do not expose the underlying surface. Peeling occurs when the coating actually comes off the metal in pieces. Slight crazing or crackingmay occur on roll <strong>for</strong>med edges or break bends at the time of <strong>for</strong>ming and should be considered as standard and shall not constitute a basis <strong>for</strong>complaint under this warranty. However, the film will not lose adhesion to the substrate when cellophane tape applied at the bend is removed.2. Chalk in excess of a numerical rating of eight (8) <strong>for</strong> vertical siding panels or a numerical rating of six (6) <strong>for</strong> roofing and non-vertical sidingpanels <strong>for</strong> a period of thirty (30) years when measured in accordance with the standard procedure specified in ASTM D-4214 (latest).NOTE: Chalk refers to the <strong>for</strong>mation of loose, removable powder evolved from the coating itself upon breakdown of its resin or binder. The testmerely utilizes dark or light colored felt rubbed against the surface to pick up a measurable amount of the chalk which is then compared to astandard. On a scale of 10 (best) to 0 (worst), a rating of eight is considered a moderate amount of chalk, while a rating of two would representextreme chalk.3. Fade or change in color in excess of five (5) units of color difference (Hunter ∆E units) <strong>for</strong> vertical siding panels or in excess of seven (7) units ofcolor difference (Hunter ∆E units) <strong>for</strong> roofing and non-vertical siding panels <strong>for</strong> a period of thirty (30) years when measured in accordance with thestandard procedure specified in ASTM D-2244 (latest) paragraph 4.3, on a washed test area.NOTE: Most coated surfaces, when exposed to the sun, will fade to some degree over a period of time. Five Hunter ∆E units is a noticeable, butnot usually objectionable, degree of color change. Colors may also darken or change hue rather than fade, particularly on exposure in pollutedenvironments. The Hunter ∆E units are intended to apply to color change in either direction in comparison with the original or unexposed color. It isunderstood that fading or color change may not be in uni<strong>for</strong>m if the surfaces are not equally exposed to the sun and elements.For purposes of determining whether an exposed coated panel meets the standards set <strong>for</strong>th in above paragraph, all chalk, dirt and other filmdeposits on the area of the panel to be tested <strong>for</strong> color must be removed by washing prior to evaluation.To wash test area, use a pad of 28/24 mesh cheesecloth and distilled water with mild soap or detergent cleaner. Wet the cheesecloth thoroughlywith the solution and rub it, using moderate hand pressure, over an area of panel approximately 4" x 4". Care must be taken to avoid anyscratching, burnishing or other physical alteration of the coating surface. After washing as described above, flush off the test area with distilledwater and allow to air dry in a vertical position.Example Warranty FormTop TOP Coat COATPrimer PRIMER Coat COATSealer SEALER Coat COATZincZINCPre-TreatmentPRE-TREATMENTProtective <strong>Metal</strong>lic BarrierGALVANIZEDBare BARE Steel STEELBacker BACKER COAT CoatPrimer PRIMER Coat COATSealer SEALER Coat COATZinc ZINC Pre-TreatmentPRE-TREATMENTProtective <strong>Metal</strong>lic BarrierGALVANIZEDExample of the Grand Rib 3® layer systemOther WarrantiesPolyester Paint Warranty• 25-year limited film integrity• 10-year against fade & chalkFor profiles: MP Panel, Shelterguard®, 5-Rib4. Exhibit accumulations of red rust caused by acid rain on non-vertical installations of Enduracote TM painted panels <strong>for</strong> a period of ten (10) yearsquantities that result in discoloration clearly visible in casual observation, except that this provision shall not apply to any accumulation of red rustwhich occurs within one-half inch of any portion of the coated surface which is cut or penetrated at any time after application of the pretreatment andpaint system to the substrate.TERMS AND CONDITIONS1. DURATION OF WARRANTYThe paint coating of Fabral roofing and siding panels is guaranteed to per<strong>for</strong>m in the manner described above <strong>for</strong> the lifetime of the structure <strong>for</strong>crack, check, or peel, or 30 years <strong>for</strong> chalk and fade, or 10 years <strong>for</strong> red rust, from the date such panels are installed by Buyer, provided installationoccurs within six months from the date of application of coating by Seller's coating facility. In no event shall the guarantee extend beyond 30 yearsand 6 months <strong>for</strong> chalk and fade, or 10 years and 6 months <strong>for</strong> red rust, from the date of application of coating by Seller's coating facility.2. CONSTRUCTION CONDITIONSNO EXPRESS WARRANTY AND NO IMPLIED WARRANTY OF MERCHANTABILITY OR IMPLIED WARRANTY OF FITNESS FOR APARTICULAR PURPOSE shall apply:(a) to roofing having a pitch of less than 2 ½:12 <strong>for</strong> Grandrib 3 ® , Alu-Tuff II, or Prime Rib panels, 1:12 <strong>for</strong> Mighti-Rib or Ultra-Rib panels.(b) to roofing or siding panels applied without protection over lumber which has been treated with preservatives or fire resistant salts, regardlesswhether such treatments are occasioned knowingly or without the knowledge of the buyer, the owner, or any other party.This exclusion includes, but is not limited to, lumber which has been treated with ACQ (Alkaline Copper Quartenary), CA (Copper Azole), CBA(Copper Boron Azole), pentachlorophenol, CCA (Chromated Copper Arsenate) salts, creosote, fluor chrome arsenate phenol, or any similartreatment <strong>for</strong> fire and rot resistance. Protection of lumber as provided <strong>for</strong> in this exclusion shall be defined as any barrier which prevents thetransfer of moisture and salts between the treated lumber and Fabral's roofing and siding material including 4 mil polyethylene, York Wrap orequivalent durable vapor barrier or solid (non-porous) insulation. No other protective barrier shall be acceptable under this provision without theexpress written approval of Fabral.(c) failure to properly insulate the products between any dissimilar metals, contact with the ground, animal wastes, decaying materials or wetabsorptive materials.(d) abnormally corrosive atmospheric conditions. This exclusion includes, but is not limited to, contamination from external sources such asmanufactured chemicals and salt spray, and internal contamination created by improper ventilation (design or operational defects) or improperhousekeeping, as defined by current Midwest Plan Service publications.Aluminum-Zinc Alloy Warranty• 20-year limited non-per<strong>for</strong>ationFor Bare Galvalume® ProductsAluminum Product Guarantee• 30-year corrosion guaranteeF-104The Energy Star ® ProgramThe Energy Star Program promotes highly reflective roof systems that reflectsolar energy. These roof systems allow buildings to stay cooler and, in turn,use less electricity <strong>for</strong> air conditioning; less electricity means a reduction inpower generation and a reduction of pollutants discharged at power plants.Fabral has attained Energy Star approval <strong>for</strong> many of its Enduracote systemcolors. Ask <strong>for</strong> Technical Bulletin #724 titled “Energy Star Approval”, <strong>for</strong>program details and a list of approved Enduracote colors.Please contact your Fabral representative <strong>for</strong> more in<strong>for</strong>mation about Fabral warranties and paint systems.4

Steel Panel ProfilesGrandrib 329 Gauge steel, Plain, and Painted Galvanized®MP Panel3/4" 9"37 3/4" FORMED WIDTH36" COVERAGE9"37 3/4" FORMED WIDTH36" COVERAGEAlu-Tuff3/4"CORRECT SIDELAPFOR ALU-TUFF,GRANDRIB 3, ANDMULTI-PURPOSESTEEL PANELS.SCREW PATTERNSIntermediate Roof Purlins and All <strong>Siding</strong>Eaves and Endlaps - Roof PurlinsBUTYL SEALANTLOCATION (OPTIONALFIELD APPLIED)PURLIN BEARINGLEG9"37 3/4" FORMED WIDTH36" COVERAGENAIL PATTERNSAll Supports3/4"Fastener Usage: 80 screws per square or 1 pound of nails per square5V CrimpUSE ON SOLID DECKINGNAIL PATTERNROOFING - EAVES, RIDGES, AND ENDLAPSROOFING - INTERMEDIATE SUPPORTSSCREW PATTERN1/2"11 1/2"26" FORMED WIDTH24" COVERAGEROOFING - EAVES, RIDGES, AND ENDLAPSROOFING - INTERMEDIATE SUPPORTSSIDING - ALL SUPPORTS1 1/4" CorrugatedNAIL PATTERNROOFING - EAVES, RIDGES, AND ENDLAPSROOFING - INTERMEDIATE SUPPORTSSIDING - ALL SUPPORTSSCREW PATTERN1/4" 1 1/4"26" OVERALL24" COVERAGEROOFING - EAVES, RIDGES, AND ENDLAPSROOFING - INTERMEDIATE SUPPORTSSIDING - ALL SUPPORTS*Not all profiles are available in all areas. Please contact Fabral <strong>for</strong> availabilty.5

Steel Panel Profiles2 1/2" CorrugatedNAIL PATTERNROOFING - EAVES, RIDGES, AND ENDLAPSROOFING - INTERMEDIATE SUPPORTSSIDING - ALL SUPPORTSSCREW PATTERN1/2"2.667"26" OVERALL24" COVERAGE (SIDING)21 1/2" COVERAGE (ROOFING)ROOFING - EAVES, RIDGES, AND ENDLAPSROOFING - INTERMEDIATE SUPPORTSSIDING - ALL SUPPORTSProcladXPRT 936Sidelap DetailSCREW PATTERNSIntermediate Roof Purlins and All <strong>Siding</strong>Eaves and Endlaps - Roof Purlins38 3/8" FORMED WIDTH36" COVERAGEOther Steel Profiles Available5/8"*Not all profiles are available in all areas. Please contact Fabral <strong>for</strong> availabilty.1 1/2” SSR24 Gauge Standing Seam <strong>Roofing</strong>16" Coverage1 1/2"Mighti-Rib®26 Gauge <strong>Roofing</strong> & <strong>Siding</strong>4 3/8"3 1/4"4 3/8"39" Formed Width36" Coverage12"1 3/16"Climaguard26 Gauge <strong>Roofing</strong>12" or 16" Coverage5 3/8"Factory Applied Sealant7/8"Grandbeam®26 Gauge <strong>Roofing</strong> & <strong>Siding</strong>36" Coverage424 1 " Formed Width9"4"7 18 " 2 "416 9 " 100°1 3 8 "134°134°*The panels above are available at certain locations and have their own particular details, flashings, and accessories. Please contact Fabral <strong>for</strong> more in<strong>for</strong>mation.6

Aluminum Panel ProfilesGrandrib 3 ®Alu-TuffROOFING - EAVES, RIDGES, AND ENDLAPS3/4"9"37 3/4" FORMED WIDTH36" COVERAGE9"37 3/4" FORMED WIDTH36" COVERAGE3/4"ROOFING - INTERMEDIATE SUPPORTSSIDING - ALL SUPPORTSStrongrib ®.0155 and .018 Aluminum, Plain, and Painted WhiteSCREW PATTERNCorrect StrongribSidelapBUTYL SEALANTLOCATION (OPTIONALFIELD APPLIED)INTERMEDIATE ROOF PURLINS AND ALL SIDING34"9"37 3/4" FORMED WIDTH36" COVERAGE2 1/2"PURLIN BEARINGLEGEAVE AND ENDLAPS - ROOF PURLINSFabribROOFING - EAVES, RIDGES, AND ENDLAPS916 " 2.667"5116 3 " FORMED WIDTH48" COVERAGEROOFING - INTERMEDIATE SUPPORTSSIDING - ALL SUPPORTSAluTwinROOFING - EAVES, RIDGES, AND ENDLAPSROOFING - INTERMEDIATE SUPPORTSSIDING - ALL SUPPORTS716 " 8"504" 1 FORMED WIDTH48" COVERAGE2 1/2" CorrugatedROOFING - EAVES, RIDGES, AND ENDLAPS21" 2.667"51 4" 1 OVERALL48" COVERAGE (SIDING)48" COVERAGE (ROOFING)ROOFING - INTERMEDIATE SUPPORTSSIDING - ALL SUPPORTS*Not all profiles are available in all areas. Please contact Fabral <strong>for</strong> availabilty. 7

Post Frame Estimating & Roof TypesEstimating <strong>Metal</strong> <strong>Roofing</strong>, <strong>Siding</strong> & FlashingsPanel lengths are to be determined by the truss top chordor actual field measurements. Remember to add <strong>for</strong> overhangsat the eaves; subtract <strong>for</strong> a gap at the ridge. <strong>Siding</strong>should be kept up away from the ground with a skirtboard.Number of PanelsThe coverage of the panel being used will determine thenumber of panels at a length (i.e.: 3’ coverage panel on a30 ft. long building would require 10 panels on each side ofthe ridge or 20 panels at the particular length.)Gambrel RoofHorizontal Measurment to a RoofDivide the building width in half, then multiply by the slopefactor (i.e.: 40’ wide building with 4/12 slope. 40 dividedby 2 equals 20’ times 1.054 equals 21’-1” in slope dimension.)Allow <strong>for</strong> 1/2” to 1” gap at peak and 1” to 2” eaveoverhang.Roof PitchSlope Factor3/12 1.0314/12 1.0545/12 1.0836/12 1.1208/12 1.20210/12 1.30212/12 1.414Transition RoofFlashing ConditionsRoof - Eave, Ridge, Gable, Sidewall, Endwall, Valley, Hip,Transition, Gambrel, Soffits<strong>Siding</strong> - Base Perimeter, Corners, Inside Corners, ManDoors, Windows, Sliding Doors, Overhead DoorsPlease contact Fabral’s Engineering Department<strong>for</strong> all your estimating & specification needs.1-800-916-14131-800-322-1030 FaxHip Roof8

Drip CapGable/RakeJ-Channel/Doors/WindowsPost Frame Building <strong>Details</strong>Ridge/PeakEaveOutside CornerSliding Door Track CoversZeeBase GuardEndwallInside CornerSidewall9

<strong>Standard</strong> Post Frame Flashing/TrimsAll flashing is 10’ 6” in length & available in steel & aluminum, unless otherwisenoted. Please contact Fabral <strong>for</strong> specifics on the trim available in your area.5 9/16"11/16"AJ6Jamb Trim(<strong>for</strong> 2x wood)1 1/2"1"8 7/8"1 5/8"6 25/32"AR3Ridge Cap4 3/8"13/16"1 1/16"AG1Gable/RakeAluminum 10'Steel 10' <strong>Standard</strong>14' in select colors4 5/8"5 1/2"5 1/2"3"RR1UniversalRidge/HipFlashSteel OnlyCustomer to specify roof pitchAR3 w/ VersaVent RX-10Ridge CapGrandrib 3 & Alutuff net free area = 10.66 sq. in. per linealfeet of ridge (5.33 per side)AE1Eave Flash13/16"6"3"4"4"2 1/2"24"SunSky RidgeRidge CapClear OnlyCP1MonoslopeRidge1/2"Steel OnlyCustomer to specify roof pitchCE1Denver Eave1/2"Steel OnlyCustomer to specify roof pitch78 "7/8"1 3/4"7/8"1 1/4"2 7/8"RJ9F-J Trim7/8"7/8"72 3/16"8 7/8"PJFBOne Piece Door TrimAH410'-6" LengthFace-Mount TrackCover <strong>for</strong> CannonballTrack with 1" TrackPlank MatchesCannonball Trim#6462246 15/16"3/4"1 5/16"10

<strong>Standard</strong> Post Frame Flashing/Trims7 1/4"10 1/8"NotchedAGRN4For Grandrib 3 40 1 4" LengthNotched Gambrel Flash6 1/4"RV1Valley FlashCustomer to specify roof pitchSoff Vent AVented Aluminum SoffitNet free area = 12.96 sq. in. perlineal ft. of soffit16"7"5"9 3/16"1"AB3Soffit BoxNet free area - 22.9 sq. in. per lineal ft. of soffit(Vented available in white steel only)5 1/2"AT1Transition FlashTypical <strong>for</strong> 8/12 to 4/12(otherwise specify pitches)1/2"RV2W-Valley FlashSteel OnlyCustomer to specify roof pitch11 1/4"2 1/2"Steel OnlyAB4Soffit Box4"5 1/2"AB1Soffit BoxNet free area = 22.9 sq. in. per lineal ft. of soffit(Vented available in white steel only)5"7 1/2"ASW1Sidewall/EndwallFlash1/2"7 1/4"2 1/2"11 1/4"2 1/2"7 1/4"AEWN4For Grandrib 3 40 1/4" LengthNotched Endwall Flash7 1/2" AB2Soffit Box7"5"Notched6 1/4"7 1/4" 2 1/2"AT1Transition FlashTypical <strong>for</strong> 8/12 to 4/12(otherwise specify pitches)1/2"Steel Only11

<strong>Standard</strong> Post Frame Flashing/Trims4 3/8"4 3/8"1 1/16"13/16"AL2 = 3 1/2"AL3 = 5 1/2"AL4 = 7 1/4"AL5 = 9 1/4"13/16"1 5/8"3/4"AC1Corner1 1/2"1 5/8"Aluminum 10'14'-6" in selectcolorsAL2,3,4,5Angle FlashingAZ2Zee7/8"2 3/4"1 1/16"1 5/8"7/8"1"3 11/16"3/4"1 1/2"AC2Inside Corner1 1/2"ABG1Base Guard1 5/8"AJ4Jamb TrimSteel Only(For 2x wood)1 1/2"9/16"2 1/4"2 5/16"1 1/2" AC3AL6CornerAngle Flashing1 1/2"AL7Angle Flashing4 1/8"Available in Lancasterservice area only1"AJ3J-ChannelFor Grandrib 3, Strongrib and allother Agri panels13/16"1 3/4"1 3/8" 3 3/8"1 5/8"6 15/16"AH510'-6" LengthFace-Mount Track Cover<strong>for</strong> Cannonball Track with2" Track Plank 3/4"(Replaces STC-503)Matches Cannonball Trim#6462251 5/16"2 3/8"AH310'-6" LengthsFits National 5100, 5103and 5105 box rail.Matches National trim #5120(Replaces STC-504)2 5/16"1/2"13/16"1 1/16"AJ2Jamb TrimSteel Only3 5/8"7 1/4"12

<strong>Standard</strong> Post Frame Flashing/Trims4 1/4"13/16"1"3 5/8"1 1/16"7/8"1 5/8"1 1/2"6"1/2"3/4"AC4CornerSteel OnlyAD1Drip Cap3 5/8"AJ5Jamb TrimSteel Only(For 4x wood)1 3/4"7/8"1 13/16"1 3/8"1 1/2" 4"AH410'-6" LengthFace-Mount TrackCover <strong>for</strong> CannonballTrack with 1" TrackPlank MatchesCannonball Trim#6462246 15/16"3/4"1 5/16"AH210'-6" LengthFits National 5110 &59 bo rail. MatchesNational trim #51222 3/8"2 9/32"1/2"1 7/16"AH610'-6" LengthFits National Top-Mount#5433 Rail with #5436Bracket or NationalTop-Mount #5460 Rail withattached bracket. MatchesNational Trim #54554"1/2"Post Frame Flashing <strong>Details</strong>BOX GABLE2" LONG FASTENER@ 24" C/C MAXFLASH AG-1ROOFINGSEALANT TAPESEALANT TAPEROOF PURLINEND RAFTERSEALANT TAPETOP & BOTTOMOF CLOSUREOUTSIDE CLOSURE(OPTIONAL)1"x6" FASCIAFASTENER @ EVERYMAIN RIB OR12" C/C MAX.7 1 4" OR 11 1 4"FASTENER24" C/C MAXFLASH AB-1, AB-2,AB-3, OR AB-4SIDING13

Post Frame Flashing <strong>Details</strong>ENDLAP1. Apply 3/32” x 1/2” butyl endlap sealant on bottom paneljust below centerline of purlin (see endlap diagram <strong>for</strong>location) on panel #1.2. Apply sidelap sealant on panel #1 and connect to endlapsealant.3. Place panel #2 so it overlaps panel #1, 12” as shown.Install screws per endlap fastening pattern.4. Apply sidelap sealant on panel #2 to connect to sidelapsealant of panel #1.5. Place panel #3 over sidelap of #1 and #2.6. Apply endlap sealant on panel #3.7. Apply sidelap sealant on panel #3 and connect withendlap sealant.8. Place panel #4 over endlap of panel #3. Install screwsper endlap pattern.9. Repeat sequence <strong>for</strong> entire roof.STEP #1STEP #2DOWN SLOPEDOWN SLOPEROOF PANEL2"OVERLAPPINGFROM PURLIN EDGEROOF PANEL2"OVERLAPPINGFROM PURLIN EDGE3 1/2"CONTINUOUS BEAD OF 3/32" x 1/2"BUTYL SEALANT TAPE3 1/2"12" Total Lap6 1/2"10" To SealantFASTENERS @ENDLAP PATTERN6 1/2"PURLINPREVAILING WINDENDLAP TAPE ALIGNWITH PURLIN EDGEINSTALLATION SEQUENCEFOR STRONGRIB, GRANDRIB 3,5V CRIMP, ALU-TWINSIDELAP TAPETHIS EDGE53142SIDELAP TAPETHIS EDGEENDLAP TAPETHIS EDGE42153EAVEOVERHANG1" TO 2"SKIRT BOARD OFTREATED LUMBER ORFOUNDATION OF BLOCK12" TO 18" FROMGROUND LEVEL"L" (IN FEET)WHEN INSTALLING 2 1/2" OR 1 1/4"CORRUGATED ROOFING USEINSTALLATION SEQUENCE AS SHOWNSTART ENDPanelNameAlu-TuffGrandrib 3Prime Rib5V2 1/2" Corrugated1 1/4" CorrugatedAlutwinFabribALLOWABLE PANEL LENGTHS (ft.) ALONGTHE SLOPE FOR 4" RAINFALL PER HOURMinimum2 1/2:122 1/2:122 1/2:122 1/2:122 1/2:122 1/2:122 1/2:122 1/2:12Slope2 1/2:1258583943281637323:1261614145 47 49291639343 1/2:12Notes For Rain-Carrying Tables1. All values based on a 1-hour duration storm of 4"/hr. intensity.2. Values represent the point at which the panel ribs will flood.3. Size and frequency of penetrations can greatly reduce the amount of water removed from a rooof.4. All panel endlaps must be caulked.5. When weather-tightness is crtical, use sealant tape in all sidelaps.64644331174136Roof Slope4:12676745321843385:127373496:1254 58352046417878533821504414

Post Frame Flashing <strong>Details</strong>EAVEINSIDE CLOSUREROOF PANELFASTENER PERSTANDARD EAVEPATTERNSEALANT TAPETOP & BOTTOM OF CLOSURE4 5 8"FLASH CE-1SEALANT TAPETOP & BOTTOMOF CLOSUREFASTENER @ EVERYRIB OR 12" C/C MAX.OUTSIDE CLOSURE(OPTIONAL)ROOF PURLINAE-1Eave Flash1316"3"SIDINGROOF TRUSS3"FASTENERPOSTTOP PLATECE-1DenverEave2 1 2"12"BOX EAVEFASTENER PERSTANDARD EAVEPATTERNMODIFIEDAL-2SEALANT TAPETOP & BOTTOMOF CLOSUREROOF PANEL5 1 2"AB-1Soffit Box7 1 4"2 1 2"FASTENER @24" C/C MAX.AB-2Soffit BoxINSIDE CLOSURE7 1 2"5 1 2"OR7 1 2"SEALANT TAPEFLASH AB-1, AB-2,AB-3, OR AB-4AS REQUIREDFASTENERFASCIA BOARD7 1 4" OR 11 1 4"EAVE PURLINROOF TRUSSOUTSIDECLOSURE(OPTIONAL)POST5 1 2"7 1 4"2 1 2"AB-3Soffit Box(Vented Availablein White steel only)11 1 4"2 1 2"SIDINGTOP PLATE7 1 2"AB-4Soffit Box11 1 4"2 1 2"PROVIDES 8" OR 12" OVERHANG WITH GRANDRIB 3, ALU-TUFF, OR STRONGRIB SIDING15

Post Frame Flashing <strong>Details</strong>VENTED EAVEINSIDE CLOSURE WITH SEALANTTAPE TOP & BOTTOMFABRAL METAL ROOF PANELFASTENER PER STANDARDEAVE PATTERNEAVE TRIMFASCIA BOARDFASCIA L-TRIM,AL-3, 4, OR 5FABRAL ALUMINUMSOFFITFABRAL METALSIDING PANELF/J TRIMTRUSS OR RAFTER16" COVERAGERIDGE/PEAK - NON VENTED2" LONG FASTENER@ EVERY MAIN RIBOR 12" C/C MAX.AR-3,RIDGE FLASHINGROOF PANELSEALANT TAPETOP & BOTTOMOF CLOSUREPURLINGAP AS REQUIREDOUTSIDE CLOSURE(ON HIP ROOFS, USE1"X1"X19'-8" SEALER STRIP& RR-1 FLAHING)If closures are omitted, Fabral suggests using screen wire betweenpanels and ridge gap area to keep insects and birds out of attic area.Closures and sealant are recommended <strong>for</strong> optimum weather resistance.16

Post Frame Flashing <strong>Details</strong>VENTED RIDGE2" LONG FASTENER@ EVERY MAIN RIBAR-3, RR-1RIDGE FLASHROOF PANELVERSAVENT RX-10GAP AS REQUIREDPURLINVersaVent RX-10 Factory Applied To Ridge CapVent Material and Ridge Cap Install As A UnitALTERNATE VENTED RIDGEFabral RR-1 Ridge Flash with CoraVent (shown). The RR-1 can be modified to fit manyother solid, plastic vents. Other solid, plastic vents (ie..Ridge Master,...) are availablefrom local lumberyards or dealers. The metal ridge flashing may have to be customizedto fit the particular vent. Mesh vents or fiber-type vents are not recommended becausea metal ridge can not be fastened securely. They are not rigid enough to give goodsupport or appearance to the metal flash. Coravent is available from Fabral.OUTSIDE CLOSUREWITH BUTYL SEALANTTOP & BOTTOMRR-1 RIDGE FLASHOPTIONAL J-CHANNELFOR SUPPORT2 1 2" FASTENER @ EVERYMAIN RIB OR 12" C/C MAX.METAL ROOFPANEL2" TO 4" ORAS REQUIREDBY VENTMANUFACTURERPANEL FASTENER PERSTANDARD PATTERN17

Post Frame Flashing <strong>Details</strong>ALTERNATE VENTED RIDGE2" LONG FASTENER@ EVERY MAIN RIBAR-3, RR-1RIDGE FLASHROOF PANELPROFILE VENTGAP AS REQUIREDPURLINProfile Vent is pre-notched and self adhesive. Fabral stocksProfile Vent <strong>for</strong> Grandrib 3, Alu-Tuff, and 5v Crimp.GABLE - STRONGRIB, GRANDRIB 3FLASH AG-12" FASTENER @24" C/C MAX.ROOFINGOPTIONALSEALANT TAPETOP & BOTTOMOF CLOSURESEALANT TAPEPURLINFASTENER @24" C/C MAXSIDINGEND RAFTEROUTSIDE CLOSURE(OPTIONAL)18

Post Frame Flashing <strong>Details</strong>GABLE - FABRIBFLASH AG-4FASTENER @24" C/C MAXROOFINGOPTIONALSEALANT TAPETOP & BOTTOMOF CLOSURESEALANT TAPEPURLINFASTENER @24" C/C MAXSIDINGEND RAFTEROUTSIDE CLOSURE(OPTIONAL)GABLE - GRANDRIB 3 , STRONGRIBFLASH AC-1 OR AC-4FASTENER @24" C/C MAXROOFINGOPTIONALSEALANT TAPETOP & BOTTOMOF CLOSURESEALANT TAPEPURLINFASTENER @24" C/C MAXSIDINGEND RAFTEROUTSIDE CLOSURE(OPTIONAL)19

Post Frame Flashing <strong>Details</strong>FLYING GABLE DETAILFASTENERROOF FELTSEALER STRIP(ASPHALT IMPREGNATED)BUTYL SEALANT TOP ANDBOTTOM OF SEALER STRIPCE1FASCIA BOARD20

Post Frame Flashing <strong>Details</strong>ENDWALLSIDINGFASTENER PER STANDARDEAVE PATTERN2" FASTENER @ EVERY MAINRIB OR 12" C/C MAX.1"INSIDE CLOSUREGIRTROOF PANELFLASH ASW-1OUTSIDE CLOSURESEALANT TAPETOP & BOTTOMOF CLOSUREPURLINENDWALL - NOTCHEDSIDINGFASTENER PER STANDARDEAVE PATTERN2" FASTENER @ EVERY MAINRIB OR 12" C/C MAX.NOTCHED FLASHAEW-N4 OR AEW-N51"INSIDE CLOSUREGIRTROOF PANELOUTSIDE CLOSURESEALANT TAPETOP & BOTTOMOF CLOSUREPURLIN21

Post Frame Flashing <strong>Details</strong>SIDEWALLSEALER STRIPWITH BUTYL SEALANTTAPEGIRTSIDINGFASTENER PER STANDARD EAVE PATTERNSPACE AS REQUIREDFLASH ASW-1FIELD BENDAS REQUIREDSEALANT TAPE2" FASTENER @24" C/C MAX.PURLINSLOPING RAFTERVALLEYMETAL ROOF PANELBUYTL SEALANTTOP & BOTTOMOF SEALER STRIPCUT PANEL ASNECESSARY6" MINIMUMLARGER VALLEYS MAY BEREQUIRED FOR LONG PANELRUNS OR HEAVY SNOWAREAS.SCREWSEACH SIDE OF MAINRIB (EAVE/ENDLAPPATTERN)RV-2SHOWNROOF STRUCTURESOLID 2x'S ORPLYWOODSEALER STRIP,1"x1"x19'-8"BLOCK CLOSUREFILLS RIB VOIDSROOF FELT ANDICE & WATER SHIELDNOTE: VALLEY FLASH MUST HAVE SOLID SUPPORT.FOR ADDITIONAL INFORMATION ON THE VALLEYDETAIL REFER TO PAGES 42 AND 43 OF THIS BOOK.22

Post Frame Flashing <strong>Details</strong>GAMBRELBUTYL SEALANT TAPETOP & BOTTOMOF CLOSUREFASTENER PERSTANDARD EAVE PATTERNINSIDE CLOSUREFLASH AT-2 ORAGR-N4 (GRANDRIB 3)2" FASTENER @ EVERY MAIN RIBOR 12" C/C MAX.BUTYL SEALANT TAPETOP & BOTTOMOF CLOSUREROOF PANELOUTSIDE CLOSURE3/1215/12NOTE: Specify both roof pitches <strong>for</strong> AT-2 flash. AGRN-4 <strong>for</strong> Grandrib 3and AGRN-5 <strong>for</strong> Strongrib are <strong>for</strong> 3/12 to 15/12 Gambrel'sTRANSITIONBUTYL SEALANT TAPETOP & BOTTOMOF CLOSUREINSIDE CLOSUREFLASH AT-12" LONG FASTENER @ EVERYMAIN RIB OR 12" C.C MAX.FASTENER PER STANDARDEAVE PATTERNBUTYL SEALANT TAPETOP & BOTTOMOF CLOSUREROOF PANELOUTSIDE CLOSURE9/123/12NOTE: Specify both roof pitches when ordering AT-1.<strong>Standard</strong> is 9/12 to 3/12.23

Post Frame Flashing <strong>Details</strong>OUTSIDE CORNERPOSTSEALANT TAPEGIRTFLASH AC-3 *SIDING2" FASTENER THROUGH PANELRIB @ 24" C/C MAX.* Available in Lancaster service area only.OUTSIDE CORNERPOSTSEALANT TAPEWALL GIRTFLASH AC-1 OR AC-4SIDINGFASTENER @ 24" C/C MAX.24

Post Frame Flashing <strong>Details</strong>INSIDE CORNERGIRTFASTENER @24" C/C MAX.FLASH AC-2POSTSEALANT TAPEBASE GUARDBARRIER BETWEEN METALAND ACQ TREATED LUMBERSIDING PANELTREATED BASEPLANKINSIDE CLOSURE(OPTIONAL)FLOOR 4"6" MIN.FASTENER PER STANDARDSIDING PATTERNFLASH ABG-1GRADE25

Post Frame Flashing <strong>Details</strong>DOOR JAMBSDOOR JAMBDOORFASTENERGIRTDOOR STOPSIDINGFLASH PJFBDOOR JAMBDOORFASTENERGIRTSIDINGDOOR STOPSEALANTFLASH AJ-3FLASH AL-2, AL-3, AL-4,AL-5, OR AL-7 DEPENDING ONWIDTH OF JAMBFIELD BEND OR CUT THIS AREAIF NECESSARYSEALANT TAPEDOORGIRT1x3 DOOR STOPSIDINGFASTENER34 "FLASH AJ-226

Post Frame Flashing <strong>Details</strong>OVERHEAD DOOR JAMBSDOOR JAMBDOORPOSTGIRT1 x 3 GUIDEFLASH AL-5 OR AL-7FASTENERSEALANT TAPESIDINGFASTENERFLASH AJ-4DOOR OPENINGFIELD BEND OR CUT THIS AREAIF NECESSARYDOOR JAMBDOORGIRT1 x 3 GUIDEDOOR JAMBDOORGIRT1 x 3 GUIDEFLASH AL-3, AL-4,AL-5 OR AL-7SEALANTSIDINGFASTENERFLASH PJFB1 PIECE DOOR TRIMSIDINGFASTENERFLASH AJ-3DOOR JAMBDOORPOSTGIRT1 x 3 GUIDEFLASH AJ-2SIDINGFASTENER34 "DOOR OPENING27

Post Frame Flashing <strong>Details</strong>DOOR HEADERFASTENER PERSIDING PATTERNFLASH AD-1SIDINGDOOR HEADERDOOR STOPMAN DOORFLASH AL-2, AL-3, AL-4,AL-5 OR AL-7OVERHEADDOORSLIDING DOOR JAMB DETAILOPTIONAL AL-3 TRIMPOSTWALL GIRTAJ-4 JAMB TRIM2 x 2 FILLER BLOCKSIDING PANELFLASH AL-6SLIDING DOORSEALANT TAPESIDINGFLASH AJ-3FASTENER28

Post Frame Flashing <strong>Details</strong>SLIDING DOOR HEADER DETAILSIDINGTRACK SUPPORT2x6 TRACK BOARDFLASH AH-2, AH-3 (SHOWN),AH-4, OR AH-5.REFER TO PAGE 11 FORCORRECT FLASHING FORPARTICULAR MANUFACTURER'SDOOR TRACK BEING USED.2x2 FILLER BLOCKSIDING BEYOND OPENINGSIDING ONSLIDING DOORDOOR GIRTTREATED BASE PLANKAD-1 OR BOTTOM RAILFROM DOOR MFR.TRANSLUCENT PANELSEALANT TAPETOP & BOTTOMOF CLOSUREFASTENER PERSTANDARD PATTERNFLASH AZ-2FASTENER @ EVERY MAINRIB OR 12" C/C MAX.SEALANT TAPETOP & BOTTOMOF CLOSUREMETAL SIDING ORTRANSLUCENT PANELINSIDE CLOSURE(OPTIONAL)GIRTOUTSIDE CLOSURE(OPTIONAL)TRANSLUCENT SIDING ORMETAL SIDINGUSE TRANSLUCENT PANELS ASSIDING PANELS TO ALLOWLIGHT INTO THE BUILDING.DO NOT USE ON ROOFS.29

Post Frame Flashing <strong>Details</strong>WINDOW DETAILSSILLWINDOW UNIT1x6 BEVELED1"FLASH AJ-32x4FASTENER PERSTANDARD PATTERNSIDINGHEAD2x4SEALANT TAPETOP & BOTTOMOF CLOSUREFASTENER PERSTANDARD PATTERNAD1 DRIP CAPWINDOW UNITINSIDE CLOSURE(OPTIONAL)JAMBWINDOW UNITFLASH AJ-3FASTENER2x4GIRTOPTIONALSEALANT TAPESIDING30

Residential Building <strong>Details</strong>CHIMNEYRIDGE/PEAKVALLEYENDWALLPIPE PENETRATIONTRANSITIONSIDEWALLEAVESKYLIGHTGABLE/RAKEHIPBasics <strong>for</strong> Residential Installation1. Determine the thickness and type of substrate to be used to support the metal roofing.Solid decking is highly recommended <strong>for</strong> all resdiential applications (i.e.,plywood, OSB).2. Refer to the Load-Span tables to select the proper fastener and spacing to meet loads on yourstructure.Nails are NOT recommended <strong>for</strong> residential applications.3. Consult local building codes and restrictions to determine acceptable methods of construction<strong>for</strong> residential applications in your area.4. Solid decking with 30# felt or Pro Master® underlayment <strong>for</strong> residential applications is recommended.Ice & water shield or similar self-adhesive membrane is recommended at all valleys,dormers, chimneys, transitions, skylights and other critical areas.5. When re-roofing with metal panels over an existing shingle roof, 2x4 purlins or 1x4 furringstrips run parallel with the ridge of the roof and must be securely fastened into the roof raftersor trusses.6. Request Fabral’s technical bulletins # 720 and # 721 <strong>for</strong> more details on residential roofing.31

Residential Load TableGRANDRIB 3 RRLoad-Span Tables For 29 Gauge Grandrib 3 & Alu-TuffAllowable Wind Uplift Loads (ps f)Spacing of Fastener RowsS ubs trate Fastener 9"3/4" Plywood # 14 Woodtite 275.65/8" Plywood # 14 Woodtite 1601/2" P lywood # 14 Woodtite 135.923/32" OSB # 14 Woodtite 115.919/32" OSB # 14 Woodtite 100.77/16" OSB # 14 Woodtite 61.5Solid 2x SPF # 14 Woodtite 293Solid 1x Pine # 14 Woodtite 207.1Solid 2x SPF # 9 WoodFast 218.7Solid 1x Pine # 9 WoodFast 168.4S crews per S quare 19012" 15" 18" 21" 24"206.7 165.4 137.8 118.1 103.4120 96 80 68.6 6081.5 67.9 58.2 51.069.5 57.9 49.7 43.5101.986.975.546.1220.0155.3164.0126.360.436.9176.0124.2131.2101.0150 12050.3 43.130.7 26.3146.7 125.7103.5 88.7109.3 93.784.2 72.2100 9037.823.1110.077.782.063.280The Above Loads and fastener quantities are based on the standard fasteningschedule shown on page 4 of this book, with the fastener having an embedmentdepth of 1" into the solid wood and penetrating the plywood or OSB. ContactFABRAL <strong>for</strong> additional design in<strong>for</strong>mation on our products.Other Residential Profiles1 1/2” SSR24 Gauge Standing Seam <strong>Roofing</strong>16" Coverage1 1/2"Climaguard26 Gauge <strong>Roofing</strong>12" or 16" Coverage5 3/8"Factory Applied Sealant7/8"5V Crimp26 Gauge <strong>Roofing</strong>1/2"26" Formed Width24" Coverage12"1" 1" 1/2"The above Fabral profiles have their own detail manuals, flashings, and accessories. Please contact Fabral <strong>for</strong> additional in<strong>for</strong>mation.32

<strong>Standard</strong> Residential Flashings/TrimAll flashing is 10’ 6” in length & available in steel & aluminum, unless otherwisenoted. Please contact Fabral <strong>for</strong> specifics on the trim available in your area.4 1/4"7/8"3"3 1/4"1 1/16"2 1/2"Soff Vent AVented Aluminum SoffitNet free area = 12.96 sq. in. perlineal ft. of soffit16"1/2"RG1ResidentialGableCE1Denver Eave1/2"Steel OnlyCustomer to specify roof pitch6"6 25/32"10 1/8"4"CP1MonoslopeRidge1/2"Steel OnlyCustomer to specify roof pitch9 3/16"AR3Ridge Cap1"RV1Valley FlashCustomer to specify roof pitch7"5"RV2W-Valley FlashSteel OnlyCustomer to specify roof pitchAT1Transition FlashTypical <strong>for</strong> 8/12 to 4/121/2"5 1/2"5 1/2"4 1/8"(otherwise specify pitches)Steel OnlyRR1UniversalRidge/HipFlashSteel OnlyCustomer to specify roof pitch4 1/8"9/16"AG4Gable9/16"7" 5"AT2Gambrel FlashTypical <strong>for</strong> 3/12 to 15/121/2"(otherwise specify pitches)4"5"AB3Soffit BoxNet free area - 22.9 sq. in. per lineal ft. of soffit(Vented available in white steel only)3 1/4"2 1/2"1 1/16"7/8"5 1/2"ASW1Sidewall/EndwallFlash1/2"11 1/4"2 1/2"1/2"WG1ResidentialGable33

Residential Flashings DetailAll residential flashings are <strong>for</strong>med <strong>for</strong> a 4/12 pitch unless otherwise requested bythe customer.RESIDENTIAL RIDGE/HIP2" LONG FASTENER@ EVERY MAIN RIBOR 12" C/C MAX.RIDGE CAPRR-1 or AR-3ROOF PANELROOF STRUCTURESEALANT TAPETOP & BOTTOM OFCLOSURE OR SEALERSTRIPOUTSIDE CLOSURE(ON HIP ROOFS USE1" x 1" x 19'-8"SEALER STRIP ANDRR-1 FLASHING)RESIDENTIAL VENTED RIDGE2" LONG FASTENER@ EVERY MAIN RIBOR 12" C/C MAX.RIDGE CAPRR-1 or AR-3ROOF PANELVERSAVENT RX-10ORPROFILEVENTROOF STRUCTURE34

Residential Flashings DetailRESIDENTIAL VENTED EAVEINSIDE CLOSURE WITH SEALANTTAPE TOP & BOTTOMFABRAL METAL ROOF PANELEAVE TRIMFASCIA BOARDTRUSS OR RAFTERFASCIA L-TRIMFABRAL ALUMINUMSOFFITFABRAL METALSIDING PANELF/J TRIM16" COVERAGERESIDENTIAL EAVEBUTYL TAPETOP & BOTTOMOF CLOSUREFASTENER PER STANDARD EAVE PATTERNROOF PANELCE-1FASTENER@ 24" C/C MAX.INSIDECLOSUREROOF STRUCTURE35

Residential Flashings DetailRESIDENTIAL GABLERG-1, WG-1OR AG-4SCREWFASTENER@ 24" C/C MAX.START GABLEBUTYL TAPEROOF PANELROOF STRUCTURECUT PANEL ASNECESSARYFINISHINGEND GABLERESIDENTIAL ENDWALLSIDING2" FASTENER @ EVERYMAIN RIBFLASH ASW-1ROOF PANELOUTSIDE CLOSUREBUTYL TAPETOP & BOTTOMOF CLOSURE36

Residential Flashings DetailRESIDENTIALGAMBRELBUTYL SEALANT TAPETOP & BOTTOMOF CLOSUREINSIDE CLOSUREFLASH AT-2 ORAGR-N4 (GRANDRIB 3)2" FASTENER@ EVERY MAINRIB OR 12" C/C MAX.FASTENER PER STANDARDEAVE PATTERNROOF PANELBUTYL SEALANT TAPETOP & BOTTOMOF CLOSUREOUTSIDE CLOSURERESIDENTIAL SIDEWALLSIDINGFASTENERFLASH ASW-12" FASTENER @ 12" C/CBUTYL SEALANTROOF PANELROOF SHEATHINGROOFING FELT ANDICE AND WATER SHIELDFOR ADDED WEATHER TIGHTNESS37

Residential Flashings DetailRESIDENTIAL TRANSITIONROOF PANELFASTENER PER EAVEFASTENING PATTERNINSIDE CLOSURE30# FELT AND ICE AND WATER SHIELDFOR ADDED WEATHERTIGHTNESSFLASH AT-1OUTSIDE CLOSUREBUTYL TAPETOP & BOTTOMOF CLOSUREFASTENER @ EVERY MAINRIB OR 12" C/C MAX.RESIDENTIAL PIPE BOOTS(OPTIONAL) SILICONESEALANT AROUNDCUT OF BOOTROOF PANELVENTILATIONPIPEPIPE BOOTBUTYL SEALANT TAPEUNDER BASE OFPIPE BOOTPLYWOOD DECKSCREWS SPACED 2" TO 3"MAX AROUND BASE TOSECUREPIPE BOOT SIZES#3 1 4" TO 5" PIPE DIA.#5 4 1 4" TO 7 1 2" DIA.#8 7" TO 13" DIA.38

Residential Flashings DetailSKYLIGHT & CHMINEY DETAILSNOTE: SEE CROSSSECTIONS A-A, B-B, C-CFor optimum weatherthightness, useice and water shield or similararound penetrations.CRICKET FIELD FORMINGALTERNATIVE CRICKET DETAILI I/2" SSR WHC1 "HIPCLOSURE"USE TO CREATEBASE/FRAME OFCRICKETTOP OF CRICKET FIELDFORMED FROM FLAT SHEETFASTEN TOP OF CRICKET TO BASEUSING #14 MP. CAULK ALL JOINTSAND SEAMS WITH ONE-PARTPOLYURETHANE SEALANT.CUT TRIANGULAR CRICKET TOPFOLD UP WIDE END OF TRIANGLE.SLIT CENTER OF FOLD AND BENDSLIGHTLY DOWN THE CENTER.FABRICATE SMALL CAPTO COVER AREA WHICHWAS SLIT39

Residential Flashings DetailSASHSKYLIGHT DETAILSSEALANTFLASHING ASW-1 - FIELD MODIFY AS REQUIREDFASTENER @ 6" C/CSEALANTICE AND WATER SHIELD AND30# FELT OR TITANIUM UDL UNDERLAYMENTFRAMESCREENJAMBSIDEWALL DETAILSECTION A-AROOF SHEATHINGROOF FRAMING1/2" PLYWOOD1/2" RIGID INSULATIONSEALANTSASHCUSTOM DIVERTER FLASHCONTINUE SUCH THATTHE DIVERTER ANDVALLEY FLASH OVERLAP6" MINROOF PANELINSIDE CLOSUREICE AND WATER SHIELD AND30# FELT OR TITANIUM UDLUNDERLAYMENTSEALANT TAPETOP & BOTTOMOF CLOSUREFRAMEDRYWALLPLYWOODHEADERROOF SHEATHINGBATT INSULATIONFASTENER @ 6" C/C MAX.CRICKET FIELD FORMINGSECTION B-BSEALANTSEALANT TAPEBETWEEN FLASHAND ROOF PANELFASTENER @ 6" C/CROOF PANELFLASHING -REVERSEAL FLASHINGCONTINUOUS SIKAFLEXCAULK @ PERIMETERSIDEWALL DETAILALTERNATE SECTION A-AICE AND WATERSHIELD AND 30# FELTOR TITANIUM UDLUNDERLAYMENTICE AND WATER SHIELD AND30# FELT OR TITANIUM UDLUNDERLAYMENTASW-1 FLASHINGFIELD MODIFIEDTO FIT2" FASTENER @ EVERYMAIN RIB OR 12" C/C MAX.BUTYL TAPETOP & BOTTOMOF CLOSUREROOF PANELSASHSEALANTFRAMEROOF SHEATHINGOUTSIDE CLOSUREFASTENERHEADERENDWALL DETAILSECTION C-C40

Residential Flashings DetailCHIMNEY DETAILSAL FLASHINGSEALANTSAW CUT REGLET1/2" - 1" DEEPBLOW OUT DUST & FILL WITH SIKAFLEXSEALANT. SET FLASH & FASTEN WITHCOMPATIBLE MASONRY ANCHORFLASHING ASW-1 - FIELD MODIFYAS REQUIRED ICE AND WATER SHIELD ANDFASTENER @ 6" C/C 30# FELT OR TITANIUM UDLUNDERLAYMENTSEALANTROOF PANELALTERNATE FLASHINGSIDEWALL DETAILROOF SHEATINGAL FLASHINGSAW CUT REGLET1/2" - 1" DEEPBLOW OUT DUST & FILL WITH SIKAFLEXSEALANT. SET FLASH & FASTEN WITHCOMPATIBLE MASONRY ANCHORFLASHING -REVERSEAL FLASHINGCONTINUOUS SIKAFLEXCAULK @ PERIMETERSEALANTFASTENER @ 6" C/CROOF PANEL1/2" PLYWOOD1/2" RIGID INSULATIONCUSTOM DIVERTER FLASHCONTINUE SUCH THATTHE DIVERTER ANDVALLEY FLASH OVERLAPALTERNATE FLASHINGSIDEWALL DETAILICE AND WATER SHIELD AND30# FELT OR TITANIUM UDLUNDERLAYMENTROOF SHEATINGSEALANT TAPEBETWEEN FLASHAND ROOF PANEL6" MINROOF PANELINSIDE CLOSURESAW CUT REGLET1/2" - 1" DEEPBLOW OUT DUST & FILL WITH SIKAFLEXSEALANT. SET FLASH & FASTEN WITHCOMPATIBLE MASONRY ANCHORROOF SHEATINGBATT INSULATIONICE AND WATER SHIELD AND30# FELT OR TITANIUM UDLUNDERLAYMENTCRICKET FIELD FORMINGSEALANT TAPETOP & BOTTOMOF CLOSUREFASTENER @6" C/C MAX.SAW CUT REGLET1/2" - 1" DEEPBLOW OUT DUST & FILL WITH SIKAFLEXSEALANT. SET FLASH & FASTEN WITHCOMPATIBLE MASONRY ANCHORASW-1 FLASHINGFIELD MODIFIEDTO FIT2" FASTENER @ EVERYMAIN RIB OR 12" C/C MAX.ICE AND WATER SHIELD AND30# FELT OR TITANIUM UDLUNDERLAYMENTBUTYL TAPETOP & BOTTOMOF CLOSUREROOF PANELROOF SHEATHINGOUTSIDE COLSUREFASTENERENDWALL DETAILAL FLASHINGSEALANTALTERNATE FLASHING41

Residential Flashings DetailDORMER DETAILSDORMER DETAIL- SIDE VIEWPLAN VIEW OF SIDE OF DORMERSEALER STRIP,1" x 1" x 19'-8"BLOCK CLOSUREFILLS RIB VOIDSBUTYL SEALANTTOP & BOTTOMOF SEALER STRIP6" MINVALLEY FLASHINGSCREWSEACH SIDE OF MAINRIB (EAVE/ENDLAPPATTERN) AND ONEADDITIONAL, CENTRALLYLOCATED IN THE PAN OFTHE PANELRV-1 ORRV-2 (SHOWN)SECTION B-BSOLID DECKROOF FELT ANDICE & WATER SHIELDSOLID SUPPORT IS REQUIRED UNDER THE VALLEY. EPDM LINING ISRECOMMENDED UNDER LAPPED PANELS AND VALLEY FLASHING.LINING MUST CONTINUE DOWN TO EAVE LINE.42

Residential Flashings DetailDORMER DETAILSPLAN VIEW OF TOP OF DORMERSEALER STRIPBUTYL SEALANTTOP & BOTTOMOF SEALER STRIPSCREW6" MINRIDGE CAP; EXTEND TO VALLEYPEAK; CUT, FOLD, TRIM, SEAL,AND FASTEN TO VALLEY PEAKSCREWSEACH SIDE OF MAINRIB (EAVE/ENDLAPPATTERN) AND ONEADDITIONAL, CENTRALLYLOCATED IN THE PAN OFTHE PANELVALLEY LININGVALLEY FLASHINGRV-2 SHOWNSOLID DECKSECTION A-AMETAL FLASHING TO COVERLAP AT VALLEY PEAKS (CAULK)CLOSURE; CAULK PERIMETERTRIM AND SEAL AT VALLEY PEAK43

AccessoriesFlat 29 gage painted and plain galvanizedsheets available in full width (40 1316" x10').Flat sheets are made in grade 33 steel <strong>for</strong>better hemming, <strong>for</strong>ming, and flexibility <strong>for</strong>field <strong>for</strong>ming.Used <strong>for</strong> field <strong>for</strong>ming crickets aroundchimneys, skylights, and penetrations.Also used <strong>for</strong> field <strong>for</strong>ming special flashingas necessary.PROFILE VENTGRANDRIB 3 & ALU-TUFF (SHOWN),5V CRIMPGrandrib 3 net free area = 10.66 sq. in. perlineal ft. of ridge (5.33 per side)Pipe BootsPipe Flashing Item Pipe SizeGray EPDM No. Min MaBase Diameter7 3 14" 3 4" 5"10 3 4" 5 4 4" 1 7 2"116 2" 1 8 7" 13"Sealant Tape316" x 1 4" x 40'332 "x 1 2" x40'Asphalt Impregnated Sealer Strip1"x1"x19'-6.8" longUSE AT VALLEYS AND HIPSTranslucent PanelsFiberglassGrandrib 3 - White, Green - 8', 10', 12'Strongrib - White - 10', 12'Fabrib - Green -12'(availability by location - check withsale service rep.)SunSky PolycarbonateGrandrib 3 & AlutuffClear & White - 8',10',12'(Available Everywhere)ClosuresInside (Eave)Outside (Ridge)Grandrib 3, Strongrib, 1 1 4" Corrugated,2 1 2" Corrugated, 5V Crimp, and Fabribavailable by location - check withsales service rep.Screws#10-16 Ultimate WoodTite5 16 " cast Zinc hex headAvailable in 1", 1 1 2", 2" , 2 1 2" and 3"USE WITH GALVALUME PANELSNails#9-16 WoodFast1 4 " hex head, EPDM/metal washer,Oxyseal Long-Life CoatingAvailable in 1", 1 1 2", 2", 2 1 2" and 3"- Plain or Painted#9-16 WoodFast300 Series Stainless SteelAvailable in 1", 1 2", 1 and 2"14" hex head, EPDM/metal washerUSE WITH ALUMINUM PANELSFabroseal with 1 4" washer <strong>for</strong>roofing -2", 2 1 2" & 3"Regular neoprene washer <strong>for</strong> siding-1 1 2", 1 3 4", 2", & 2 1 2"Plain Zinc coated and Painted#14-10 WoodTite5 16 " hex head, EPDM/metal washer,Oxyseal Long-Life coating. Plain or Painted1", 1 1 2", 2" USE AS STITCH SCREW & TOFASTEN METAL TO PLYWOOD OR OSB44

Fabral Plants NationwideSt. Joseph, MNLight Gauge/Post Frame PlantsCedar City, UT (800) 432-2725Columbia, SC (877) 972-6662Gridley, IL (800) 451-3 974Hopkinsville, KY (888) 317-6662Idabel, OK (800) 926-8509Lancaster, PA (800) 477-2741Mooresburg, TN (800) 500-0059Mt. Vernon, OH (800) 688-3550St. Joseph, MN (800) 873-3440Salem, OR (800) 477-8028Spokane, WA (800) 456-9124Tifton, GA (800) 749-8144Marshfield, WI (800) 528-0878MEMBERRural Builder MagazineGold Key RecipientAll 16 Consecutive YearsCorporate Office3449 Hempland Rd.Lancaster, PA 17601(800) 477-2741Fax (800) 283-4289www.fabral.com 11/07 APC 10k 98-32-007